Well I thought I had done my research and referenced threads here about the correct guibo to use for the 5 speed swap.

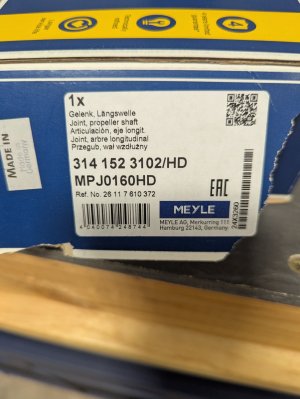

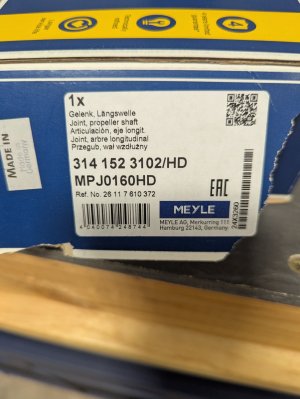

I ordered a meyle unit from FCP that referenced the standard # 26117511454.

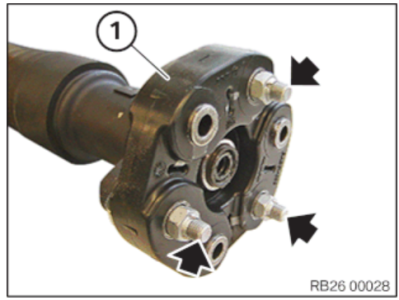

What I received is considerably thinner than what was in the car(assuming that was correct?).

1. This thinner guibo would seemingly affect how much the driveshaft is shortened.

2. If used it looks like the driveshaft will be tight against the output flange of trans.

Thoughts or experience of going down this road?

New unit is on driveshaft in pic

I ordered a meyle unit from FCP that referenced the standard # 26117511454.

BMW Drive Shaft Flex Joint (Giubo) - Meyle HD 3141523102HD

BMW Drive Shaft Flex Joint (Giubo) - Meyle HD 3141523102HD

www.fcpeuro.com

What I received is considerably thinner than what was in the car(assuming that was correct?).

1. This thinner guibo would seemingly affect how much the driveshaft is shortened.

2. If used it looks like the driveshaft will be tight against the output flange of trans.

Thoughts or experience of going down this road?

New unit is on driveshaft in pic