This seems like a question that is going to reveal some idiocy on my part, but here goes. I have a non-functioning horn button (no sound or click when pressing it) and when doing some re-wiring under the dash, I see two brown wires coming down the steering shaft that are just sitting there not connected to anything. I figured that was my problem, but then when checking in the engine bay and assessing the horn relay, I don't see the actual horn installed anywhere. My car had a CSL air dam added to it and I'm wondering if perhaps someone removed the horn during that install., or decided they didn't want a horn and therefore disconnected the wiring for it. None of it makes much sense. If anyone can post a picture of where the horn is mounted in a Euro E9 I'd greatly appreciate it. Before I start fixing the electrical portion it would be good to know there's actually a device on the other end to make a sound!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Horn location

- Thread starter e9Leveque

- Start date

Ah! Wouldn’t have thought of opening up the headlight area, and this is one part that is not listed in the blue books aside from mentioning the horn relay. Thanks for the input. Let there be sound!

There should be 2, one on each side. And I believe they are 2 different frequencies/tones if you're really fussy.

Also fun to rebuild!

Also fun to rebuild!

Hmm. So pulled the left one and when I put 12v across it, I get nothing. I didn’t realize this was a piece that could “go bad”. Looks like I have some work to do

Does the relay by the battery click when you push horn button?

Only the original ones are rebuildable. Someone replaced one of mine and it's not so easy to open. And I didn't have much luck in rebuilding the older one. Haven't given up though. Since I only had one sort of working horn I decided to create the sound of twin tone horns and used an audio program to create sawtooth waves with the frequencies stamped on the horns. There doesn't seem to be a way to attach that sound here. The frequencies are 410 and 510 Hz.There should be 2, one on each side. And I believe they are 2 different frequencies/tones if you're really fussy.

Also fun to rebuild!

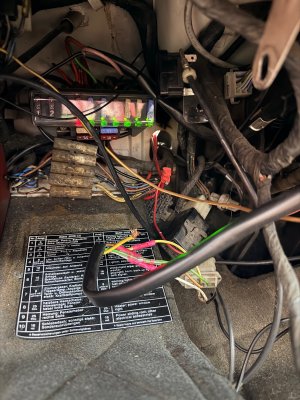

No, the relay doesn’t click. I have a replacement relay and I’ll pop that on to see what happens, but there is a lot about the wiring in this vehicle that seems odd. I see the yellow/brown wire horn button wire feeding into a white plastic wiring harness, and then the same emerging and going up into the steering column, then a yellow/brown emerging from the steering column but that one just crosses over in front of the fusebox to enter the side panel area to the left of the fusebox. Seems very random. Also, coming out of the steering column are two brown wires with spade terminals but not hooked up to anything. And from the hazard switch is a black wire with spade terminal also not hooked up to anything. I know that there are some features that are options (the trunk flashlight, for example) but in those cases I see the wires laid but the ends are cut rather than having these spade terminals with sticky electrician tape around them. Time to spend some time with the wiring diagram. It still seems that I should get a horn sound by hooking a 12v up directly to the horn, though, so the fact that it’s silent seems to be a problem

Overall a little bit of chaos in this wiring area. I would love to see what this looked like originally so I know how far off that mark I am.

Overall a little bit of chaos in this wiring area. I would love to see what this looked like originally so I know how far off that mark I am.

Attachments

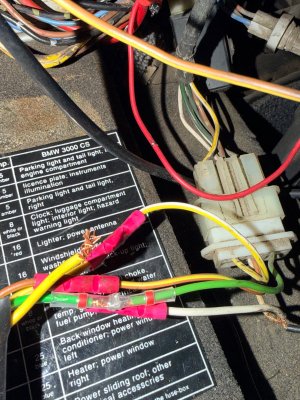

Looks familiar. The steel plate in my pic might be sandwiched between the 2 plastic halves.

That didn't clear much up, I meant to say my pic is what's inside

Ok the plot thickens. Yes, took mine apart and it’s the same as yours. If I just rest the plate on the bottom piece I can get a vibrating sound which is clearly correct, but it’s not reliable. Maybe some greasing is in order. White lithium ok for these parts?

Yes, your wiring has been heavily modified. The only connectors I saw that are OEM are the ones with the yellowed clear plastic jackets over the spade connectors. Those are a little hard to find, but are still available. There is are color codes for the wiring that make troubleshooting much easier when using the schematic. Since it's hard to find correctly sized and color coded wires to do repairs on cars this old, I've had good luck buying a wiring harness from (slightly) newer cars on eBay or salvage yards and splicing in new sections by making soldered butt splices and then using heat shrink tubing to cover the splice. Very clean and reliable. The factory used a slightly sticky black cloth tape to wrap the wiring bundle and control the wires. Don't buy the cheap Chinese version, the European ones are better, they don't get sticky.Time to spend some time with the wiring diagram. It still seems that I should get a horn sound by hooking a 12v up directly to the horn, though, so the fact that it’s silent seems to be a problem

Overall a little bit of chaos in this wiring area. I would love to see what this looked like originally so I know how far off that mark I am.

The first part I bought for my car is the contact that rides on the steering shaft so your horn honks when your press on the horn button to complete the circuit. Yep, the old one was bad when I took it out to check.

Last edited:

That sounds like a solid idea (purchasing older wiring harness). I assume you mean something like this https://ebay.us/m/bjRUMg

Part of me wonders how much I want to try to untangle this. Overall everything works, except the horn. The wipers go, the wiper motors work (well, after I replaced one), the lights turn on, etc. It looks chaotic as hell there but maybe it’s a controlled chaos and I shouldn’t mess with it, especially because it’s something uncomfortable and tight quarters there. Just seems so wrong to leave it though…

And how did you know it was the contact and not any other part?

Part of me wonders how much I want to try to untangle this. Overall everything works, except the horn. The wipers go, the wiper motors work (well, after I replaced one), the lights turn on, etc. It looks chaotic as hell there but maybe it’s a controlled chaos and I shouldn’t mess with it, especially because it’s something uncomfortable and tight quarters there. Just seems so wrong to leave it though…

And how did you know it was the contact and not any other part?

Exciting!Ok the plot thickens. Yes, took mine apart and it’s the same as yours. If I just rest the plate on the bottom piece I can get a vibrating sound which is clearly correct, but it’s not reliable. Maybe some greasing is in order. White lithium ok for these parts?

I may have used a general bearing grease (red) but can't say for certain. Probably used a little wd40 to loosen things up.

My horn contact diagnosis was easy, the contact tip was broken. You can test the circuit and the slip ring by testing the wires that go to the horn. One should be hot, and one should should short to ground when the horn button is pressed. You'll need a willing assistant since you can't be in two places at once.That sounds like a solid idea (purchasing older wiring harness). I assume you mean something like this https://ebay.us/m/bjRUMg

Part of me wonders how much I want to try to untangle this. Overall everything works, except the horn. The wipers go, the wiper motors work (well, after I replaced one), the lights turn on, etc. It looks chaotic as hell there but maybe it’s a controlled chaos and I shouldn’t mess with it, especially because it’s something uncomfortable and tight quarters there. Just seems so wrong to leave it though…

And how did you know it was the contact and not any other part?

The horns, being exposed to the environment at the front of the car, get rusty and seize up as seen in the photos posted earlier in this thread. Derusting with Evap O Rust or a generic version can go a long way to getting things going. Followed by cleaning contacts of course.

Everything used to be rebuildable, but that slowly went away as parts producers figured out how to make parts cheaper and faster. Original parts are part of the charm of our cars, but I won't think twice of replacing my original starter with the newer version which is smaller and more powerful.

No, the harness you posted is too new, in my opinion. Cars that new have radically different electrical systems with different load, connectors and probably some color codes. I'd suggest something from a car about a decade newer than yours, like this one. https://www.ebay.com/itm/157314170182

Goodness, prices have risen since I started working on cars.

Yes, it's tempting to leave well enough alone. Tracing electrical circuits can be time consuming, but I'd be concerned about the condition of your wires since you can't be sure how well those connections were done. At the least I'd give them all a tug to make sure they are solid and possibly give the a wrap of electrical tape if there was any hint of copper showing. There are products that will put a signal on a wire that you can follow with a probe to trace where the wire goes that's useful when you don't have a proper color code to confirm you are working with the right wire.

I've also seen a little 3D printed jig that allows you to use a paint pen to put your own wire trace on a wire you are wanting to match to a standard color code, assuming you are starting with the correct base color wire that is. You could do that piecemeal if you just need to replace a few wires rather then spending a bundle on an entire old harness.

Oh, and check your fuses, the fusible link on ceramic bullet fuses tends to oxidize over time and can cause issues with trouble shooting. I had a tail light that showed 12v but wouldn't light up. It turned out that the fuse was oxidized and would let a trickle of voltage through but not enough current to light the bulb. It would be the same for a horn as well, but since you applied 12v straight to the horn and got no joy, you know the horn is in need of help.

Last edited:

Swap hi beam and horn relays and try again.