taylorcom

Well-Known Member

Well ... removing the brake booster seems like a pretty big deal, since the coolant reserve tank, several hoses and other stuff is in the way. And once that's done, how do you free the steering box from the splines on the u-joint and the splines on the Pitman arm? Does the steering shaft retract somehow?

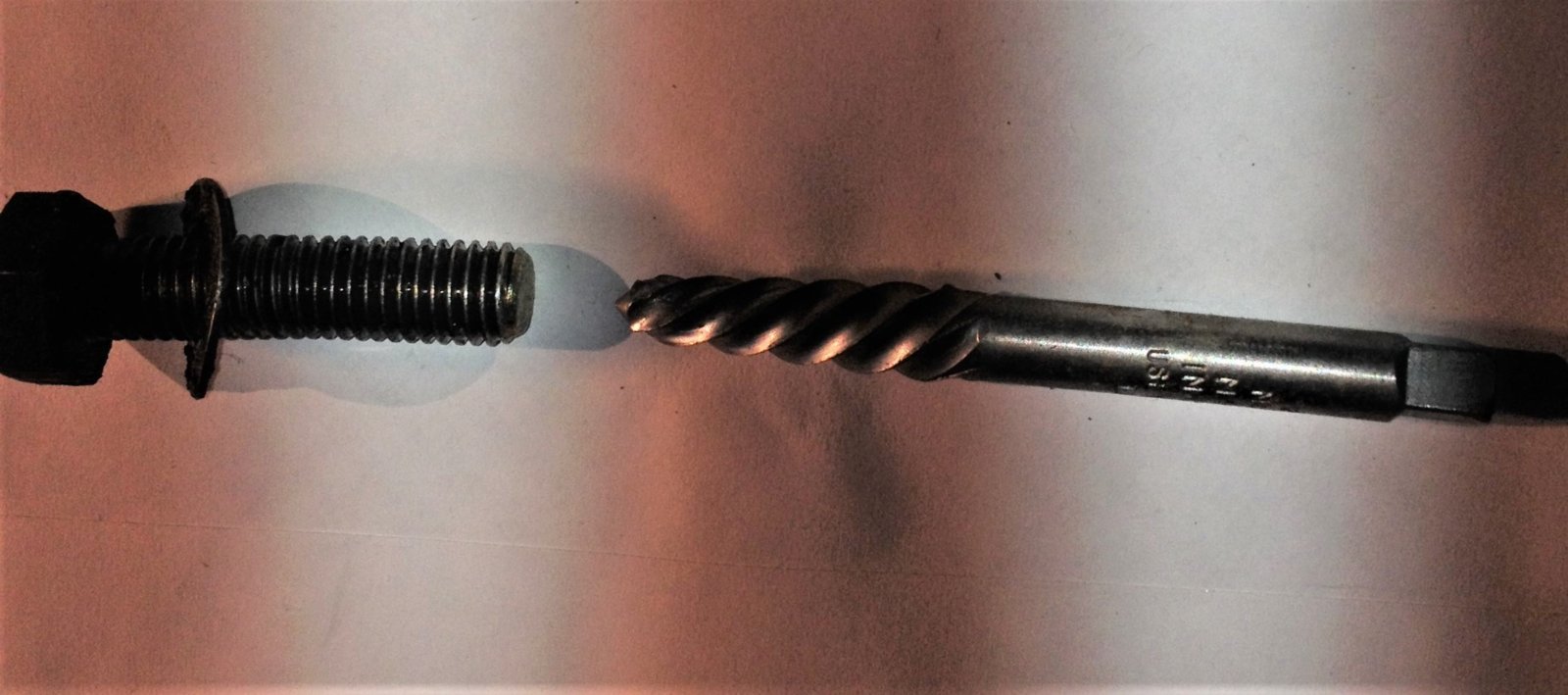

Maybe 3moons idea might be worth trying first: inserting a left-handed drill bit into the bolt hole in the box, w. the box in place. Then if that doesn't work, trying an "easy out" screw extractor (probably a smaller extractor than the one pictured).

Maybe 3moons idea might be worth trying first: inserting a left-handed drill bit into the bolt hole in the box, w. the box in place. Then if that doesn't work, trying an "easy out" screw extractor (probably a smaller extractor than the one pictured).