bmw art car

Well-Known Member

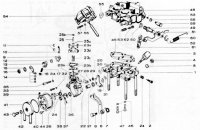

i had/have a list if issues with my carbs

mostly i wonder how to set them back to a base setting.

and then balance them from there and all that...

both of my small knuckled screws were tightened on one side down all the way

and it cracked the lower ficture. i took em off and fixed them so that they can

be cranked with the wheel again.

now that would be a base figure as a lenght?

and how can i crank the fuel down and air supply up?

if i turn in the base screw all the way and back it off 1 1/2 turns.

and how about the idle screw what if i turn it all the way out

what will it affect?

mostly i wonder how to set them back to a base setting.

and then balance them from there and all that...

both of my small knuckled screws were tightened on one side down all the way

and it cracked the lower ficture. i took em off and fixed them so that they can

be cranked with the wheel again.

now that would be a base figure as a lenght?

and how can i crank the fuel down and air supply up?

if i turn in the base screw all the way and back it off 1 1/2 turns.

and how about the idle screw what if i turn it all the way out

what will it affect?