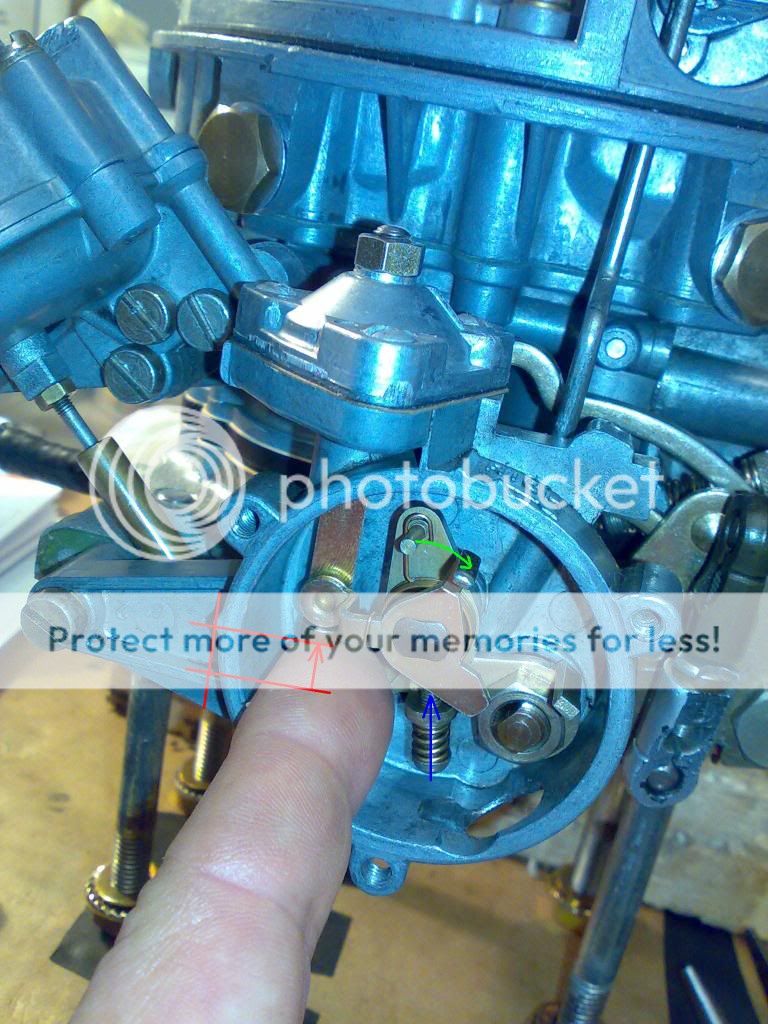

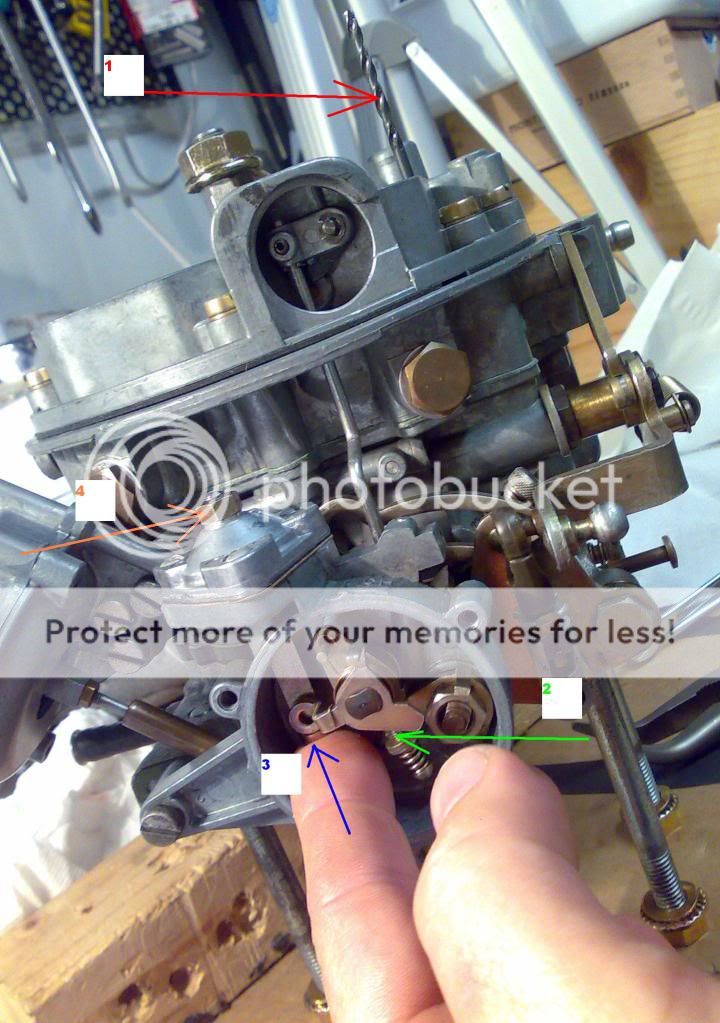

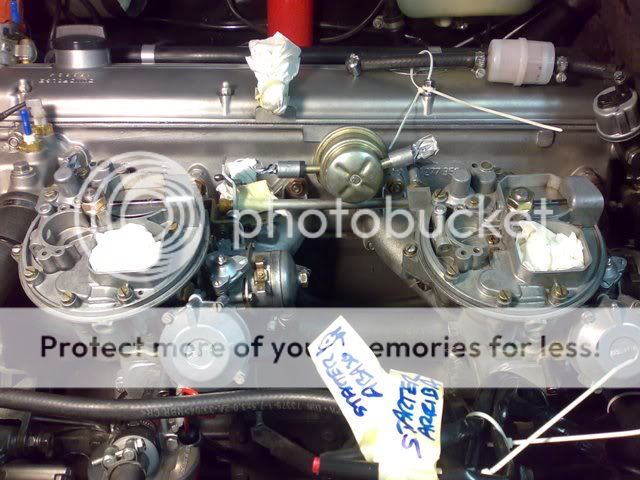

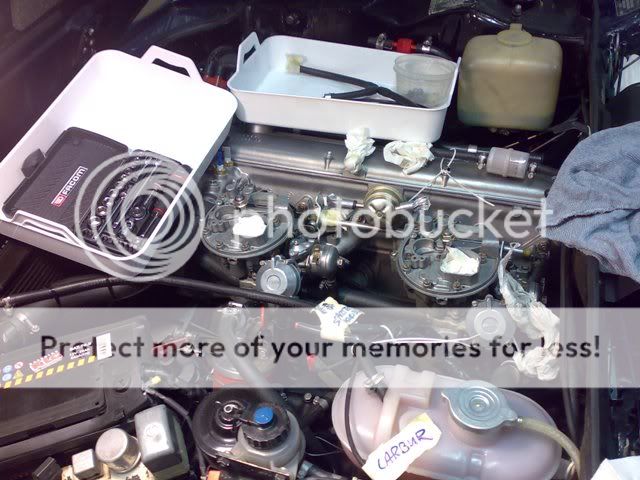

hunting the carbs problem, zeniths

so, it has been a long time up and down with the carbs

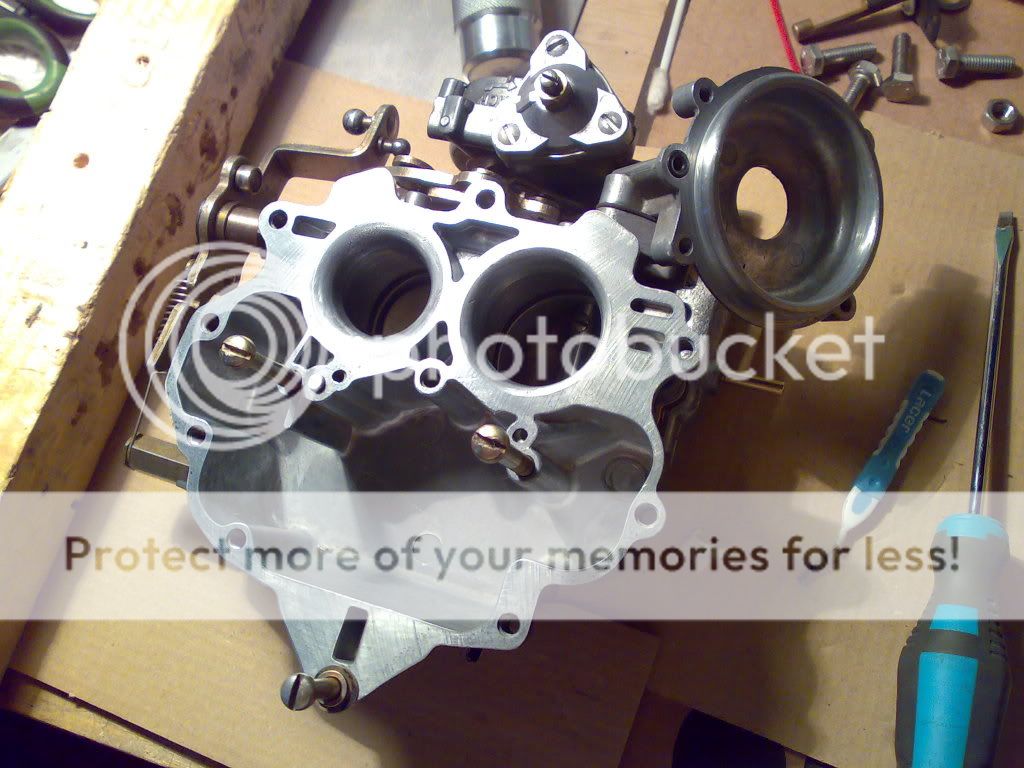

really fed up with them, no way to synchronise both, to get a good and smooth iddle

and when the iddle (thanks to porsche61, and stevehose among others) was reached, the transition (1800 to 2200 rpm´s) was not good, and so on,...

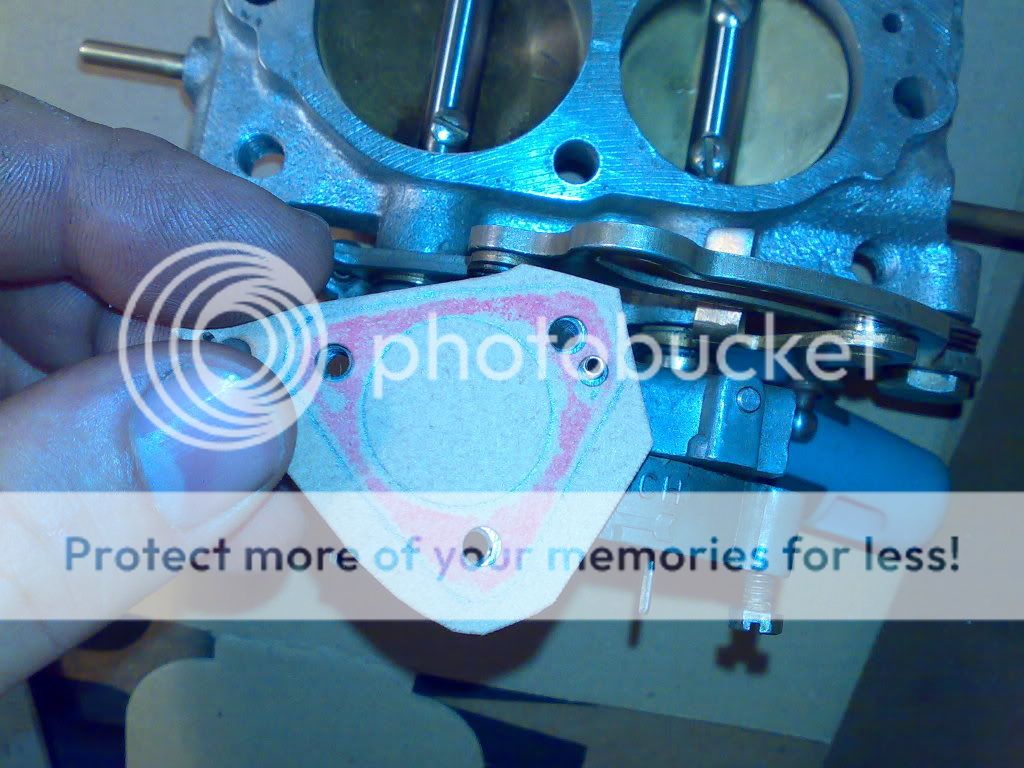

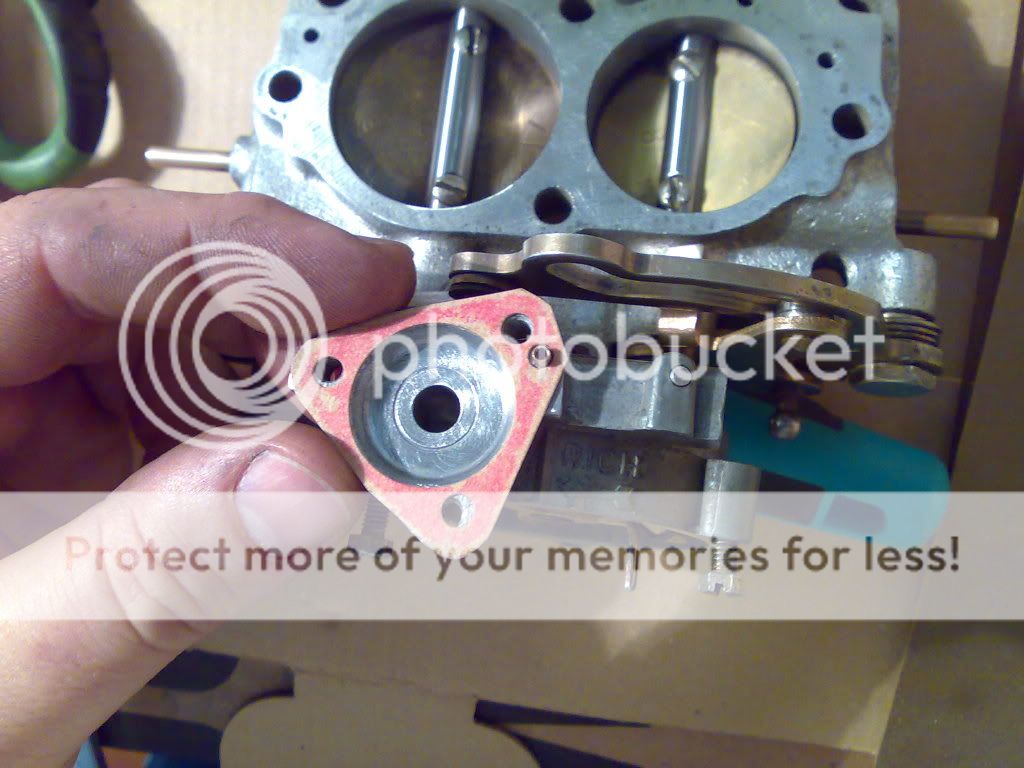

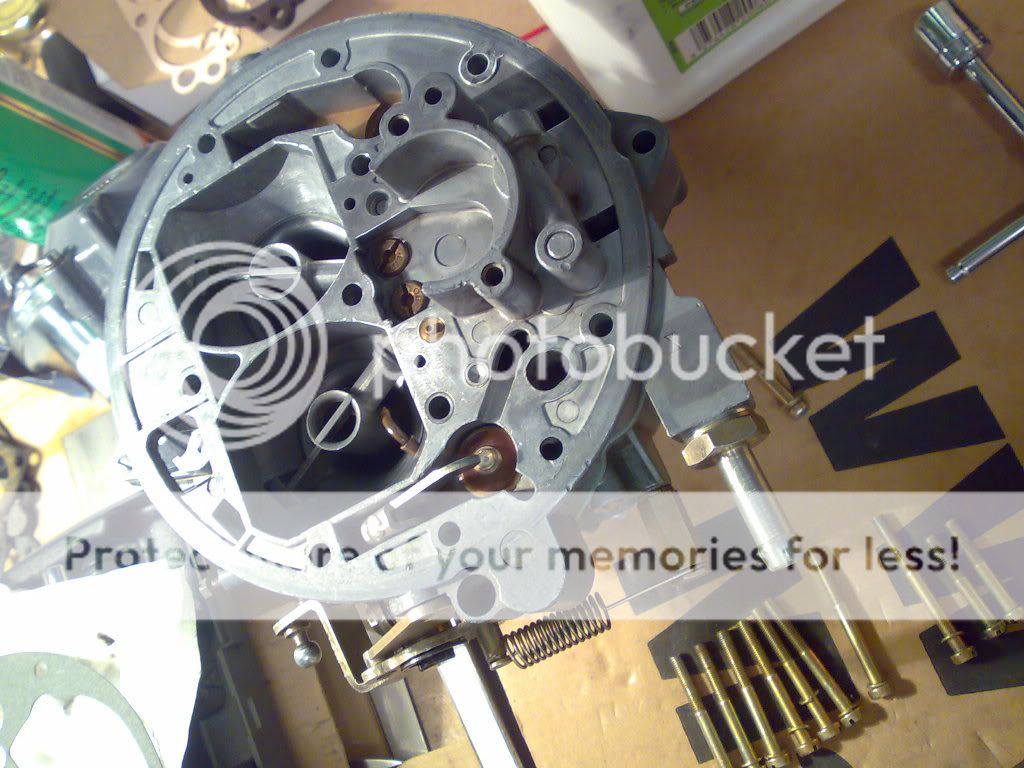

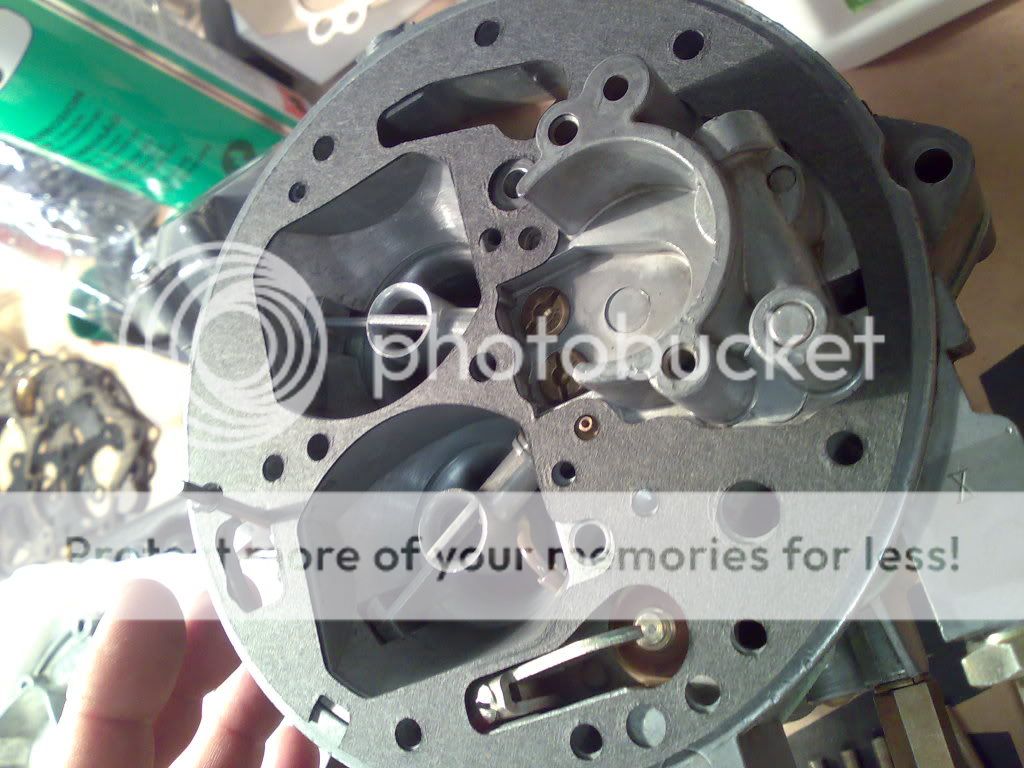

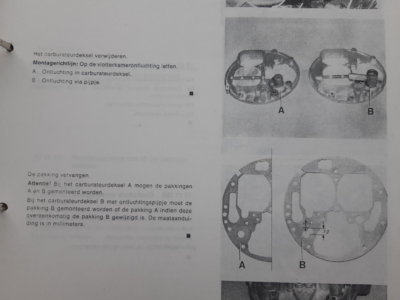

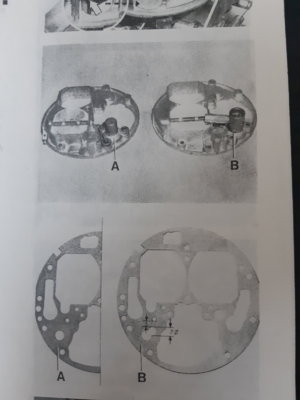

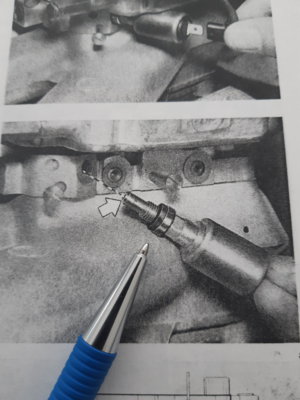

apologies for not translating all this (probably the pics are selfexplaining), if questions, i will be really happy to answer:

-------------------------------------------------------------

empezamos

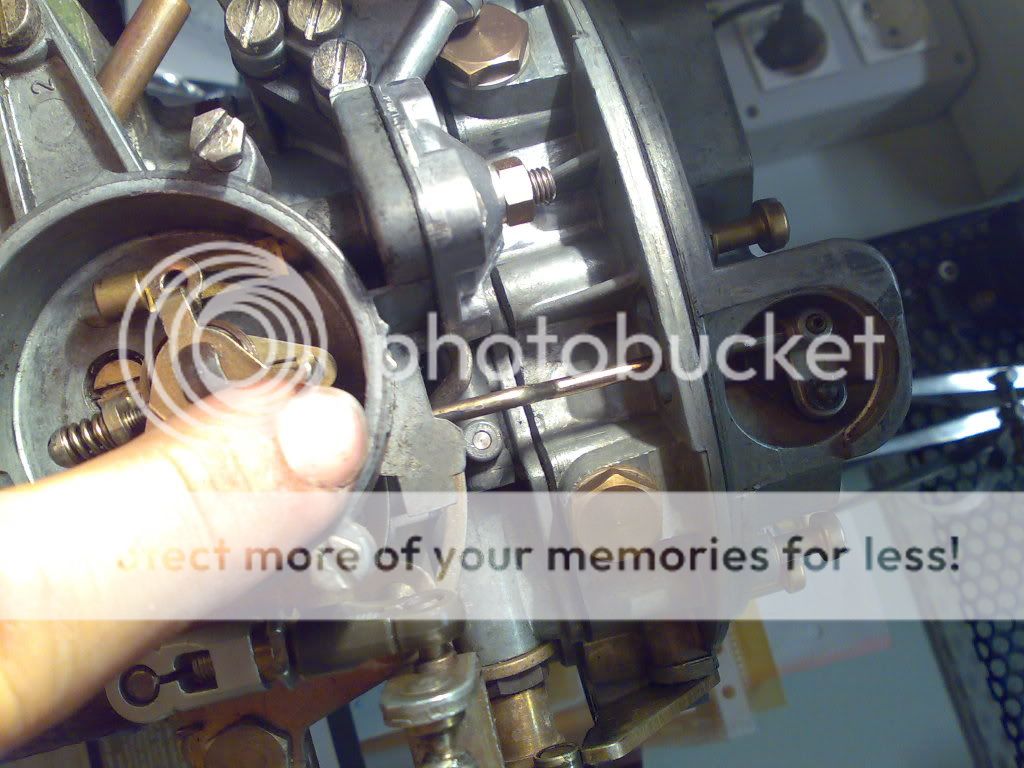

sacamos las conexiones electricas y nos rompemos las manos soltando las tuercas del carbur trasero, la buena noticia es que una vez sueltas con la llave, se sacan facil a mano

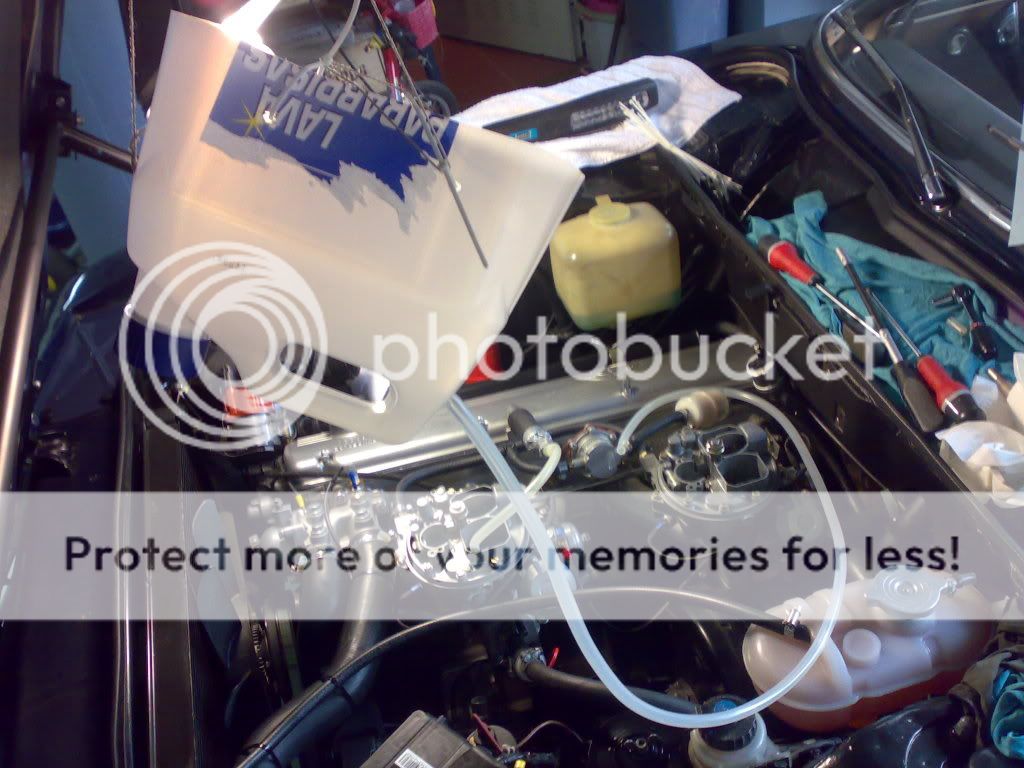

vacio el refrigerante, y la buena noticia es que sale bastante limpio (un año en el circuito) y sin aceite o porquerias

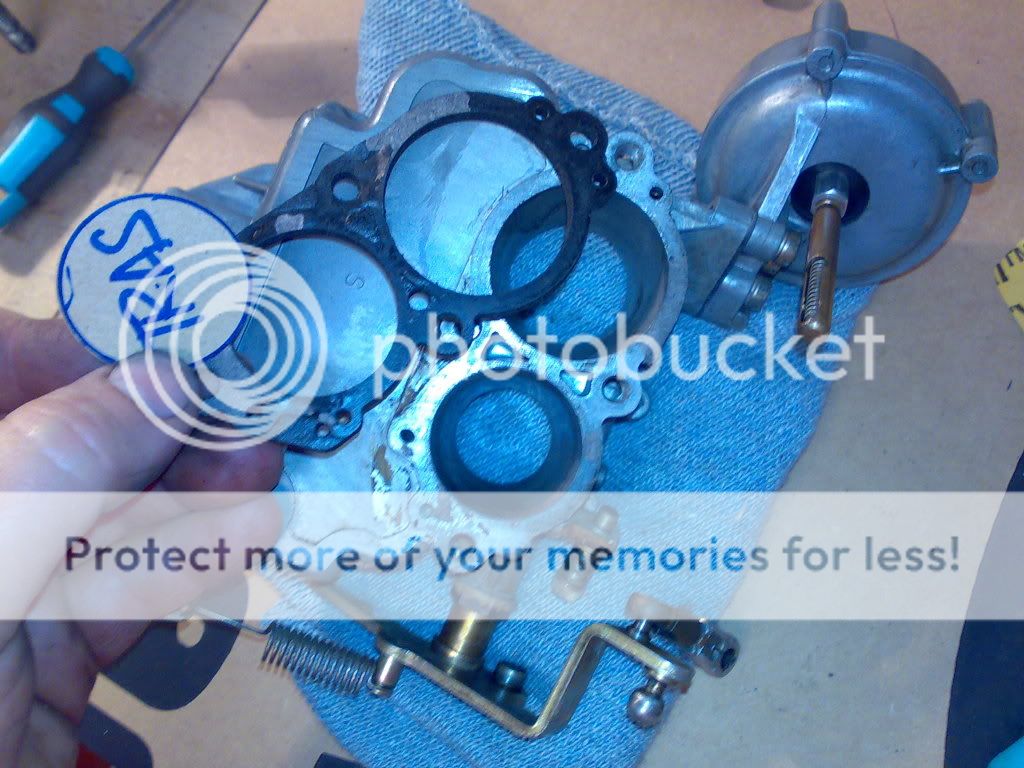

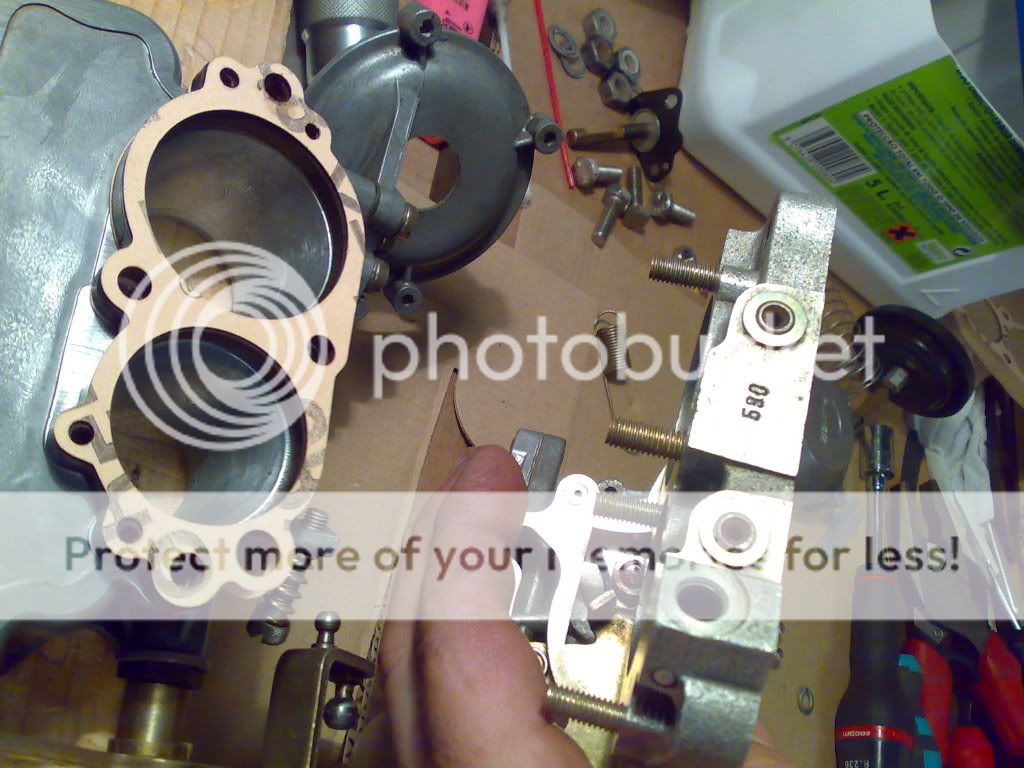

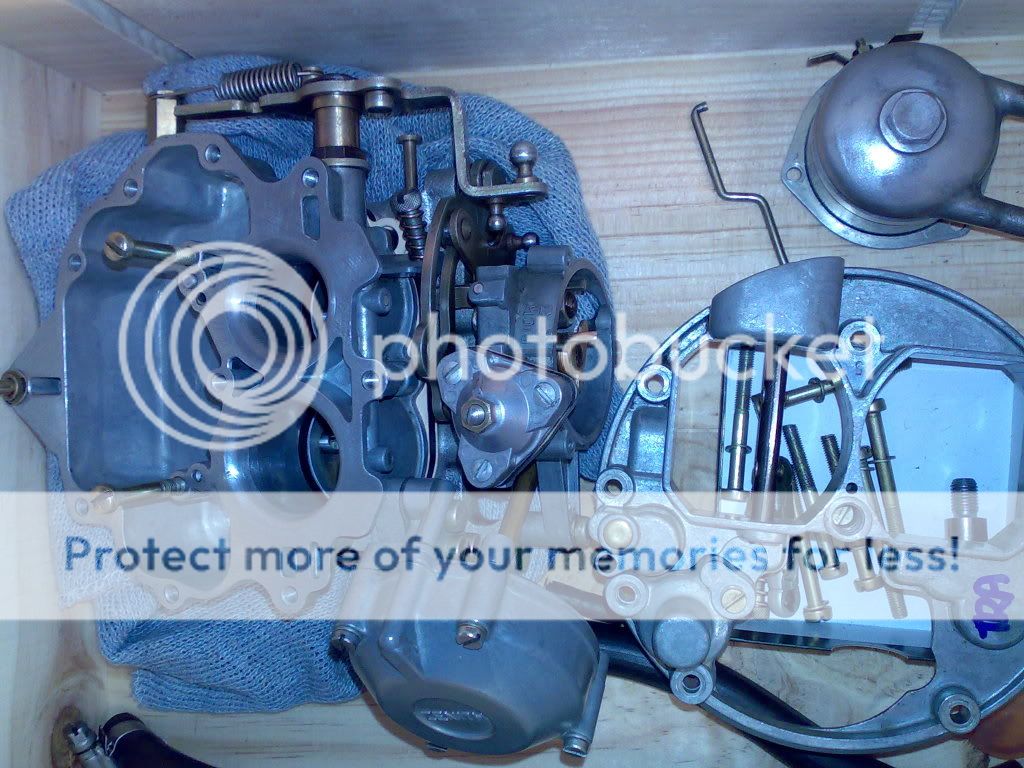

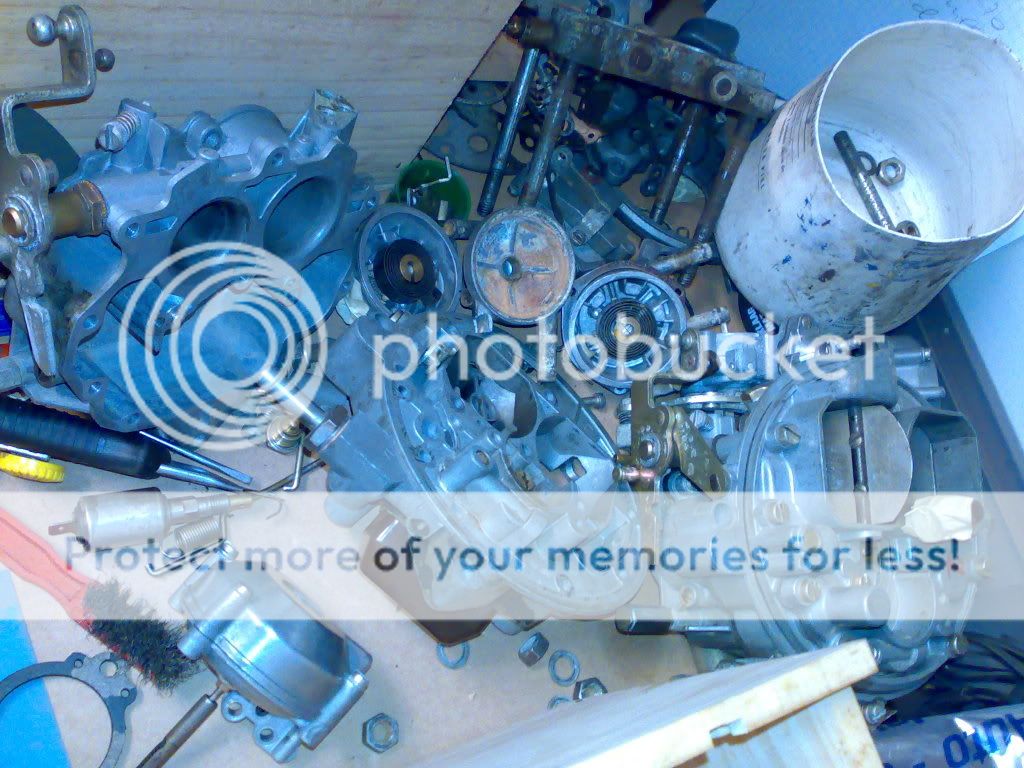

corto los tubos del circuito del carburador, esto se podria evitar, pero no quiero quitar las cazoletas en el motor, asi que corto y me llevo todo la banco

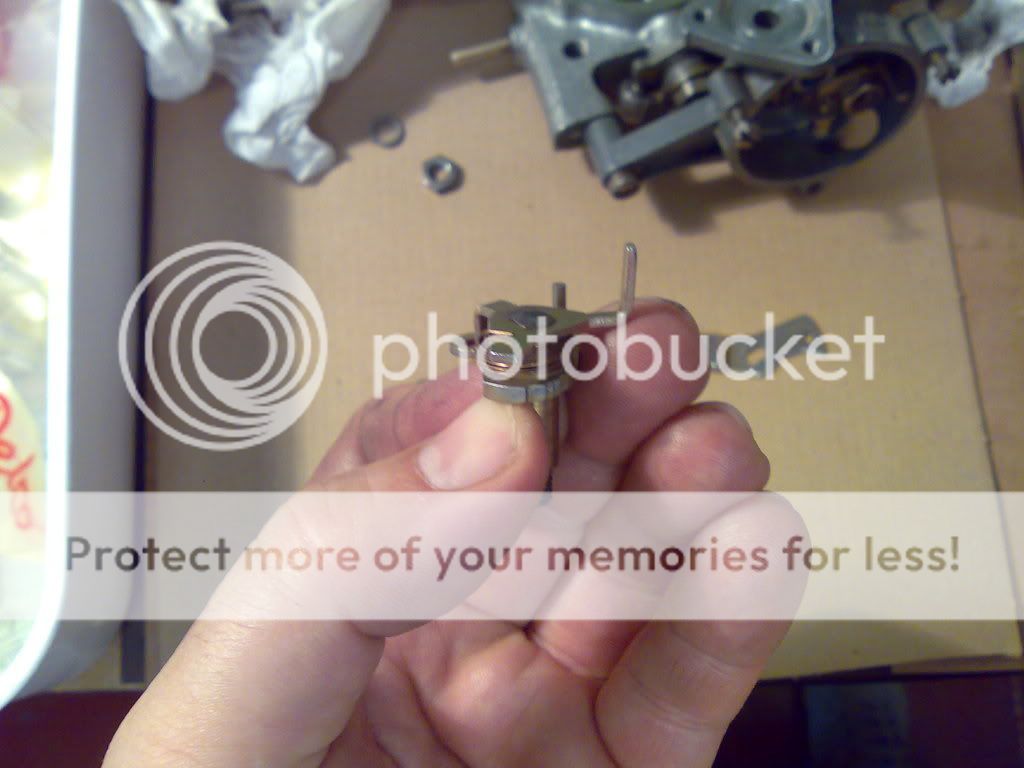

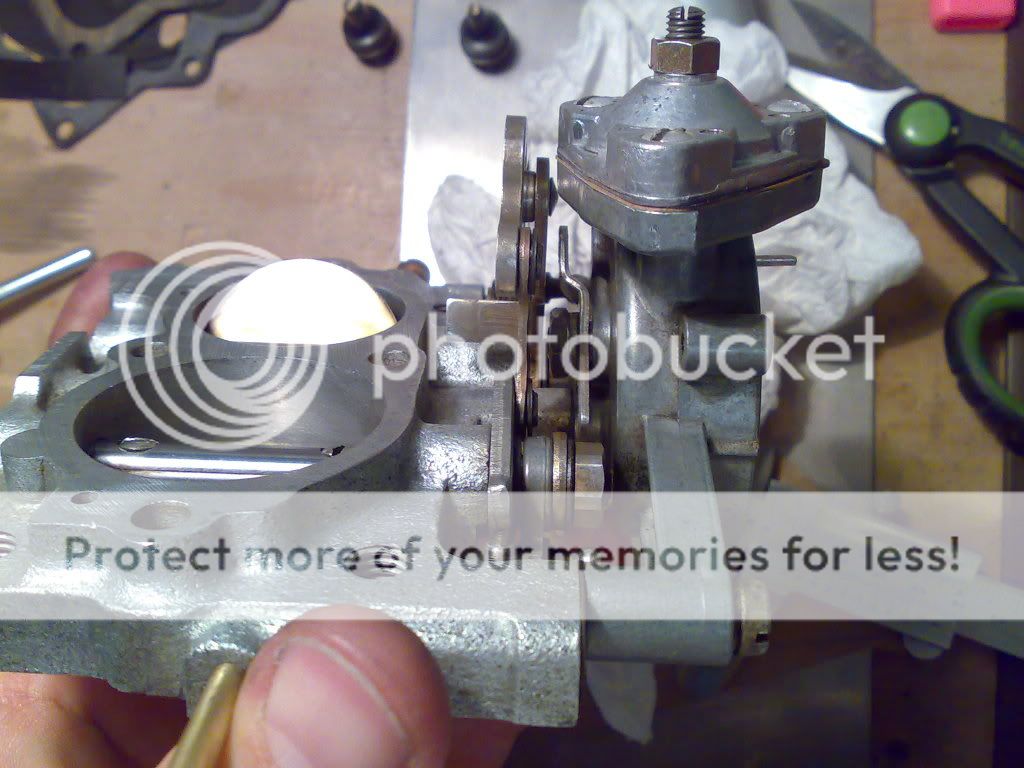

bomba de gasolina mecanica

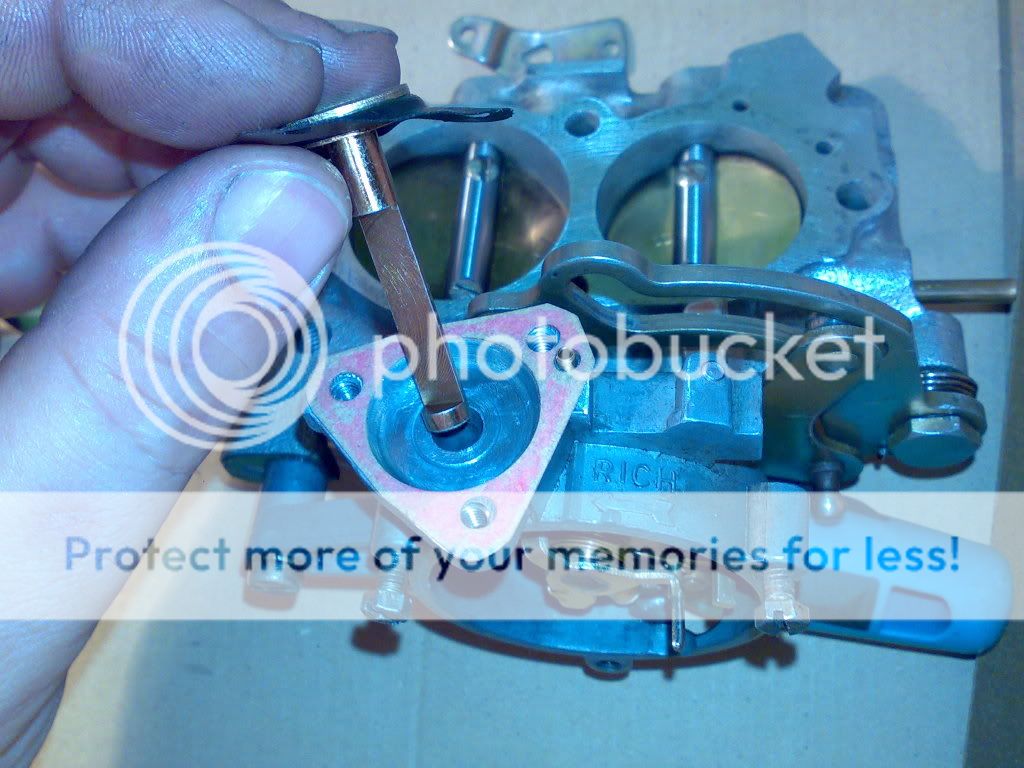

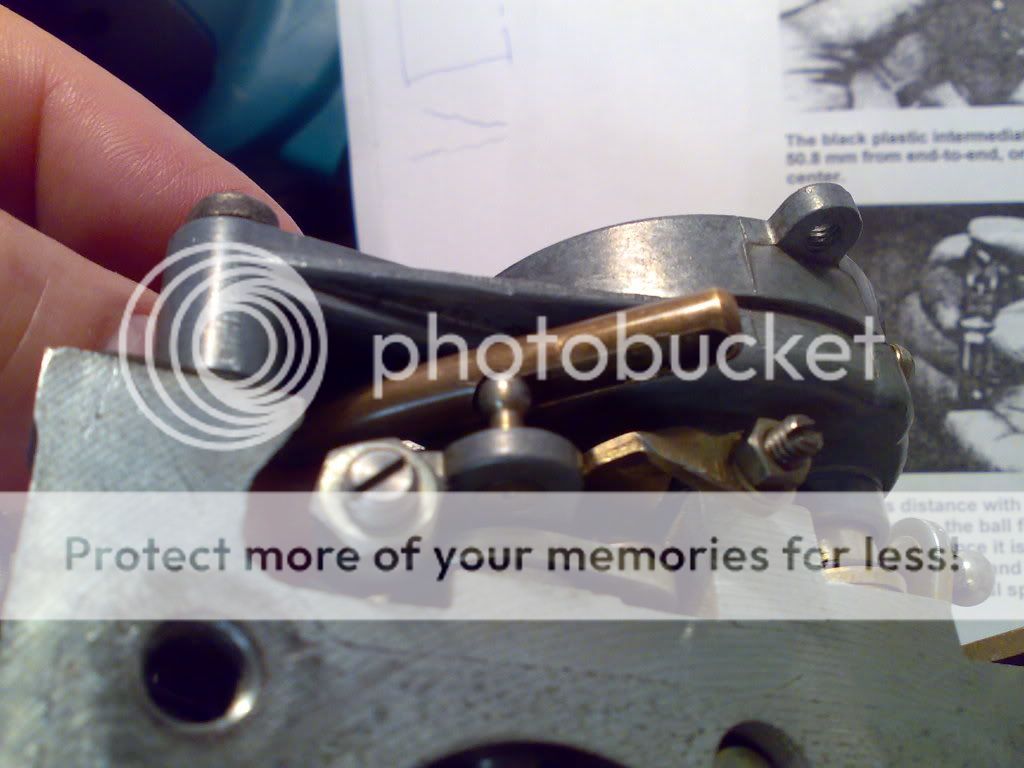

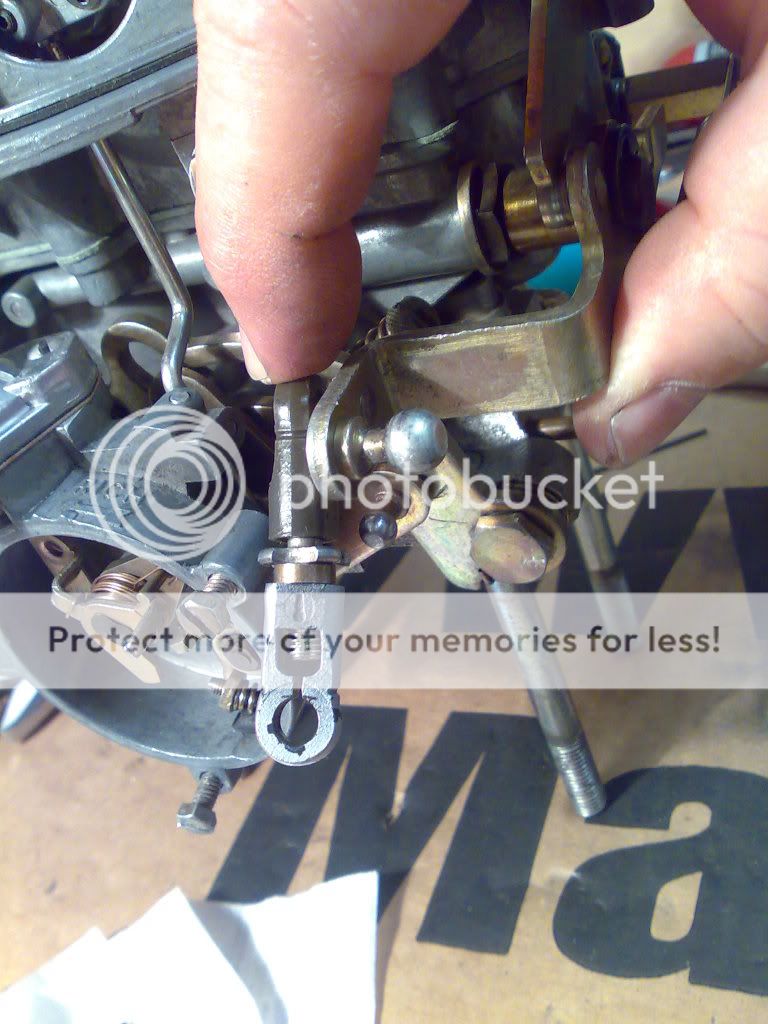

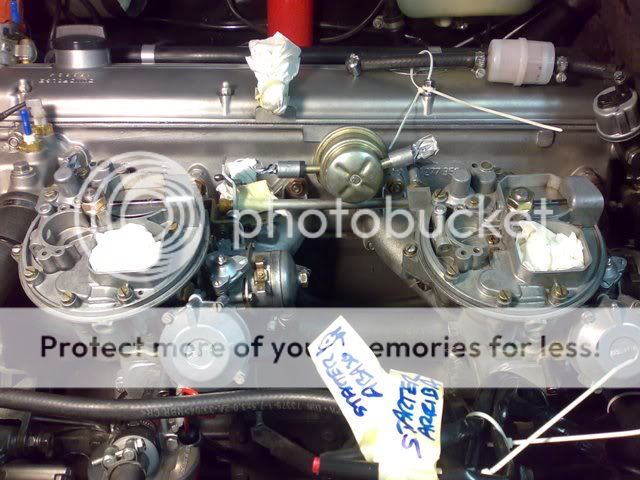

suelto vastagos de carbur trasero

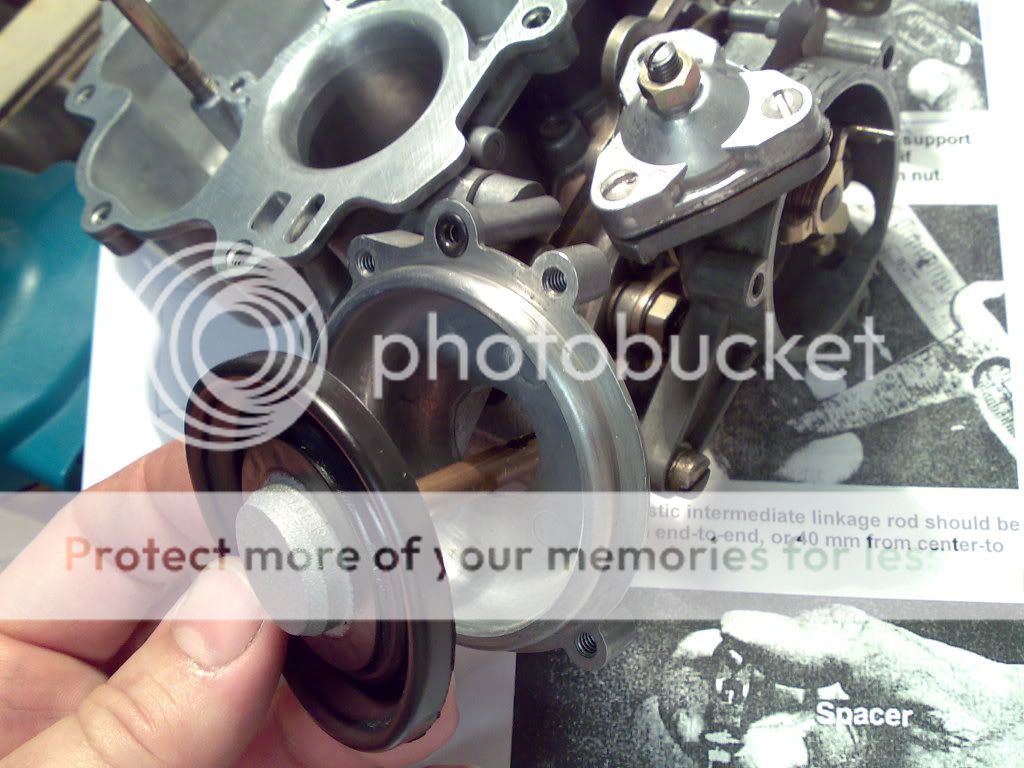

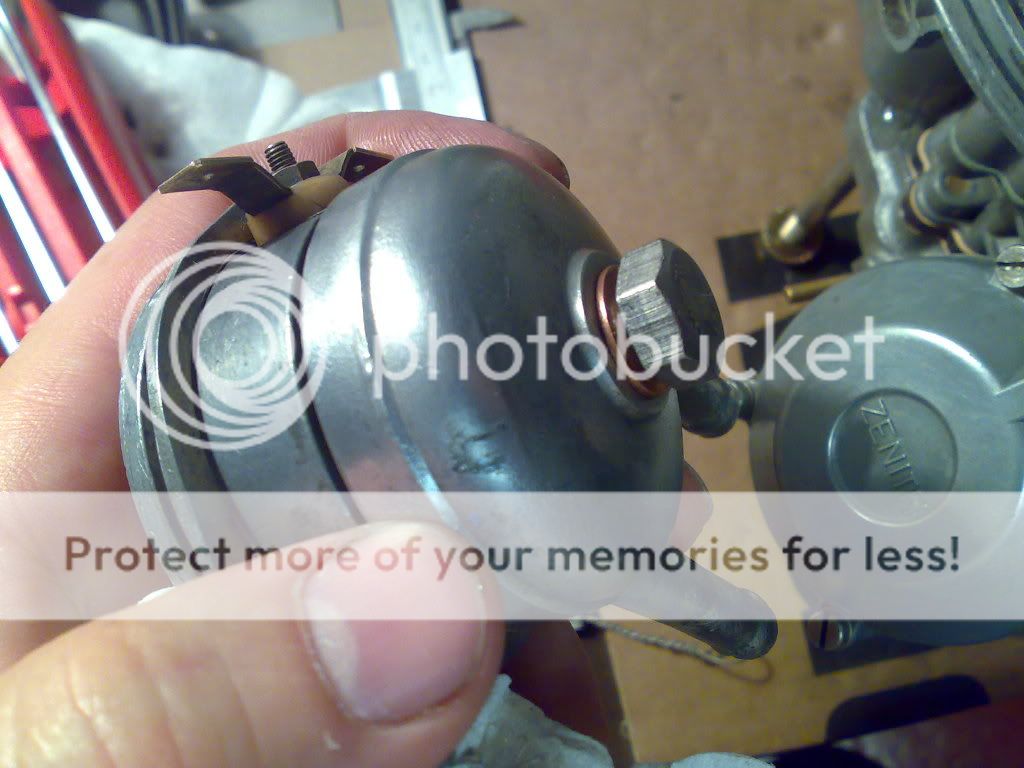

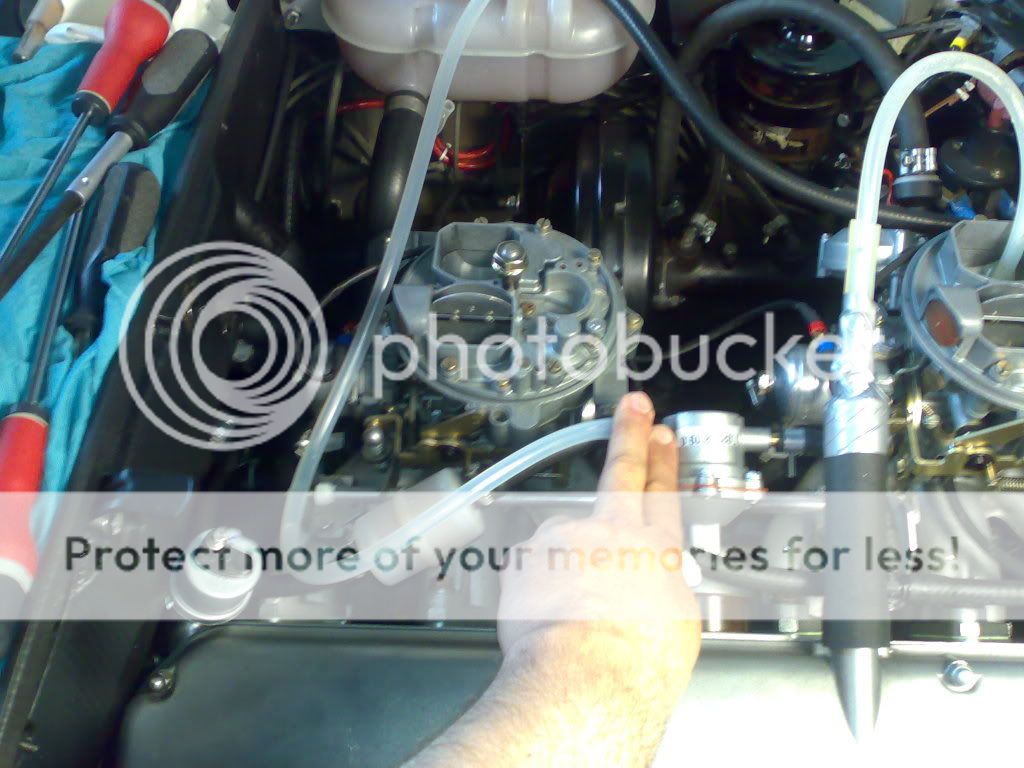

y ya esta en la mano

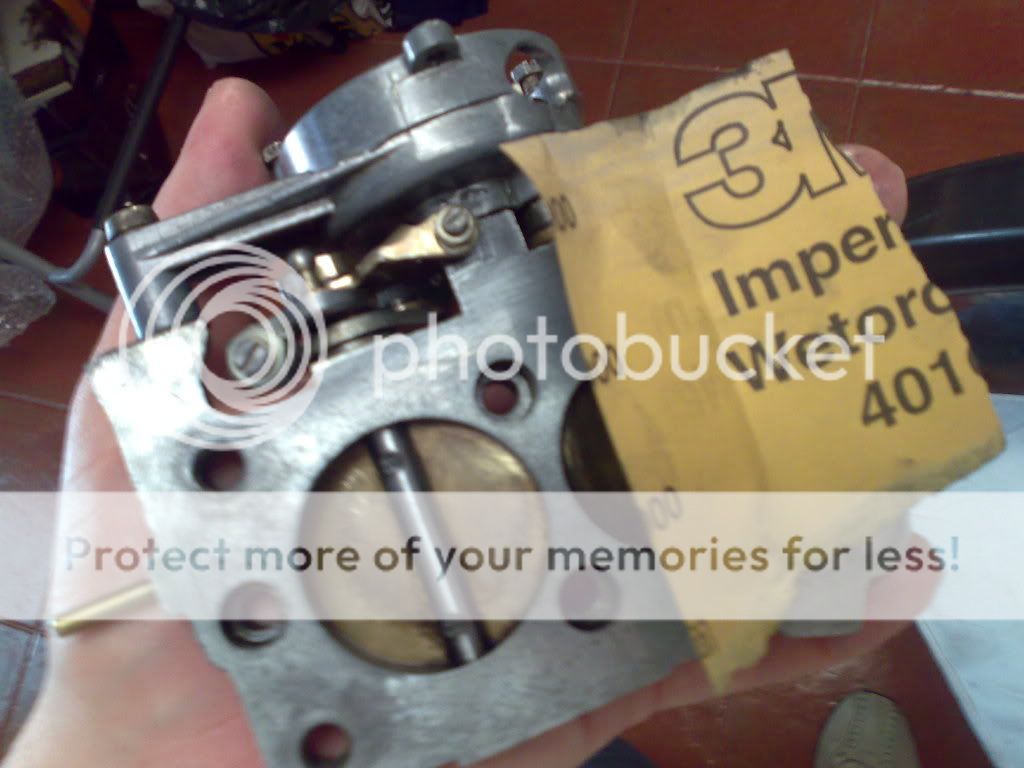

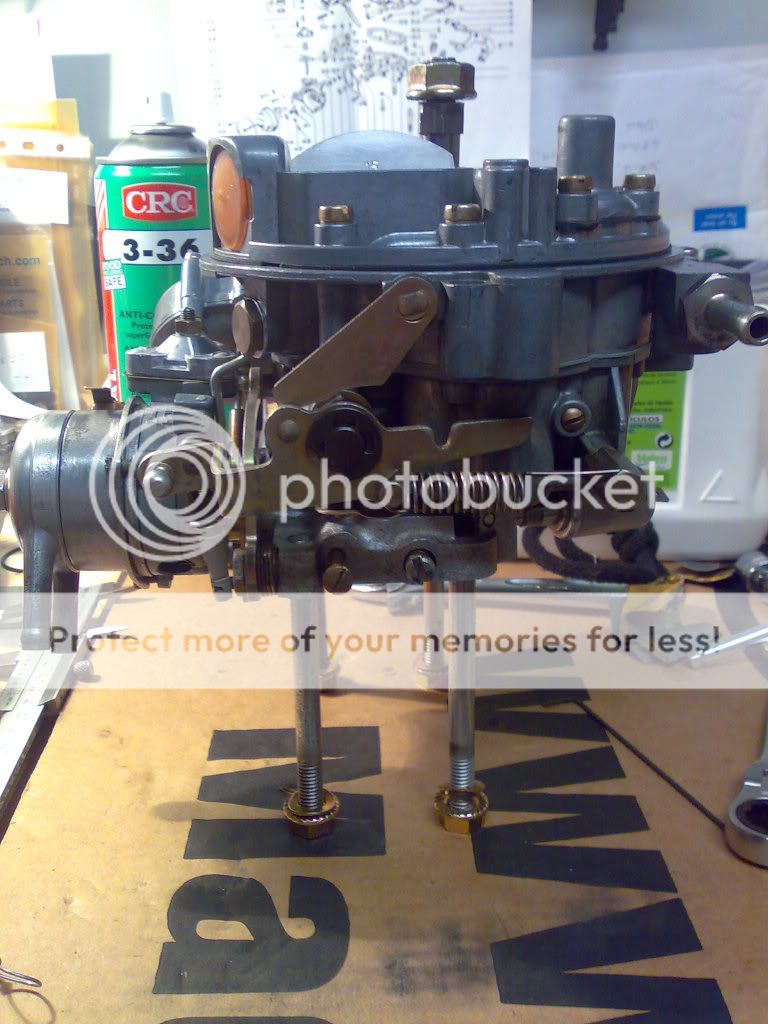

idem delantero

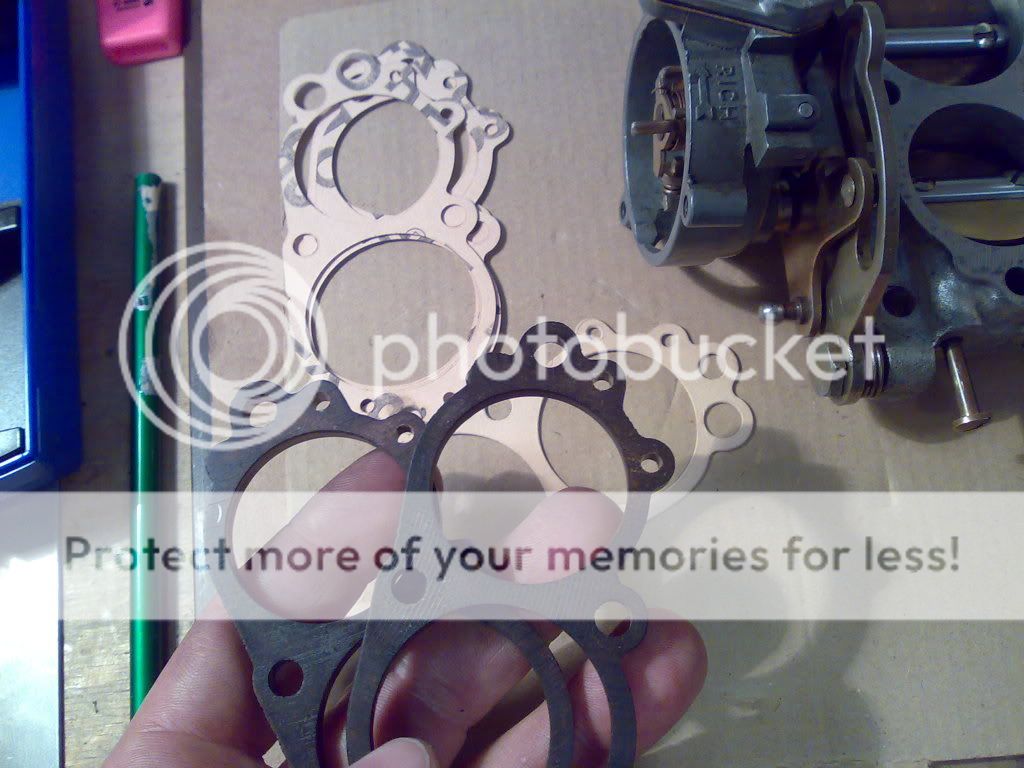

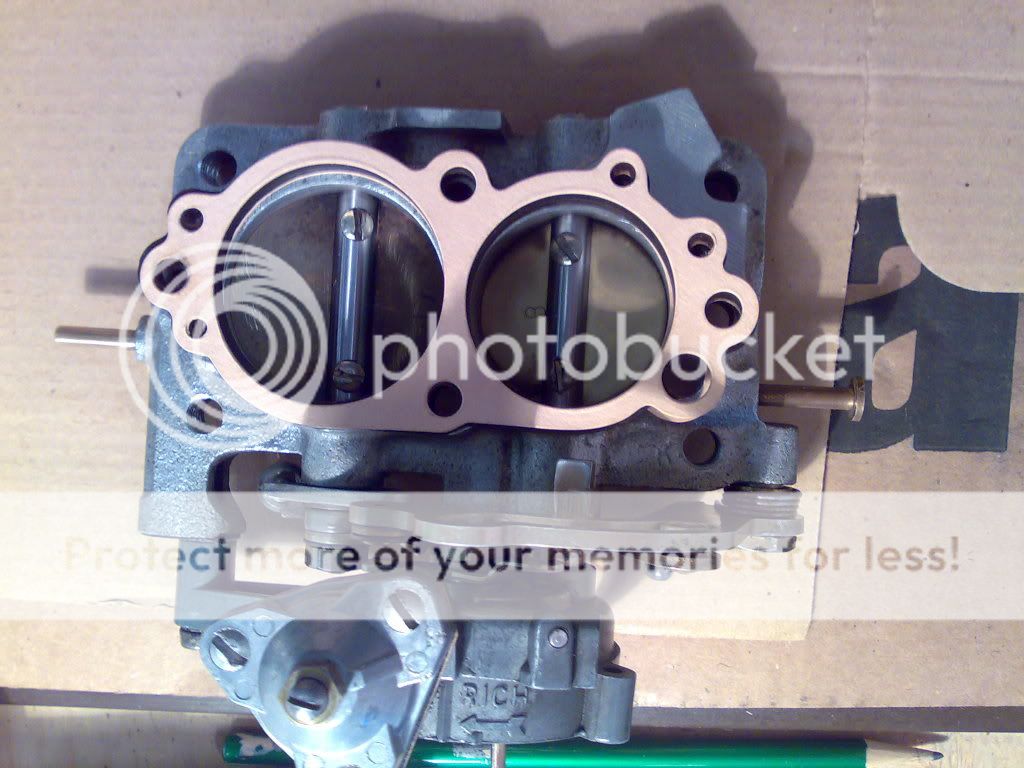

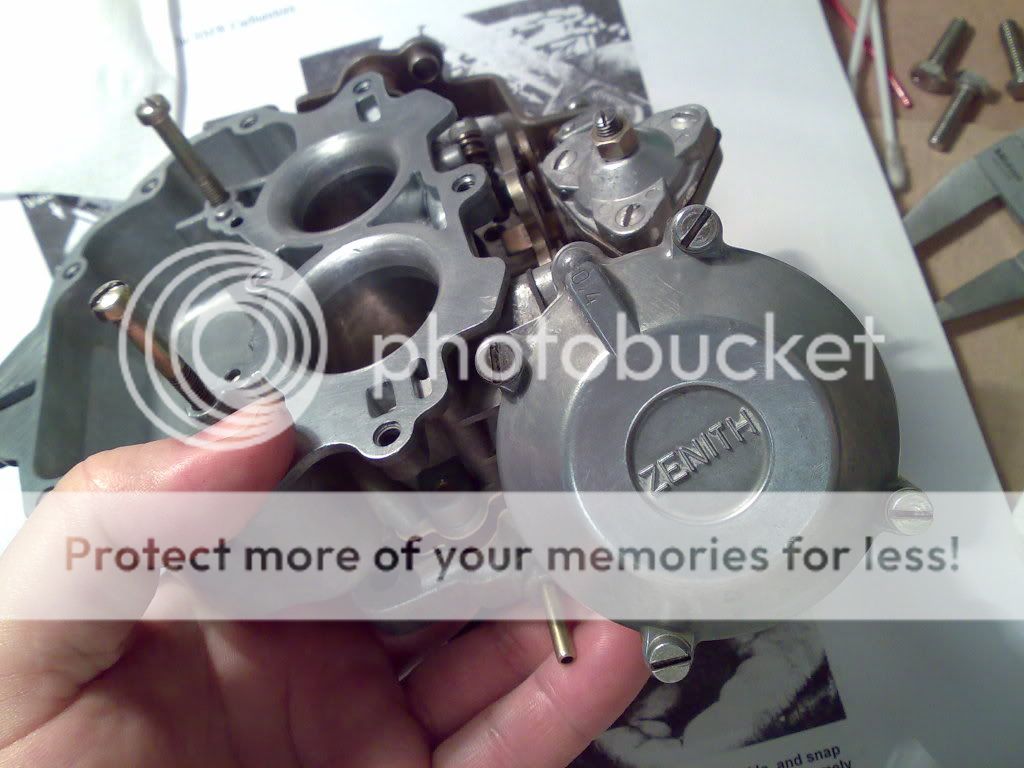

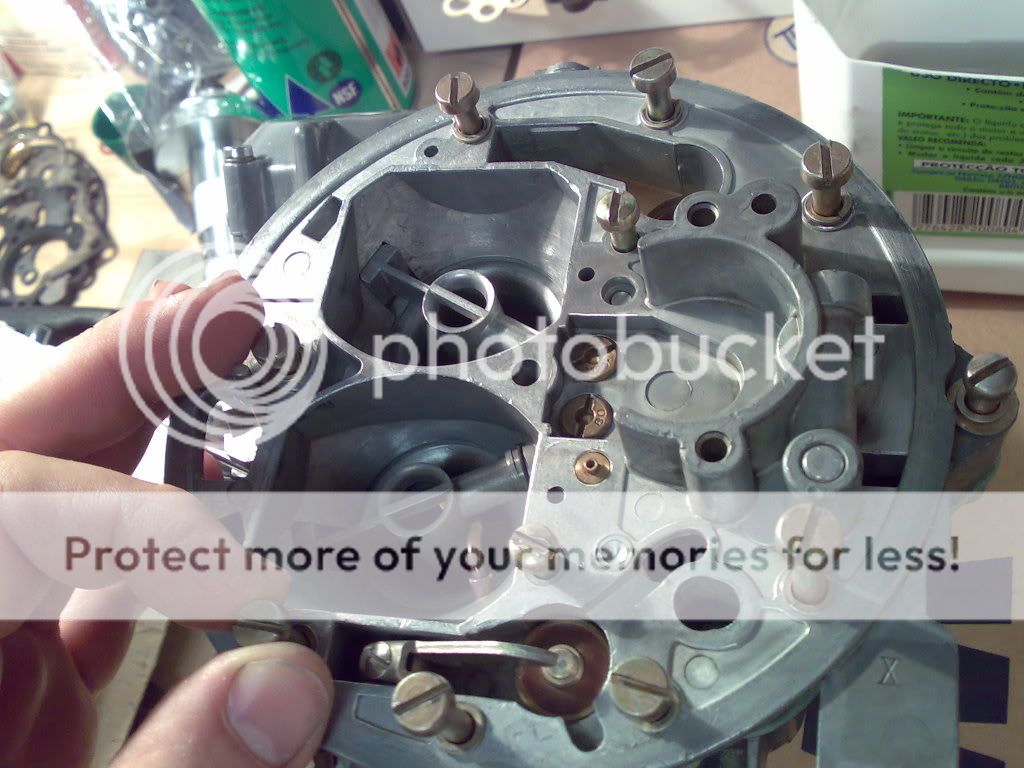

se pulen las bases de los carburadores con lija de agua del 1200, para eliminar cualquier resto, y se pasa un spray de lubricacion para que quede limpio hasta el dia del montaje

suelto bomba del todo

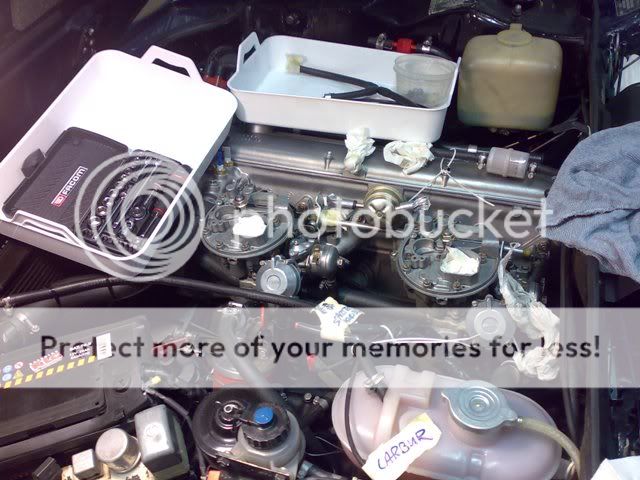

proteger con trapos

so, it has been a long time up and down with the carbs

really fed up with them, no way to synchronise both, to get a good and smooth iddle

and when the iddle (thanks to porsche61, and stevehose among others) was reached, the transition (1800 to 2200 rpm´s) was not good, and so on,...

apologies for not translating all this (probably the pics are selfexplaining), if questions, i will be really happy to answer:

-------------------------------------------------------------

empezamos

sacamos las conexiones electricas y nos rompemos las manos soltando las tuercas del carbur trasero, la buena noticia es que una vez sueltas con la llave, se sacan facil a mano

vacio el refrigerante, y la buena noticia es que sale bastante limpio (un año en el circuito) y sin aceite o porquerias

corto los tubos del circuito del carburador, esto se podria evitar, pero no quiero quitar las cazoletas en el motor, asi que corto y me llevo todo la banco

bomba de gasolina mecanica

suelto vastagos de carbur trasero

y ya esta en la mano

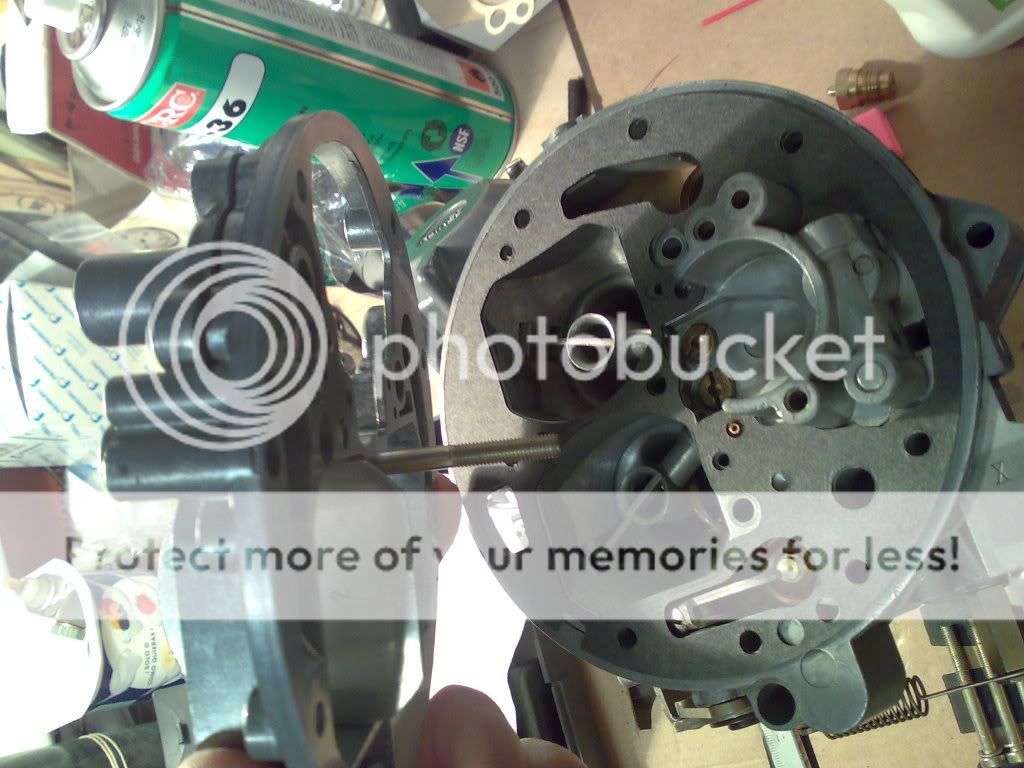

idem delantero

se pulen las bases de los carburadores con lija de agua del 1200, para eliminar cualquier resto, y se pasa un spray de lubricacion para que quede limpio hasta el dia del montaje

suelto bomba del todo

proteger con trapos

Last edited: