Update (ref to this post:

https://e9coupe.com/forum/threads/hunting-the-carbs-problem.8569/post-339585);

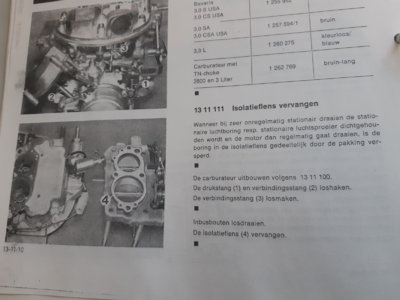

Following the picture in the tech instructions showing the sealing rings of the Idle shut off valve, I've been looking for them.

However:

- I noticed that on the site of Walloth & Neesch there are pictures of NOS parts idle shut off valve WITHOUT these rings.

-To confuse it even more, W&N show the Electric air valve WITH the metal+rubber rings.

.....So I'm not sure what is right in the end for the idle shut off valve; with our without sealing rings.

But for sure the locktite solution by

@deQuincey will work and it's universally available.

Other option is to search for some generic parts, in the end they are *just* rings with a defined thickness with a simple sealing function. Benefit is that then the sensor can be removed an re-installed a bit easier.

View attachment 131595