You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is this how it is suposed to be?? Same on both sides.

- Thread starter Frederick

- Start date

Yes, though I never looked till now.

LOL, that is somewhat of a relief. Did not look bent or replaced. Thanks for reply.

I just don't drive in the rain!. Seriously, my car is a one owner and well cared for E3. I just cannot believe that gap had any sealer in it in the past.

Great pics. Thanks

Two questions: What is a "brazed joint" and what is "terostat" ? OH, three questions, Where can I get the "blue book?" I have a CD for my 2002 and only the german version downloaded from W&N, which is not terribly useful.

Two questions: What is a "brazed joint" and what is "terostat" ? OH, three questions, Where can I get the "blue book?" I have a CD for my 2002 and only the german version downloaded from W&N, which is not terribly useful.

brazing is another term for body soldering, they used tin in the past, today I guess polyester body fillers are more widely used

I guess "terostat" was the used seal/foam by BMW at the time on the edges between body and fender (seam sealer)

I guess "terostat" was the used seal/foam by BMW at the time on the edges between body and fender (seam sealer)

Last edited:

Usually they used tin to fill gaps or smoothen surfaces. Use of lead is very unlikely. Tin brazing was done on nearly every corner of the E3 shell.

"Terostat" is just a product name. There were and are others that start with "Tero-", undercoating and so on. Terostat is a double-sided self-adhesive tape, usually white or black, a bit like chewing gum. Stays elastic for very long and does not absorb water or other liquids. "Sealing tape" should be the term.

"Terostat" is just a product name. There were and are others that start with "Tero-", undercoating and so on. Terostat is a double-sided self-adhesive tape, usually white or black, a bit like chewing gum. Stays elastic for very long and does not absorb water or other liquids. "Sealing tape" should be the term.

you can use sealing cord found in a local hardware store, it is grey and round and used for applications like waterproofing glass installed into wood window frames. On your car, you lay it between the sheet metal flanges and it compresses when you bolt your parts together and seals the joint and is not absorbent and looks identical to whatever was used when your car was first built and you've assembled it! Pluse, the round cord form tends to fill the joint more completely, discouraging water from passing through the joint. Your mileage may vary.

Amazing. Once again, ask a question, get the correct answer, and instructions, and advice, and photos. Amazing tribe we have here. In this Brave New World I expect that soon when you pose a question an e9 member will show up at your door within 24 hours with the parts and the necessary experience and R&R and paint.

Wow!

Wow!

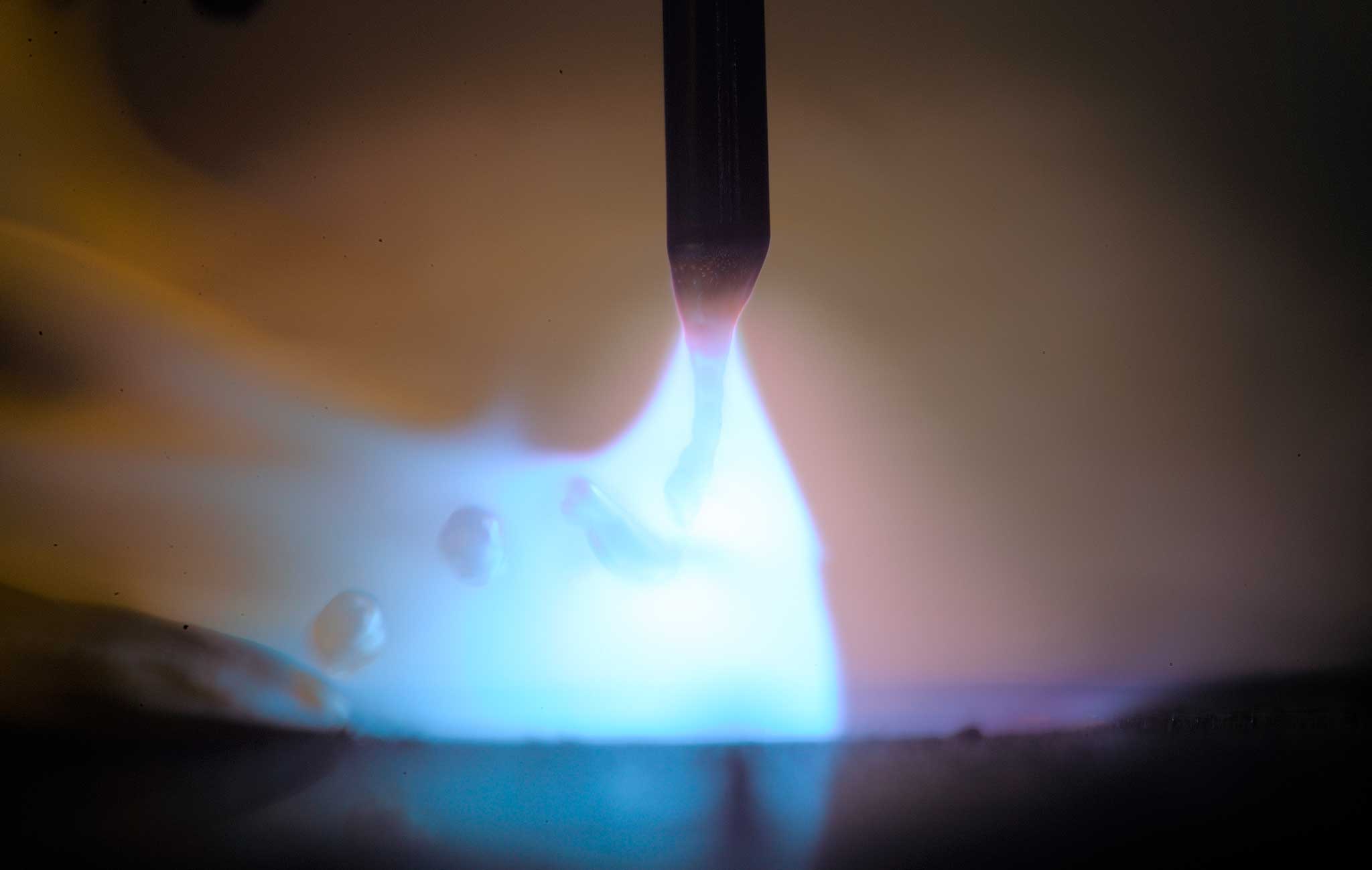

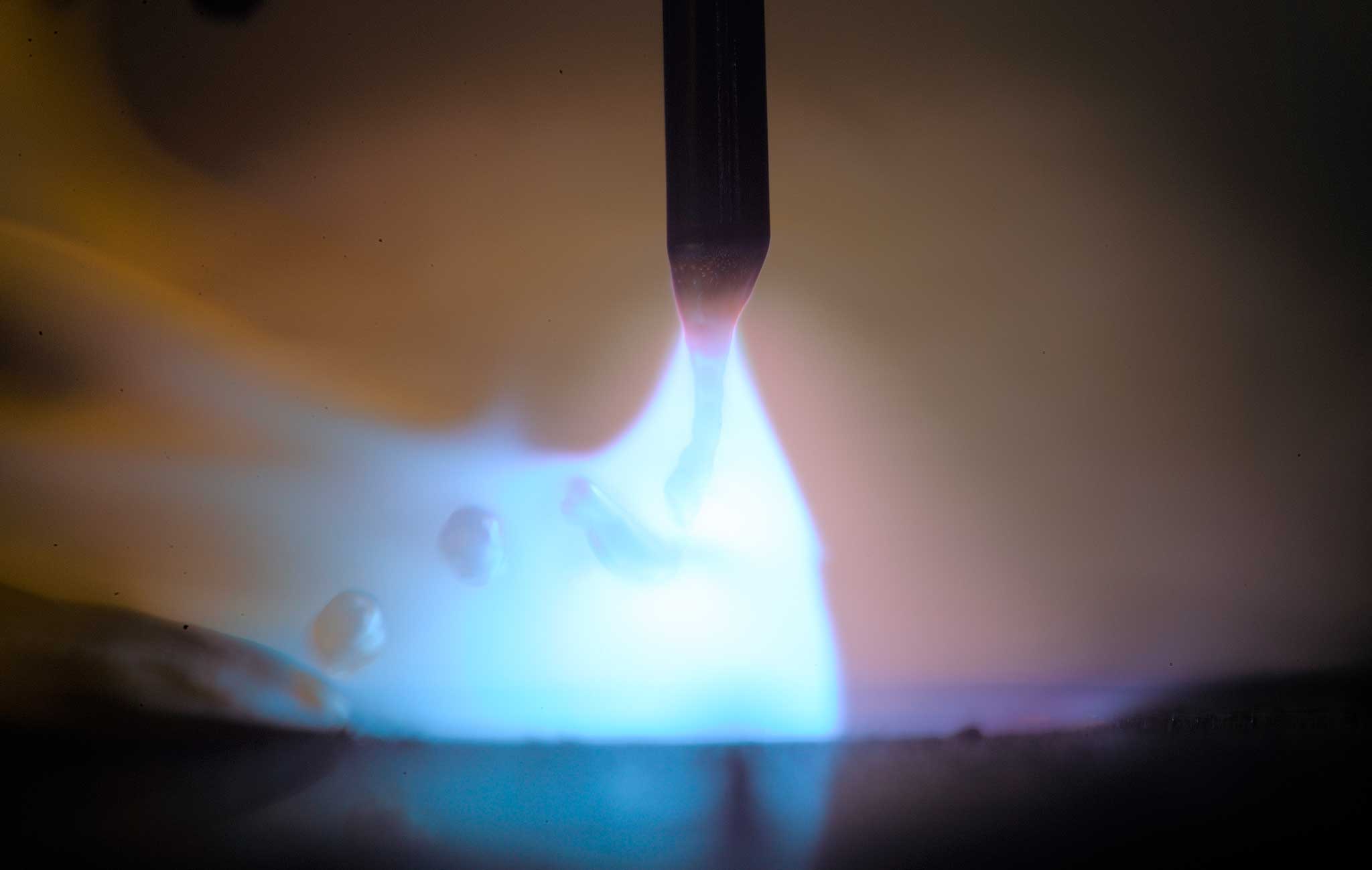

Brazing is distinct from soldering. The difference is it uses higher-strength materials that melt at a higher temperature than soldering materials but still below the melting temperature of the base materials.

You certainly wouldn't use polyester body fillers between two butt-joined body panels as the joint would likely crack. Either a softer more compliant material or a stronger material like brazing compounds.

In my limited experience, I have only seen reference to lead bodywork for the E9 from the factory, not tin, though I suppose that's possible. Lead was the traditional material for auto bodywork though polyester body fillers have supplanted its use because of lead's cost, toxicity, and skills needed to get good results.

You certainly wouldn't use polyester body fillers between two butt-joined body panels as the joint would likely crack. Either a softer more compliant material or a stronger material like brazing compounds.

In my limited experience, I have only seen reference to lead bodywork for the E9 from the factory, not tin, though I suppose that's possible. Lead was the traditional material for auto bodywork though polyester body fillers have supplanted its use because of lead's cost, toxicity, and skills needed to get good results.

What is the Difference Between Welding, Brazing and Soldering?

Welding, brazing and soldering are all methods for joining two or more pieces of material – primarily metals. The key difference among these processes is the temperature used to create the joint.

www.twi-global.com