Howdy.

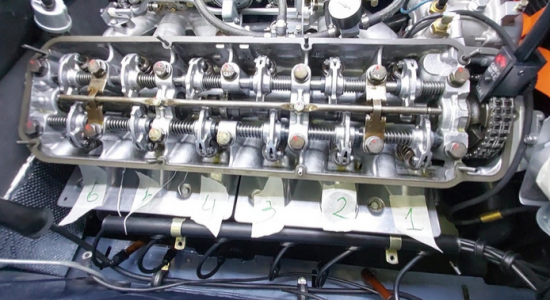

This is the kind of things that i do best, providing useful hands-on documentation for people that love the emotion to have dirty hands and white smiles in their faces while taking care of their e9 coupes or e3 sedans

I take the information comming from the blue books, and bring my own experience to this, as always with some pics to clarify the evolution. Because as i said 14 years ago i think that wen you see that someone has done it you feel that you can do it too.

This is the kind of things that i do best, providing useful hands-on documentation for people that love the emotion to have dirty hands and white smiles in their faces while taking care of their e9 coupes or e3 sedans

I take the information comming from the blue books, and bring my own experience to this, as always with some pics to clarify the evolution. Because as i said 14 years ago i think that wen you see that someone has done it you feel that you can do it too.

Last edited: