You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LAN my renewed engine M30B30 Running in process

- Thread starter deQuincey

- Start date

check the dwell angle, using the strobo gun,

found that if gap is 0,4mm loose, dwell is 32degrees

so I set gap at 0,4mm tight, now dwell is 35 degrees

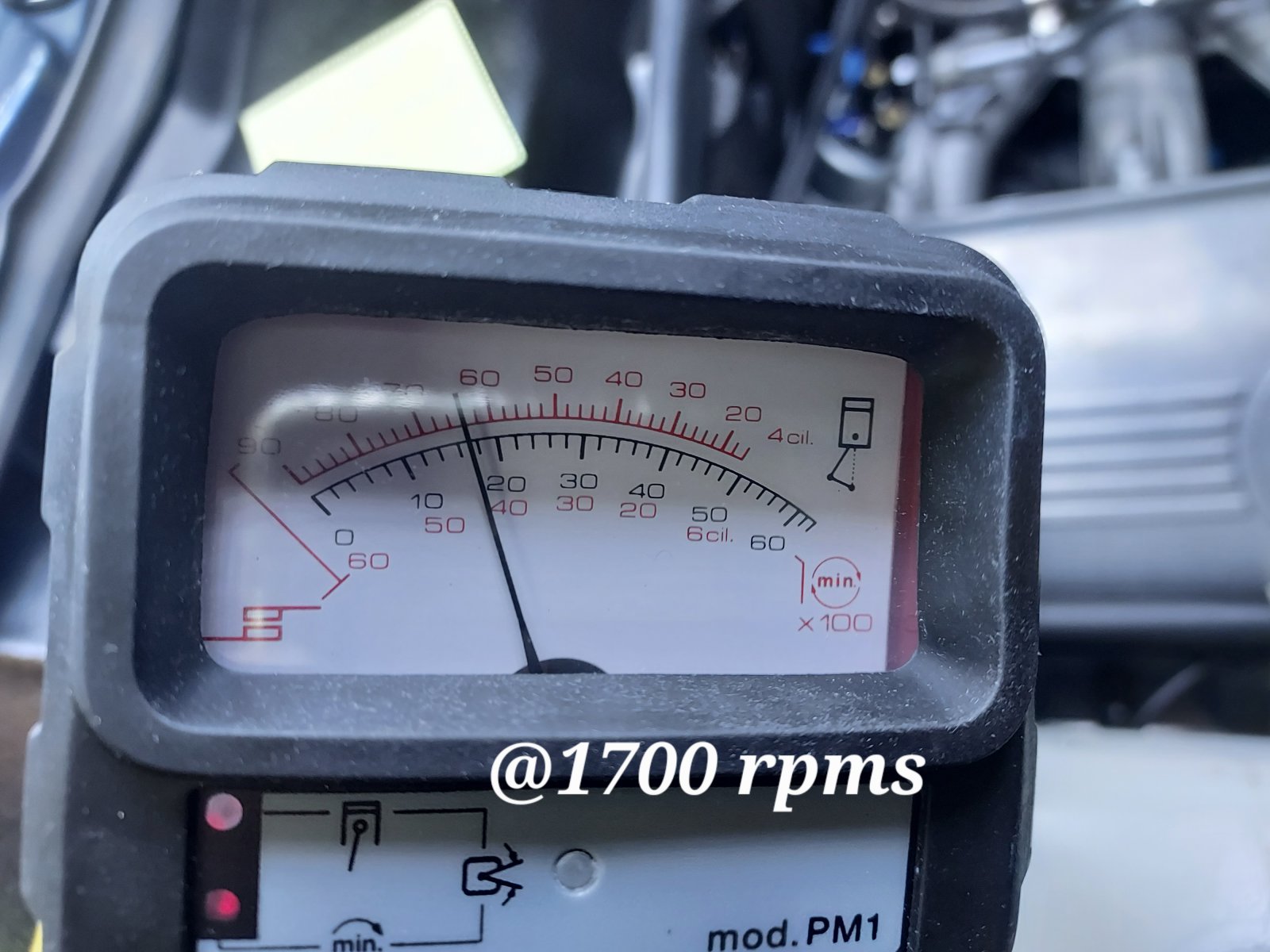

I check dwell at 900, 1700 and 3000 rpms, change only one degree,

so, now, remove advance hose at distributor, and cap it

raise rpms until 1700,

aim the strobo at the window and find the ball…

if needed rotate distributor…

found that if gap is 0,4mm loose, dwell is 32degrees

so I set gap at 0,4mm tight, now dwell is 35 degrees

I check dwell at 900, 1700 and 3000 rpms, change only one degree,

so, now, remove advance hose at distributor, and cap it

raise rpms until 1700,

aim the strobo at the window and find the ball…

if needed rotate distributor…

Last edited:

It must be said that there is a direct relationship between dwell and advance, with the dwell at 32 the ball still did not appear and it was the Z that was aligned with the mark, that is, the advance was a couple of degrees greater, I calculate that instead 22° would be 24°. When I adjusted the dwell to 35° the ball appeared aligned with the mark.

Last edited:

Thanks to Google...

"

It must be said that there is a direct relationship between dwell and advance, with the dwell at 32 the ball still did not appear and it was the Z that was aligned with the mark, that is, the advance was a couple of degrees greater, I calculate that instead 22° would be 24°. When I adjusted the dwell to 35° the ball appeared aligned with the mark.

"

"

It must be said that there is a direct relationship between dwell and advance, with the dwell at 32 the ball still did not appear and it was the Z that was aligned with the mark, that is, the advance was a couple of degrees greater, I calculate that instead 22° would be 24°. When I adjusted the dwell to 35° the ball appeared aligned with the mark.

"

oh i just dictated it to my phone and posted it, thank you for translationThanks to Google...

"

It must be said that there is a direct relationship between dwell and advance, with the dwell at 32 the ball still did not appear and it was the Z that was aligned with the mark, that is, the advance was a couple of degrees greater, I calculate that instead 22° would be 24°. When I adjusted the dwell to 35° the ball appeared aligned with the mark.

"

thoughts:

It must be said that there is a direct relationship between dwell and advance, with the dwell at 32 the ball still did not appear and it was the Z letter that was aligned with the mark,

that is, the advance was a couple of degrees earlier, I calculate that instead 22° was 24°.

When I adjusted the dwell to 35° the ball appeared perfectly aligned with the mark.

You can always adjust the distributor by rotating it in any dwell position, that is, with the dwell of 32, I would also have been able to align the ball.

What is significant is that this difference of about three degrees in the dwell (from 35 to 32) also means a difference in the advance.

recapitulation:

i have learnt two things,

1- the first is that the greater the separation of the GAP between the points, the smaller the dwel angle is

2- and the second, an evolution of the dwel angle at the points, for example due to wear, vibrations,... If the dwell is reduced (as In this case, from 35 to 32), it will mean that the engine ignition advance is increased. (from 22º to 24º)

It must be said that there is a direct relationship between dwell and advance, with the dwell at 32 the ball still did not appear and it was the Z letter that was aligned with the mark,

that is, the advance was a couple of degrees earlier, I calculate that instead 22° was 24°.

When I adjusted the dwell to 35° the ball appeared perfectly aligned with the mark.

You can always adjust the distributor by rotating it in any dwell position, that is, with the dwell of 32, I would also have been able to align the ball.

What is significant is that this difference of about three degrees in the dwell (from 35 to 32) also means a difference in the advance.

recapitulation:

i have learnt two things,

1- the first is that the greater the separation of the GAP between the points, the smaller the dwel angle is

2- and the second, an evolution of the dwel angle at the points, for example due to wear, vibrations,... If the dwell is reduced (as In this case, from 35 to 32), it will mean that the engine ignition advance is increased. (from 22º to 24º)

Last edited:

Now carburetor tune and synchro....

remove the rear knurled bolt, try to get:

1- CO% as close as possible to 2% using the iddle screw

2- while iddle is at 900rpms

3- by means of the air screws at the carbs

Results at iddle

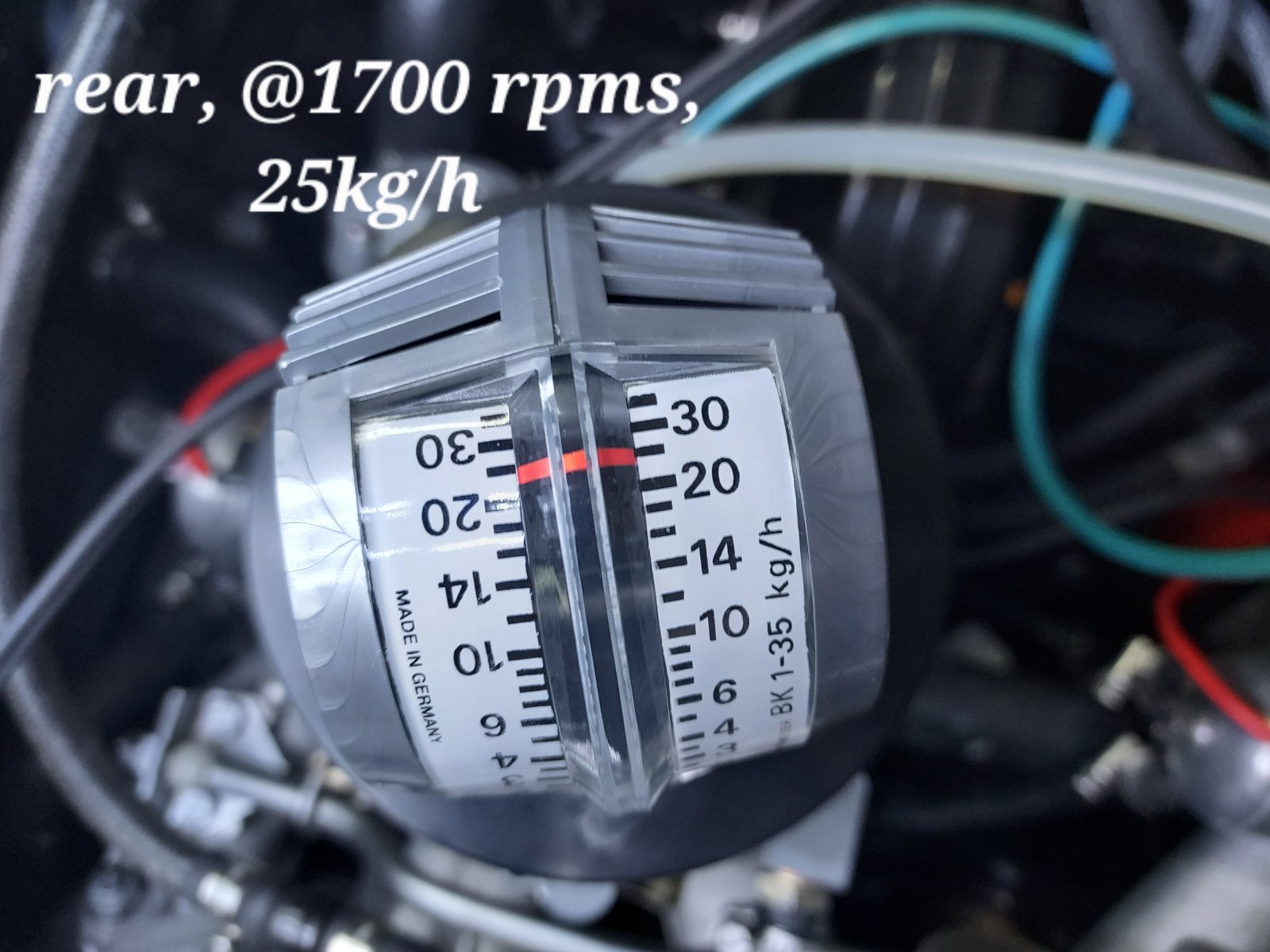

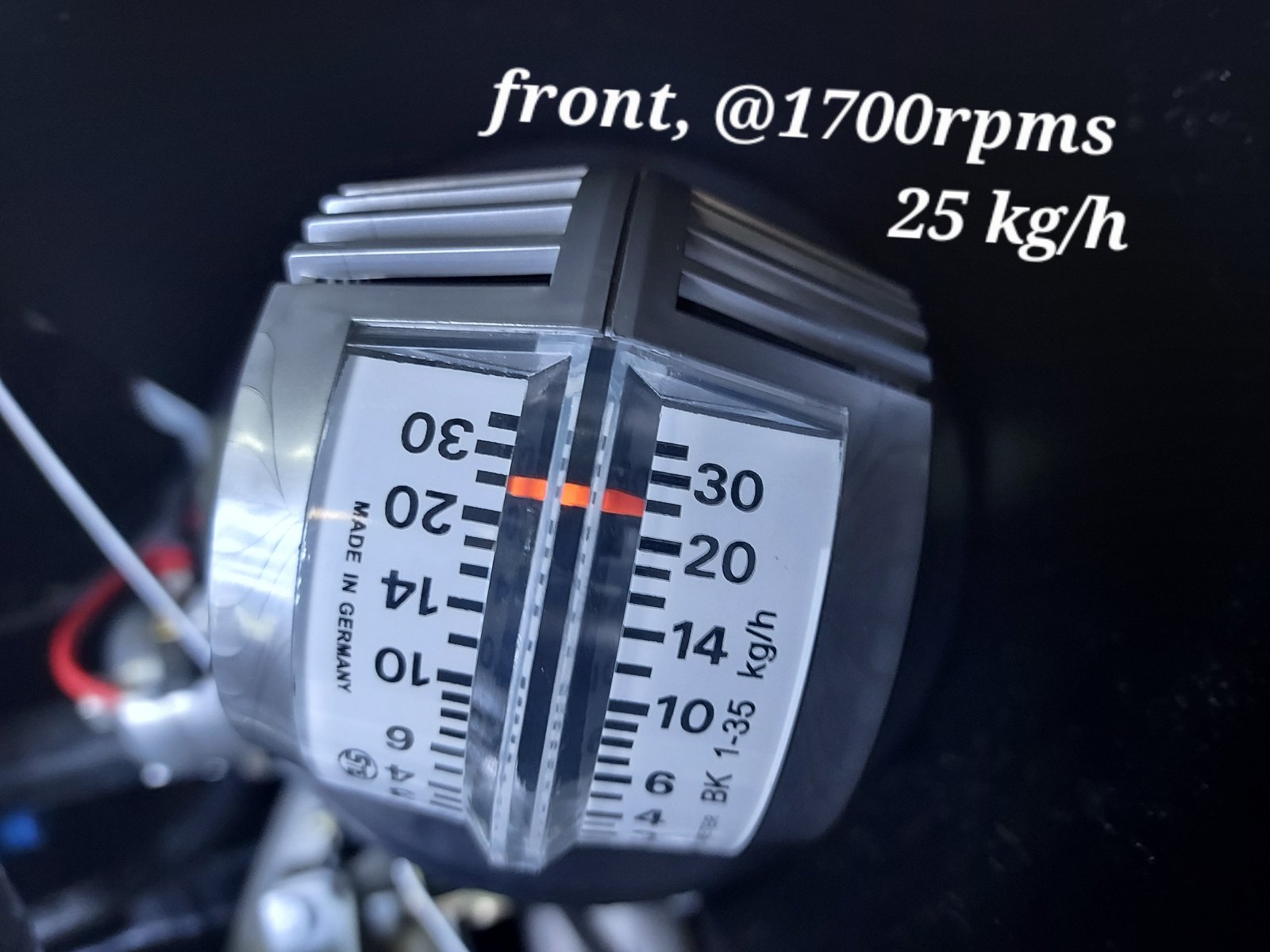

Now engage the knurled bolt and rise rpms until 1700

by means of knurled bolt set equal air flow at both carbs

remove the rear knurled bolt, try to get:

1- CO% as close as possible to 2% using the iddle screw

2- while iddle is at 900rpms

3- by means of the air screws at the carbs

Results at iddle

Now engage the knurled bolt and rise rpms until 1700

by means of knurled bolt set equal air flow at both carbs

Last edited:

so 1000km mark passed, made the whole process: headbolts / valve gap / carbs synchro

iddle 980rpms

CO% is 2%

result sounds good to me:

iddle 980rpms

CO% is 2%

result sounds good to me:

Last edited:

320km since 1000km

getting better and smoother; valve gap sound is the best one that i have done

eng revving very well, reaching the 4500rpms in a second

fast cruising, and very very quiet, the insulation job using modern materials is amazing

happy

getting better and smoother; valve gap sound is the best one that i have done

eng revving very well, reaching the 4500rpms in a second

fast cruising, and very very quiet, the insulation job using modern materials is amazing

happy

Last edited:

important check of tyre pressure; very accurate motometer gauge

2,5 bar front

2,2 bar rear

2,5 bar front

2,2 bar rear