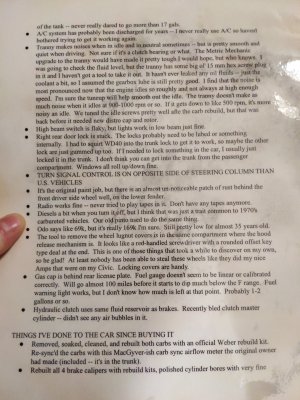

The dieseling has been there since I bought the car. Even noted on some documents I found that came with the car dating back to 2006. See attached - this is the from the 2nd owner passing the tribal knowledge down to the 3rd.

The second caretaker’s notes indicate that the weber carbs were “recently” rebuilt. This begets many inquiries, including why, or in other words, what issue/s needed correction?

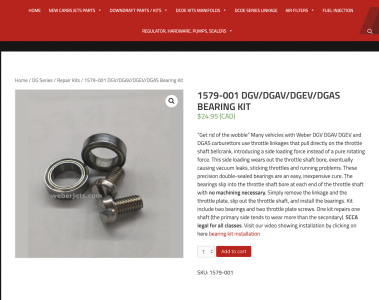

The common Weber 32/26 downdraft carb has a few shortcomings, including throttle shaft wear due to side loading, so that excessive movement can result in intermittent vacuum leaks and (unwanted) fuel mixture changes. This issue is often

imperfectly mitigated by slightly enrichening the mixture via the mixture screw/s or larger idle jets and/or main jet changes -- and sometimes, imaginative ignition timing changes. (Repair kits for worn throttle shafts may still be available. This is NOT to say that this is your problem, but excessive shaft movement is worth exploring.)

It is interesting to note that some 32/26 DGV carburetors were deemed to be acceptable for use by the California Air Resources Board. This does not automatically ensure that any compliant Weber achieves the exact same fuel mixture production results as the Zenith carburetor it replaces. Since Webers were not original equipment, there is no one-size-fits-all owners manual blueprint for weber jetting. Many jet sizes may work with M30 engines, but some recipes work better than others, especially with different driving applications in a 50-year-old engine. To a certain degree, the same logic applies to ignition timing. One expects that your Jacobs coil and/or CD ignition system or your Allison ignition could have worked fairly well with your fine wire spark plugs. That said, could those aftermarket ignition upgrades have been intended to correct the very symptoms referenced in your post?

The run on/ dieseling condition probably reached its apogee in the 1970s and 1980's due to manufacturers’ attempts to meet stricter CO and NO emissions standards. Some manufacturers attempted to satisfy reduced emissions (and fuel economy) standards by pushing the limits of workable lean mixtures along with higher engine operating temperatures to the point of compromising engine performance and - creating conditions ripe for run on and/or dieseling. The many available jetting choices for your Weber carburetors (including slightly larger idle jets) arguably provides a workaround for difficult-to-meet mixture concerns while providing improved engine operation.

In theory, if the idle solenoids are working as designed, removing the engine’s fuel source should eliminate run on/dieseling. When this does not work, you might consider whether there are other residual fuel sources. (Worn throttle shafts or other worn or maladjusted carburetor parts, including one or more leaky accelerator pump gaskets, might possibly account for some of this. Could this be a reason for the “recent” rebuilds?) At the same time, consider eliminating any residual ignition source induced by excessive pressure or temperatures. If your engine has higher than normal compression, or an aftermarket camshaft - or hot spots caused by combustion chambers loaded with unburnt carbon deposits, you might consider resorting to:

larger idle jets, lower idle speed, reduced engine operating temperatures, colder range spark plugs, thicker base gaskets or remapped/retarded ignition timing.

Another imperfect “fix” might be using higher octane (less volatile) fuel.

For illustration purposes only. No recommendation for specific jet applications.