Hi all,

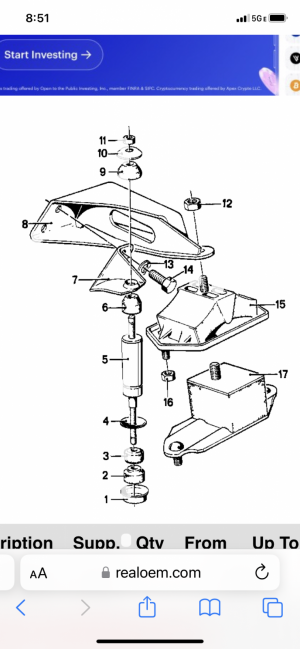

Is there anything I should disconnect (hoses etc.) before raising up the engine to replace the mounts? Is it safe to jack up the engine with a floor jack and 2x4 under the oil pan? The repair manual of course recommends using a hoist, which I don't have. Any advice would be greatly appreciated as this will be my first time attempting this repair.

Thanks,

Travis

Is there anything I should disconnect (hoses etc.) before raising up the engine to replace the mounts? Is it safe to jack up the engine with a floor jack and 2x4 under the oil pan? The repair manual of course recommends using a hoist, which I don't have. Any advice would be greatly appreciated as this will be my first time attempting this repair.

Thanks,

Travis