'69 2800cs

Well-Known Member

My starting point was shiny paint and a seemingly perfect quarter panel. The cosmetic rocker cover was in excellent condition. But....there was a small fiberglass patch in front of the passenger rear wheel.

Time to find out whats going on inside that rocker!

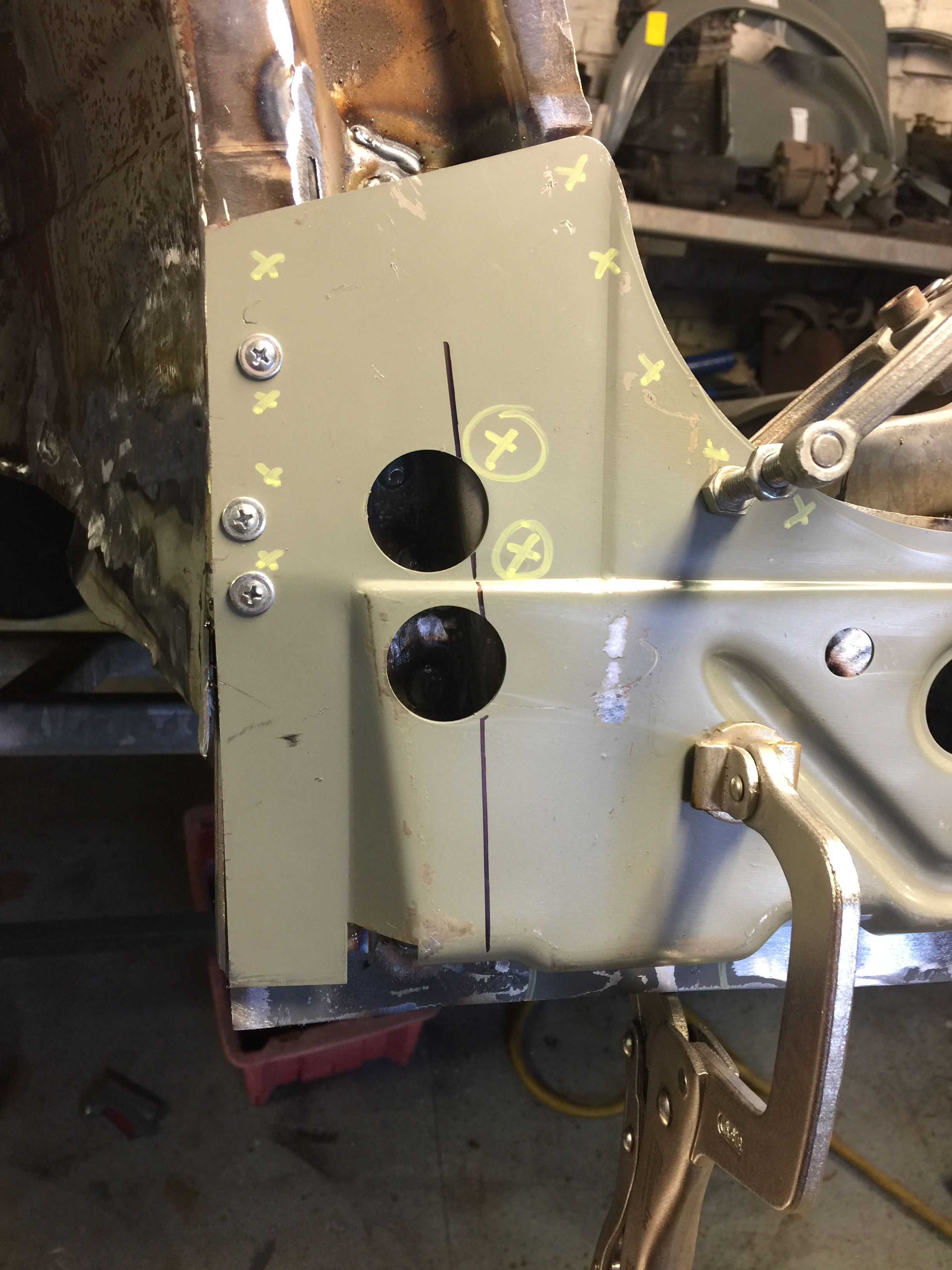

I took the door off and reinforced-

Time to find out whats going on inside that rocker!

I took the door off and reinforced-