bimmerboy73

Well-Known Member

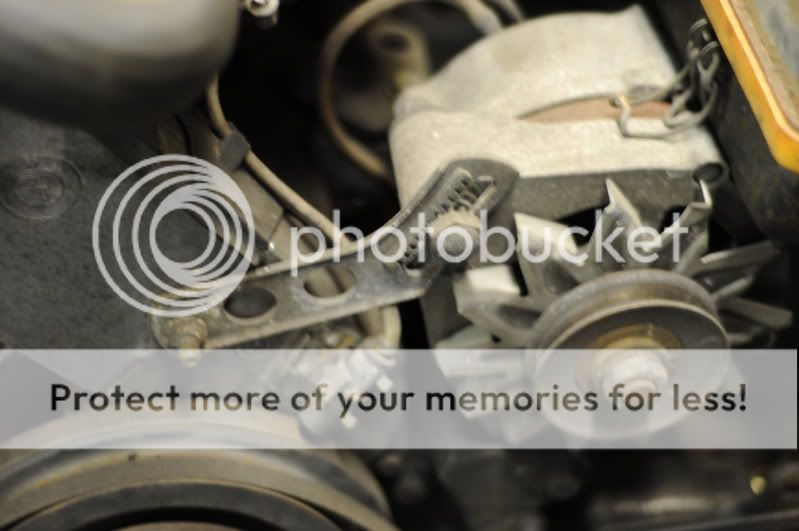

My alternator recently conked out on me so i was going to go ahead and replace it with the 80amp variety from an 85 635 csi. I've browsed the forum and am fairly square on what needs to be done and how to go about it. Question is, i know the bracket to mount the alt is slightly different and so you have to use the e24 bracket to install it, but were their a couple of variations? The shop owner has a couple of m30's laying around the shop and said i am welcomed to take whatever mounting hardware i need from them. However, there are 2 different types from what i can tell. Referencing Maximillian, it would seem as though this one is correct:

The only difference i can see is the hole cut into the top of it but figured i'd ask just in case.

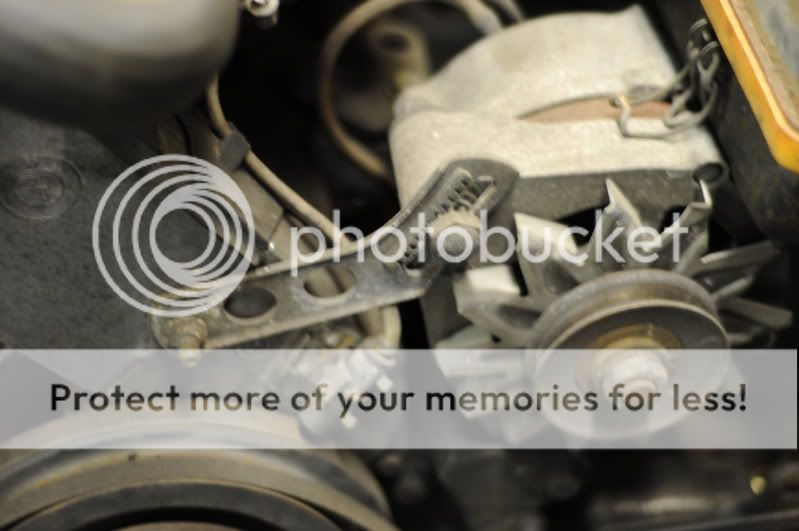

The other bracket that i saw was this one:

Never seen it before and it seems a little on the flimsy side. Any clue what engine this came off of? It had a tarp covering it up so i couldnt get a good look at it to ID it.

As always, thanks in advance...

Richard

The only difference i can see is the hole cut into the top of it but figured i'd ask just in case.

The other bracket that i saw was this one:

Never seen it before and it seems a little on the flimsy side. Any clue what engine this came off of? It had a tarp covering it up so i couldnt get a good look at it to ID it.

As always, thanks in advance...

Richard