rear trunk interior trim renewal. FINISHED plus

i am finding the cardboards of the trim panels quite damaged by humidity, it is a very poor material for this kind of use because it is not really prepared to avoid moisture

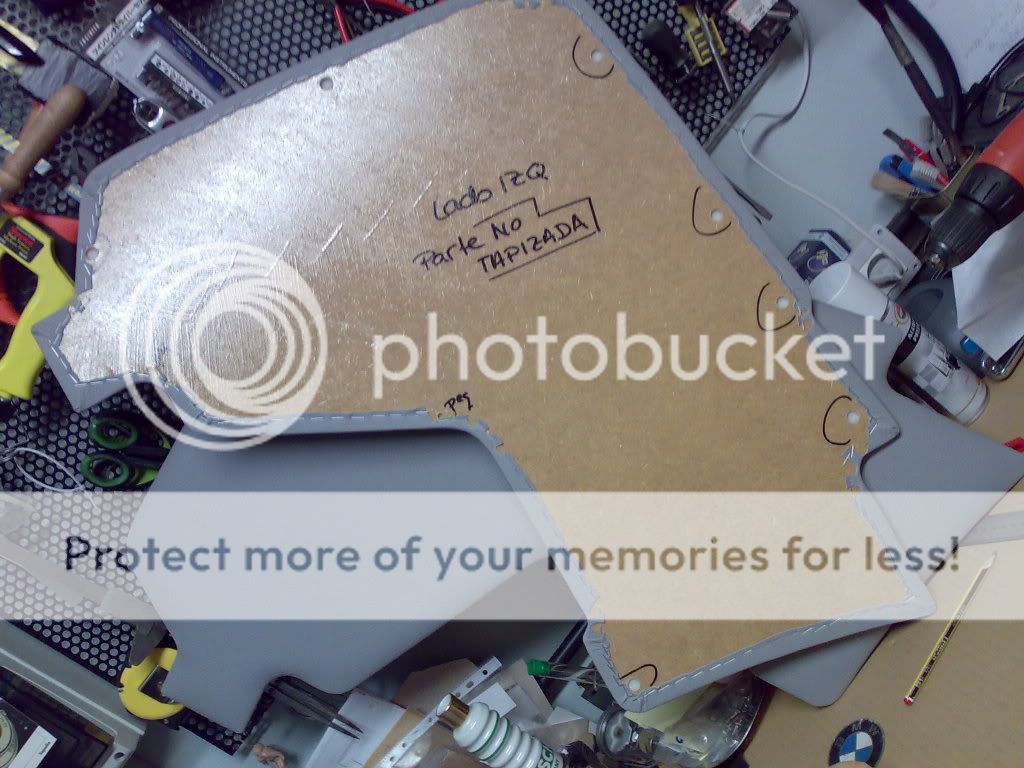

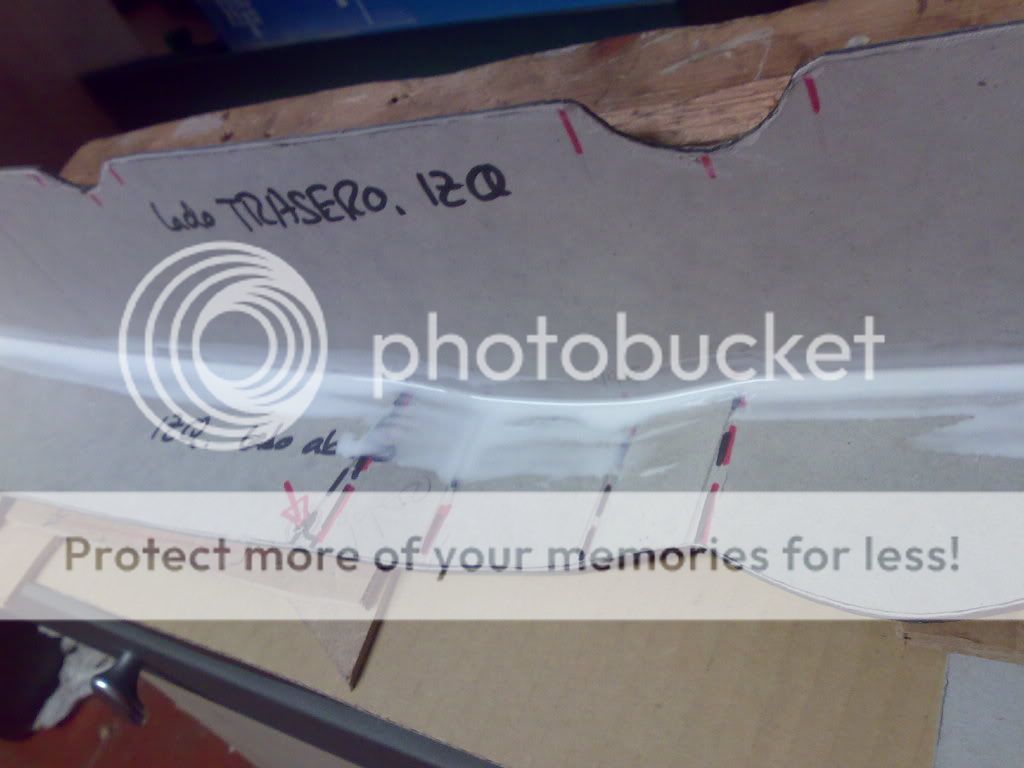

removal of the trim panels:

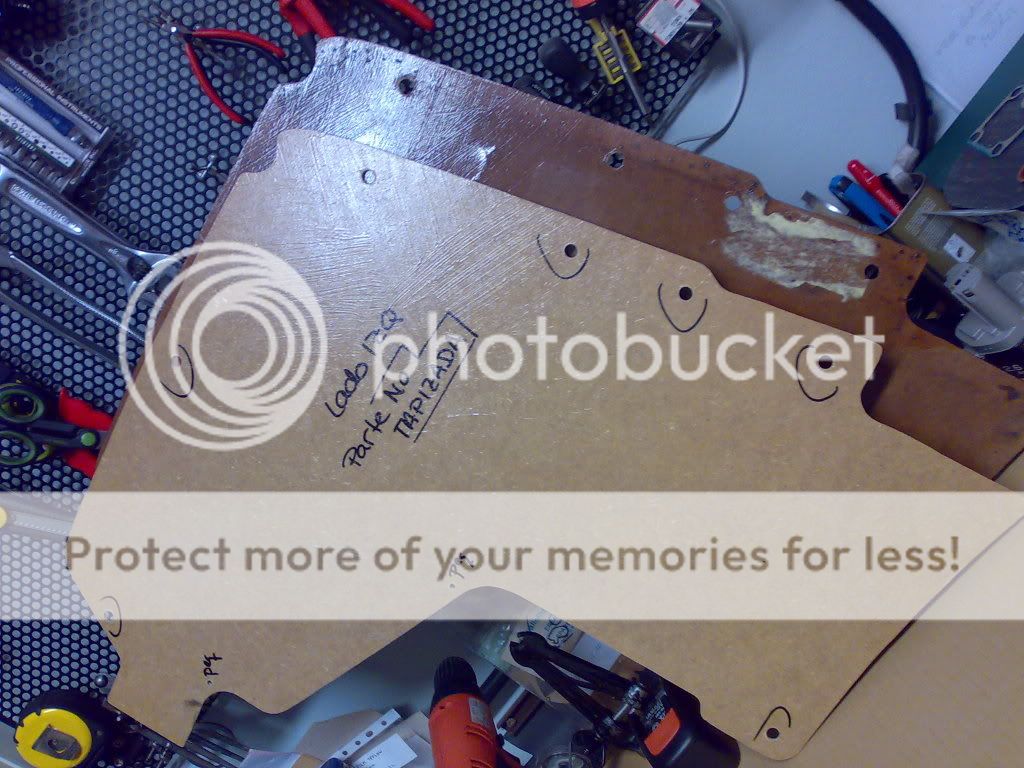

condition found of panels:

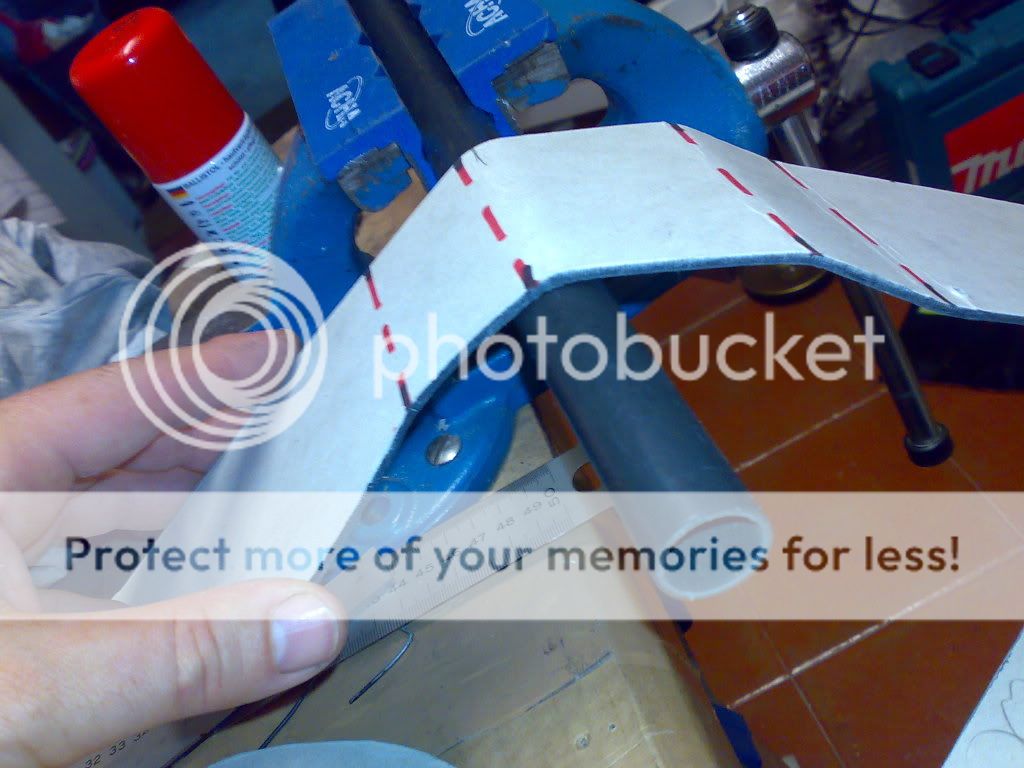

remove staples:

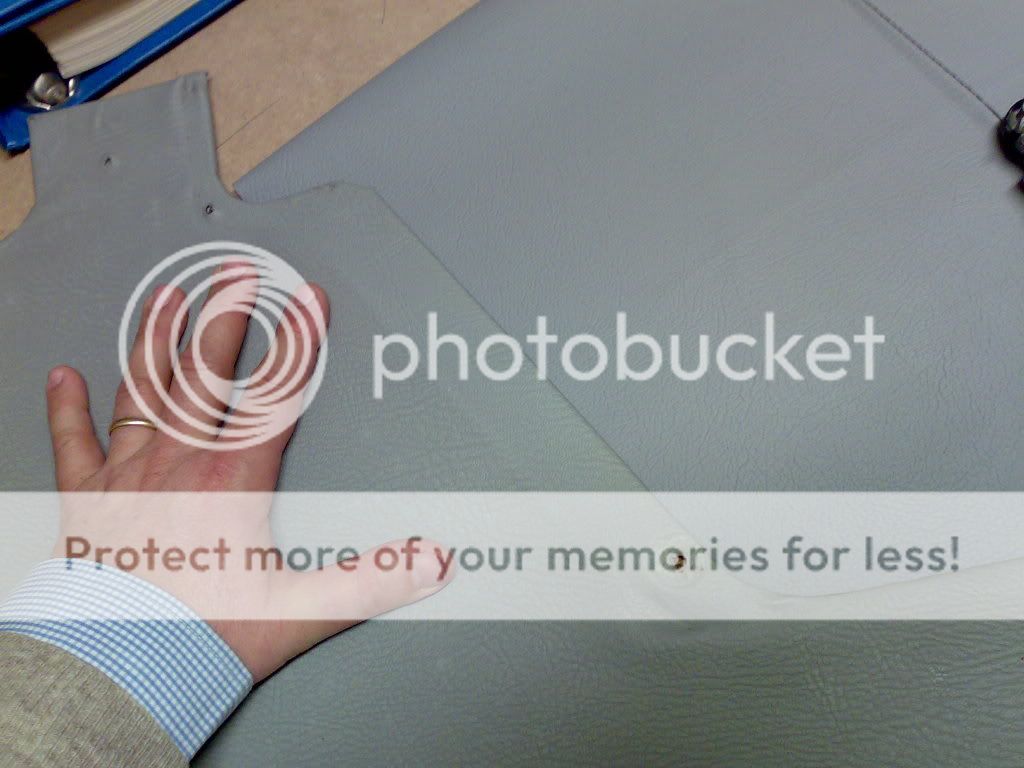

remove textile skin:

clean with soap and water

cardboard:

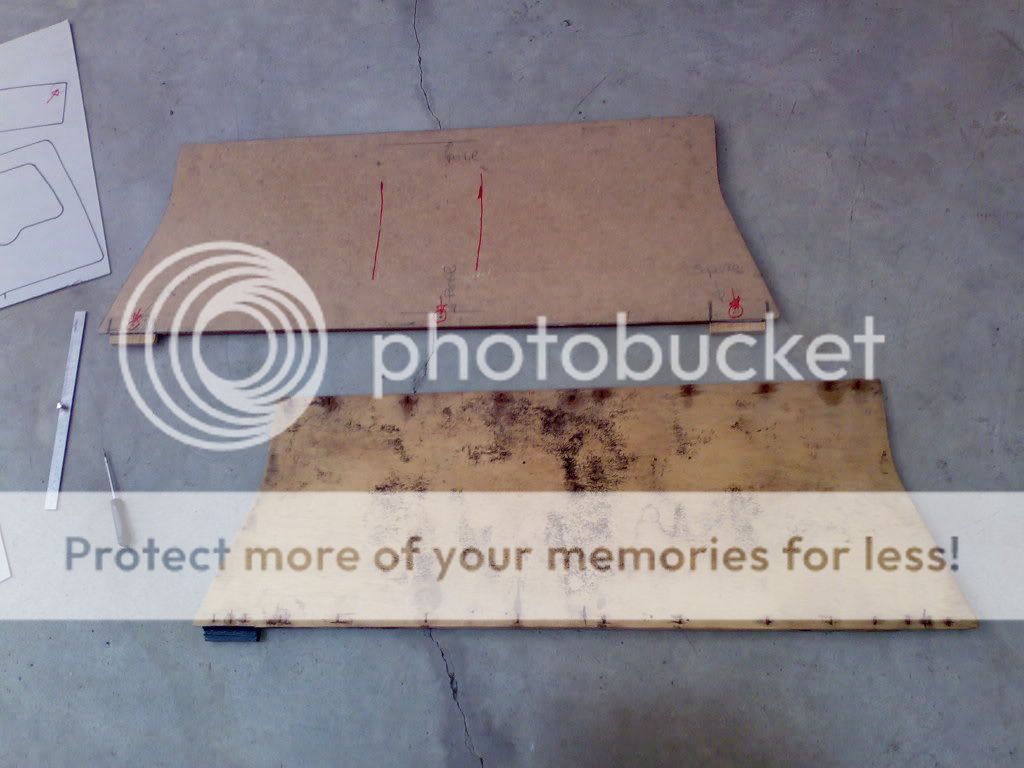

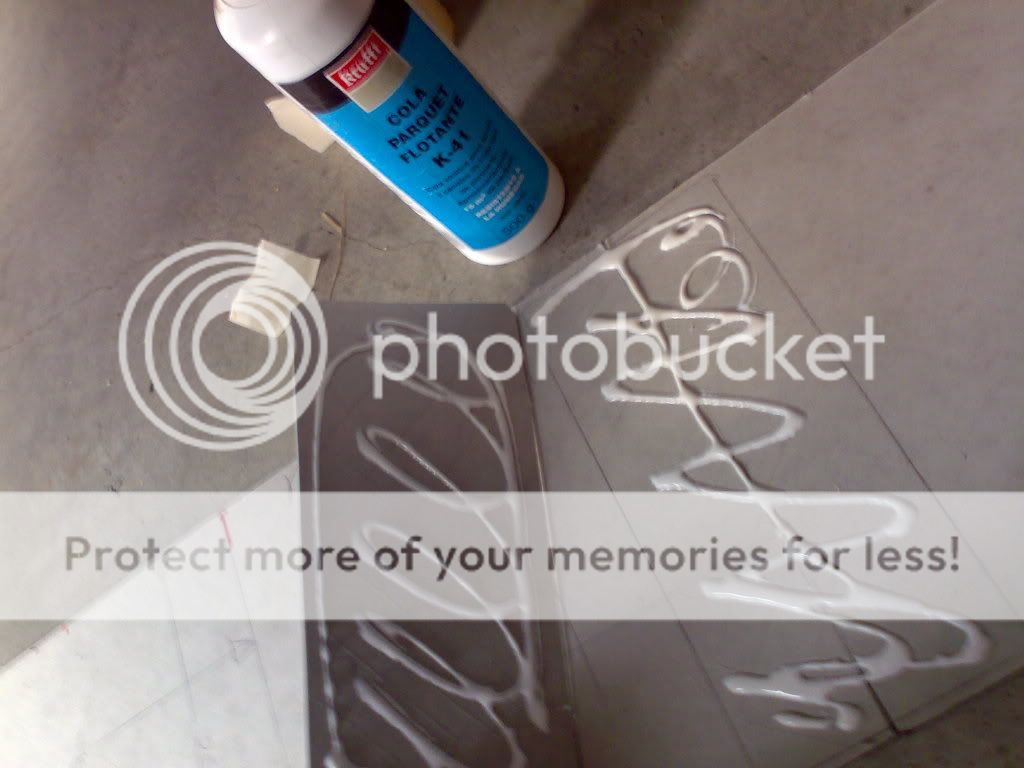

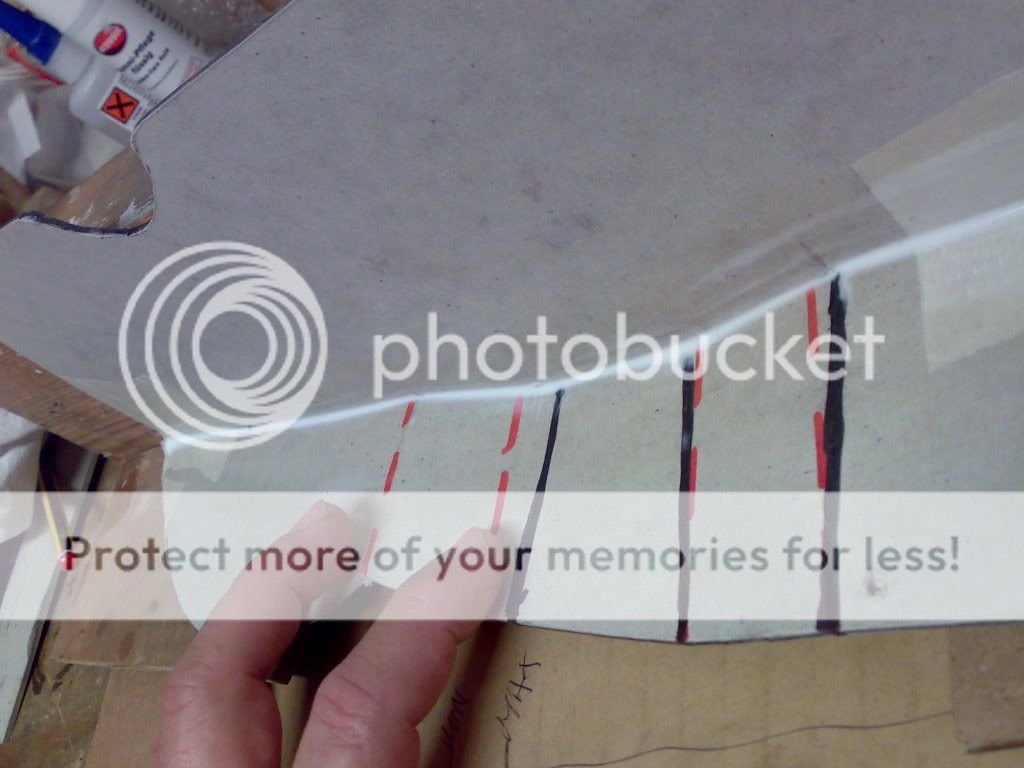

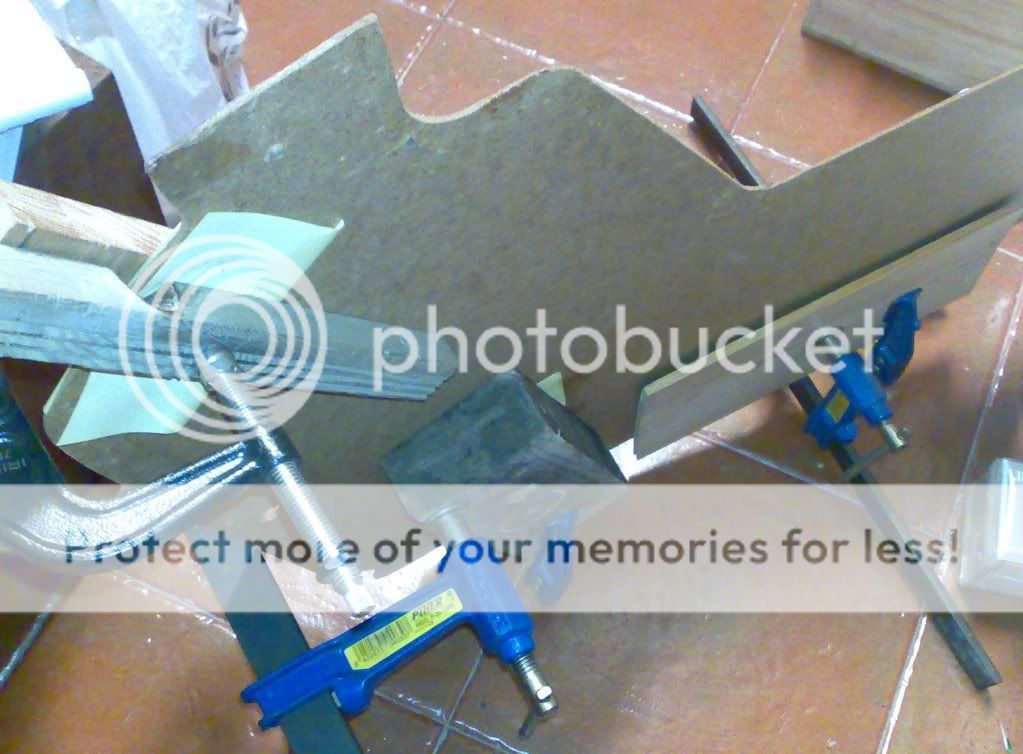

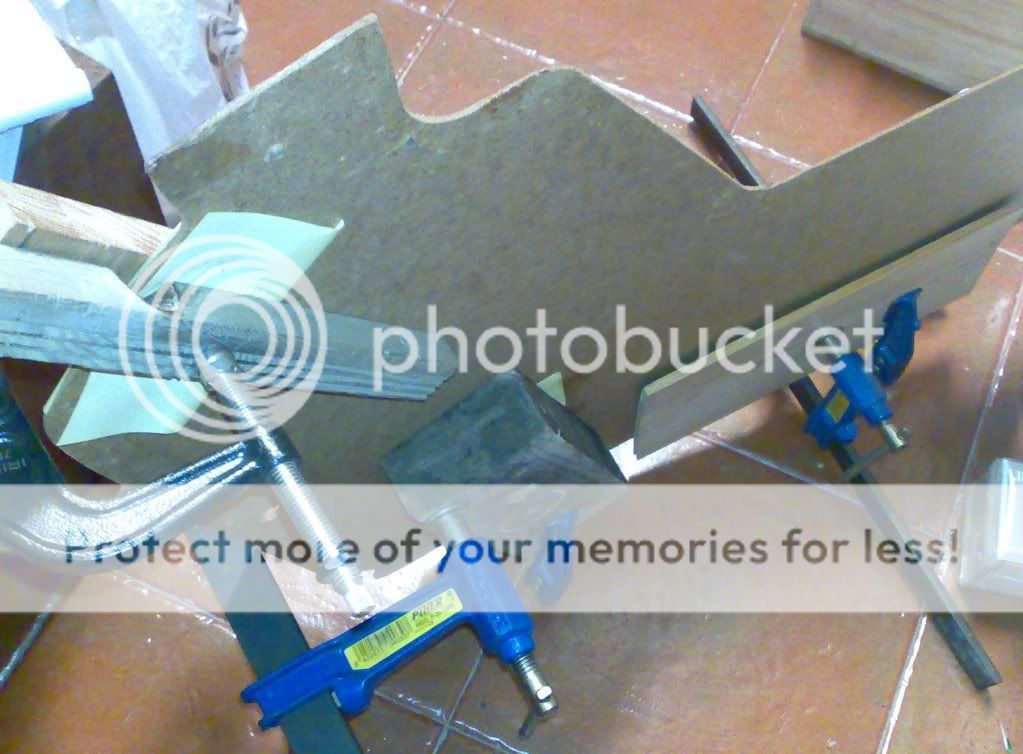

some repairs of broken areas with white glue, using wood blocks to press and reshape

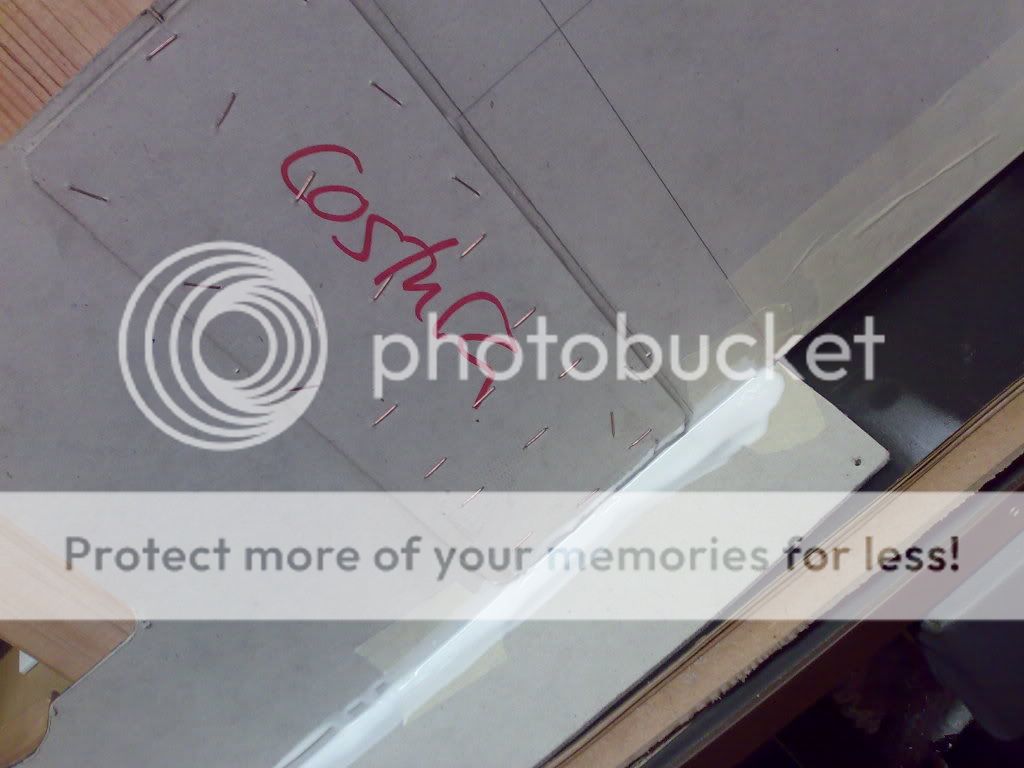

aspect of repaired cracks

using LATEX for closing the cardboard to moisture and water:

initially is white, but

let it dry:

after drying, you can see half done, it becomes transparent

to be continued...

i am finding the cardboards of the trim panels quite damaged by humidity, it is a very poor material for this kind of use because it is not really prepared to avoid moisture

removal of the trim panels:

condition found of panels:

remove staples:

remove textile skin:

clean with soap and water

cardboard:

some repairs of broken areas with white glue, using wood blocks to press and reshape

aspect of repaired cracks

using LATEX for closing the cardboard to moisture and water:

initially is white, but

let it dry:

after drying, you can see half done, it becomes transparent

to be continued...

Last edited: