Hi guys

I just rebuilt my rear brake pressure regulator valve.

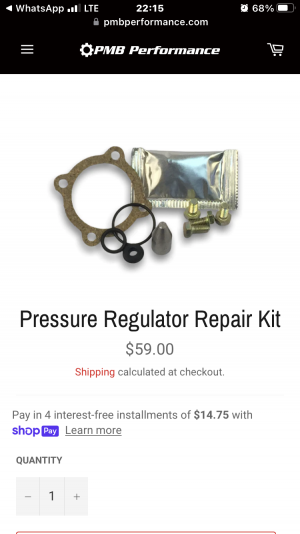

I used a pmb kit that is meant for an early Porsche.

Anyway I took mine off and cleaned it and glass bead blasted it before I took it apart.

It was easier to keep the blast media out that way .

It is spring loaded so I put it in a hydraulic press so that I could hold it while I removed the 4 m6 screws holding it together.

Once I had the screws out , I slowly released the hydraulic press to let the spring pressure off.

It separated by about 20 mm then the spring was free.

I took all of the internals out and cleaned them.

There is a type of sliding piston which has 2 seals on it , 1 o-ring and 1 radial seal.

They need replacing, the o-ring is easy.

The radial seal is difficult to do.

The kit comes with a tapered tool which you put onto the end of your piston , then you have to push the new seal up the taper and onto the shaft until it pops into its groove.

I used hot water to make the seal softer and I used lubricant to help also.

It was not easy !!!

Note the tapered tool in the Porsche kit was too short for the Bmw part which left a reduced diameter with a step ahead of it on the shaft , a kind of “ trough “so I made up the difference by wrapping masking tape around and around the shaft until it was the same diameter as the tool and the shaft , I didn’t want the seal to fall into the “ trough “.

Once that was done I was able to slide the seal up the the taper , over the masking tape and on into its groove on the shaft.

Then when all of the seals and o-rings are replaced, and greased up , you use the 4 new screws to put it back together. The screws are longer than the originals so they are long enough to pull the spring down so you don’t need to use a press.

I hope that might be of some help, if others are planning on rebuilding theirs.

I just rebuilt my rear brake pressure regulator valve.

I used a pmb kit that is meant for an early Porsche.

Anyway I took mine off and cleaned it and glass bead blasted it before I took it apart.

It was easier to keep the blast media out that way .

It is spring loaded so I put it in a hydraulic press so that I could hold it while I removed the 4 m6 screws holding it together.

Once I had the screws out , I slowly released the hydraulic press to let the spring pressure off.

It separated by about 20 mm then the spring was free.

I took all of the internals out and cleaned them.

There is a type of sliding piston which has 2 seals on it , 1 o-ring and 1 radial seal.

They need replacing, the o-ring is easy.

The radial seal is difficult to do.

The kit comes with a tapered tool which you put onto the end of your piston , then you have to push the new seal up the taper and onto the shaft until it pops into its groove.

I used hot water to make the seal softer and I used lubricant to help also.

It was not easy !!!

Note the tapered tool in the Porsche kit was too short for the Bmw part which left a reduced diameter with a step ahead of it on the shaft , a kind of “ trough “so I made up the difference by wrapping masking tape around and around the shaft until it was the same diameter as the tool and the shaft , I didn’t want the seal to fall into the “ trough “.

Once that was done I was able to slide the seal up the the taper , over the masking tape and on into its groove on the shaft.

Then when all of the seals and o-rings are replaced, and greased up , you use the 4 new screws to put it back together. The screws are longer than the originals so they are long enough to pull the spring down so you don’t need to use a press.

I hope that might be of some help, if others are planning on rebuilding theirs.

Attachments

-

9D2A2E62-1CFB-47BB-A0A6-CC39120109CE.png585.5 KB · Views: 175

9D2A2E62-1CFB-47BB-A0A6-CC39120109CE.png585.5 KB · Views: 175 -

182C5C8E-DEF0-407C-800E-A34EFF03948F.png3.4 MB · Views: 162

182C5C8E-DEF0-407C-800E-A34EFF03948F.png3.4 MB · Views: 162 -

B0B7355A-D561-4793-9D7F-C4F04B47BF33.png2.8 MB · Views: 145

B0B7355A-D561-4793-9D7F-C4F04B47BF33.png2.8 MB · Views: 145 -

5E61C697-1CAC-4DE5-86EB-D8BABB9AAAA0.jpeg366.4 KB · Views: 129

5E61C697-1CAC-4DE5-86EB-D8BABB9AAAA0.jpeg366.4 KB · Views: 129 -

975BB701-654C-463D-85F5-1805BDBC7A30.jpeg324.8 KB · Views: 135

975BB701-654C-463D-85F5-1805BDBC7A30.jpeg324.8 KB · Views: 135 -

85ED4AF9-DDDB-4931-B799-C899D1808437.jpeg196.6 KB · Views: 131

85ED4AF9-DDDB-4931-B799-C899D1808437.jpeg196.6 KB · Views: 131 -

A2482E84-F213-4021-B2C2-CE4ECEE33830.jpeg381.2 KB · Views: 134

A2482E84-F213-4021-B2C2-CE4ECEE33830.jpeg381.2 KB · Views: 134 -

8AB9DCC8-41D1-46BC-99CB-660678AAE72D.jpeg168.6 KB · Views: 129

8AB9DCC8-41D1-46BC-99CB-660678AAE72D.jpeg168.6 KB · Views: 129 -

E5D361A3-98E0-4639-8968-19B5C3CEF578.jpeg164.7 KB · Views: 135

E5D361A3-98E0-4639-8968-19B5C3CEF578.jpeg164.7 KB · Views: 135 -

3CDC96CF-2B55-4B98-9CAD-AEDEEFFEDEA5.jpeg179 KB · Views: 138

3CDC96CF-2B55-4B98-9CAD-AEDEEFFEDEA5.jpeg179 KB · Views: 138 -

7188DD6C-C961-4229-92DE-5FCC3D31512C.jpeg240.2 KB · Views: 138

7188DD6C-C961-4229-92DE-5FCC3D31512C.jpeg240.2 KB · Views: 138

Last edited: