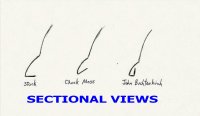

John Buchtenkirch

Well-Known Member

if car is already painted, this is a easier way of doing it without paint damage.....

tire rack rents them,,,,,,,

It really depends more on how far you go and how much it distorts the metal --- believe me I have seen several fender roller jobs that needed paint work and even plastic work after being rolled. The way I did it I only have to touch up the lip that faces down and now also faces into the tire, I will get away with doing it with a touch up brush which is the beauty of owning a solid color car versus metallic paint. ~ John Buchtenkirch