HI

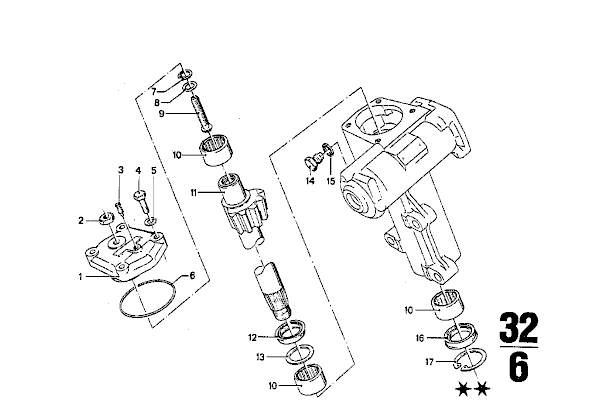

I would use the rebuilding skills of Jay Stratton if I did not leave in Canada (read expensive shipping). So I am wondering if the shaft seal (32131111871; #16 below) is replaced from the exterior or the interior of the steering box? Advise on the other 'seal' will be appreciated. BTW - there is lil or no 'slop' in the steering box and the seals are not showing any sign of leaks; just be precautionary.

Regards,

Bill

s

I would use the rebuilding skills of Jay Stratton if I did not leave in Canada (read expensive shipping). So I am wondering if the shaft seal (32131111871; #16 below) is replaced from the exterior or the interior of the steering box? Advise on the other 'seal' will be appreciated. BTW - there is lil or no 'slop' in the steering box and the seals are not showing any sign of leaks; just be precautionary.

Regards,

Bill

s

Last edited: