I used to have one of those and did the swaping from one carb to the other. Not very convenient.

well, it is not mine, i only wanted to check it as i have some doubts with the vacuum meters

To answer your original question: on my car, which has the exact same engine and carbs as yours, my 1000rpm idle would read 9-10kg/h per carb.

mine, reads 12kg/h per carb (this is the mark between 10 and 14)

That´s after tuning the mixture with this very helpfull fellow:

http://www.gunson.co.uk/item.aspx?cat=673&item=1822

interesting, we should discuss this method with a beer next october:-D

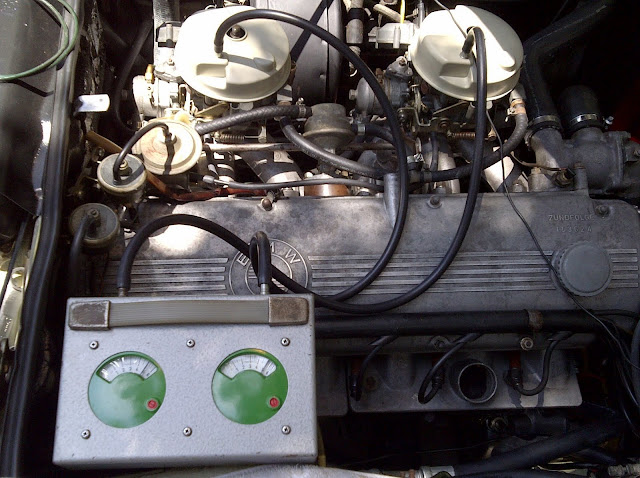

But I don´t use SK Syncrometer anymore, I´ve found to get better sync with a twosome of these

http://www.scheuerlein-werkzeuge.de...ontestuhren/synchrontester-boehm-2-uhren.html

Important to use the 0.6-Version as the 0.4 will be overloaded by the big vacuum that the M30 creates in the zentih manifold (1.5 Liters of displacement sucking...).

this is my system, i bought two vacuum meters (0 to -1bar)

the question is that i am plugging them here:

and i don´t like the meassurement, the needle is constantly shaking while reading

you are right that the sync is very straightforward with this method, and also the high rev and the burl knob adjust

having those two, connected directly to the manifold (I use the connector on the brake booster side of the manifold as I´ve blocked the connection to the air filter anyway) I get a very precise reading and can play with the revs, sync not only idle but also load conditions and can watch the sync when revving up, thus optimizing the burl knob adjustment in the linkage.

do i understand you well?, are you connecting to the same point as me ? ( i have blocked the air filter connection also ) if that is the case,...do you have the mentioned vibration in the needle of the gauge ? or do you have a steady condition ?

@dequincey: As my carbs are currently nicely synched and have no reason to go off synch; I´d be happy to borrow you may pair of gauges. Provide me with an adress (you´ve got my email) and I´ll post them to you.

thank you so much for this kind offer, i assume that my gauges are similar to yours, (this is a 0 to -1bar reading scale)