Hi guys

I fixed the Slipping sunroof motor so my sunroof slides along and rises up to close properly now as it should

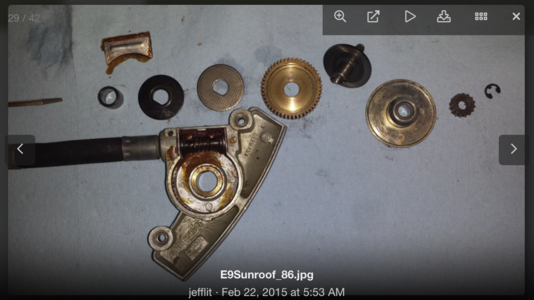

I stripped the sunroof motor gearbox.

I cleaned everything and then I made 3 changes to it before reassembling it.

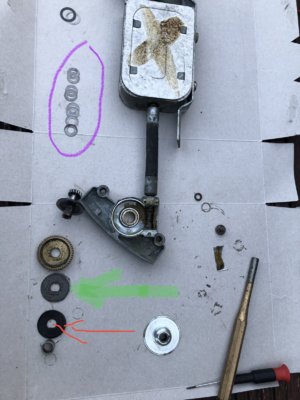

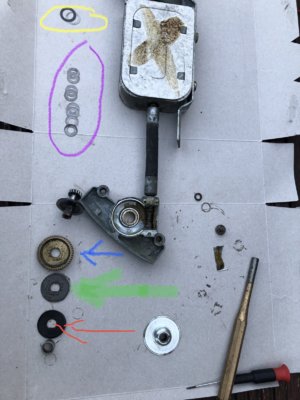

1. I media blasted the face of the brass drive gear ( arrowed in blue ) to give more grip.

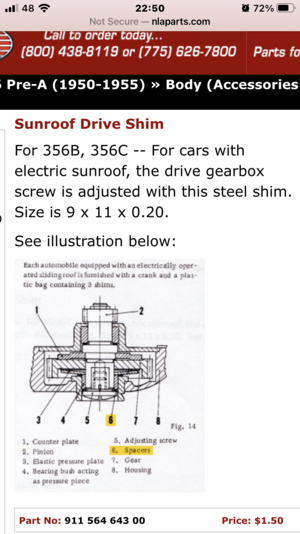

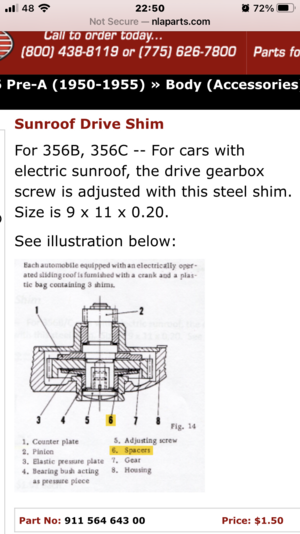

2. I took the 2 larger diameter shims (circled in yellow ) and measured them ,they were 0.2mm thick and 0.1mm thick. I then got a friend of mine to machine a new shim 0.5mm thick ( anything thinner and he could not part it off on the lathe) I then took away the 0.2 shim and replaced it with the new 0.5mm one. This change now increased the preload tension on the concave clutch pressure plate ( red arrow ) by 0.3mm .

3. I turned the friction plate (green arrow ) around 180 degrees. From the factory it comes with a dimpled / textured surface on both sides .one side wears smooth over the years. So I flipped it around to allow the fresh dimpled side to now be in contact with the brass drive gear thus increasing its friction grip on the brass drive gear.

the stack of smaller shims I left as they were- just cleaned them and reused them (circled in purple)

make sure all friction faces are dry and lubricant free before reassembling everything.

When you do re install the “stack of parts back into the housing you will have to crimp / dot punch the housing (white arrows ) to keep the assembly together. Once fitted back into the car the 2 m4 screws also keep it all together.

By the way I don’t think the diameters mentioned on the Porsche sketch are correct for our roofs so if you are getting shims made or if you are buying some, take the time to measure your own one beforehand.

Also a word of warning !!!

If the plastic end of your sunroof cables are brittle from old age but still in 1 piece ... when you make your sunroof motor work properly they may now give up under the increased load.

one of mine was broken already ,beforehand I had glued it back together temporarily so that I could get everything sliding again. But once I fixed the motor the glued part gave up predictably... ( I had another one on order in the post to replace it anyway)