Busy day yesterday. I want to make some space in the garage because it is getting tough to move with all these parts laying about. That means getting some parts ready to go to powder coat and to the machine shop.

I finally got the final gland nut off the front struts. Those gland nuts were a tough, welded on with time and grit. The next job with the struts is to get the one broken bolt out of the bottom. Using alternate heat and oil before resorting to drilling...and fingers crossed.

Pressure washed the front sub-frame so it is ready to drop off for powder coating this week after the rest of the parts have been washed.

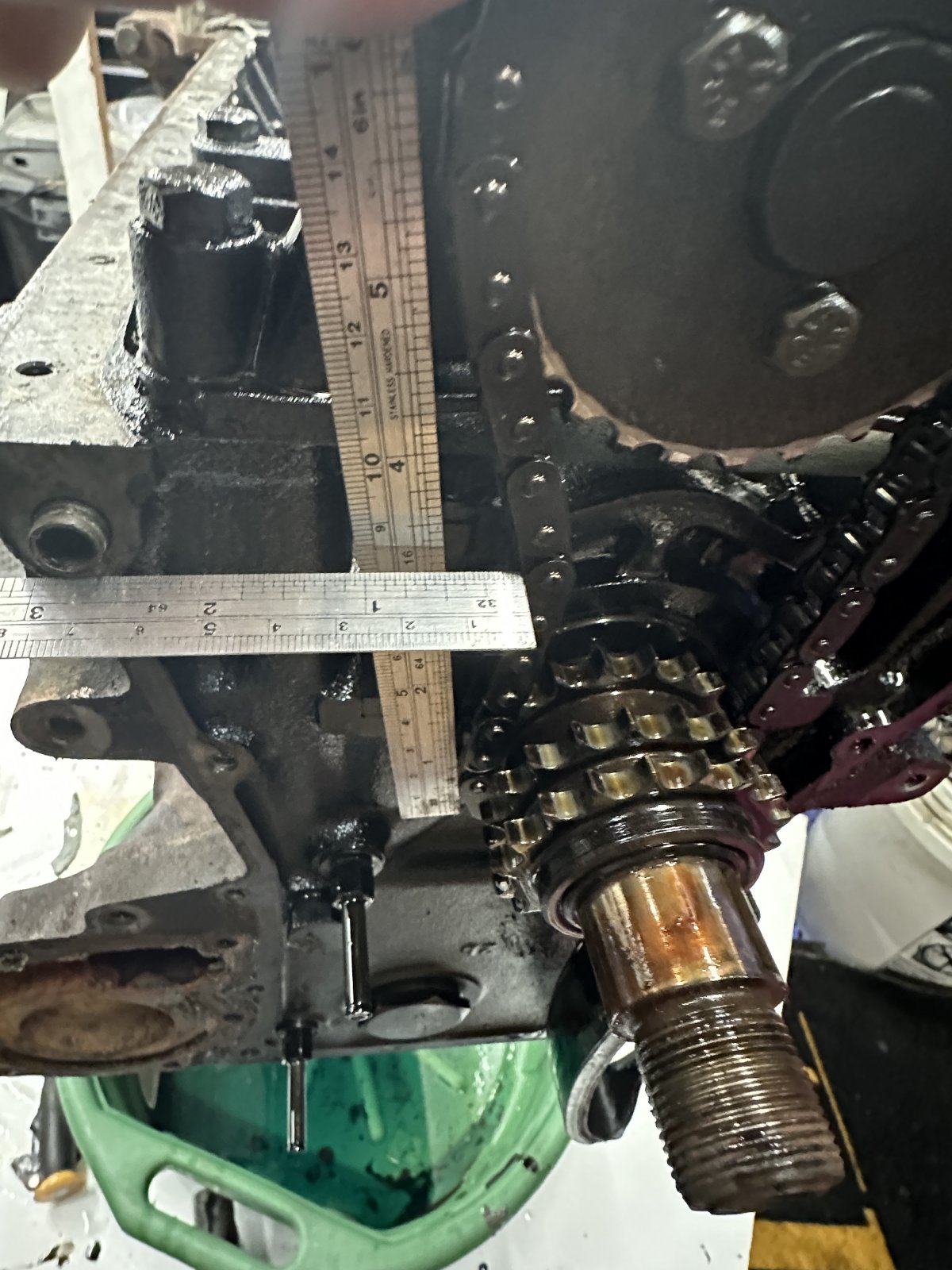

The engine is in the path into the garage, so that needs to go too. The head is off and pistons are out. The surprise here is that there is really no piston ring ridge. Rod bearings were in great shape, but the oil pump drive chain seemed loose.

I am dropping off the head at the machine shop Monday. They will take it apart, make some evaluation of the valves and guides and then some more parts to buy.

I finally got the final gland nut off the front struts. Those gland nuts were a tough, welded on with time and grit. The next job with the struts is to get the one broken bolt out of the bottom. Using alternate heat and oil before resorting to drilling...and fingers crossed.

Pressure washed the front sub-frame so it is ready to drop off for powder coating this week after the rest of the parts have been washed.

The engine is in the path into the garage, so that needs to go too. The head is off and pistons are out. The surprise here is that there is really no piston ring ridge. Rod bearings were in great shape, but the oil pump drive chain seemed loose.

I am dropping off the head at the machine shop Monday. They will take it apart, make some evaluation of the valves and guides and then some more parts to buy.