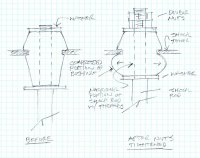

Wider end topside or other way around? Seems like the wider side should go below to keep it from popping through the tower hole from forces below but parts diagram shows wider side is on top side. What say the experts?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Which way does the rear shock bushing go?

- Thread starter Stevehose

- Start date

Thanks

Wider side on top. Once you tighten the top bolt it will compress the small bottom end under the tower.

exactly, just the contrary that you would expect, i did wrong first time, and i had to correct it, it is in my thread,...

post #90

http://www.e9coupe.com/forum/showthread.php?t=14519&page=9

Last edited:

DQ, how did you decide that you were wrong and it goes large end up? On the E3 I'm quite sure it goes the other way around, large side down.

hi luis,

because a was aware of the difference between the drawing and my feeling of what was reasonable

then it started to pop out after a short testing ride :-(

i saw the height of the top different from right to left

So the downward pulling force is greater than the upward pushing force? That's why I axed the question, I'd think you'd want that fat end on the bottom for bumps.

So the downward pulling force is greater than the upward pushing force? That's why I axed the question, I'd think you'd want that fat end on the bottom for bumps.

i am not a lazy slowly driver, mostly through highly bent roads

i can tell that after changing to the mentioned position they have kept on their place perfectly

That's the crux of it. Compressing the shock takes a lot more force than expanding it since it wants to do that naturally. So that's why I would think the large side goes on the bottom but if they slipped out for DQ, I'm not sure whats going on...

.. That's why I axed the question...

And I haven't heard that since I lived in Detroit...

That's the crux of it. Compressing the shock takes a lot more force than expanding it since it wants to do that naturally. So that's why I would think the large side goes on the bottom but if they slipped out for DQ, I'm not sure whats going on...

peter c. responds to my post this way, "me that I did it wrong in the first place-it only took about 100 miles before I heard the shafts clunking around back there "

sfdon said the same

Ok so one more question, wouldn't the steel inner sleeve prevent this compression?

Perhaps this will help you sleep better at night.... ;-)

I don't recall there being any inner metal sleeve. Did one come with the replacement bushing?

Part #10, I bought 2 new ones with the new rubber bushings (#11) and my existing bushings have them mounted inside:

Part #10, I bought 2 new ones with the new rubber bushings (#11) and my existing bushings have them mounted inside:

absolutely steve, there is a steel tube inside each rubber bushing, but as far as i recall the tube is slightly shorter than the bushing, hence the possibility of sven's nice explanation

top, wider part of the bushing is very stiff, so i assume that when you compress it by means of the top nut, the first thing you do is compressing the lower part of it, when you reach the steel-steel contact between washers and inner steel tube then you continue doing the nut until it reaches the prescribed torque

makes sense

what i assure is that the right position is the one that is shown in bmw diagrams, it works, and the contrary doesn't