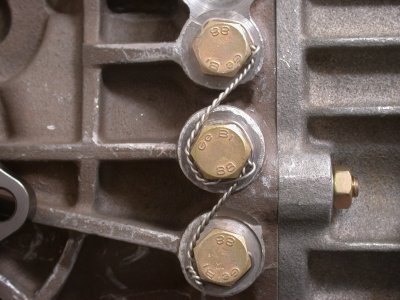

Preparing to finally replace front struts. Looking at the wire at the bottom that ties the 3 bolt heads together, I realize I must remove this and replace when I have installed new strut. What is the trick to creating this art of the twisted wire that feeds around and between these three bolt heads? Special tool? Oh, and should this be a stainless steel wire of a certain thickness? Thanks for your input. Mike

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wire keeper technique

- Thread starter bluecoupe30!

- Start date

6 in. Safety Wire Twisting Pliers

Amazing deals on this 6 In. Safety Wire Pliers at Harbor Freight. Quality tools & low prices.

Vice grips?

Ok at that price, it is worth a try. But what is technique? Clockwise, counter clockwise, upside down with a twist? Hmmm?View attachment 162885

6 in. Safety Wire Twisting Pliers

Amazing deals on this 6 In. Safety Wire Pliers at Harbor Freight. Quality tools & low prices.www.harborfreight.com

Yes, thinking of that as there are really only 2 of these and then I am done. Probably should practice first.Vice grips?

Just be sure you orient the wire so the tension is on keeping the bolt from unscrewing.

Yeah, I guess that is the whole point. I am sure once I begin, it will all make sense.Thanks.Just be sure you orient the wire so the tension is on keeping the bolt from unscrewing.

That is such a cool tool. Never seen it before. AND Harbor frieght is having big sale!

I used to do a lot of safety wiring.What is the trick to creating this art of the twisted wire that feeds around and between these three bolt heads?

Special tool? Oh, and should this be a stainless steel wire of a certain thickness?

I have an old pair of Robinson pliers, but as Steve said vise grip pliers will work too, just not as quickly.

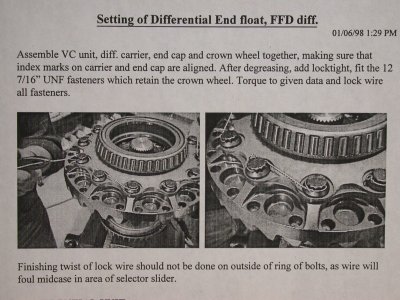

These are my hands wiring a CART Indycar spool in 1998...

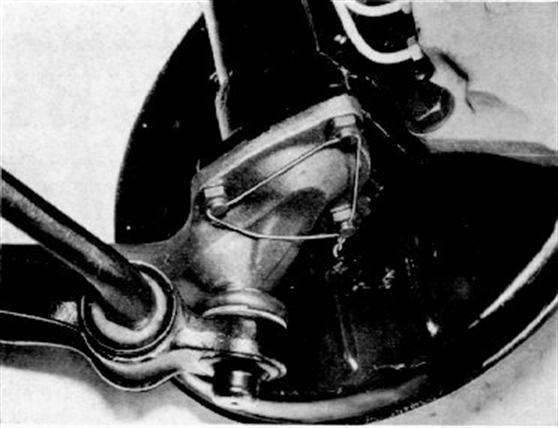

Here's a recent 3-bolt example on a 70s Porsche 935 transmission, using 0.042" stainless safety wire.

This is GREAT! Thank you for posting. Like I said, this is some kind of an art, in my opinion. Important safety step, but can be incorporated to show the talent and creativity of the installer. I see I may have do do some practice before I feel I can do a final install. Thanks Jon.

Yes, it will take some practice.I see I may have do do some practice before I feel I can do a final install. Thanks Jon.

When I was doing repetitive work, I knew the amount of wire required. Otherwise I have to estimate the wire length, with some excess to snip off when done.

On multi-bolt wirings, it sucks to run out of wire before you reach the last bolt head... :-(

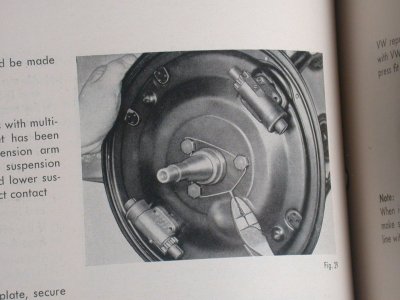

The wiring job in the workshop manual is pretty basic:

This would be a good post to recommend all the places to safety wire. I know they @paul cain and others have added to the list.

Oil bar?

Oil bar?

That is how mine was and how I safetied it. I have safety wire if anyone needs a couple feet.

Yes I’ve wired here as well with drilled banjo bolts like these:This would be a good post to recommend all the places to safety wire. I know they @paul cain and others have added to the list.

Oil bar?

The art that Jon posted is done with pretty thin stainless wire. The workshop photo appears to show a much heavier/thicker wire that may have enough stiffness to obviate the need to twist and wrap as Jon does.The wiring job in the workshop manual is pretty basic:

Found a nice MAC brand in a hock shop years ago for $3.I bought it 'cause it looked neat but never used it till I did the struts on my 6.When Snapon had a warehouse in PHX, I would cruise the hock shops looking for various wrenches and sockets If they had any rust etc or damaged chrome on them, they would change them out for new ones Also found my Lincoln MIG welder, with bottles for $245.

Yes I did. what you posted, Jon, is cool and involves a technique that I wanted to try. So thanks for posting.Well, Mike asked about "creating this art of the twisted wire", but yes the factory work was pretty basic.

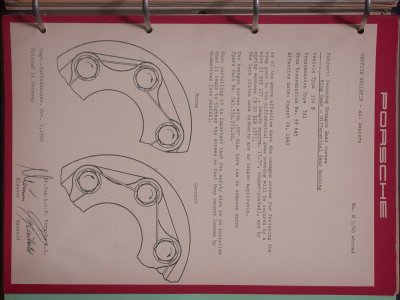

Here are similar examples from Porsche in the 356 era...

View attachment 162912

View attachment 162913