SJFry

Member

Hi,

This is my first post here, so if I screwed something up, please be kind.

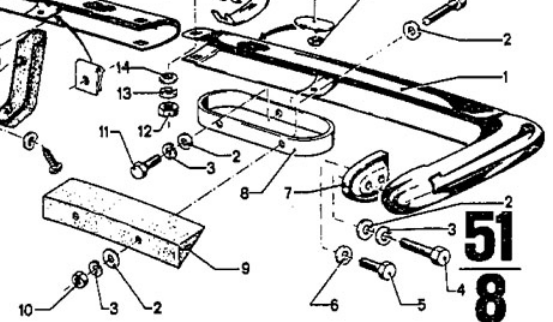

I'm looking for the drivers side bracket cover for the rear bumper. It's item #9 shown in the schematic (the rubber piece). The part number is 51121823117. If you have a pair that you don't want to split up, that would be fine too. I'll take em both.

It's needed for my 1973 3.0CS. I managed to rip/mangle mine recently and would like to replace it.

Thanks in advance,

Keith

This is my first post here, so if I screwed something up, please be kind.

I'm looking for the drivers side bracket cover for the rear bumper. It's item #9 shown in the schematic (the rubber piece). The part number is 51121823117. If you have a pair that you don't want to split up, that would be fine too. I'll take em both.

It's needed for my 1973 3.0CS. I managed to rip/mangle mine recently and would like to replace it.

Thanks in advance,

Keith