jmackro

Well-Known Member

OK, so why does e9coupe.com need yet another thread about installing e28 window motors? Well, I thought I could pass on a few tips that I learned while converting both front doors on my 1970 2800CS from the original "sardine can" style motor & gearbox to the e28 style with integrated motor/ gearbox. These are things that I figured out on my own, and didn't find documented elsewhere.

The best reference that I found for this conversion are the two websites created by e9coupe.com contributor kurtd at:

https://sites.google.com/site/kdelimon/windowmotorconversion1

https://sites.google.com/site/kdelimon/windowmotorconversion2

Those sites are terrific, but I have a few things to add and/or things that I did differently. Where I differ from the kurtd recommendations, I'm not suggesting that my way is better; I'm just offering an alternate approach that made more sense to me.

1) CHOICE OF MOTOR

The right door of the e9 (passenger side door) uses the e28 motor with the part number 12V 1730 821 027. I believe that motor comes from the left rear of the e28. The left door of the e9 (driver side door) uses the e28 motor with the part number ending in 026. Note that the drive gear on the gearbox will have 8 teeth - later motor/gearboxes with 10 teeth won't mesh properly with the large gear on the window regulator.

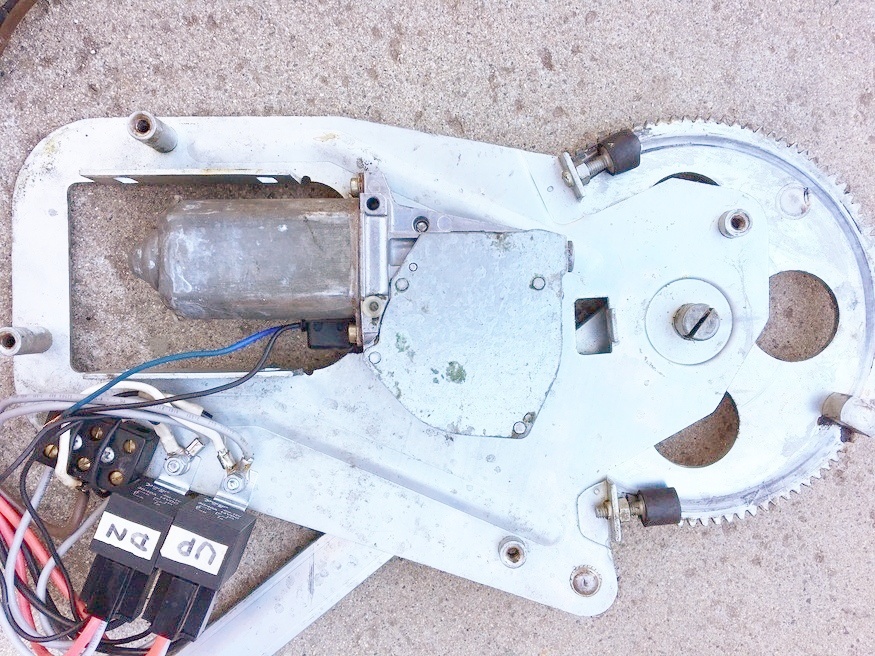

The first photo (thanks to hbchris) below shows a pair of e28 motors, and demonstrates the motor/gearboxes' "handedness". The second photo shows how a p/n 027 e28 motor fits a right front e9 regulator.

The best reference that I found for this conversion are the two websites created by e9coupe.com contributor kurtd at:

https://sites.google.com/site/kdelimon/windowmotorconversion1

https://sites.google.com/site/kdelimon/windowmotorconversion2

Those sites are terrific, but I have a few things to add and/or things that I did differently. Where I differ from the kurtd recommendations, I'm not suggesting that my way is better; I'm just offering an alternate approach that made more sense to me.

1) CHOICE OF MOTOR

The right door of the e9 (passenger side door) uses the e28 motor with the part number 12V 1730 821 027. I believe that motor comes from the left rear of the e28. The left door of the e9 (driver side door) uses the e28 motor with the part number ending in 026. Note that the drive gear on the gearbox will have 8 teeth - later motor/gearboxes with 10 teeth won't mesh properly with the large gear on the window regulator.

The first photo (thanks to hbchris) below shows a pair of e28 motors, and demonstrates the motor/gearboxes' "handedness". The second photo shows how a p/n 027 e28 motor fits a right front e9 regulator.

Last edited: