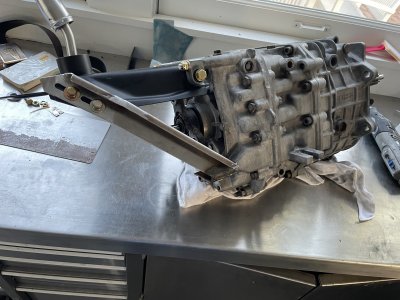

In July, in a moment of Bring-a-Trailer weakness I high bid another 1974 Fjord 3.0 CS coupe. This time the car had been restored by Clem Pappas who lives in Florida and was a sometime poster on this forum. Clem and his subcontractors had 'gone deep' in a significant body work and painting project on this U.S. Market 3.0 CS. You can find it here at: https://bringatrailer.com/listing/1974-bmw-3-0cs-62/. The car arrived in California and the first inspection was a relief. The body and paint work were slightly better than expected and there was a lot of new parts on the car not mentioned in the auction. Unlike the Patricia Mayer project this one will be mostly finishing work. I thought it would be fun to document 100 different things that are needed to bring the car to a serious level of finishing. So, I will be posting occasionally with lots of small projects that are required on this example. Project No. 1 was getting rid of the the U.S. Federal bumpers. See attached pics and the review on the Vietnamese supplier of bumpers. Project 2 is welding in all of the U.S. reflector holes, turning into a much larger painting project. Project 3 is to rebuild a set of trunk inner fender liners that are unique to the 1974-75 model. This involves getting a third liner as sacrificial material that is grafted into the original liner. Then lots of repairing of cracks.

Attachments

-

IMG_7588.jpg509.4 KB · Views: 463

IMG_7588.jpg509.4 KB · Views: 463 -

IMG_7088.jpg201.7 KB · Views: 518

IMG_7088.jpg201.7 KB · Views: 518 -

IMG_7158 (1).jpg312.7 KB · Views: 431

IMG_7158 (1).jpg312.7 KB · Views: 431 -

IMG_7150 (2).jpg280.6 KB · Views: 408

IMG_7150 (2).jpg280.6 KB · Views: 408 -

IMG_7587.jpg470.3 KB · Views: 424

IMG_7587.jpg470.3 KB · Views: 424 -

IMG_7545.jpg184.1 KB · Views: 395

IMG_7545.jpg184.1 KB · Views: 395 -

IMG_7153.jpg296.1 KB · Views: 380

IMG_7153.jpg296.1 KB · Views: 380 -

IMG_7484.jpg265.3 KB · Views: 387

IMG_7484.jpg265.3 KB · Views: 387 -

IMG_7119.jpg320.1 KB · Views: 395

IMG_7119.jpg320.1 KB · Views: 395 -

IMG_7118.jpg271.7 KB · Views: 391

IMG_7118.jpg271.7 KB · Views: 391 -

IMG_7091.jpg354.4 KB · Views: 452

IMG_7091.jpg354.4 KB · Views: 452 -

IMG_7678.jpg312.4 KB · Views: 430

IMG_7678.jpg312.4 KB · Views: 430

Last edited by a moderator: