Brilliant!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to: Remove rubber around the gas flap

- Thread starter Stan

- Start date

Great write-up Erik, and a terrific out-of-the-box solution. You're right; getting that the flange "over the hump" of that rear bolt is tough! Hopefully I won't have to do this again anytime soon, but I'll be cutting that notch if I do!

Great topic.

I have bought part of fender with the boot and flap to check it before I will try it on my car.

This is one of the topics it would be great to listen someone from Karmann factory describing how it was done at production line.

I have bought part of fender with the boot and flap to check it before I will try it on my car.

This is one of the topics it would be great to listen someone from Karmann factory describing how it was done at production line.

Isn't it that what I wrote?

Just open the flap to 45degree position and block the movement by inserting a small allen key at that position

With the short part showing downward.

You may install the flap easily now. Once installed move the flap and the allen key will fall into the boot

Thomas

Not sure it is possible to slid the Allen key with the rubber boot on. As far as I saw there is a little free space but two keys slided with short part of the key.

I'm having a test bench trying to safely remove rubber boot from cut rear fender

Interested to know if you @Krzysztof can apply the method that Breiti & TomHom discusssed.

If you get it to work, can you make some pics?

If you get it to work, can you make some pics?

I don't remember how I managed to remove the allen key when I did it that way, maybe I cut the allen key to appropriate size?

So let's see another approach (this describes the procedure for installing the flap)

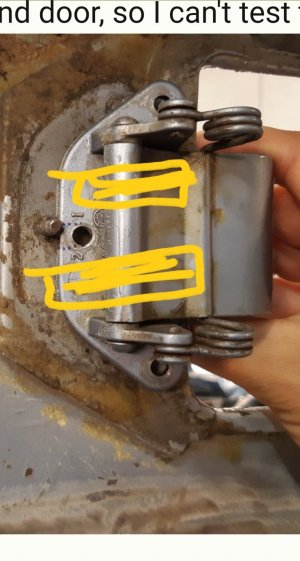

Take a strip from your Lidl home handyman utensils box, bend and cut it so it can be put like this:

Use a vise to bring hinge in the 45° position.

Place the strip as shown using a washer as a shim.

Voilà!

The hinge will stay in this position and you should be able to mount the flap easily.

So let's see another approach (this describes the procedure for installing the flap)

Take a strip from your Lidl home handyman utensils box, bend and cut it so it can be put like this:

Use a vise to bring hinge in the 45° position.

Place the strip as shown using a washer as a shim.

Voilà!

The hinge will stay in this position and you should be able to mount the flap easily.

Last edited:

Hi,

Finally spring time is here...

so I spent some time trying to figure out how to deal with the flap, the rubber for both... montage and assembly back.

I used small part of fender with the rubber boot (original and in good condition). The setup has be bought with no screws but the flap was keeping tight still with the part of grey material (s.c. elephant skin) between the body and the rubber boot. The rubber blind plugs were also in.

For the first time I used more or less the brute-force method applying anti-rust oil on the junction rubber-material-fender. After some time I pushed dull, flat screwdriver between the fender and the elephant skin to protect rubber. Junction has been released but it was difficult to take the flap out. Trying to find stable position of the spring I was able to take the flap's hinge out. Now I was able to play with different scenarios.

It is true the rubber boot itself is not helping for the whole process. Also almost each time the flap is touching the external fender surface (risk for the cars with nice paint).

Situation gets worse trying to put all in together as there is too less area and it seems to be the only position all is fitting in somehow but than there is a point where we have no space and no orientation where to screw all with the rubber pushing the hinge out of the threaded bolts.

Proposal from Erik is helping but still it is very difficult with the rubber boot being installed same time.

Trick from Thomas is also useful. The hinge spring is slightly moving but it is much better. But still coordination with the nuts, lack of space of hand and socket is a pain.

I spent some time wondering how the workers in Karmann could do that. I went through different approaches in between and finally...

I have noticed that springs are not always at full tension. Especially with the the position similar (but deeper) to flap being close. On the production line, taking into account time and possible risk of the whole process it has to be somehow straightforward action.

The question was:

- which position would be the most safe and simple?

The answer was always:

- to mount it with no tension and with a good access to the screws

How to make it real?

1. Have the flap hinges released from spring tension

2. Mount the base only first (no flap scratching the paint for the most difficult part)

3. Assure proper access by rolling out the rubber boot for most of the time (only possible with new or original parts with not cracks)

Ad.1 Releasing the "tension" from the process

As I have mentioned earlier I found out that for more than fully close position, springs are almost loose. It is the best position to slide them out from the flap using flat screwdriver

To make process completely safe I slide out the hinge shaft out. It was easy even for rusty part.

Ad.2 Taking care about the "hygiene" by assuring the best possible access to the screws

Rolling out the rubber boot (keeping only the screw mount section in) is greatly improving the mounting process.

If we combine it with the fact that we have only hinge base to mount now - it is much simple than trying to do all blindly.

It was fairly easy to put the nuts with my bare hand even with the limited thread access coming from the thickness of the rubber boot base.

Ad.3 Final assembly

Having the base screwed into I realized the most important part in in front of me.

I tool the flap and the shaft. I was able to slide the shaft, still having the rubber boot loose.

The last few millimeters require more precision to hit the opening on the other side. I helped myself applying tension with the flat screwdriver

Next step is to put the springs into the flap holes.

As it was mentioned the less spring tension is with the flap close position (or further).

Different tools might be used but I help myself with the pliers.

It seems to be the most dangerous part of the process but we're not dealing here with new paint of the fender anymore, right (of course I would suggest to protect the flap opening and maybe flap edges with some thin foam or thick tape (e.g. isolation)

The danger is for our hands and maybe unexpected movements but spring in such position is still not really strong.

Once springs are in we can unfold the boot and move/slide it into the edge of the flap, including the part behind the hinge. Silicone grease will help here and protect the edges against water for future car use.

As the final step don't forget about the rubber blind plugs if there were removed before.

After the whole process I have repeated the steps in reverse order. It is not as simple as montage but it is again more safe for our cars in my humble opinion.

I'm not really sure if that was the process used in the plant but for me it was really simple one with no periods I was considering to quit as it was for previous tries, with the whole hinge's mechanism.

Maybe it will be an option for someone. For me it looks like the right path to follow in the future.

For sure any cracks on the rubber boot might end up with the damage of that part.

As you could see I was making my tests on old, original part but still in good condition. No idea about W&N replacement but shouldn't be much different or maybe even easier?

What do you think?

Finally spring time is here...

so I spent some time trying to figure out how to deal with the flap, the rubber for both... montage and assembly back.

I used small part of fender with the rubber boot (original and in good condition). The setup has be bought with no screws but the flap was keeping tight still with the part of grey material (s.c. elephant skin) between the body and the rubber boot. The rubber blind plugs were also in.

For the first time I used more or less the brute-force method applying anti-rust oil on the junction rubber-material-fender. After some time I pushed dull, flat screwdriver between the fender and the elephant skin to protect rubber. Junction has been released but it was difficult to take the flap out. Trying to find stable position of the spring I was able to take the flap's hinge out. Now I was able to play with different scenarios.

It is true the rubber boot itself is not helping for the whole process. Also almost each time the flap is touching the external fender surface (risk for the cars with nice paint).

Situation gets worse trying to put all in together as there is too less area and it seems to be the only position all is fitting in somehow but than there is a point where we have no space and no orientation where to screw all with the rubber pushing the hinge out of the threaded bolts.

Proposal from Erik is helping but still it is very difficult with the rubber boot being installed same time.

Trick from Thomas is also useful. The hinge spring is slightly moving but it is much better. But still coordination with the nuts, lack of space of hand and socket is a pain.

I spent some time wondering how the workers in Karmann could do that. I went through different approaches in between and finally...

I have noticed that springs are not always at full tension. Especially with the the position similar (but deeper) to flap being close. On the production line, taking into account time and possible risk of the whole process it has to be somehow straightforward action.

The question was:

- which position would be the most safe and simple?

The answer was always:

- to mount it with no tension and with a good access to the screws

How to make it real?

1. Have the flap hinges released from spring tension

2. Mount the base only first (no flap scratching the paint for the most difficult part)

3. Assure proper access by rolling out the rubber boot for most of the time (only possible with new or original parts with not cracks)

Ad.1 Releasing the "tension" from the process

As I have mentioned earlier I found out that for more than fully close position, springs are almost loose. It is the best position to slide them out from the flap using flat screwdriver

To make process completely safe I slide out the hinge shaft out. It was easy even for rusty part.

Ad.2 Taking care about the "hygiene" by assuring the best possible access to the screws

Rolling out the rubber boot (keeping only the screw mount section in) is greatly improving the mounting process.

If we combine it with the fact that we have only hinge base to mount now - it is much simple than trying to do all blindly.

It was fairly easy to put the nuts with my bare hand even with the limited thread access coming from the thickness of the rubber boot base.

Ad.3 Final assembly

Having the base screwed into I realized the most important part in in front of me.

I tool the flap and the shaft. I was able to slide the shaft, still having the rubber boot loose.

The last few millimeters require more precision to hit the opening on the other side. I helped myself applying tension with the flat screwdriver

Next step is to put the springs into the flap holes.

As it was mentioned the less spring tension is with the flap close position (or further).

Different tools might be used but I help myself with the pliers.

It seems to be the most dangerous part of the process but we're not dealing here with new paint of the fender anymore, right (of course I would suggest to protect the flap opening and maybe flap edges with some thin foam or thick tape (e.g. isolation)

The danger is for our hands and maybe unexpected movements but spring in such position is still not really strong.

Once springs are in we can unfold the boot and move/slide it into the edge of the flap, including the part behind the hinge. Silicone grease will help here and protect the edges against water for future car use.

As the final step don't forget about the rubber blind plugs if there were removed before.

After the whole process I have repeated the steps in reverse order. It is not as simple as montage but it is again more safe for our cars in my humble opinion.

I'm not really sure if that was the process used in the plant but for me it was really simple one with no periods I was considering to quit as it was for previous tries, with the whole hinge's mechanism.

Maybe it will be an option for someone. For me it looks like the right path to follow in the future.

For sure any cracks on the rubber boot might end up with the damage of that part.

As you could see I was making my tests on old, original part but still in good condition. No idea about W&N replacement but shouldn't be much different or maybe even easier?

What do you think?

Last edited:

I Install the lid today and will share my experience with you.

The easiest way to install the lid is;

Move the hinge by hand to the "zero" point.

Means, where stuck the spring power in the middle from open and close.

Move the lid in the open over the screws, done.

Protect the paint outside with tape help.

Breiti

The easiest way to install the lid is;

Move the hinge by hand to the "zero" point.

Means, where stuck the spring power in the middle from open and close.

Move the lid in the open over the screws, done.

Protect the paint outside with tape help.

Breiti

Attachments

I used a screw of about 1 cm as in the picture.

Place it it on the underside of the door hinge.

Then it was easy to put on the door.

I installed the nuts through the holes in the rubber.

I have to press a little sideways on the holes to get the 8 mm socket wrench to stand straight above.

Had 2 nuts inside the socket to get one, easy on.

Also used some paper tape to keep the nuts in place for so long.

When you move the door the screw will fall down.

Place it it on the underside of the door hinge.

Then it was easy to put on the door.

I installed the nuts through the holes in the rubber.

I have to press a little sideways on the holes to get the 8 mm socket wrench to stand straight above.

Had 2 nuts inside the socket to get one, easy on.

Also used some paper tape to keep the nuts in place for so long.

When you move the door the screw will fall down.

Last edited:

Very glad I found this thread, took the tank out over the winter to fix a shock tower. Well, the shop was cold in the winter & there were other things to do, so I just finished the welding which came out better than I thought it wood. The boot to isolate the fumes around the fill neck had been slit, and in getting that door undone that slit got bigger. Is it possible to get a new boot, what is the official name of the boot, and who might be selling one (in the US)

Rod, W+N makes a repop of the boot. i probably have a decent used one if needed. if you buy a used one, you want it to be flexible. i can tell you that the W+N one has their logo on it, where it is somewhat visible when the gas door is open (if i remember correctly). the new repop is 63 euro plus shipping

I would be interested in your used one, if you would tell me the proper way to do the deal here on the forum, assuming what you have is "flexible" I'm thinking we have a deal. I don't want to wait for the mail from overseas~Rod, W+N makes a repop of the boot. i probably have a decent used one if needed. if you buy a used one, you want it to be flexible. i can tell you that the W+N one has their logo on it, where it is somewhat visible when the gas door is open (if i remember correctly). the new repop is 63 euro plus shipping

View attachment 202317

let me go look to be sure i have 2 used ones ... i am 90% sure that i do. will get back to you via PM

i have looked at the 2 that i have - the one i was thinking of parting with looks pretty good, but the lip is not as pliable as the other one. the one i was going to keep is very pliable, but doesn't look as good. so before i offer one up, i want to ask if anybody has installed the W+N one with no issues?

Last edited: