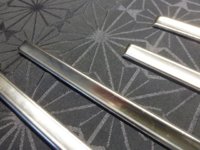

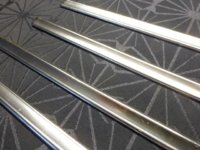

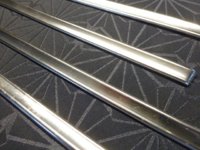

Couldn't the above solid aluminium strip from speedway motors be used to remake the original ones? I do not privatly own a lathe, but using the aluminium bar, one could mill off half the height of the profile, while still leaving a dome every 15 cm or so that could be drilled to accept a normal metric M3 or M4 bolt? The dome would pass through the doorpanel, and hold a screw/bolt from behind, perhaps with a few washers, could work just fine. Are there 4 pieces in total in an E9, or 6? I think its rougly 4 hours of labour, and you'd still need to buy the stock material. Roughly 250 euro/car? Costly business.

Benefit of using solid stock material is that any end style can be ground easily by hand to match, and it's strong enough to withstand dents.

Wasn't Stan looking into reproducing them?

Erik

Benefit of using solid stock material is that any end style can be ground easily by hand to match, and it's strong enough to withstand dents.

Wasn't Stan looking into reproducing them?

Erik