Oh Hose- you have been down in the Quarter again….

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

installing bilstein 24-008136 rear shocks on a e9 car

- Thread starter bimoverde

- Start date

@Stevehose and @Luis A. : In the thread below, you seem to indicate that you went along with what @Sven and @deQuincey were suggesting: Putting the wider end of the bushing at the top. Therefore installing the bushing from the top (inside the trunk) instead of from the bottom. Just like in the schematic above, part 11. Did you change your mind and do it the other way for some reason?

Which way does the rear shock bushing go?

Wider end topside or other way around? Seems like the wider side should go below to keep it from popping through the tower hole from forces below but parts diagram shows wider side is on top side. What say the experts?e9coupe.com

I have to say that when using that big Carl Nelson washer, it would make it a lot easier to slide it on the collar of the bushing first and then push the narrow end of the bushing with the washer already installed from the bottom. Instead of pushing the narrow end down from the top and then having to try and slip the big washer onto it from the bottom inside the shock tower.

my explanation,

“it is very easy, the system is composed of two parts, the rubber bushing, and a short metal bushing that goes inside the first one, this little metal bushing blocks the rubber one inside, so if you need to dissasemble the rubber one you will need to remove the metal one first

you must proceed this way,

yes i used a little ammount of vaseline, you introduce the rubber piece from the top of the wheel arch (inside the boot), then you introduce the metal bushing inside the rubber piece from the top again (i coated it with a little vaseline again), and then you come from the bottom with your shock rod, you place the top washer and the nut you do the nut until contact but no more

then you use the jack to get the weight of the car on the shock, you place the jack on the wheel hub support from inside, and you lift it until the weight is on that shock, and in this position you introduce the nut on the shock rod and you give 25Nm torque

p.s. i made a mistake considering that the rubber part could be introduced from the bottom of the wheel arch. it is wrong, it must be introduced from the top”

Yes, the larger side sits on top with the washer.

@Bmachine : I took like 50 pictures when I did this last year and I'm still not 100% certain what I ended up doing.

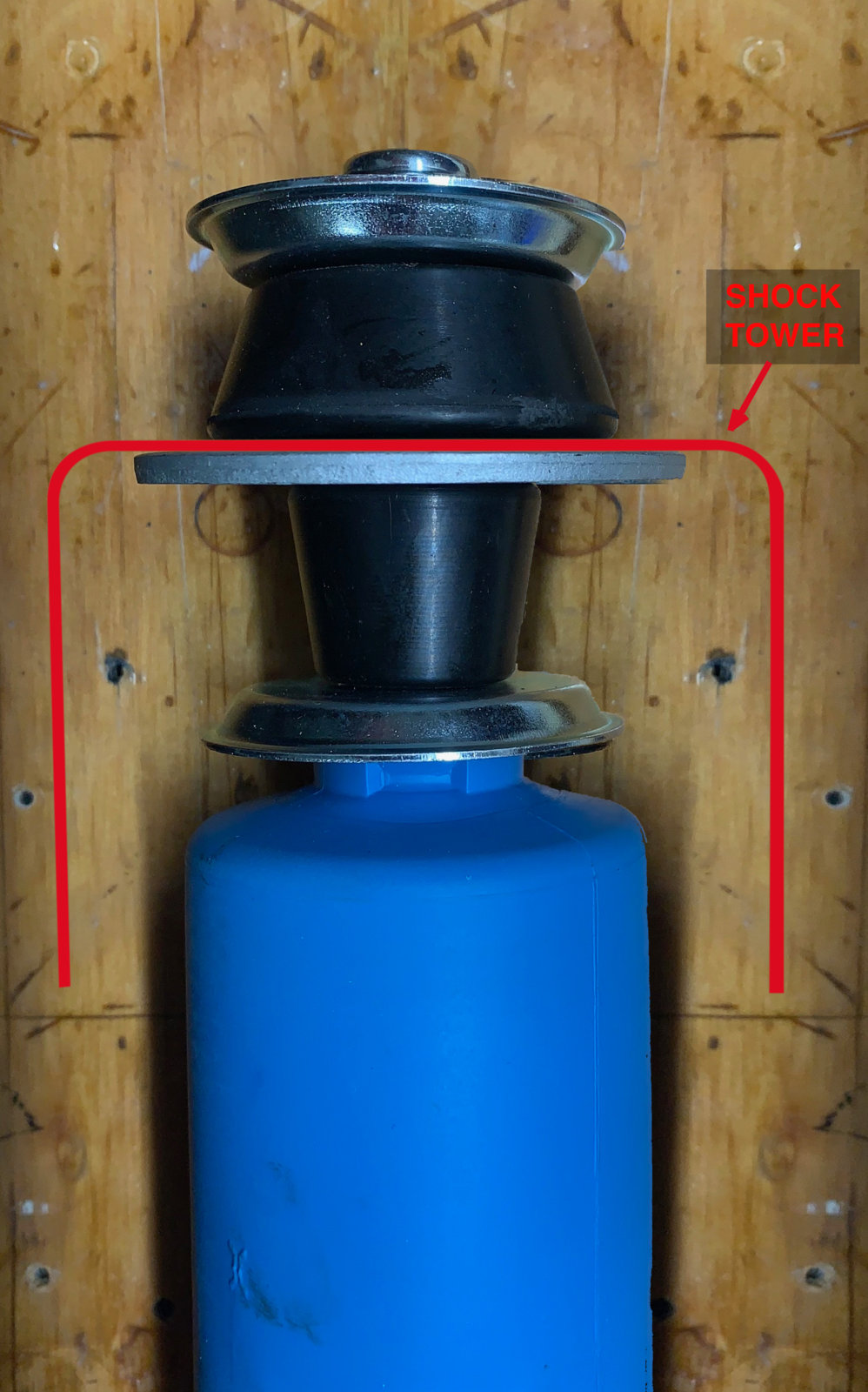

A few pieces of photographic evidence:

What I found when I removed the Bilsteins. Confirmation that the original rubber piece should not go small side up as mine got chewed up as seen:

E3 and E9 pieces for reference. Note they each use a different steel bushing:

These are the last 2 photos in my series leading me to believe I used the E9 rubber piece not the E3 one. Can't recall why... I think I didn't see the need for the E3 piece and supporting washer since my towers are intact and the lower rebound force of the replacement shocks plus running original 14" wheels, I believe place far less stress on the towers than Bilsteins and mongo 16's with modern rubber.

Hope that helps.

Do let us know what you end up doing.

A few pieces of photographic evidence:

What I found when I removed the Bilsteins. Confirmation that the original rubber piece should not go small side up as mine got chewed up as seen:

E3 and E9 pieces for reference. Note they each use a different steel bushing:

These are the last 2 photos in my series leading me to believe I used the E9 rubber piece not the E3 one. Can't recall why... I think I didn't see the need for the E3 piece and supporting washer since my towers are intact and the lower rebound force of the replacement shocks plus running original 14" wheels, I believe place far less stress on the towers than Bilsteins and mongo 16's with modern rubber.

Hope that helps.

Do let us know what you end up doing.

So it should go like this then:

Yes.

do not put the big thick washer, it is not an stable system

unless you weld it to the turret

It is recommended by Carl Nelson to avoid the issue of cracked rear shock towers.do not put the big thick washer, it is not an stable system

unless you weld it to the turret

I’m not sure that’s going to help, I had them when my tower let loose.It is recommended by Carl Nelson to avoid the issue of cracked rear shock towers.

At least there is twice the surface area with that washer and Carl has been doing it for 40 years. Not a panacea just a bit of extra safety.

It is recommended by Carl Nelson to avoid the issue of cracked rear shock towers.

i know that we all love CN, but that might not be a sufficient reason, love is sometimes causing more problems than benefits (i did not knew it was a CN invention, not judging the inventor here)

try to look at it as a mechanical system, if the tower and the washer are not welded together it might be difficult for them to work together, i assume that the idea is to spread the force in a bigger surface which is a good idea

the force exerted by the shock is not perfectly perpendicular in all of its travel

the relative displacement forces might not be good for the system

i would not use it

Last edited:

As Chris said, Carl has been doing it for 40 years on countless coupes. So, while it may not be a perfect solution, there seems to be plenty of empirical evidence to show that it is an improvement over not using anything

As Chris said, Carl has been doing it for 40 years on countless coupes. So, while it may not be a perfect solution, there seems to be plenty of empirical evidence to show that it is an improvement over not using anything

no, but it is your cat,....

I don’t have a horse (or even a cat ) in this race. But as a general rule, I tend to trust the opinion of people who have many years and many cars worth of experience.

In this particular case it seems that the worst that can happen by using this large washer is that it would not improve things. That seems like a low risk proposition to me.

But I’m always interested in hearing different opinions. What would be the rationale against using it?

In this particular case it seems that the worst that can happen by using this large washer is that it would not improve things. That seems like a low risk proposition to me.

But I’m always interested in hearing different opinions. What would be the rationale against using it?

Last edited:

I would tend to agree with DeQ here: the washer will concentrate the load mostly on its edges. When only the rubber is used, there is not such a load concentration; the rubber tends to deform mostly on the edge and therewith spread the load.

Secondly, I think that (correct me if I'm wrong) most blown shock tower have a tear that originates from one of the spotwelds. Taking a rough, eye ball approach: doesn't the edge of the washer line up with roughly the circle that the spot welds make? If they match, then the (-if first argument above is true-) it would concentrate the load exactly at the weakest spot(s). Not sure if that is wise.

If I were to use a washer, I'd try to make it to it's max dimension possible about 8-9cm/ 2,5 to 3 inch), and round the edges. I'm guessing that the above depicted washer only has a dimension half of the width of the tower's flat spot, wider would be better: every 1 mm add 3.14 mm of more material to spread the forces.

I'm struggling what happens as the shock mount changes angle during driving. No clear thoughts in my mind on that...

Secondly, I think that (correct me if I'm wrong) most blown shock tower have a tear that originates from one of the spotwelds. Taking a rough, eye ball approach: doesn't the edge of the washer line up with roughly the circle that the spot welds make? If they match, then the (-if first argument above is true-) it would concentrate the load exactly at the weakest spot(s). Not sure if that is wise.

If I were to use a washer, I'd try to make it to it's max dimension possible about 8-9cm/ 2,5 to 3 inch), and round the edges. I'm guessing that the above depicted washer only has a dimension half of the width of the tower's flat spot, wider would be better: every 1 mm add 3.14 mm of more material to spread the forces.

I'm struggling what happens as the shock mount changes angle during driving. No clear thoughts in my mind on that...

Last edited:

I would tend to agree with DeQ here: the washer will concentrate the load mostly on its edges. When only the rubber is used, there is not such a load concentration; the rubber tends to deform mostly on the edge and therewith spread the load.

Secondly, I think that (correct me if I'm wrong) most blown shock tower have a tear that originates from one of the spotwelds. Taking a rough, eye ball approach: doesn't the edge of the washer line up with roughly the circle that the spot welds make? If they match, then the (-if first argument above is true-) it would concentrate the load exactly at the weakest spot(s). Not sure if that is wise.

If I were to use a washer, I'd try to make it to it's max dimension possible about 8-9cm/ 2,5 to 3 inch), and round the edges. I'm guessing that the above depicted washer only has a dimension half of the width of the tower's flat spot, wider would be better: every 1 mm add 3.14 mm of more material to spread the forces.

I'm struggling what happens as the shock mount chances angle during driving. No clear thoughts in my mind on that...

you talk as an engineer, you speak my language

i agree

You make all kinds of good points as usual Erik. But using your own “wider would be better” isn’t a wider washer better than the much narrower rubber bushing? Any way you look at it, a washer will spread the load over a much larger area. Therefore, in my mind at least, it will reduce metal fatigue on any specific weak point, wouldn’t it?I would tend to agree with DeQ here: the washer will concentrate the load mostly on its edges. When only the rubber is used, there is not such a load concentration; the rubber tends to deform mostly on the edge and therewith spread the load.

Secondly, I think that (correct me if I'm wrong) most blown shock tower have a tear that originates from one of the spotwelds. Taking a rough, eye ball approach: doesn't the edge of the washer line up with roughly the circle that the spot welds make? If they match, then the (-if first argument above is true-) it would concentrate the load exactly at the weakest spot(s). Not sure if that is wise.

If I were to use a washer, I'd try to make it to it's max dimension possible about 8-9cm/ 2,5 to 3 inch), and round the edges. I'm guessing that the above depicted washer only has a dimension half of the width of the tower's flat spot, wider would be better: every 1 mm add 3.14 mm of more material to spread the forces.

I'm struggling what happens as the shock mount changes angle during driving. No clear thoughts in my mind on that...

Last edited:

I don’t have a horse (or even a cat ) in this race. But as a general rule, I tend to trust the opinion of people who have many years and many cars worth of experience.

In this particular case it seems that the worst that can happen by using is this large washer is that it would not improve things. That seems like a risk proposition to me.

But I’m always interested in hearing different opinions. What would be the rationale against using it?

You make all kinds of good points as usual Erik. But using your own “wider would be better” isn’t a wider washer better than the much narrower rubber bushing? Any way you look at it, a washer will spread the load over a much larger area. Therefore, in my mind at least, it will reduce metal fatigue on any specific weak point, wouldn’t it?

quote: "Therefore, in my mind at least, it will reduce metal fatigue on any specific weak point, wouldn’t it?"

No if it is not welded, shear forces will be present, relative displacement, uncontrolled positioning

moreover the rubber part is designed to fit and sit in a certain thickness not in a double one

it is not a good design

i know that we all love CN, but that might not be a sufficient reason, love is sometimes causing more problems than benefits (i did not knew it was a CN invention, not judging the inventor here)

try to look at it as a mechanical system, if the tower and the washer are not welded together it might be difficult for them to work together, i assume that the idea is to spread the force in a bigger surface which is a good idea

the force exerted by the shock is not perfectly perpendicular in all of its travel

the relative displacement forces might not be good for the system

i would not use it

i gave my points here,

Thank you

you are welcome