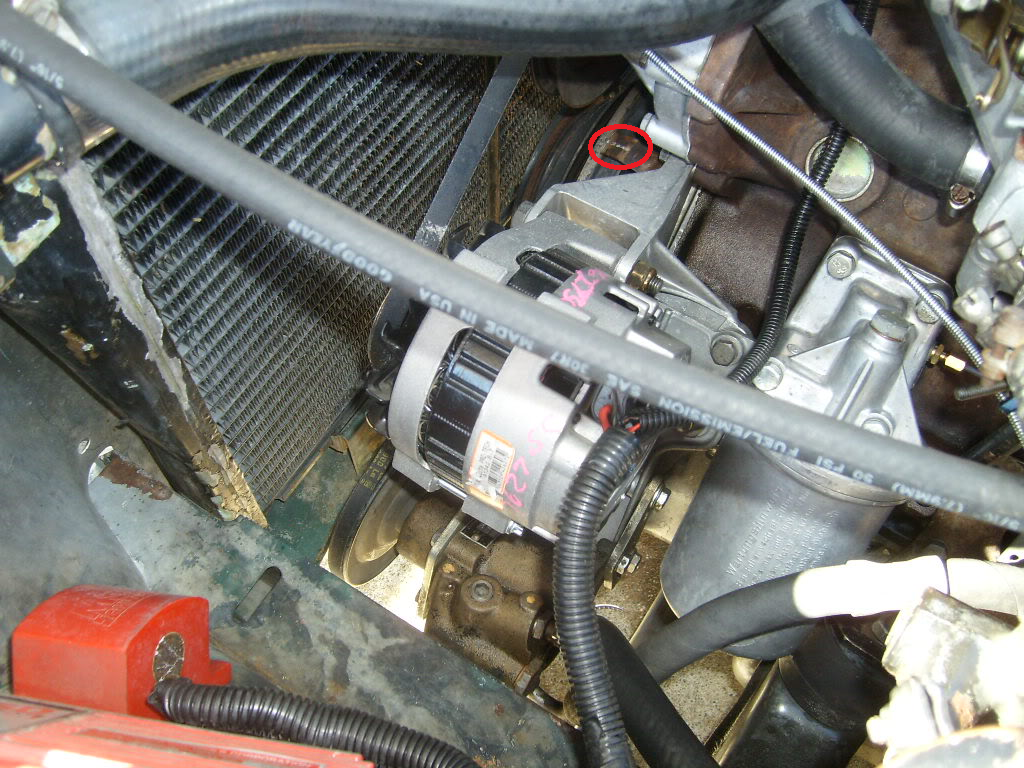

Appears you could have a flywheel from a manual Motronic 1.1 engine.

That raised area is the TDC section that is read by one of the 2 magnetic position sensors on the bell housing. As a guess, I would say that it is about 120 degrees away from the window where you would look for the T l O mark that is on the flywheel for normal timing purposes. Set your front dampener correctly and then paint the TO mark on the flywheel. Count 7 teeth from there to have the correct mark for setting your distributor and paint that spot too.

Now that is about what I am talking :razz:

I figured something was not right about this.

Thanks so much for the info.

I will try this procedure and report back.

7 teeth equates to about 22 degress?