Planing to do this complete process. please help and feel free to contribute

it will involve:

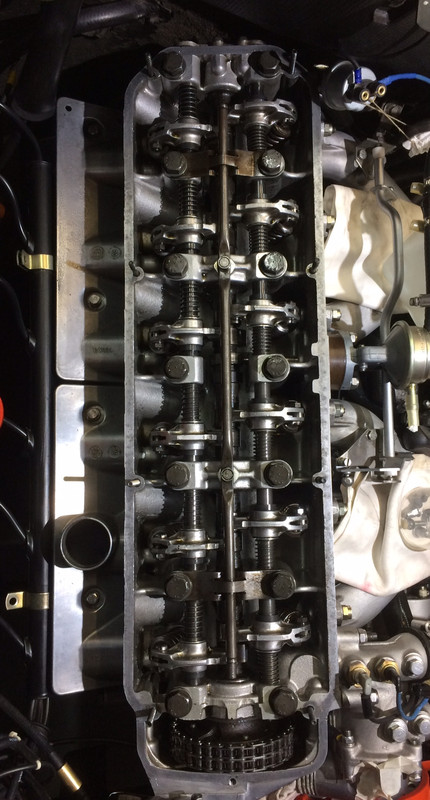

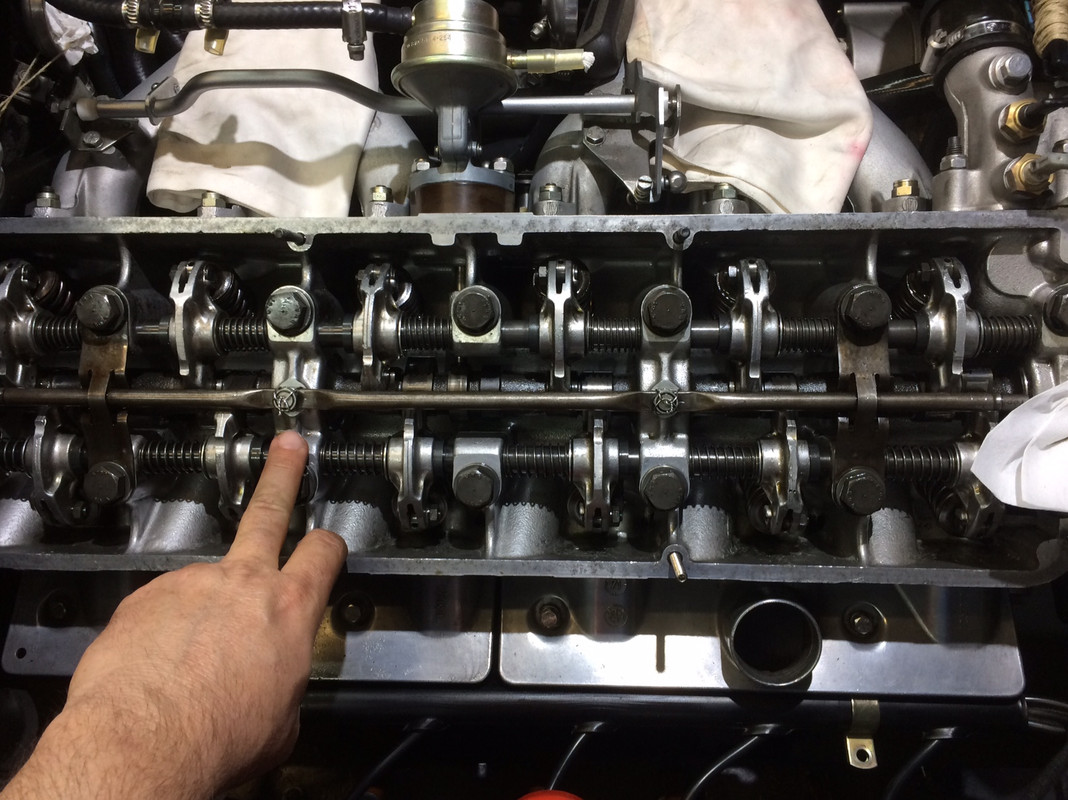

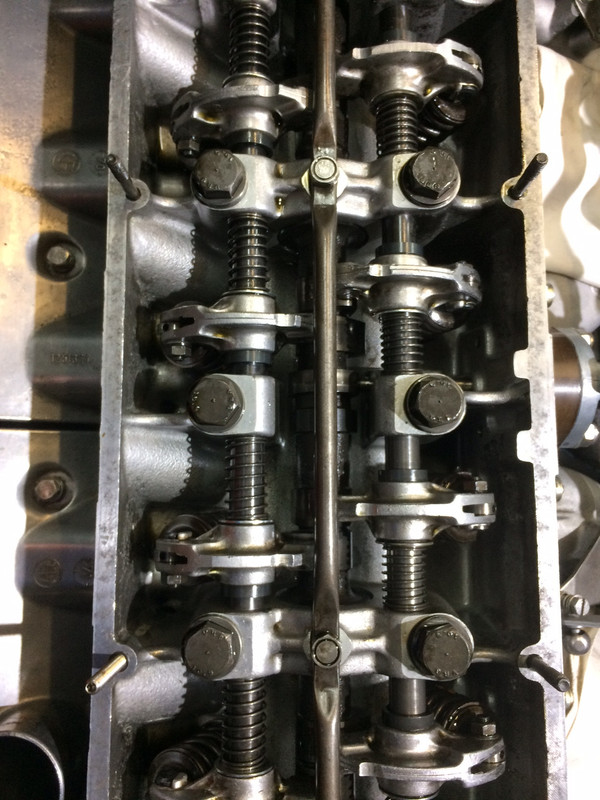

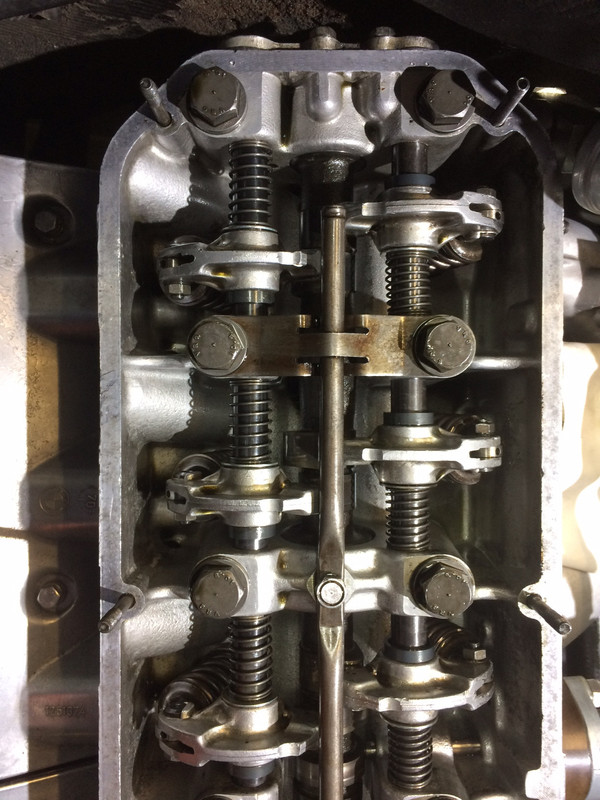

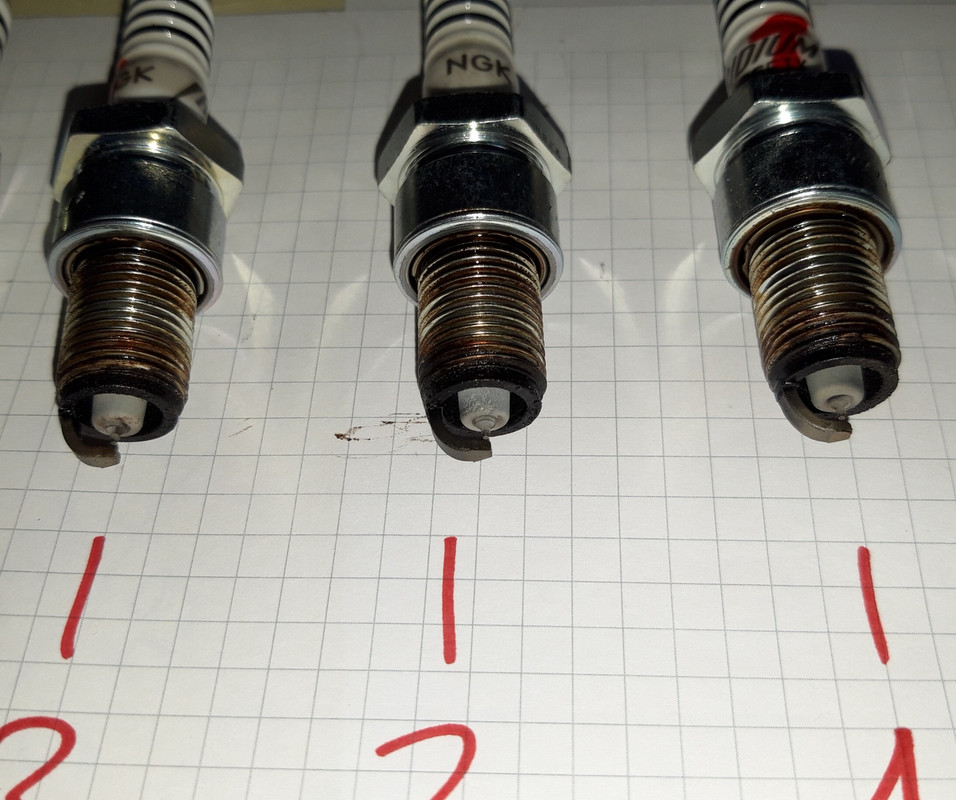

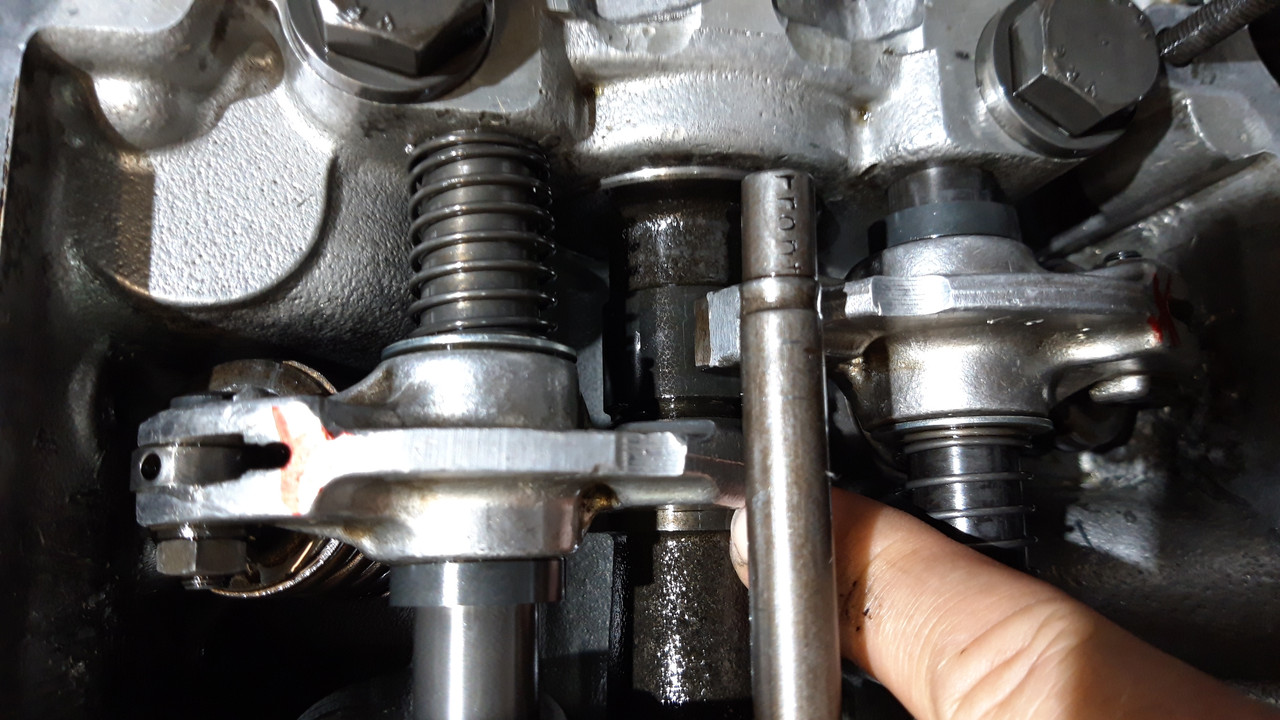

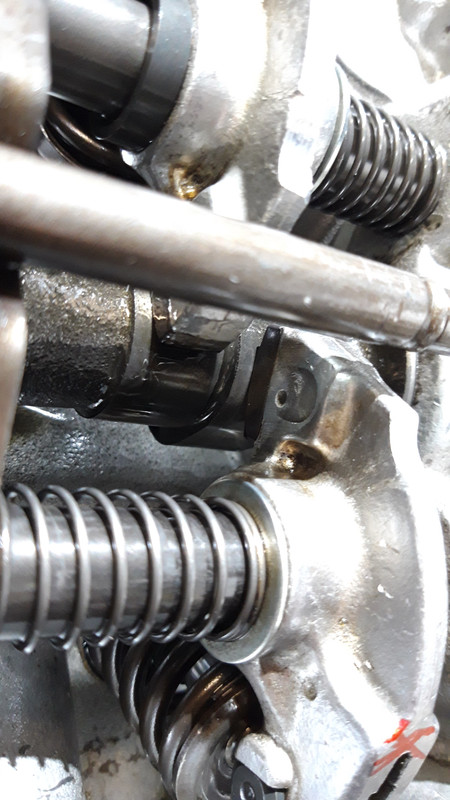

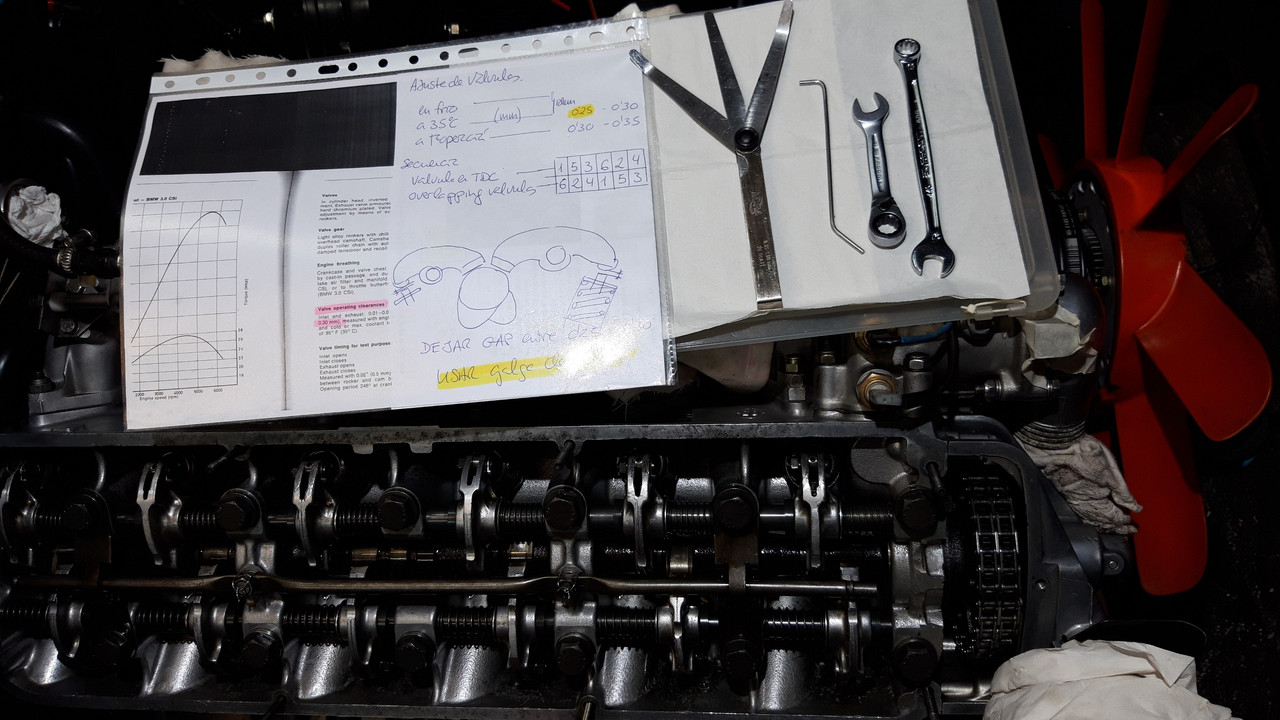

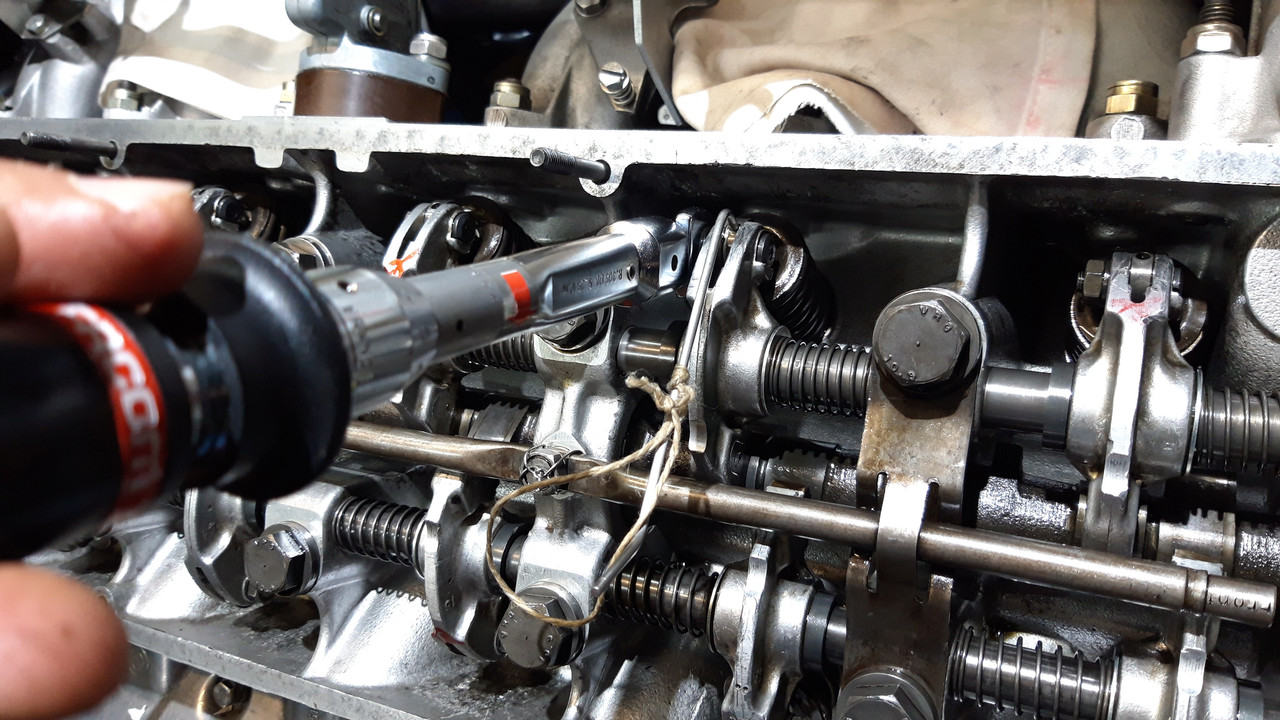

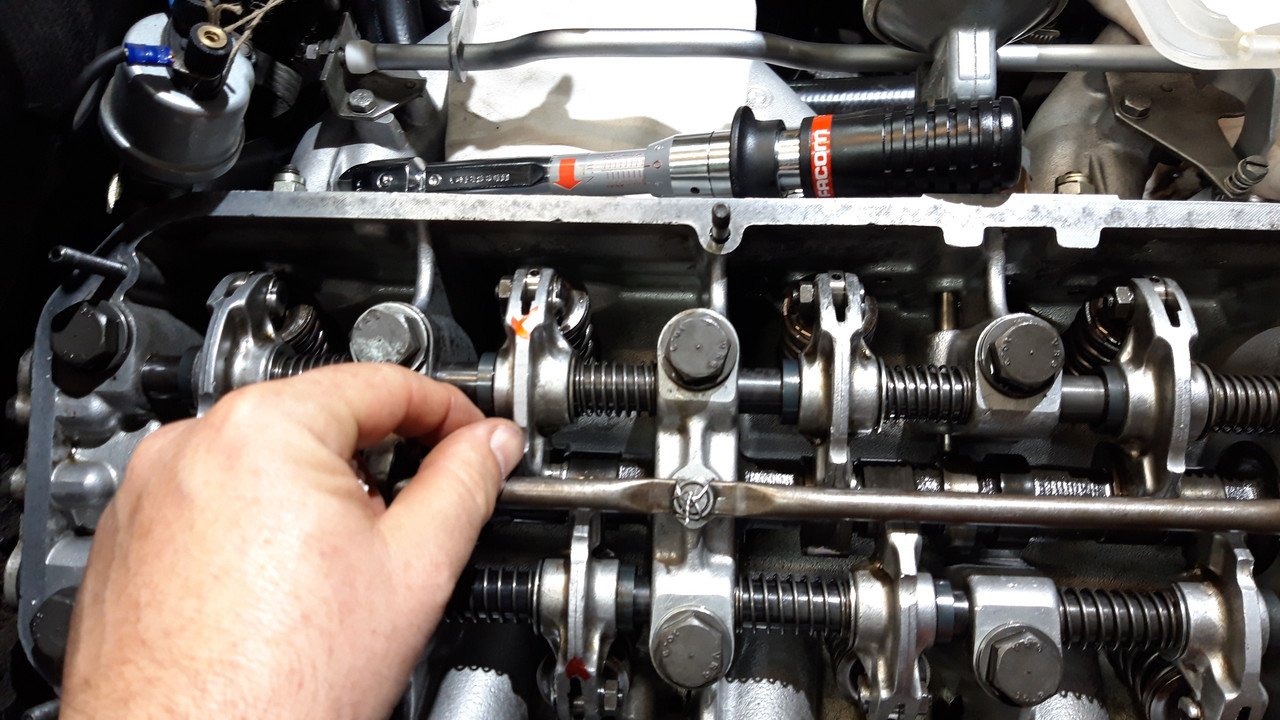

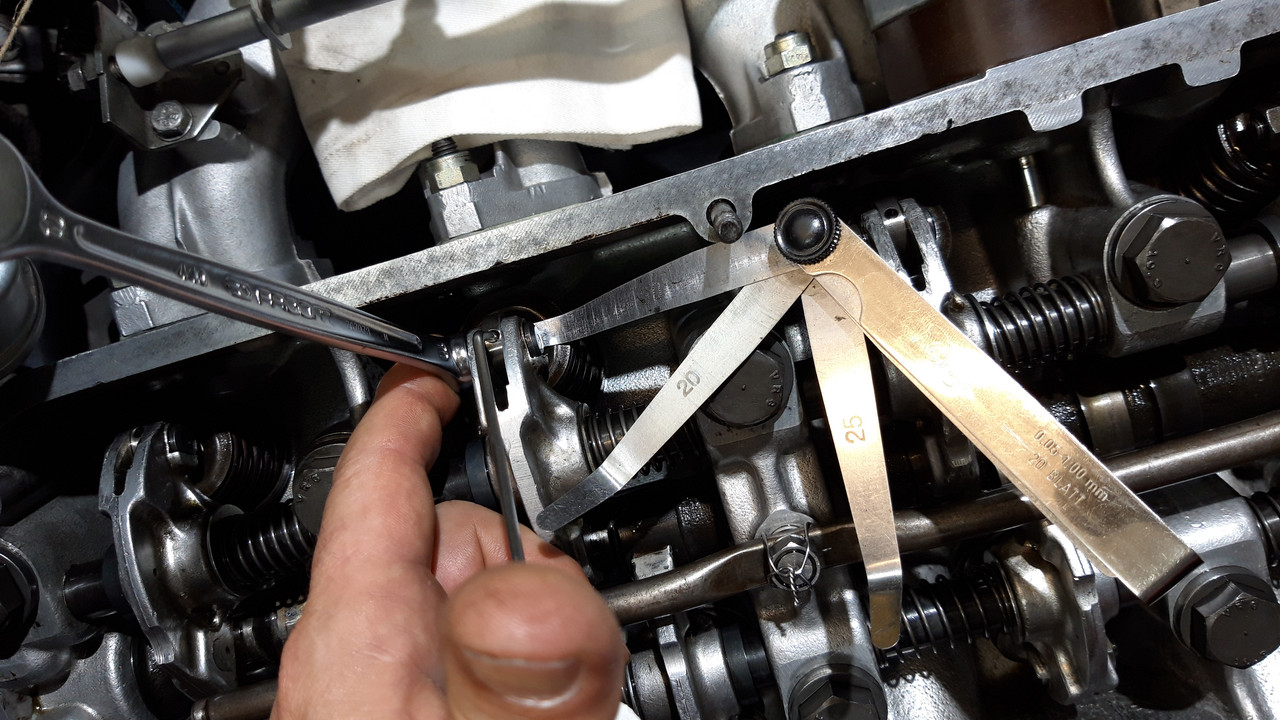

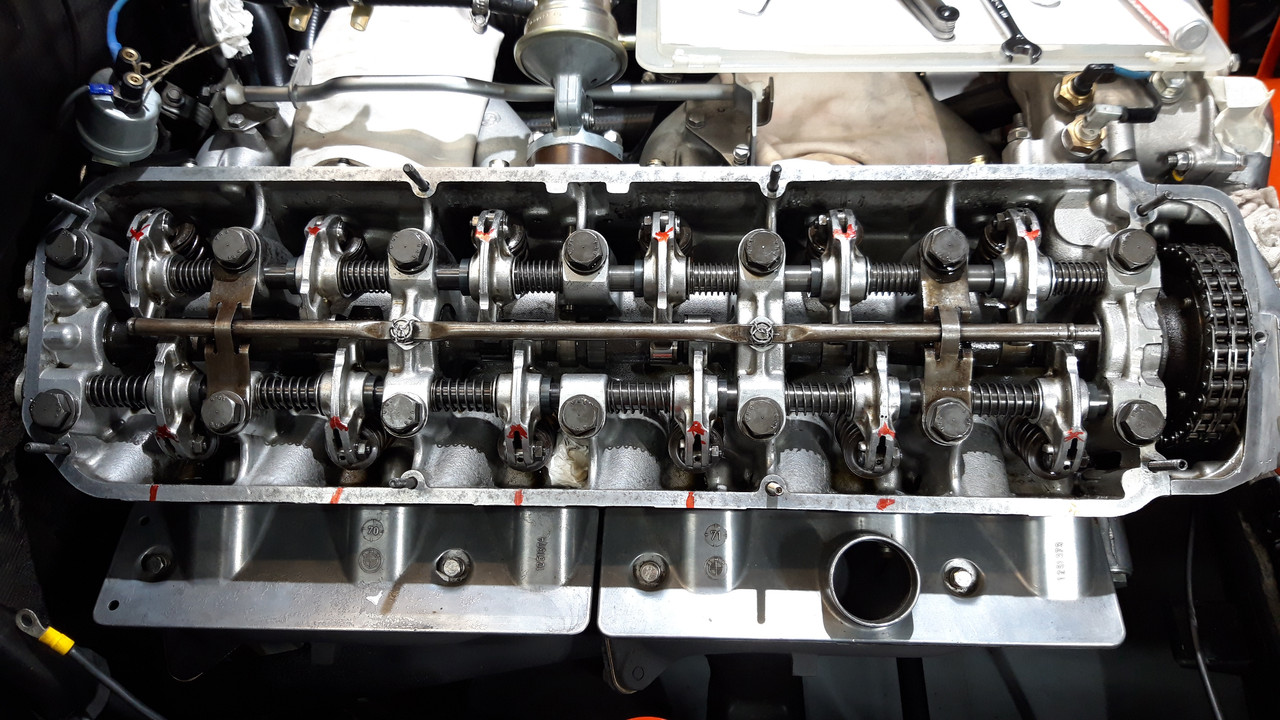

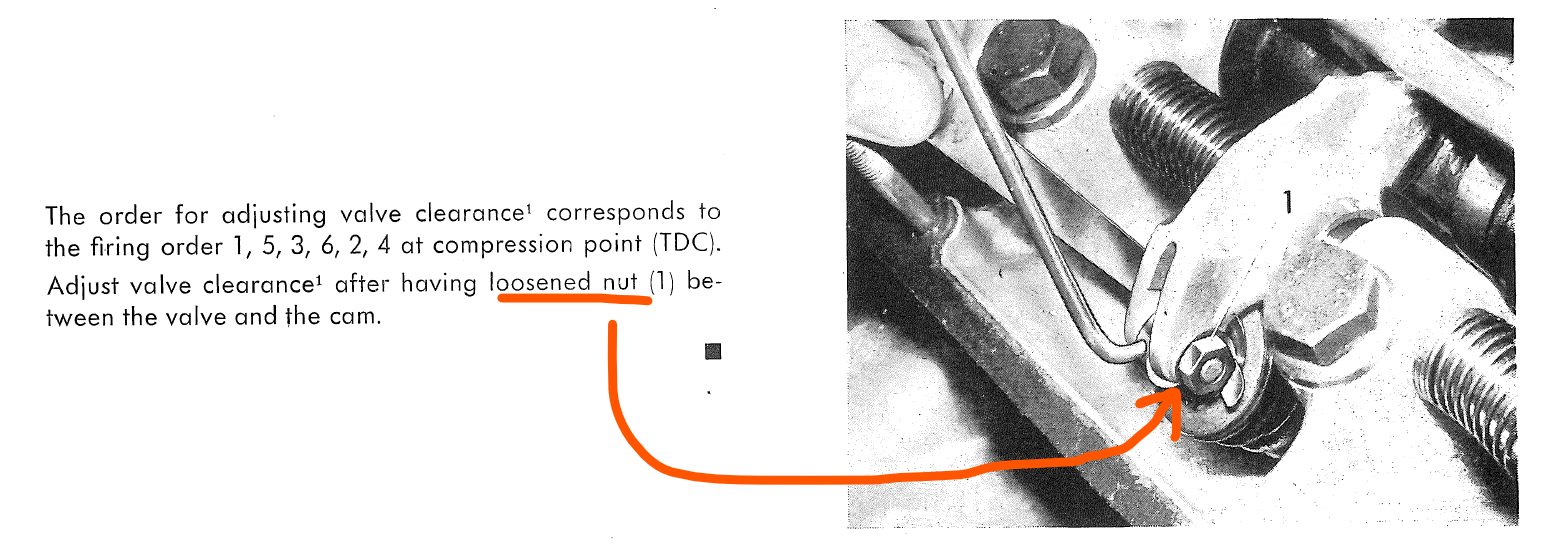

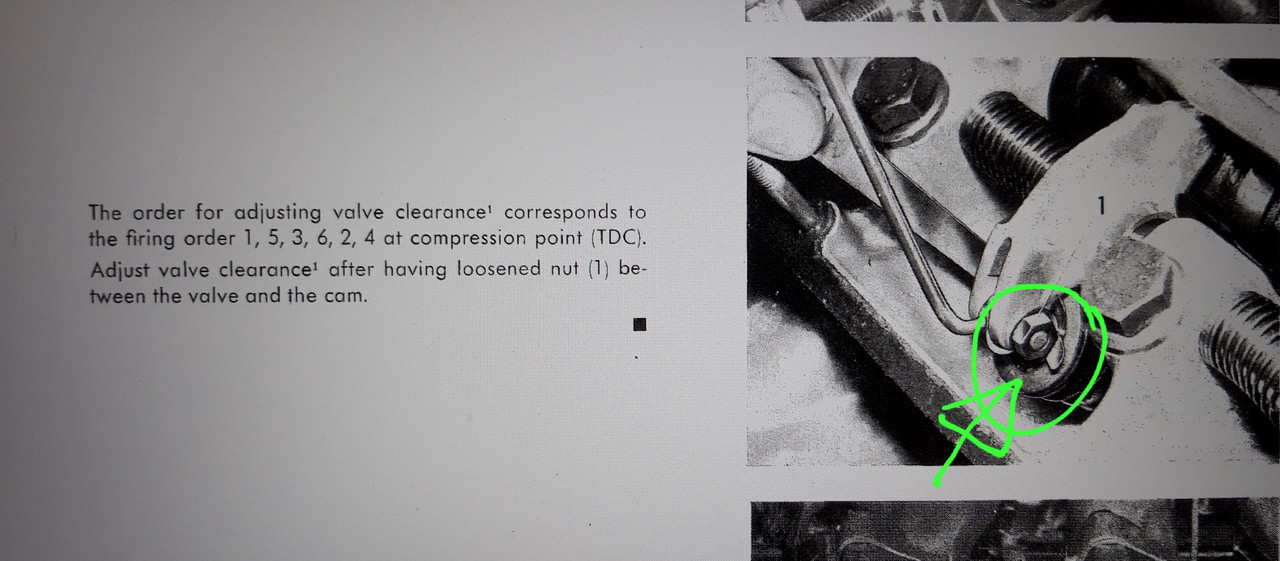

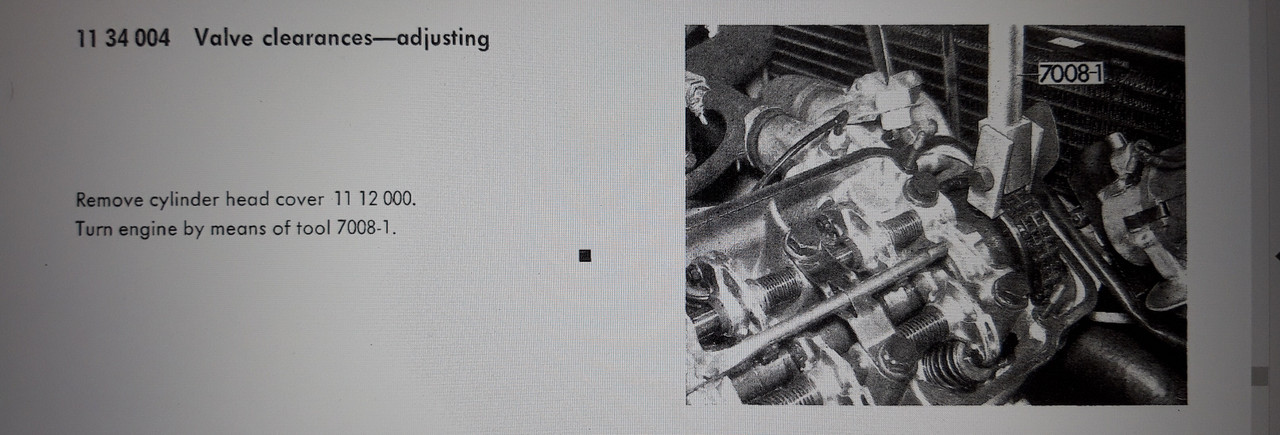

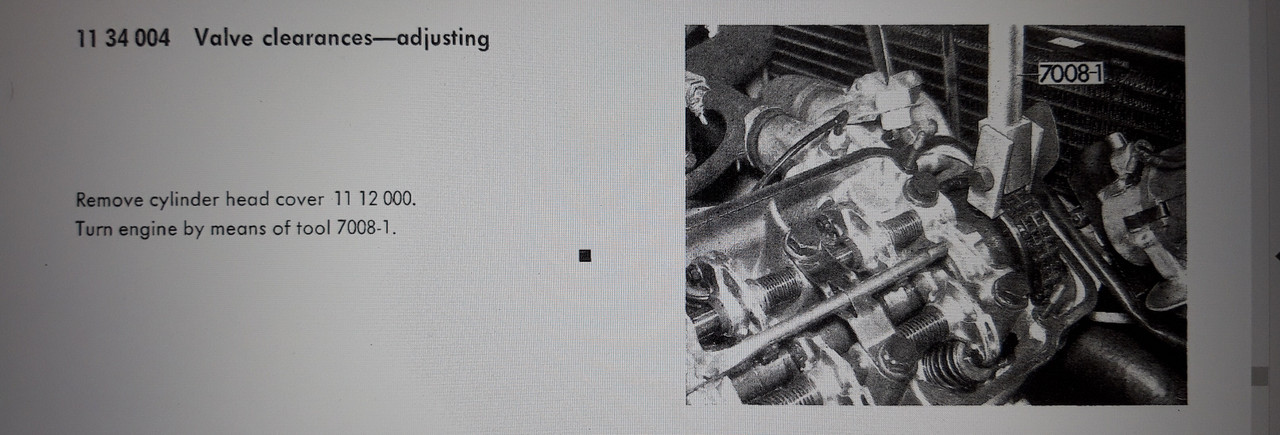

1- VALVE CLEARANCE ADJUSTMENT

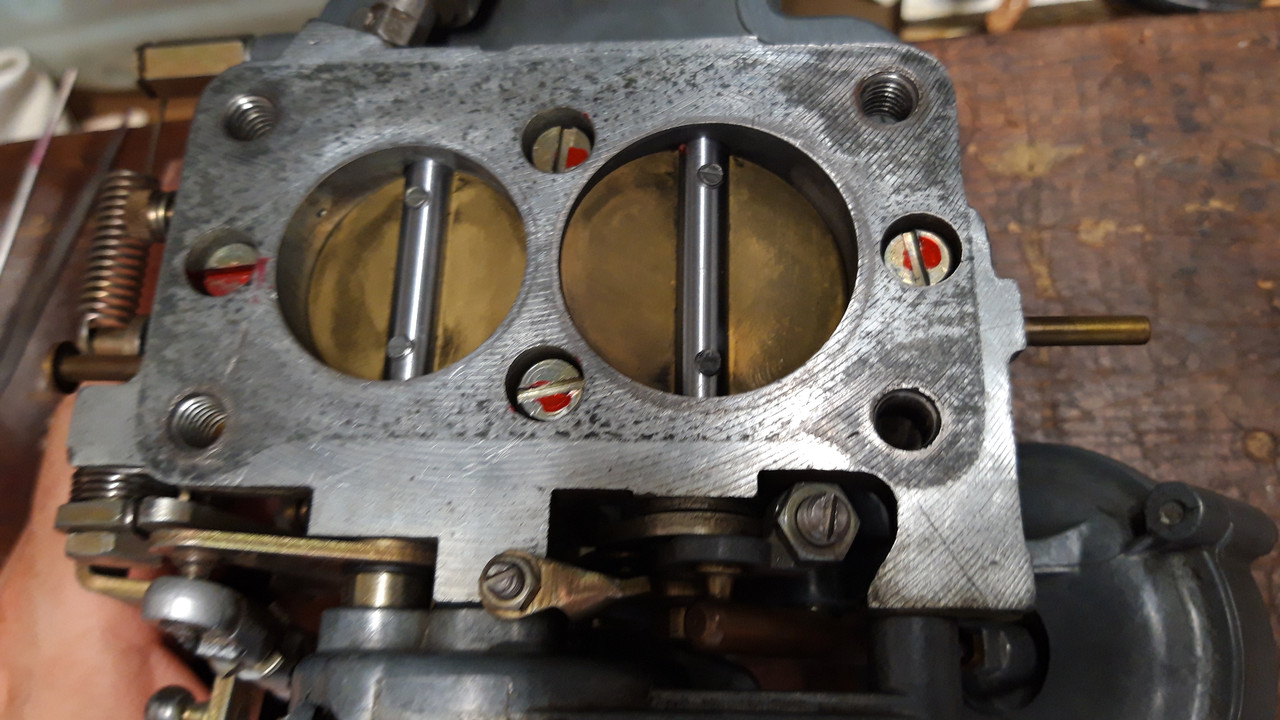

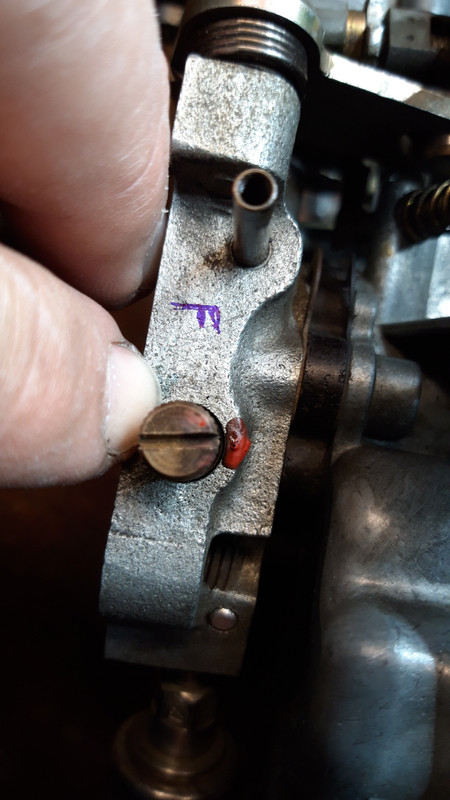

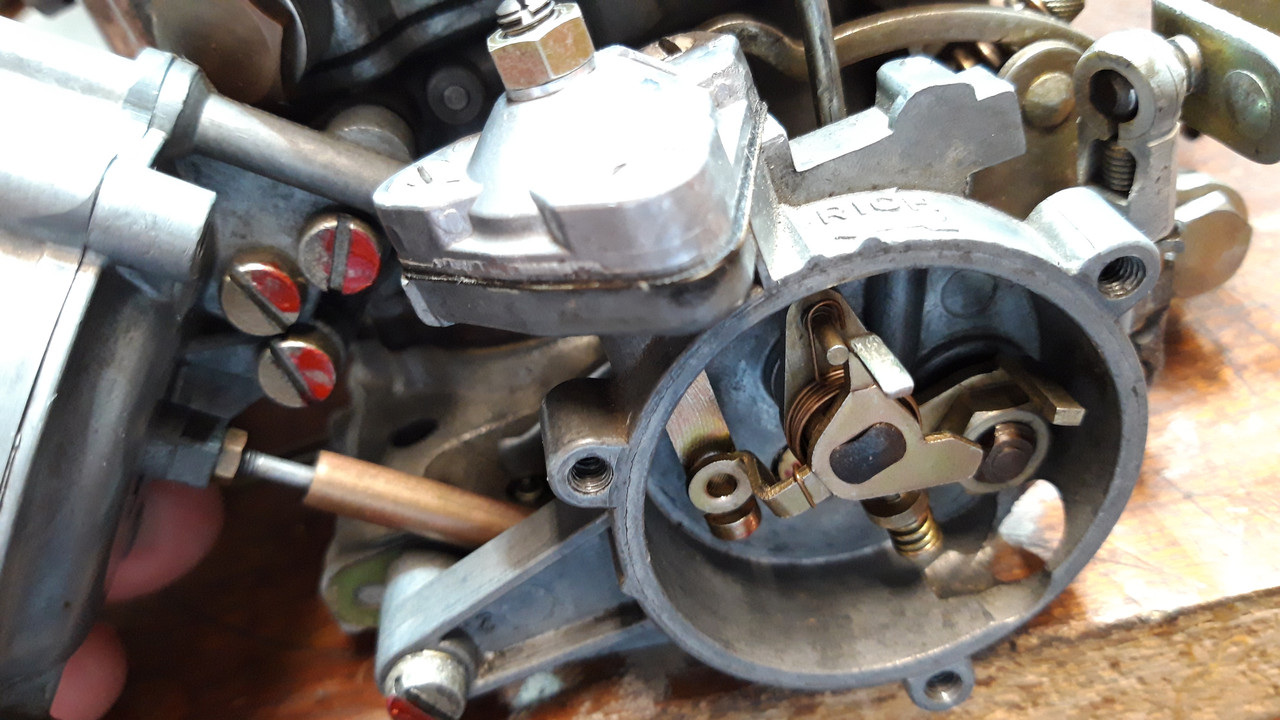

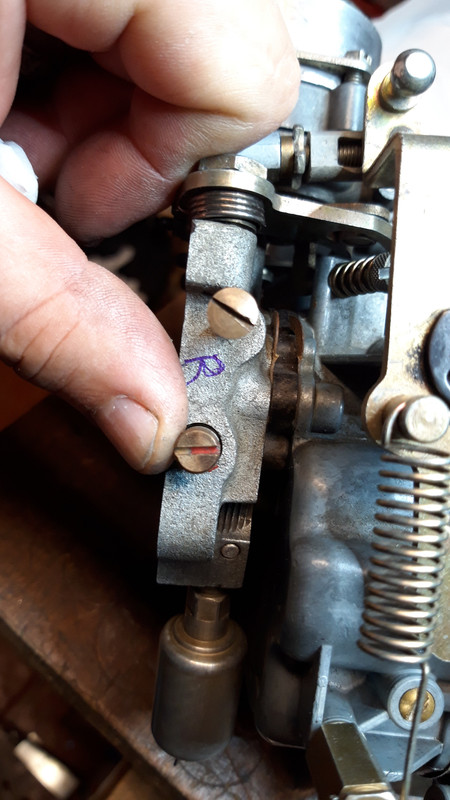

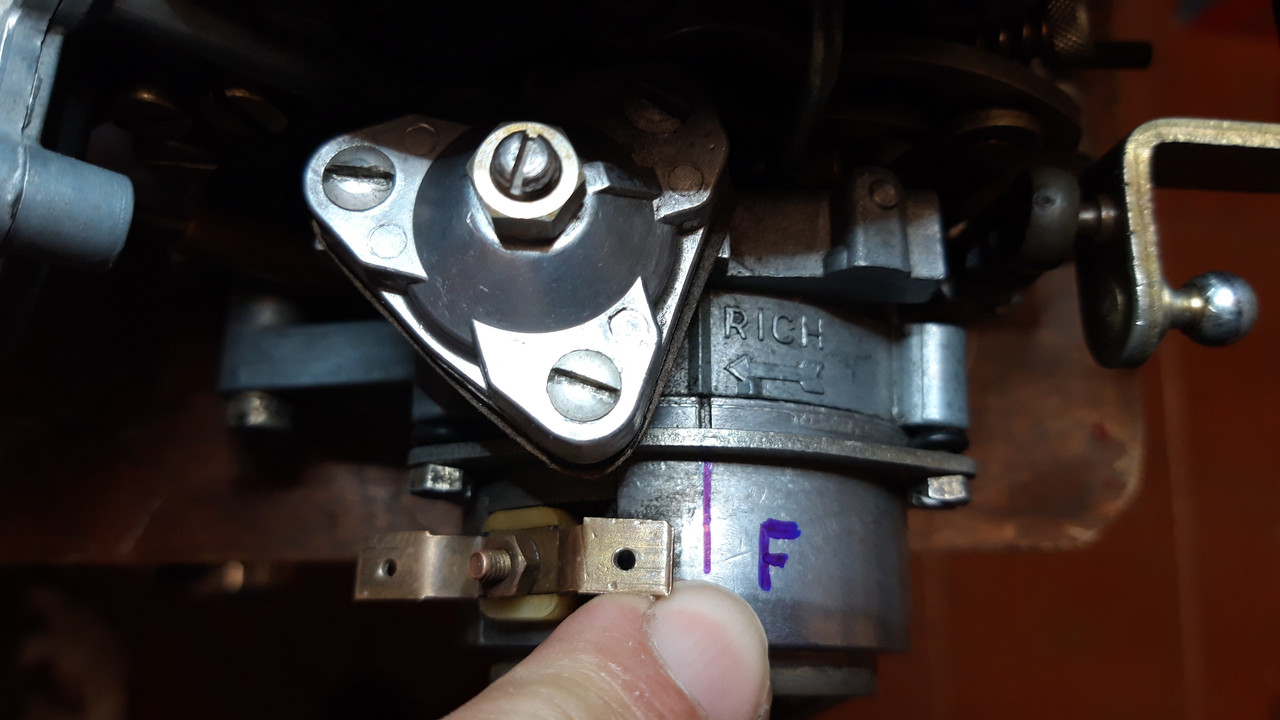

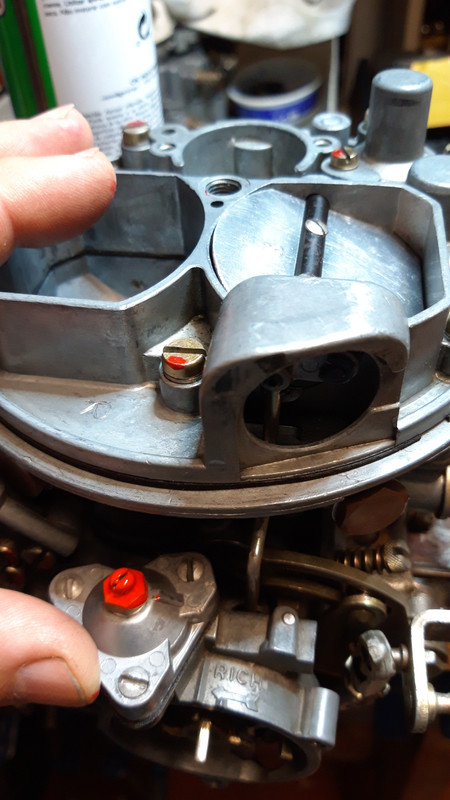

2- IGNITION

3- CARBURETOR TUNING AND SYNCHRONIZATION

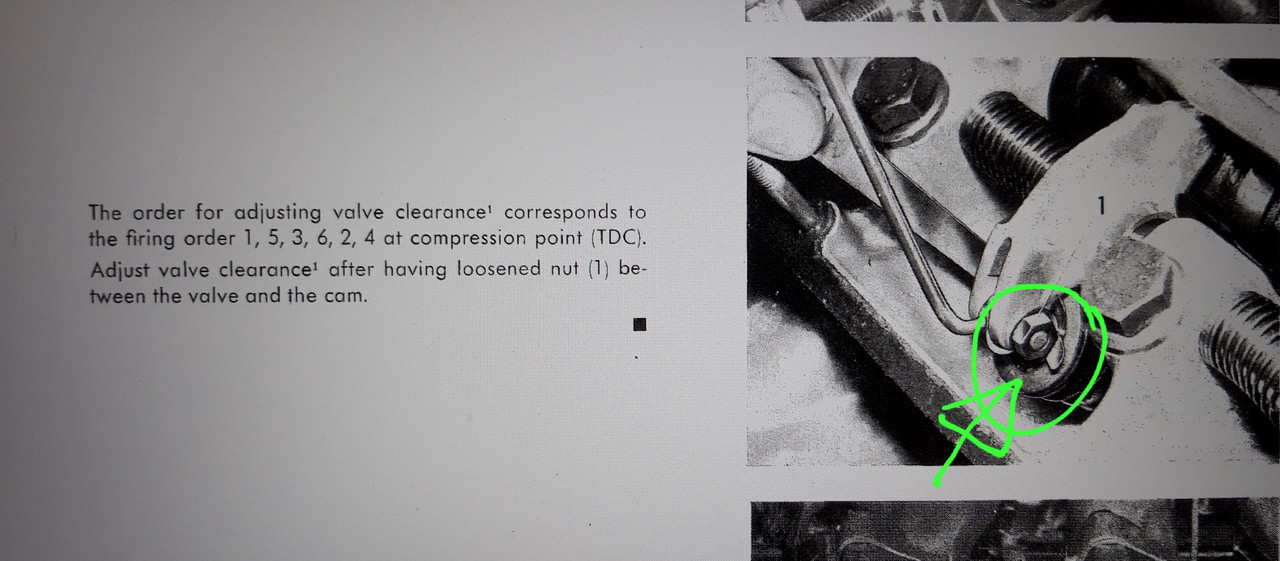

1st- VALVE CLEARANCE ADJUSTMENT

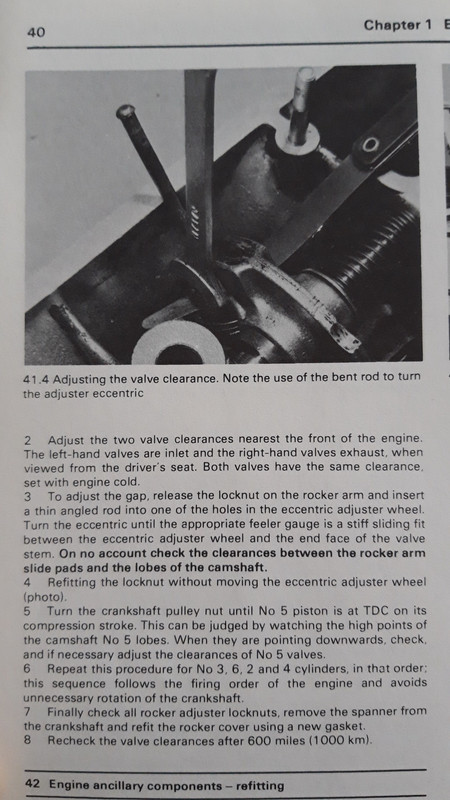

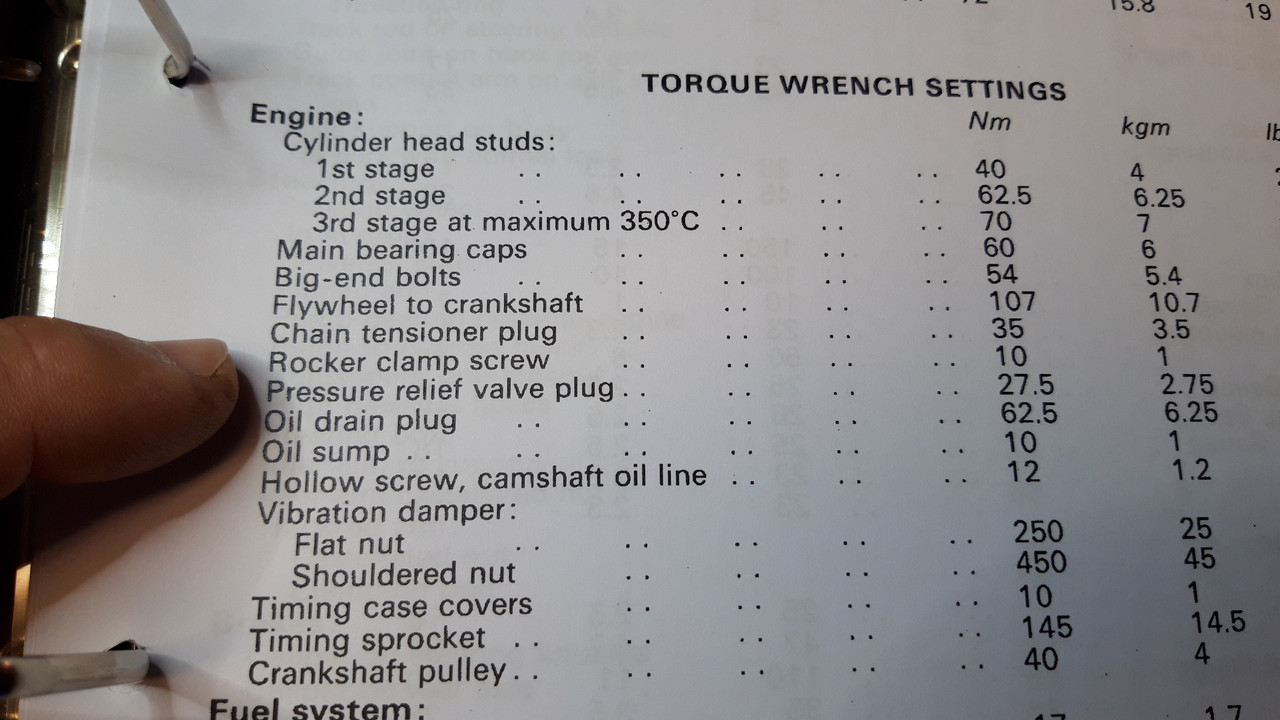

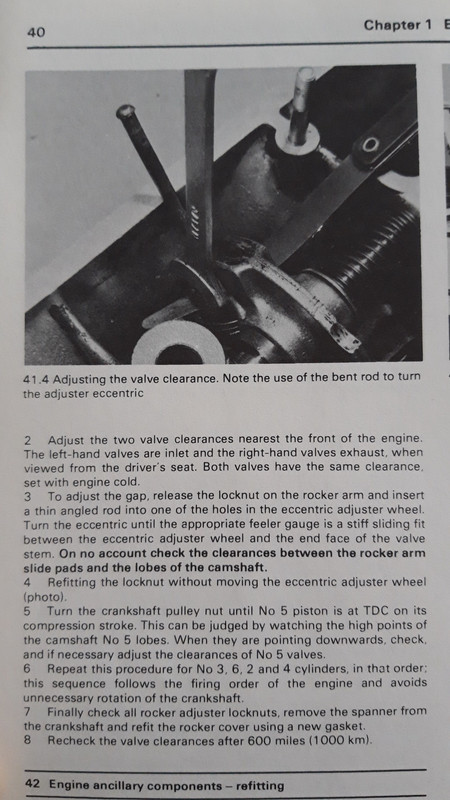

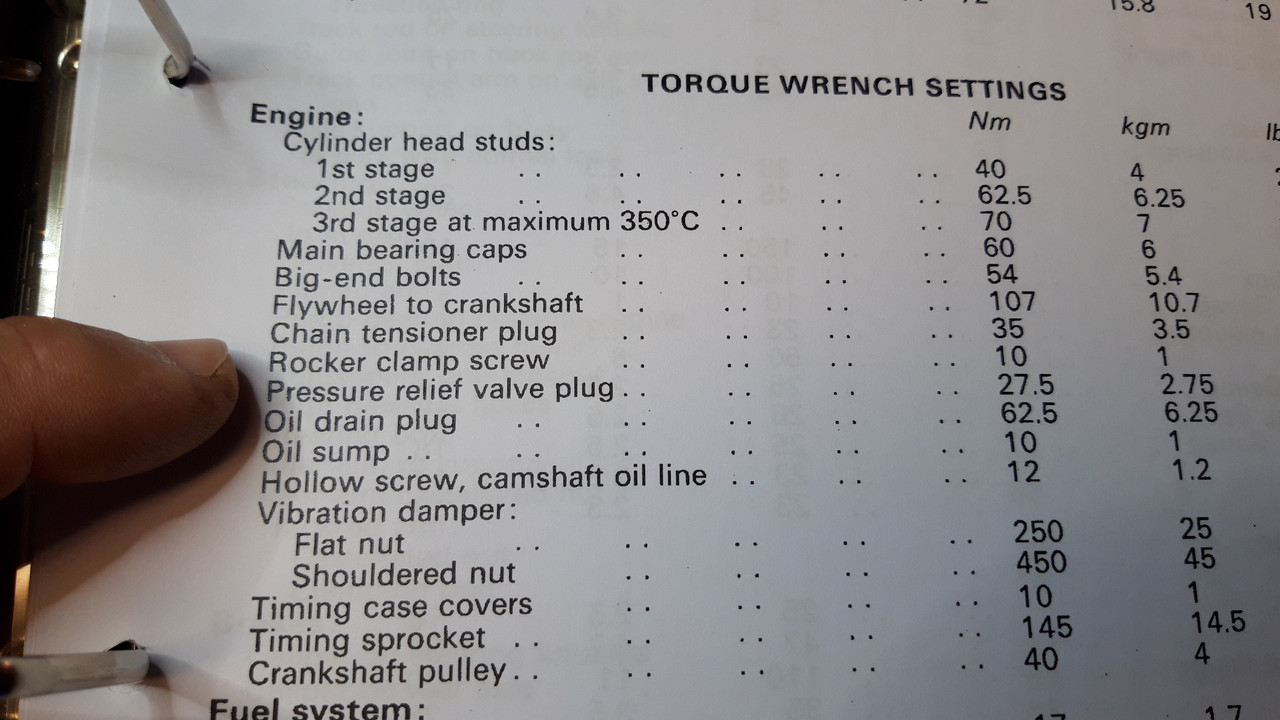

10 N.m is the torque that should be applied to the securing nut

some details to address this,

please read carefully, ON NO ACCOUNT CHECK CLEARANCES BETWEEN ROCKER ARM SLIDE PADS AND THE LOBES OF THE CAMSHAFT

it will involve:

1- VALVE CLEARANCE ADJUSTMENT

2- IGNITION

3- CARBURETOR TUNING AND SYNCHRONIZATION

1st- VALVE CLEARANCE ADJUSTMENT

10 N.m is the torque that should be applied to the securing nut

some details to address this,

please read carefully, ON NO ACCOUNT CHECK CLEARANCES BETWEEN ROCKER ARM SLIDE PADS AND THE LOBES OF THE CAMSHAFT

Last edited: