You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lan-Engine M30B30 tuning thread, steps, values, specs, and so on

- Thread starter deQuincey

- Start date

... after all this inmense job, (it started september the 20th), just last week i was finally able to put her on the ground with clean tyres

i was expecting to check the engine start on the first day of 2021

but,...nothing

at the beginning it was quite normal to expect some time to fill the filters bowl, and the carburetor reservoirs, but that point was far passed and indeed no sign of spark, combustion, or explosion of any kind

what was happening ?

we had fuel, plenty of it, so electricity and more specifically ignition came to my mind as the possible culprit

i was expecting to check the engine start on the first day of 2021

but,...nothing

at the beginning it was quite normal to expect some time to fill the filters bowl, and the carburetor reservoirs, but that point was far passed and indeed no sign of spark, combustion, or explosion of any kind

what was happening ?

we had fuel, plenty of it, so electricity and more specifically ignition came to my mind as the possible culprit

Last edited:

Last edited:

the thing is that there was no explosion at all, not even one, or half one

too big the fail for such a little error...

too big the fail for such a little error...

Last edited:

I don't believe that is causing your problem, have you pulled a plug wire or 2 and checked for spark?

I don't believe that is causing your problem, have you pulled a plug wire or 2 and checked for spark?

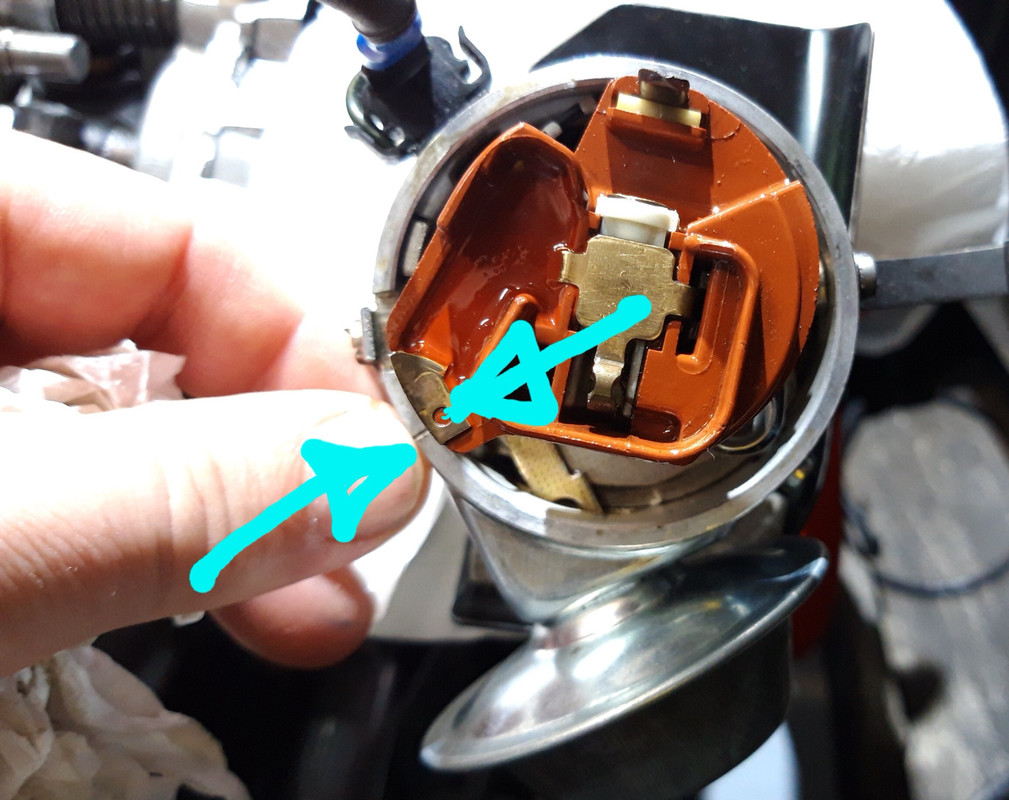

i couldnt believe it either, but, look....

Looks like a rev limiting rotor

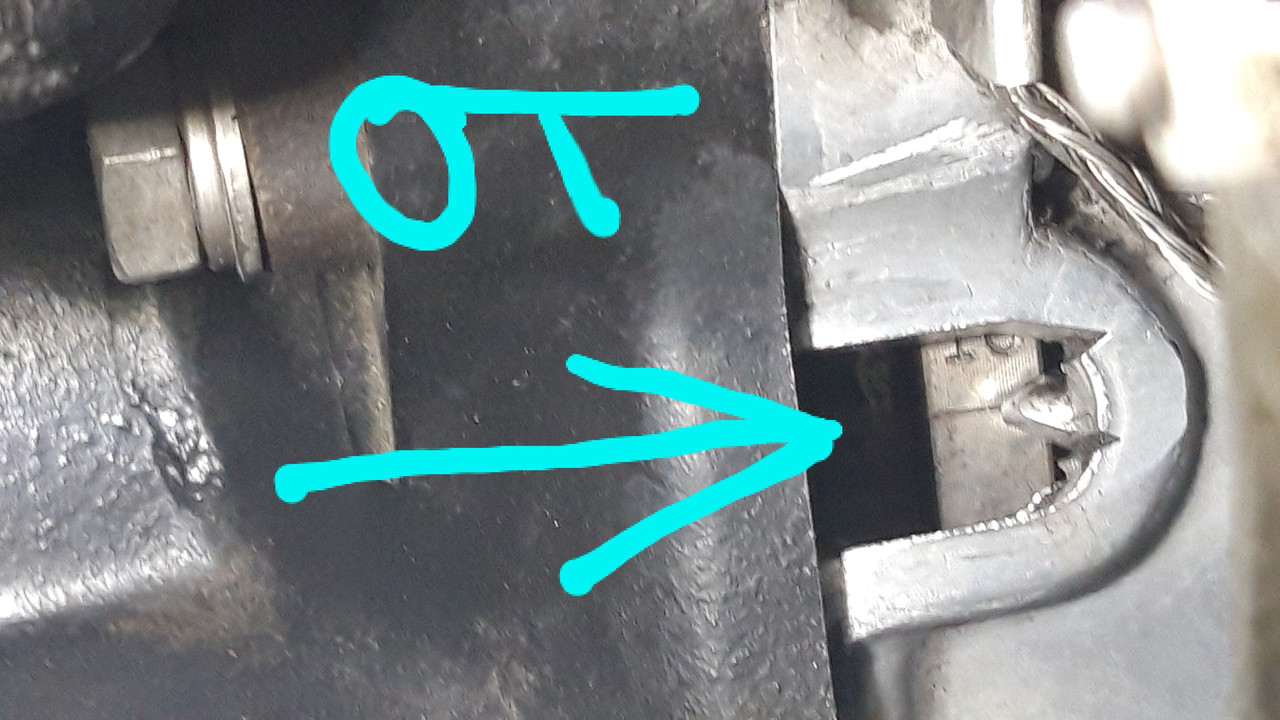

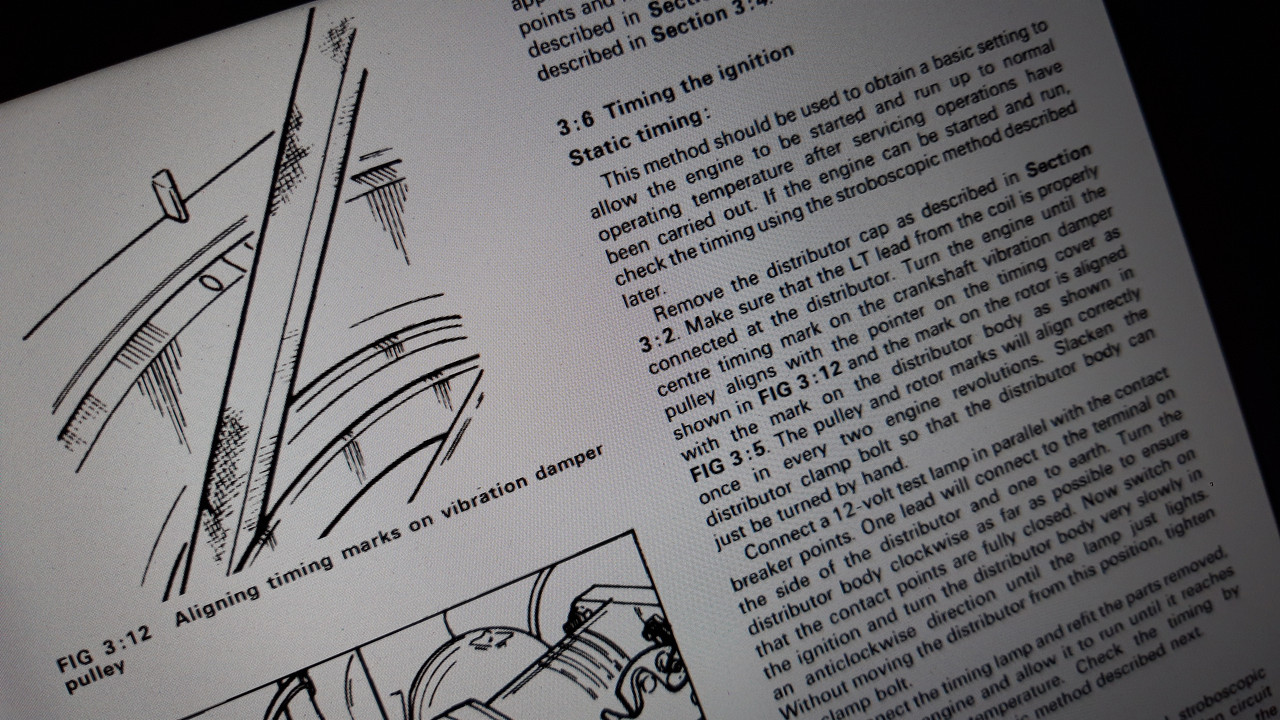

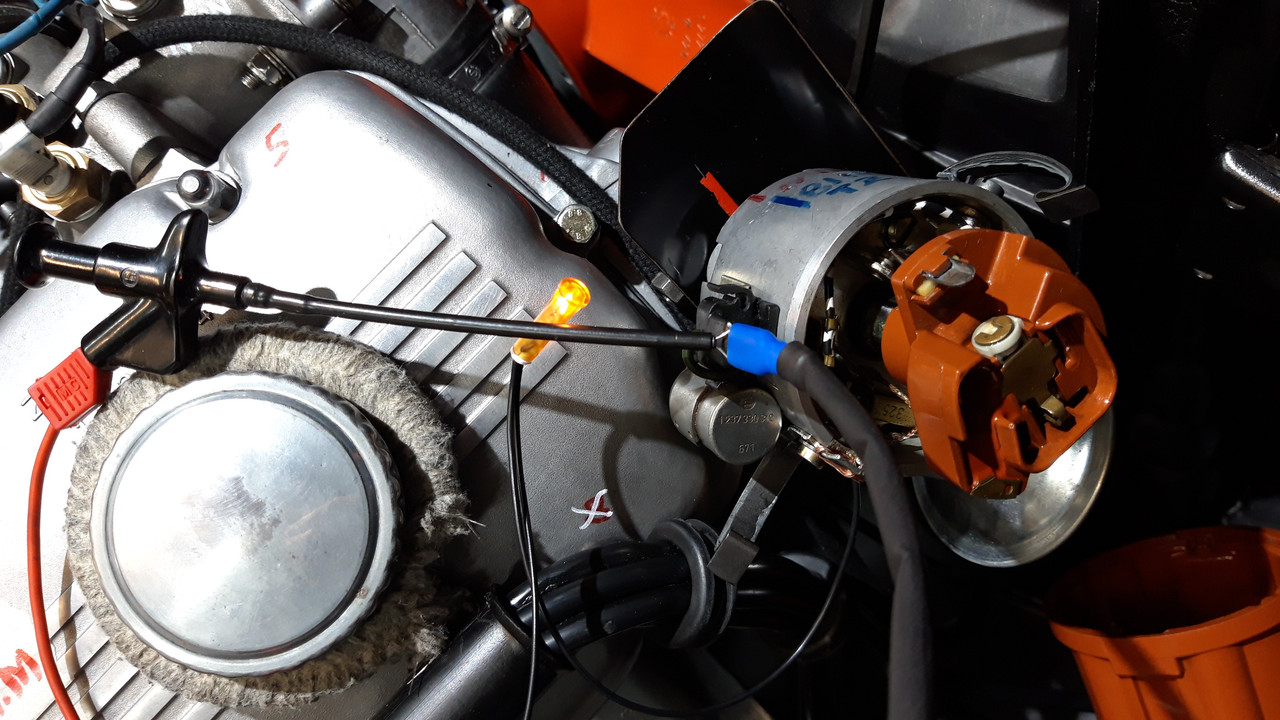

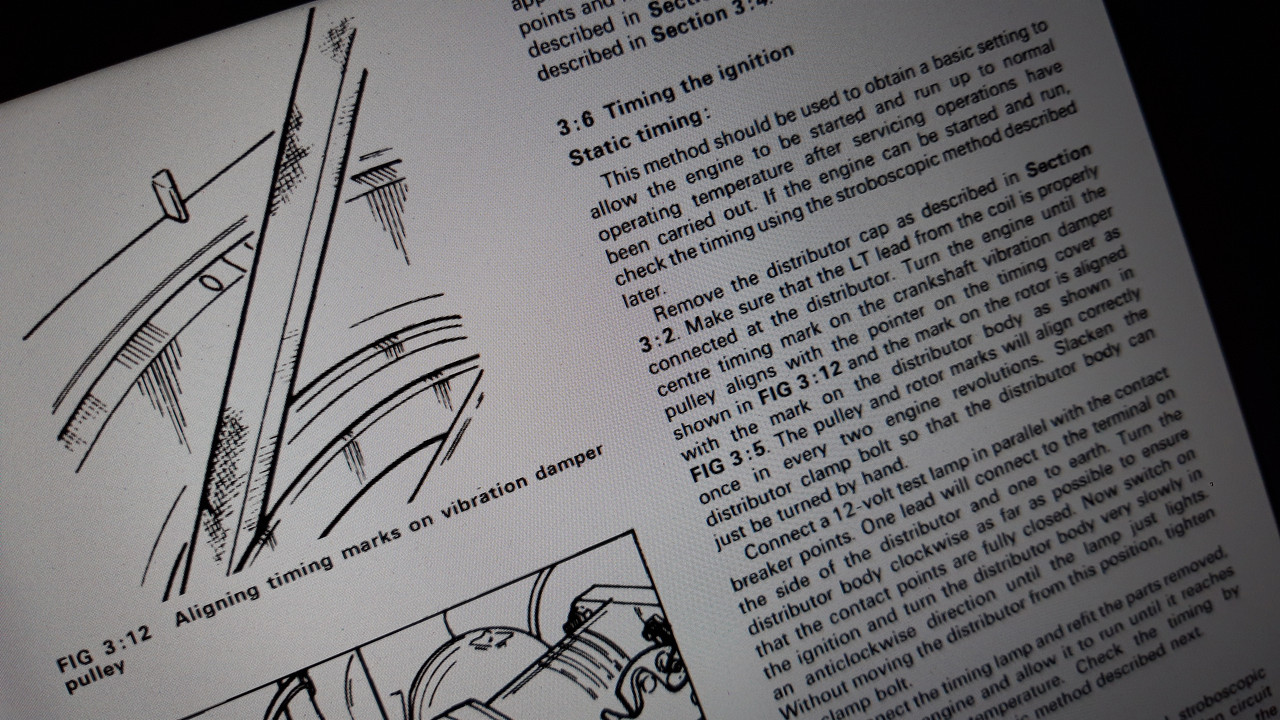

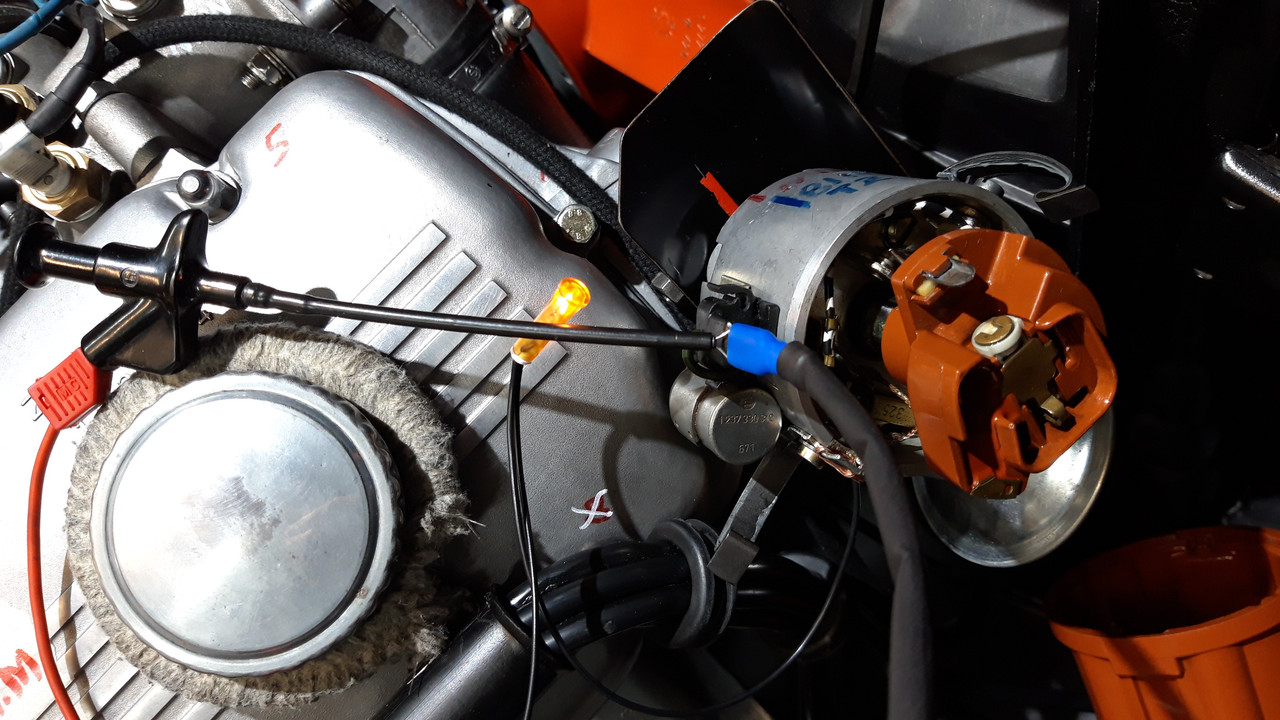

so i took the haynes advise as how to set static timing by means of a test lamp

and prepared my setup using a 12volt test lamp

it worked very well

set your engine at OT as previous pictures shown, slacken the clamp bolt so you can rotate the dizzy, first you turn the dizzy clockwise far enough so you are sure that points are closed, then you switch the ignition on and then very slowly turn the dizzy anti-clockwise until light is on, and there fix the clamp bolt

you get a couple of extra checks using this trick, first is you have light so you are sure that there is electricity going on there, second, you will hear a loud click as the HT lead produces an arc, that means that your coil is working

you can see that this job meant that i just turned the dizzy body clockwise an equivalent to those 5mm, which meant effectively putting the mark in the middle

put everything in its place again, and then the engine started like a champ

amazing, problem solved

and prepared my setup using a 12volt test lamp

it worked very well

set your engine at OT as previous pictures shown, slacken the clamp bolt so you can rotate the dizzy, first you turn the dizzy clockwise far enough so you are sure that points are closed, then you switch the ignition on and then very slowly turn the dizzy anti-clockwise until light is on, and there fix the clamp bolt

you get a couple of extra checks using this trick, first is you have light so you are sure that there is electricity going on there, second, you will hear a loud click as the HT lead produces an arc, that means that your coil is working

you can see that this job meant that i just turned the dizzy body clockwise an equivalent to those 5mm, which meant effectively putting the mark in the middle

put everything in its place again, and then the engine started like a champ

amazing, problem solved

Last edited:

my recap,

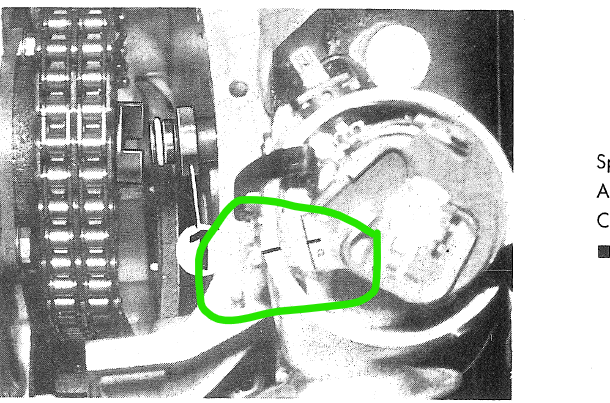

it seem to me that when i fitted the dizzy back in its place i was too much influenced by the position of the body according to the alignment marks that i always do during stroboscopic timing procedure

but as you know the rotor turns freely while you are introducing the dizzy back in its place, this is why you should pre-set it 35mm before the mark

the whole operation is a bit complex as you are introducing the dizzy rod into a very tight cylinder with a rubber seal on it, so errors can occur

my guess is that even being very careful i slipped just one helicoidal tooth of the gear and this produced the slight misalignment, which was finally corrected by rotating the dizzy body during the static ignition setting procedure

moreover the check that you have to perform to see that the mark on dizzy body is aligned with the centre of the rotor plate is tricky, as both elements are separated in height around 40mm making very difficult to make a proper alignment that will always be influenced by your viewing angle

....your thoughts ?

thank you

it seem to me that when i fitted the dizzy back in its place i was too much influenced by the position of the body according to the alignment marks that i always do during stroboscopic timing procedure

but as you know the rotor turns freely while you are introducing the dizzy back in its place, this is why you should pre-set it 35mm before the mark

the whole operation is a bit complex as you are introducing the dizzy rod into a very tight cylinder with a rubber seal on it, so errors can occur

my guess is that even being very careful i slipped just one helicoidal tooth of the gear and this produced the slight misalignment, which was finally corrected by rotating the dizzy body during the static ignition setting procedure

moreover the check that you have to perform to see that the mark on dizzy body is aligned with the centre of the rotor plate is tricky, as both elements are separated in height around 40mm making very difficult to make a proper alignment that will always be influenced by your viewing angle

....your thoughts ?

thank you

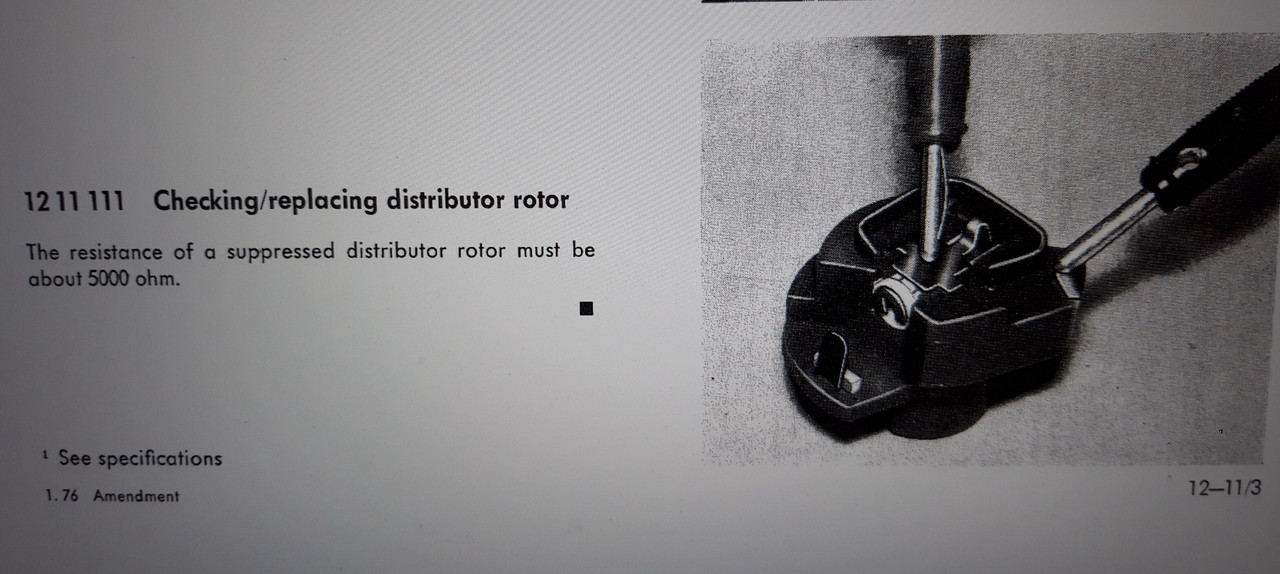

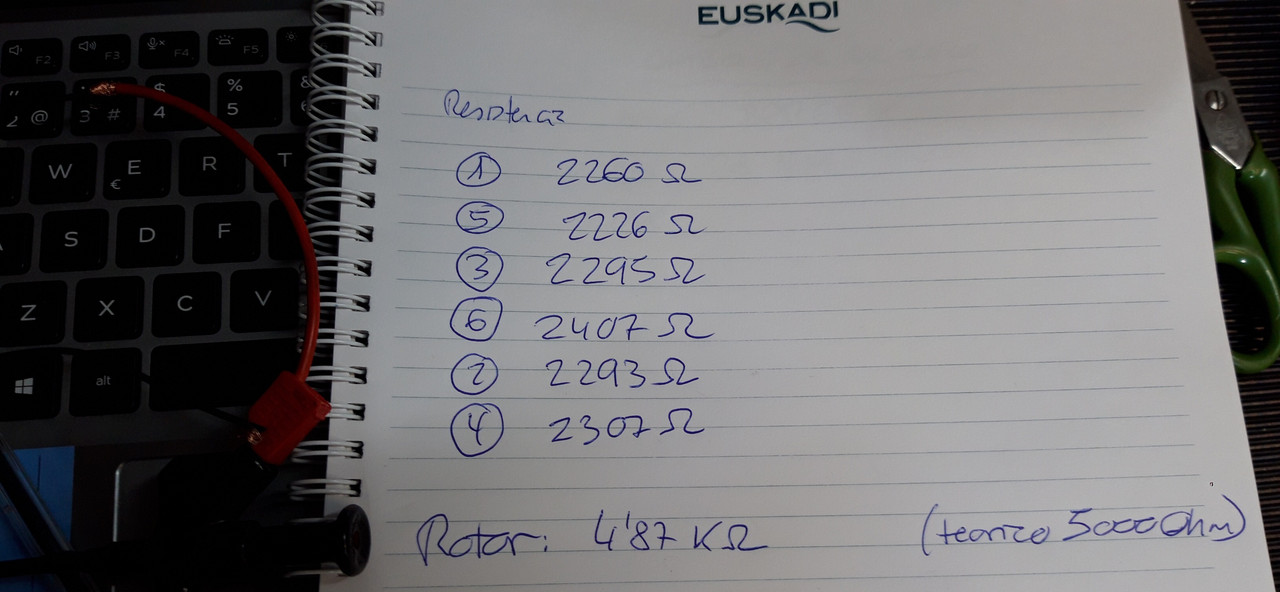

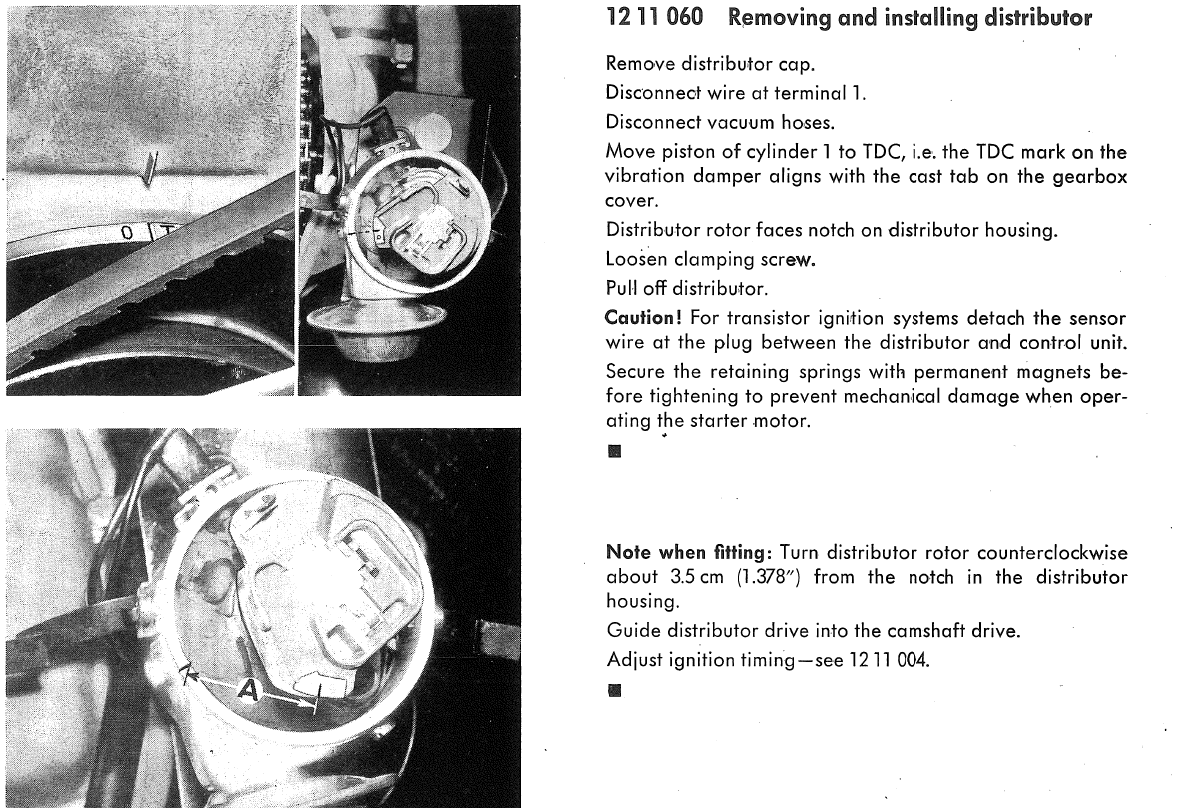

some pics from manual.

here is the removing and refitting procedure

here is the removing and refitting procedure

finishing this with ignition and synchro:

photos afre self explaining, copied it from our local forum.

---------------------------------------------------------------

dwell 34,8 grados,

reajusto el delco con 1700rpms y strobo a bola (22 BTDC)

- 1/4 de vuelta

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2Fm21Np2hn%2Fcarb-1.jpg&hash=d02de9c9582bfd177bafce7643f99805)

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2FCxjCYPGH%2Fcarb-2.jpg&hash=51639be25e51ea0b7b2bf96dc1b0b628)

a 1700 rpms

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2F9XKy951Y%2Fcarb1700-1.jpg&hash=e05d5bcc7e4c647bec967e3c8c903f5e)

18kg/h de aire

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2F5yhvWLjR%2Fcarb1700-2.jpg&hash=b51b2ad23d3a104b62a2ddff4d069d6a)

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2FfytXPBWd%2Fcarb1700-3.jpg&hash=a2d60b40b9df6d51be9db63282e63547)

y el CO en 2,7%

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2FNfXm7Jzq%2Fcarb1700-4.jpg&hash=4b6a6e927751ba60a40ea86e5f860d9d)

a 980 rpms

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2FJhMNhNKw%2Fcarb900-1.jpg&hash=67c2b4df8e2041f7df26e2e5f4e199ff)

un poco menos de 12 kg/h

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2FPqymvCFC%2Fcarb900-2.jpg&hash=982c2980e1dff9a6c586f53dcd815f0f)

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2F1tzDGyLJ%2Fcarb900-3.jpg&hash=a33a31f2986e868628b62b9ba0c3adde)

y 3,1 a 3,2 % de CO (valor correcto entre 3 y 4%)

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2FydrcnwKB%2Fcarb900-4.jpg&hash=04d0ee353550ff3fc91fdb703b5763fe)

la instalacion incluye una cartulina para evitar que el carbu delantero se vea afectado por el ventilador

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2FBnGDhTr8%2Feng-1.jpg&hash=76806e62dcd5f961f1ed0bbd4ce4942d)

photos afre self explaining, copied it from our local forum.

---------------------------------------------------------------

dwell 34,8 grados,

reajusto el delco con 1700rpms y strobo a bola (22 BTDC)

- 1/4 de vuelta

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2Fm21Np2hn%2Fcarb-1.jpg&hash=d02de9c9582bfd177bafce7643f99805)

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2FCxjCYPGH%2Fcarb-2.jpg&hash=51639be25e51ea0b7b2bf96dc1b0b628)

a 1700 rpms

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2F9XKy951Y%2Fcarb1700-1.jpg&hash=e05d5bcc7e4c647bec967e3c8c903f5e)

18kg/h de aire

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2F5yhvWLjR%2Fcarb1700-2.jpg&hash=b51b2ad23d3a104b62a2ddff4d069d6a)

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2FfytXPBWd%2Fcarb1700-3.jpg&hash=a2d60b40b9df6d51be9db63282e63547)

y el CO en 2,7%

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2FNfXm7Jzq%2Fcarb1700-4.jpg&hash=4b6a6e927751ba60a40ea86e5f860d9d)

a 980 rpms

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2FJhMNhNKw%2Fcarb900-1.jpg&hash=67c2b4df8e2041f7df26e2e5f4e199ff)

un poco menos de 12 kg/h

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2FPqymvCFC%2Fcarb900-2.jpg&hash=982c2980e1dff9a6c586f53dcd815f0f)

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2F1tzDGyLJ%2Fcarb900-3.jpg&hash=a33a31f2986e868628b62b9ba0c3adde)

y 3,1 a 3,2 % de CO (valor correcto entre 3 y 4%)

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2FydrcnwKB%2Fcarb900-4.jpg&hash=04d0ee353550ff3fc91fdb703b5763fe)

la instalacion incluye una cartulina para evitar que el carbu delantero se vea afectado por el ventilador

![[IMG] [IMG]](/forum/proxy.php?image=https%3A%2F%2Fi.postimg.cc%2FBnGDhTr8%2Feng-1.jpg&hash=76806e62dcd5f961f1ed0bbd4ce4942d)

.

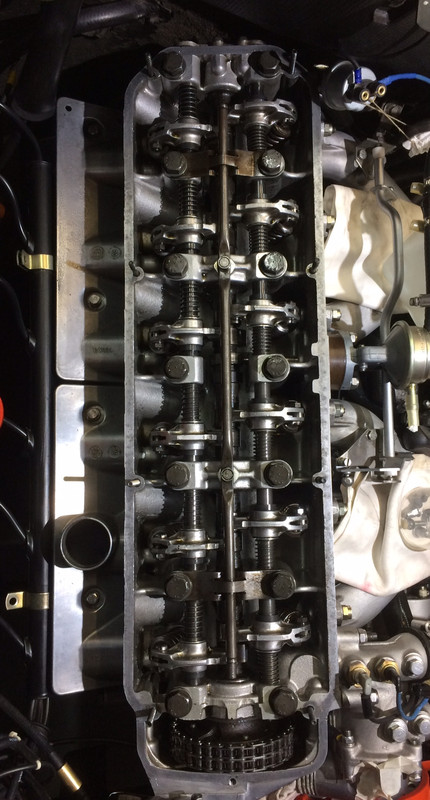

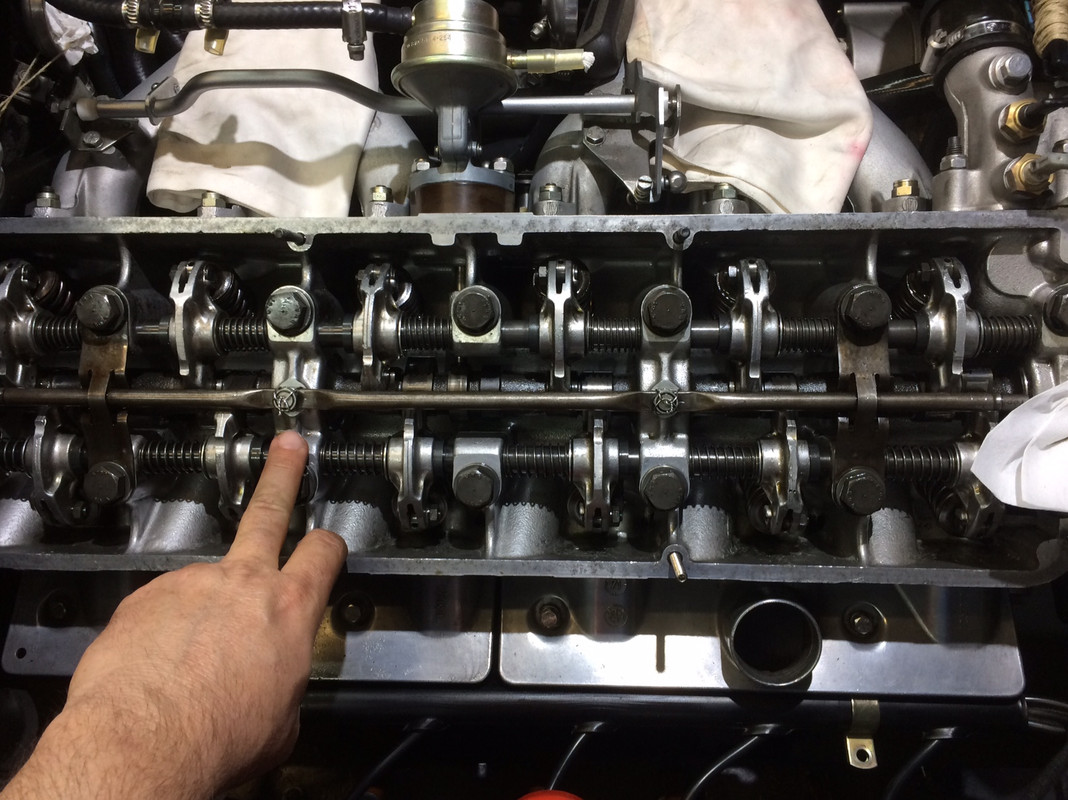

Again filter and oil change

4600km since oct2023

4600km since oct2023

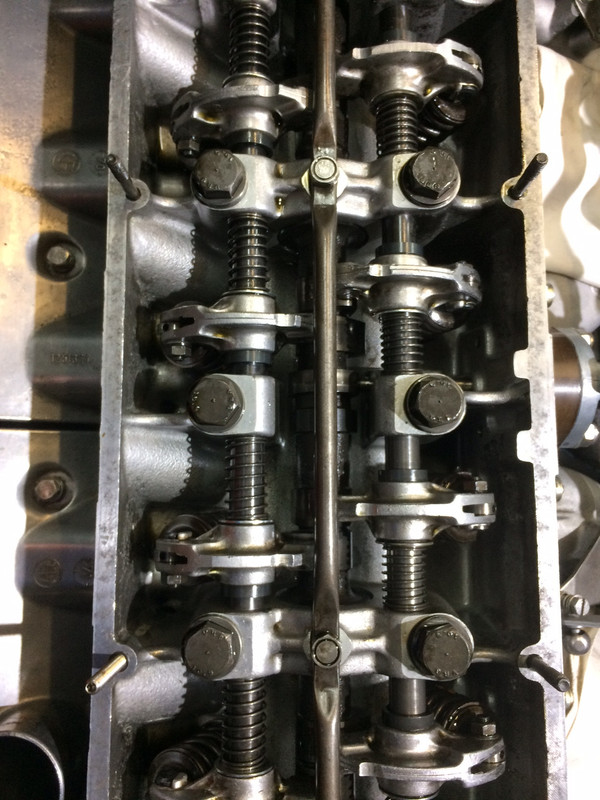

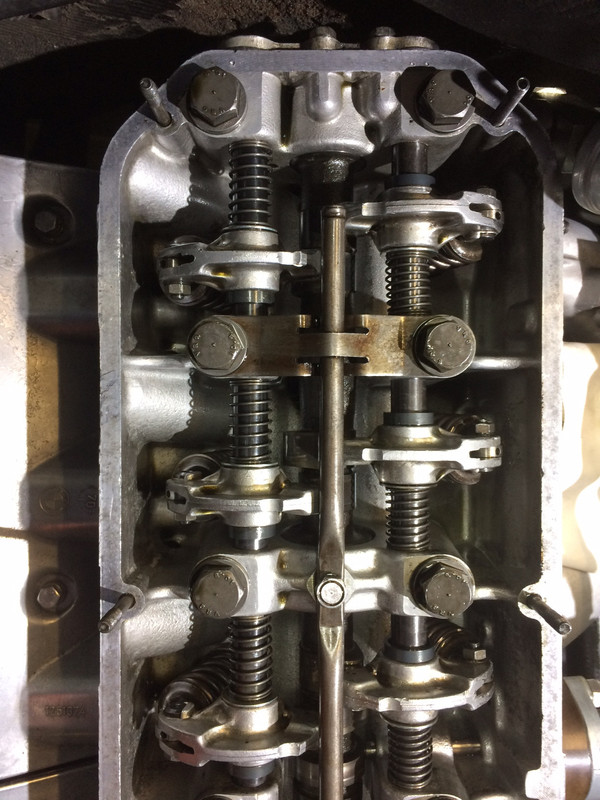

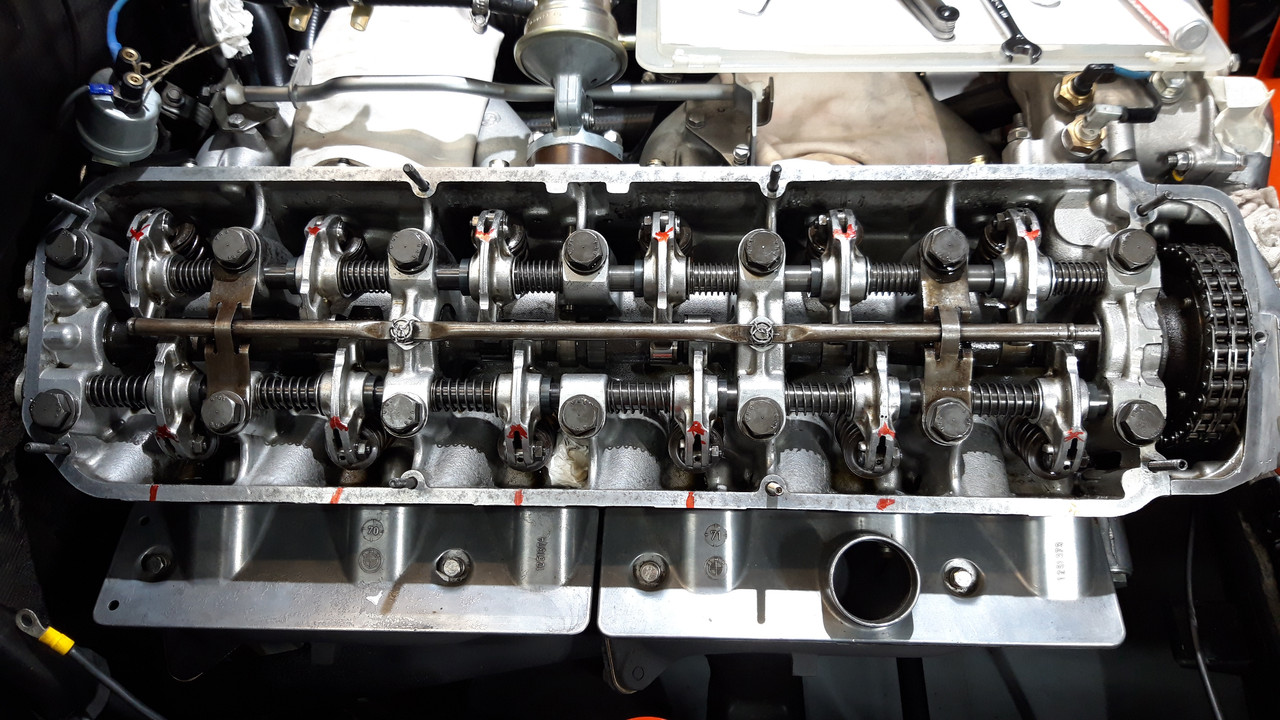

There is a one mark (triangle) on the oil supply line which should be on the front side. (Driving direction).i use two markers,

first check, if ok red mark, if not i fix it and paint red mark

once done, i make a complete turn to recheck

if ok i paint a blue mark, if not, fix once more, a new recheck turn and if ok a blue mark

but in the first turn, the exhaust valve of the second cyl gave a wrong check, so i had to fix, and the nut was too big for the wrench, WTH ?

If it is on the other side the oil drops fall next to the lubrication point.

Attachments

There is a one mark (triangle) on the oil supply line which should be on the front side. (Driving direction).

If it is on the other side the oil drops fall next to the lubrication point.

i wonder what is the purpose of your explanation

maybe you are complementing something, or maybe not,

for your detailed reading, my engine has not triangle, it has a clear nice sign with the word “front”

you can see it at the beginning of this thread

Jesus- I looked at 2 engines yesterday where the oiler bar was installed backwards by the engine shop. Very sad. We see it every year over and over.

Forum members need to know that oiler bars are asymmetric- The tiny arrow is the tell. Do not trust the big arrow.

They probably will never see an oil bar like yours- we know it is not factory because “front” is not a German word. Your bar looks expensive and nice.

I’m in Spain on the 27th, back to Porto and then Mijas working the first week of December.!

There is a car you would like there- maybe you can visit?

Forum members need to know that oiler bars are asymmetric- The tiny arrow is the tell. Do not trust the big arrow.

They probably will never see an oil bar like yours- we know it is not factory because “front” is not a German word. Your bar looks expensive and nice.

I’m in Spain on the 27th, back to Porto and then Mijas working the first week of December.!

There is a car you would like there- maybe you can visit?

Last edited:

Hello deQuincey,i wonder what is the purpose of your explanation

maybe you are complementing something, or maybe not,

for your detailed reading, my engine has not triangle, it has a clear nice sign with the word “front”

you can see it at the beginning of this thread

View attachment 192596

My post was only complementary to the forum members.

Your post is very useful for members and e9/e3 fanatics. It takes a lot of time to make such a post. Thanks!

Mit freundlichen Grüßen/with best regards

Jesus- I looked at 2 engines yesterday where the oiler bar was installed backwards by the engine shop. Very sad. We see it every year over and over.

Forum members need to know that oiler bars are asymmetric- The tiny arrow is the tell. Do not trust the big arrow.

They probably will never see an oil bar like yours- we know it is not factory because “front” is not a German word. Your bar looks expensive and nice.

I’m in Spain on the 27th, back to Porto and then Mijas working the first week of September.

There is a car you would like there- maybe you can visit?

assume that you are visiting portugal and spain from November the 27th - on at least until first week of december. (setpember might be a misspell)

very kind of you, but mijas is too much far away from my place in Das Baskenland, that is another continent, i wonder how was the flods over there, valencia is war zone now

good luck

if you come to the north please do tell