Remember me? It's been 19 months since my last confession.

People say that if you do what you love, you'll never work a day in your life. Those people are wrong and I think they are actually lying.

I initially had the car towed from my house to my shop in the beginning of January, 2023. My plan was to essentially clean everything and swap the engines. Then scope creep set in and next thing you know, my only revenue in January was replacing a brake light switch on a customer's car in his garage. To add insult to injury, I had to warranty that part in November, so not a great month! I had customers looking to get their cars in and I felt quite guilty having this project taking up my workspace, so I had to make that happen.

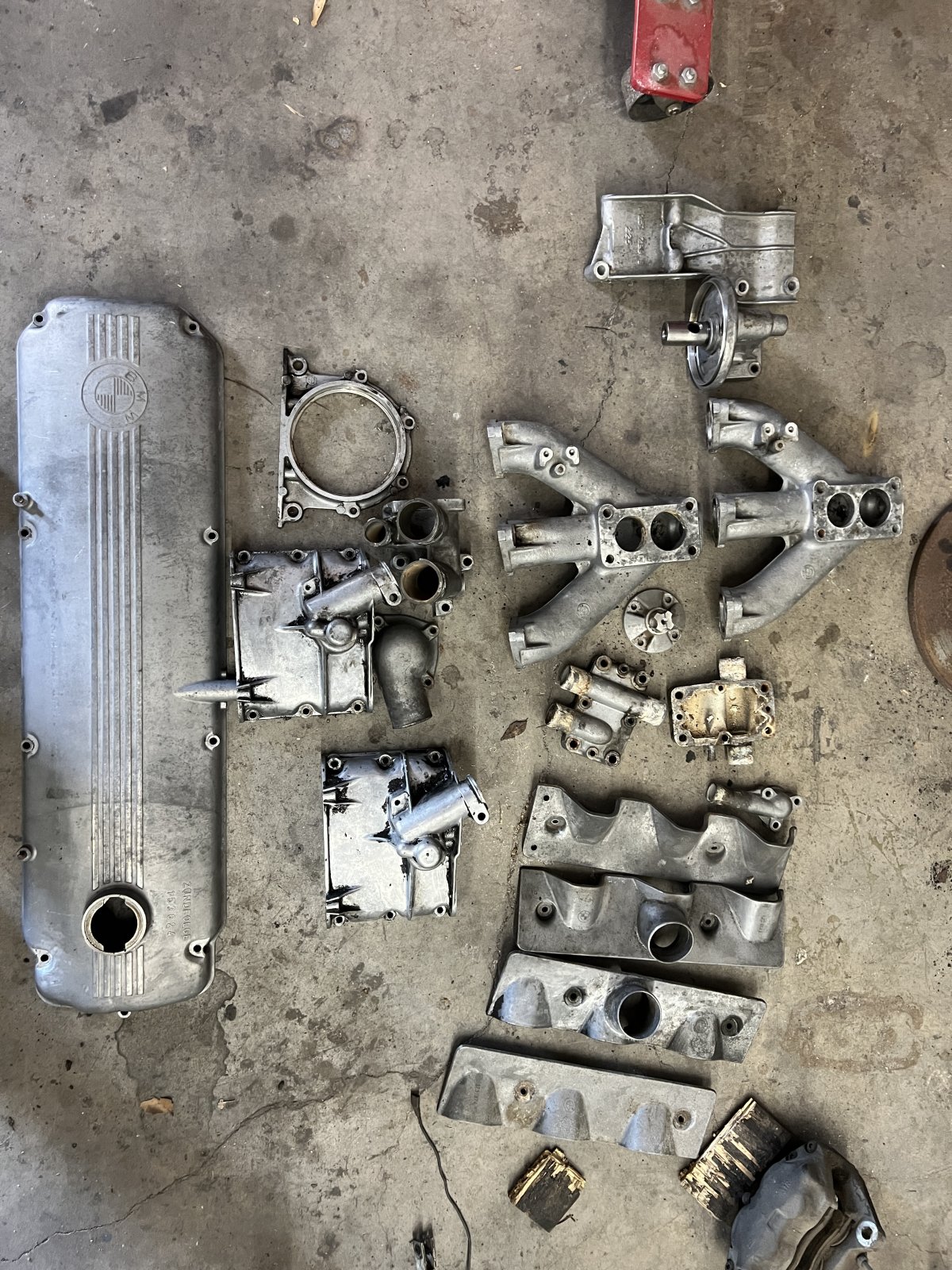

Anyway, lets start where I left off. February 1, I got all of the aluminum parts together from the original engine and a few of the pieces from the replacement engine that were easy to grab. I wasn't going to do a whole refresh on the new motor because it was a running engine and its main purpose is to make this a functional vehicle. I had made contact with a guy that does vapor blasting and he's about a mile and a half from my shop, so doesn't get much better than that. I dropped all of this off plus more. Interestingly, both engines had replacement heads and the timing covers measured identically but the date codes inside made it pretty simple to figure out which is which.

While that stuff was away, I looked at some other things that might make me happy and I decided to see how the rear bumper, tail lights and the license plate trim would clean up. The latter is the early chromed brass part, so something I was looking forward to seeing. Not bad for a first pass.

I primed and painted the brake booster. I thought using my floor jack handle was a relatively elegant solution and the paint laid down quite nicely. I was able to save the original, worn sticker. Matches all the other decals under the hood.

February 10th, I picked up all of my freshly cleaned aluminum bits and had an interesting discovery about my original valve cover. I think it also answers a question or two about what might have happened to the original engine.

I'd like to find another with the small roundel like this but this one has some character and I'm amazed it was never swapped out so I'm not upset about it!

One of the things I had been doing while the car has been in the shop is conditioning the leather. When I removed the right rear seat, I found these markings and thought they were worth sharing.

I was working on getting a load of hardware to be plated, but some bolts are supposed to be black-oxide (brake caliper bolts, steering knuckle bolts, etc). I have a great shop nearby that does only this and I used them on my E12 project. The best part is that they'll do a very small batch of bolts and charge very reasonable money to do it. The plater I've been using has $150 batch minimums and it can go up for rack plating, so it's a welcome change. I had ordered the hardware kits that Walloth and Nesch sell and while to the chagrin of some, I swapped in my painted tension strut washers, I had most everything I needed for the subframe, thought that kit does not include the bolts to mount the steering box. I find that odd. It was during the process of sourcing those bolts that I discovered that most everything I sourced for the car is in fact wrong. Just like when I had the subframe powder coated the wrong color, we now have this situation where I had a few bolts refinished in black oxide and I now have more.

The four subframe bolts, the three steering box bolts, the two control arm bolts, brake caliper bolts, steering arm bolts, the idler arm bolt and the bolts for the anti-roll bar brackets are in fact black oxide on this car (and I have confirmed this with photos of 227236). Yay.

And then moving on to more plating discoveries. All of this is from my original power steering pump and the banjo bolts for the box as well as the spacers and washers for the control arms. Everything here is clear zinc. I have to really think about some stuff now.

People say that if you do what you love, you'll never work a day in your life. Those people are wrong and I think they are actually lying.

I initially had the car towed from my house to my shop in the beginning of January, 2023. My plan was to essentially clean everything and swap the engines. Then scope creep set in and next thing you know, my only revenue in January was replacing a brake light switch on a customer's car in his garage. To add insult to injury, I had to warranty that part in November, so not a great month! I had customers looking to get their cars in and I felt quite guilty having this project taking up my workspace, so I had to make that happen.

Anyway, lets start where I left off. February 1, I got all of the aluminum parts together from the original engine and a few of the pieces from the replacement engine that were easy to grab. I wasn't going to do a whole refresh on the new motor because it was a running engine and its main purpose is to make this a functional vehicle. I had made contact with a guy that does vapor blasting and he's about a mile and a half from my shop, so doesn't get much better than that. I dropped all of this off plus more. Interestingly, both engines had replacement heads and the timing covers measured identically but the date codes inside made it pretty simple to figure out which is which.

While that stuff was away, I looked at some other things that might make me happy and I decided to see how the rear bumper, tail lights and the license plate trim would clean up. The latter is the early chromed brass part, so something I was looking forward to seeing. Not bad for a first pass.

I primed and painted the brake booster. I thought using my floor jack handle was a relatively elegant solution and the paint laid down quite nicely. I was able to save the original, worn sticker. Matches all the other decals under the hood.

February 10th, I picked up all of my freshly cleaned aluminum bits and had an interesting discovery about my original valve cover. I think it also answers a question or two about what might have happened to the original engine.

I'd like to find another with the small roundel like this but this one has some character and I'm amazed it was never swapped out so I'm not upset about it!

One of the things I had been doing while the car has been in the shop is conditioning the leather. When I removed the right rear seat, I found these markings and thought they were worth sharing.

I was working on getting a load of hardware to be plated, but some bolts are supposed to be black-oxide (brake caliper bolts, steering knuckle bolts, etc). I have a great shop nearby that does only this and I used them on my E12 project. The best part is that they'll do a very small batch of bolts and charge very reasonable money to do it. The plater I've been using has $150 batch minimums and it can go up for rack plating, so it's a welcome change. I had ordered the hardware kits that Walloth and Nesch sell and while to the chagrin of some, I swapped in my painted tension strut washers, I had most everything I needed for the subframe, thought that kit does not include the bolts to mount the steering box. I find that odd. It was during the process of sourcing those bolts that I discovered that most everything I sourced for the car is in fact wrong. Just like when I had the subframe powder coated the wrong color, we now have this situation where I had a few bolts refinished in black oxide and I now have more.

The four subframe bolts, the three steering box bolts, the two control arm bolts, brake caliper bolts, steering arm bolts, the idler arm bolt and the bolts for the anti-roll bar brackets are in fact black oxide on this car (and I have confirmed this with photos of 227236). Yay.

And then moving on to more plating discoveries. All of this is from my original power steering pump and the banjo bolts for the box as well as the spacers and washers for the control arms. Everything here is clear zinc. I have to really think about some stuff now.