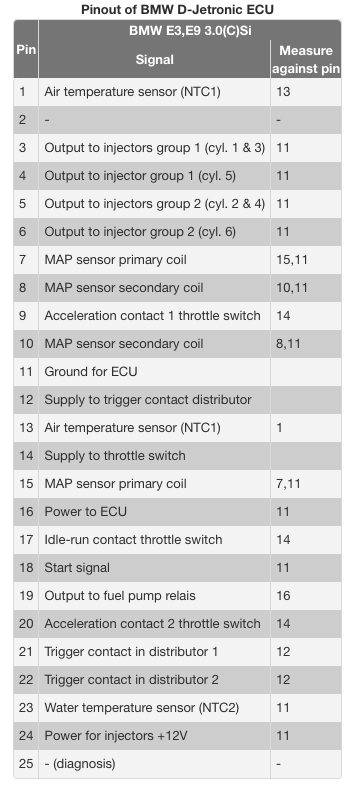

Neon - I believe you can deduce the pin out information from the picture Don has posted. The MAP is labelled with 7, 8, 10 and 15. If you follow the 15 connection, you will see that it leads to pin number 15 on the ECU. I believe the other three connections follow this same pattern. Thus, MAP connection 7 is connected to Pin 7 on the ECU, and so on.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Non Running Engine Good Compression and Ignition Spark Present Noid Light Test no Signal

- Thread starter neon

- Start date

What Chris just said. Here's a pin out from jetronic.org that confirms:

Relays near battery are horn and lights.

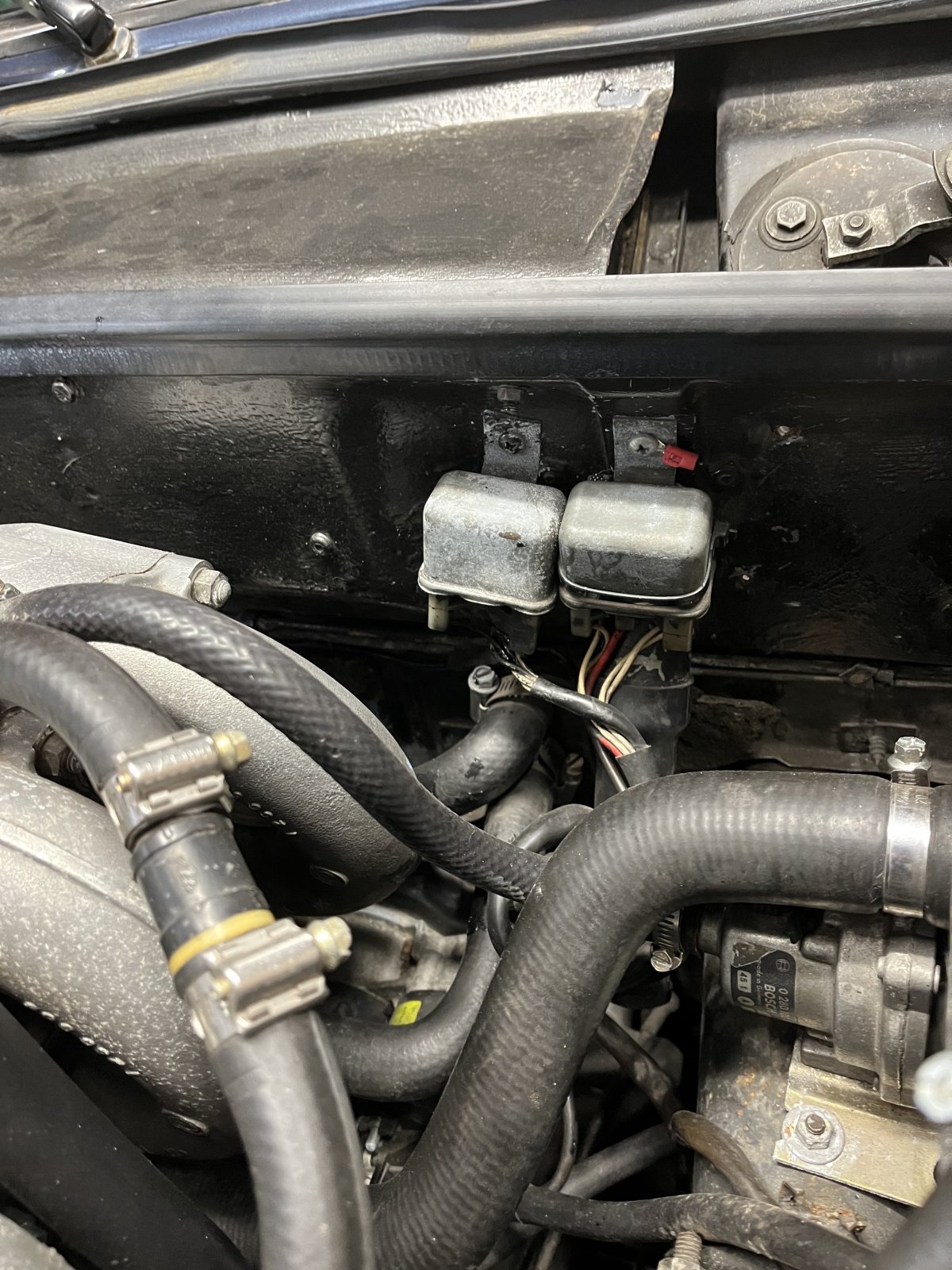

Like Bill said, there are only two FI related relays in the engine compartment: 1) main and 2) cold start. Here's a pic of them in my car.

And here's the ground point that sfdon mentioned:

There's also a fuel pump relay under the back seat next to the ECU.

As long as the main relay is sending power to the ECU, which it sounds like it is, then I think you can rule the relays out in terms of the noid lights not lighting. My understanding is that the trigger points initiate the injection pulse and then a combination of readings from the MAP and the trigger points (engine speed) determine the injection duration. Like @sfdon said early on, if there's no noid light flashing then your injectors aren't firing at all.

It seems to me that would leave the ground issue that sfdon mentioned; MAP issues: either a broken/bad connection between the MAP and the ECU, or the failure listed below.

Failure Modes

And here's the ground point that sfdon mentioned:

There's also a fuel pump relay under the back seat next to the ECU.

As long as the main relay is sending power to the ECU, which it sounds like it is, then I think you can rule the relays out in terms of the noid lights not lighting. My understanding is that the trigger points initiate the injection pulse and then a combination of readings from the MAP and the trigger points (engine speed) determine the injection duration. Like @sfdon said early on, if there's no noid light flashing then your injectors aren't firing at all.

It seems to me that would leave the ground issue that sfdon mentioned; MAP issues: either a broken/bad connection between the MAP and the ECU, or the failure listed below.

Failure Modes

- Open or shorted primary or secondary coils: Results in no injection pulses, the car is inoperable.

- MPS info

- Failure Modes

- Open or shorted primary or secondary coils: Results in no injection pulses, the car is inoperable.

- Vacuum leaks: Depending on the extent of the leak, the car can run slightly rich to very rich across the entire load range.

- Failed aneroid cell: Causes the car to run rich at idle, with poor part-load response.

- Maladjustment: Many owners and mechanics have tried to adjust the sensor by removing the epoxy-covered "plug" and turning the adjustment screw inside - this often results in unpredictable behavior, as adjustment of this sensor accurately requires a bench setup that only a few shops have.

- Notes: This is the most important sensor in the D-Jetronic system. As noted above, make absolutely certain that the sensor you have is properly matched to your FI setup. Mismatched sensors can cause drivability problems.

TPS info

The car will still run even if the throttle switch is removed! It will accelerate slowly, and the idle may be poor, but it will run. Proper adjustment of the throttle switch is critical. If the idle switch does not actuate when the throttle is closed, the idle circuit in the ECU will not be activated and poor idle performance will result. Additionally, cars with ECU's that provide over-run fuel shutoff will not shut off the fuel if the idle switch isn't actuated when the throttle is closed while coasting. Proper adjustment of the throttle is also important. If the throttle cable and pedal stop are not properly adjusted so that the throttle is completely open when the throttle is fully depressed, fewer acceleration pulses will be provided to the ECU for acceleration enrichment, and you'll be restricting your full-throttle input, reducing horsepower.

Triggerpoint info

- Function: Sends timing pulses to the ECU to provide engine speed data and synchronize injection pulses.

- Failure Modes:

- "Bouncing" or dirty contacts: A "bouncing" contact causes multiple injection pulses to be generated, resulting in a very rich mixture. Can only be checked by using an oscilloscope.

- Dirty (intermittent opens) contacts: Dirty contacts can result in missing injection pulses, leading to bucking and drivability problems. Can only be checked by using an oscilloscope.

- Open contact (not switching): Causes one bank of injectors to not fire. Easy to check with a noid light that plugs into your injector connector. Available from local auto parts stores (e.g. Checker).

- Worn cam rubbing blocks: When the blocks wear down very low, both switches turn "on" for most if not all of the rotation of the shaft. When both switches are on, this can lead to a no-start situation and very erratic operation.

- Misaligned switch: There is a fair amount of "slop" in the fitting of the switch to the distributor than can lead to problems. Make certain the switch is in the middle of the range of positioning in the distributor body.

- Notes: These contacts are very low current and are reliable, lasting in excess of 100K miles. Make sure if you install new contacts that you use a dab of Bosch distributor lube on the distributor contact lobes. Failed trigger contacts will prevent your car from starting and running. Later models of the contacts have a shield that keeps the lube from being sprayed onto the contact points.

Dana: the FI relays are below the MAP, mounted on the plate holding the MAP behind the booster (except when they're not as per coupe de grace...)The relays behind the battery are headights, horn, etc.

Last edited:

That's a good place for them! Perhaps Fritz and Heinrich, having had a beer or two at lunch, decided to change their location!Like Bill said, there are only two FI related relays in the engine compartment: 1) main and 2) cold start. Here's a pic of them in my car.

View attachment 151048

And here's the ground point that sfdon mentioned:

View attachment 151049

There's also a fuel pump relay under the back seat next to the ECU.

As long as the main relay is sending power to the ECU, which it sounds like it is, then I think you can rule the relays out in terms of the noid lights not lighting. My understanding is that the trigger points initiate the injection pulse and then a combination of readings from the MAP and the trigger points (engine speed) determine the injection duration. Like @sfdon said early on, if there's no noid light flashing then your injectors aren't firing at all.

It seems to me that would leave the ground issue that sfdon mentioned; MAP issues: either a broken/bad connection between the MAP and the ECU, or the failure listed below.

Failure Modes

@sfdon - if the the trigger points weren't connected to the ECU or they weren't sending any pulse at all, would that also make the injectors not fire?

- Open or shorted primary or secondary coils: Results in no injection pulses, the car is inoperable.

Sfdon, Bill - Just a limited follow up. The MAP vacuum test was ok, held 15 in of Hg for 5 + min. The outer pins to the coil1 were 90 ohms, the inner pins I had trouble accessing but will report tomorrow hopefully, and also willAllow me to add a few things to SF Don's excellent suggestions. Having had problems with the MAP and Throttle Position Switch, I hope I can help. The main relay is located (usually) in front of the brake booster: there are two relays there, the one on the left is the main, the one on the right is the Cold Start relay. There is no separate relay that controls the injectors. If the Main relay is bad, you won't get power to the ECU via wires 16 (powers the computer) and 24 (powers the injectors.)

The MAP should hold a 15" vacuum for at least 10 seconds. If not, the copper diaphragm in the MAP is torn and the MAP will have to be rebuilt. A MAP with a torn diahragm makes the ECU think the engine wants to accelerate real fast and will dump a lot of gas into the engine ALL THE TIME...result, much smoke and poor driveability. Also It will be difficult to start the engine if at all. You can check the continuity of the two coils in the MAP (one coil is the two outside pins, the other coil is the two inner pins) but this test doesn't reveal anything if the diaphragm is torn.

Another concern is the Throttle Position Switch: if the PC board copper traces are worn you can get poor engine performance as you are describing. You can check if the TPS is the problem by disconnecting it and driving. If your problems disappear, you'll know it isn't the TPS.

As for trigger points about all you can do is borrow a set from SF Don and see if there is any improvement. I actually added a switch into one of the wires in the trigger circuit to see if I could replicate my hesitation problems but it wasn't definitive.

Good luck...D-Jet is great when it works ...but it is getting old, so don't sell your carburetors if you have them.

Yes, jetronic.org is a great resource, but I find that Volker is reluctant to impart too much of what he knows..

Sfdon - hey thanks, I kind of thought so but the photo in the shop manual seemed to indicate resistors Many thanks“noticed that what I think are resistors, sitting just behind the brake vaccum booster cannnister, are not connected. There are several wires in this car under dash not connected so i never paid these any mind. However, if I understand some shop manual photo correctly, these are associated with the signal to the injectors. Is that what I am looking at here in the attached photo ?”

on a new car you would see into those plastic housings and know they are protecting spade connectors.

Dana in CT

Hey guys - MAP held 15 in or HG for several minutes. I will report back hopefully more tomorrow. Appreciate all the information Sfdon and Bill !!Allow me to add a few things to SF Don's excellent suggestions. Having had problems with the MAP and Throttle Position Switch, I hope I can help. The main relay is located (usually) in front of the brake booster: there are two relays there, the one on the left is the main, the one on the right is the Cold Start relay. There is no separate relay that controls the injectors. If the Main relay is bad, you won't get power to the ECU via wires 16 (powers the computer) and 24 (powers the injectors.)

The MAP should hold a 15" vacuum for at least 10 seconds. If not, the copper diaphragm in the MAP is torn and the MAP will have to be rebuilt. A MAP with a torn diahragm makes the ECU think the engine wants to accelerate real fast and will dump a lot of gas into the engine ALL THE TIME...result, much smoke and poor driveability. Also It will be difficult to start the engine if at all. You can check the continuity of the two coils in the MAP (one coil is the two outside pins, the other coil is the two inner pins) but this test doesn't reveal anything if the diaphragm is torn.

Another concern is the Throttle Position Switch: if the PC board copper traces are worn you can get poor engine performance as you are describing. You can check if the TPS is the problem by disconnecting it and driving. If your problems disappear, you'll know it isn't the TPS.

As for trigger points about all you can do is borrow a set from SF Don and see if there is any improvement. I actually added a switch into one of the wires in the trigger circuit to see if I could replicate my hesitation problems but it wasn't definitive.

Good luck...D-Jet is great when it works ...but it is getting old, so don't sell your carburetors if you have them.

Yes, jetronic.org is a great resource, but I find that Volker is reluctant to impart too much of what he knows..

Dana clueless in CT

PS also will check those grounds - lots to doHey guys - MAP held 15 in or HG for several minutes. I will report back hopefully more tomorrow. Appreciate all the information Sfdon and Bill !!

Dana clueless in CT

D

Bill and Sfdon - MAP testing I think is ok. Outer prongs 90 Ohms, inner prongs 330 ohms. Continuity is perfect all four wires from MAP plug to ECU plug. Held pressure 15 inch Hg for 5 min. Grounds that I can find are both ok. How would you recommend testing for trigger pulse from distributor. The noid light test showed no signal to the injectors. Thanks so much

Dana

Dana

Hey Chris - appreciate it. I eventually found the fuel inject wiring diagram in the blue book . I was able to confirm continuity on all the wires 7,8,10.15 from the MAP plug back to the ecu plug.Neon - I believe you can deduce the pin out information from the picture Don has posted. The MAP is labelled with 7, 8, 10 and 15. If you follow the 15 connection, you will see that it leads to pin number 15 on the ECU. I believe the other three connections follow this same pattern. Thus, MAP connection 7 is connected to Pin 7 on the ECU, and so on.

Thanks much

Dana in CT

I’m leaving in the am for a drive in Texas- if you want to borrow parts- act quickly

Have fun!I’m leaving in the am for a drive in Texas- if you want to borrow parts- act quickly

Coupedegrace - thanks for that nice table of pin out. Do you know if is possible to just test at the ecu harness plug on the appropriate wires as per diagram for the trigger impulse using a VOM, or may be by setting up a noid light to detect the

Maybe a set of trigger points ?

Thanks so very much enjoy the driving !!

Dana

Sfdon - That is so generous of you to offer. I would love to when you get back lets discuss then At this point, not sure what to ask for !Have fun!

Maybe a set of trigger points ?

Thanks so very much enjoy the driving !!

Dana

i have the three relays on the left inner fender

one is fog lght- one is high beams - one is front light - i installed

one is fog lght- one is high beams - one is front light - i installed

I'll add my 2 cent after chasing issues and having my D-jet on 2 factory testers. The actual connections at the TPS (and other locations) can become compromised. The wire covering gets brittle and can have small hard to see cracks. I changed my TPS to an NOS one with no improvement. It wasn't until the plug was changed with a few mm of the TPS harness wire snipped off did my issue resolve itself.

The two wires running to the temp sensor by the air slide is another that can be an issue due to the high heat environment its in. You may want to look really closely at those and replace the plug, boot and 6 inches of wire.

I learned all this by talking with Terry and Don over many conversations and lots of cursing...

The two wires running to the temp sensor by the air slide is another that can be an issue due to the high heat environment its in. You may want to look really closely at those and replace the plug, boot and 6 inches of wire.

I learned all this by talking with Terry and Don over many conversations and lots of cursing...

Last edited: