HI

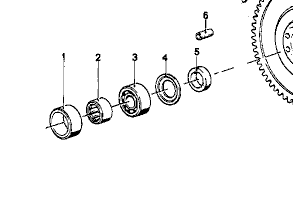

I am exchanging my 265/6 gearbox. The one I installed at the beginning of the summer (while dreaming about several road trips) has lay shaft bearing issues. Cheaper to buy another that was reconditioned than to rebuild or buy a rebuilt one. Any-ho...while removing the gearbox I noticed that the needle bearing (2) I installed inside a new sleeve (1) this Spring before reassembling the fly wheel, clutch, bell housing and gearbox is toast.

My 1st question is that I remember setting the sleeve and bearing flush the crankshaft; is it possible the input shaft of the gearbox pushed apart the needle bearing because it was not seated deep enough into the driveshaft?

When I install the replacement gearbox, I will be using the pilot bearing suggested in a previous post. Silly me, in hindsight, to not research this more back then. See link and post #2 https://e9coupe.com/forum/threads/which-pilot-bearing-to-use.34085/#post-282719 My 2nd question is, how far do you seat the pilot bearing into the driveshaft?

THX again!

Bill

I am exchanging my 265/6 gearbox. The one I installed at the beginning of the summer (while dreaming about several road trips) has lay shaft bearing issues. Cheaper to buy another that was reconditioned than to rebuild or buy a rebuilt one. Any-ho...while removing the gearbox I noticed that the needle bearing (2) I installed inside a new sleeve (1) this Spring before reassembling the fly wheel, clutch, bell housing and gearbox is toast.

My 1st question is that I remember setting the sleeve and bearing flush the crankshaft; is it possible the input shaft of the gearbox pushed apart the needle bearing because it was not seated deep enough into the driveshaft?

When I install the replacement gearbox, I will be using the pilot bearing suggested in a previous post. Silly me, in hindsight, to not research this more back then. See link and post #2 https://e9coupe.com/forum/threads/which-pilot-bearing-to-use.34085/#post-282719 My 2nd question is, how far do you seat the pilot bearing into the driveshaft?

THX again!

Bill