I suppose the other way to look at , is if I went into a dealer today to buy a car that was so amazing that I had to have one even if I had to wait for the dealer to swap it over for me , I would be happy just to know that the conversion was even possible .I wonder in 1973 or early 1974 when you went into a bmw showroom and you walked around as you do looking at all of the new cars and then you sat down with the salesman and agreed to buy a new e9 coupe , you would obviously pay a deposit and sign a bunch of paperwork you would know that it would take some time for “your” car to come in . Let’s say maybe you were told 6 to 8 weeks before your car would be ready .

Did the new owners actually know that they were buying converted LHD cars ????

Just wondering as I can’t imagine I would be happy today if I bought a brand new car and was told oh ya we have to swap it over from LHD before you can have it .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RHD 3.0 CSI with a 2265 vin number

- Thread starter Barry.b

- Start date

Having worked for BMW back in the 1970`s as far as I remember RHd conversions were only done in the UK during the 2800 period, from the start of the 3.0 period the cars were RHD from the factory. Having seen some of the converted cars they were not done to BMW factory standards, the brakes were one of the big problems to solve. In some cases a clutch master cylinder was attached to the brake pedal and a clutch slave cylinder was used to activate the original LHD brake booster....looking at your pictures Barry that car does not look like a conversion as the pressing around the bulkhead hole looks like it is factory RHD.....

Hi roundelHaving worked for BMW back in the 1970`s as far as I remember RHd conversions were only done in the UK during the 2800 period, from the start of the 3.0 period the cars were RHD from the factory. Having seen some of the converted cars they were not done to BMW factory standards, the brakes were one of the big problems to solve. In some cases a clutch master cylinder was attached to the brake pedal and a clutch slave cylinder was used to activate the original LHD brake booster....looking at your pictures Barry that car does not look like a conversion as the pressing around the bulkhead hole looks like it is factory RHD.....

Thanks for the info, it doesn’t look modified to me either to be honest with you , I think I should maybe take off the sound deadening or maybe get some more detailed photos of the brake setup to maybe see if it compares to an original RHD or a converted LHD .

As according to BMW archives it was probably built on sept 4th 1973 and probably delivered to the uk on September 17th 1973 so even Bmw themselves are not sure about my car , and according to the internet you could get a factory RHD directly from the factory from September 1973 ( the month my car was manufactured). Maybe my car had already left the store room in BMW and was delivered to karmann as a crate of parts and a build sheet when she got one of the first factory bulkheads from the new tooling which produced the RHD bulkheads and then when the vin number was stamped onto the bulkhead of the shell

It just so happened to be 2265... to match the crate of parts and paperwork from the BMW stores .

I am trying to visualise an assembly / manufacturing scene, which may be what actually happens on a workshop assembly line .

So who created the Vin number first ?

Was it the guy in the body assembly line at karmann who selected the next available vin number from his records and he recorded it on the build sheet , then this was referred to when making the vin plate and this number was then stamped onto the awaiting engine and gearbox and then recorded on the paperwork for the car , or was it first created at the engine machine shop at BMW or was it created for the first time in the BMW offices when creating the new build sheet and workshop notes.

I would love to know , I might need a time machine to answer all of that though

Anyway thanks again !!!

Attachments

Barry, It could be that since 2265xxx production was ending and 435xxxx RHD production was just starting that Karmann built a few of the 2265xxx CSis as RHD. Factory workers don’t get to pick VINs anymore than they get to pick which mirrors to install. Each coupe is assigned a four digit code (3435, 7011, etc) that tells the workers which model they are assembling: LHD/RHD, euro/NA market, stick/automatic, injected/carb. You can see these codes in RealOEM when parts cross many different build codes. Your bulkhead certainly looks to be factory. It would be interesting to see if other RHD 2265xxx owners could share their VINs, are they all near the end of the 2265xxx line? Also, are there any 2800CS RHD conversion owners here who could share pics of their brake boosters to see if they were cobbled together as Roundel has observed (total long shot I know)? Good luck in your odyssey!

i would say 99% that your car was buily as RHD at the factory. If you look how many E9`s were sold in the UK before September `73 there is no way they were converted in the UK.

As I said the cars converted in the UK were not up to BMW standards, and by then there was a big RHD market in the UK, Australia, New Zealand, Japan, etc...too many numbers to be converted in these countries.......I have seen a lot of RHD 1971/73 E9`s over the years that were 100% factory built......I thought that the chassis number was put on the car at the end of the production process, thats why the Karman number existed as they used that to build the cars to the customers spec ?? But I might be wrong....

As I recall the factory always closed for August...which is why the updated models appeared in September. Is your car the updated version ?...

As I said the cars converted in the UK were not up to BMW standards, and by then there was a big RHD market in the UK, Australia, New Zealand, Japan, etc...too many numbers to be converted in these countries.......I have seen a lot of RHD 1971/73 E9`s over the years that were 100% factory built......I thought that the chassis number was put on the car at the end of the production process, thats why the Karman number existed as they used that to build the cars to the customers spec ?? But I might be wrong....

As I recall the factory always closed for August...which is why the updated models appeared in September. Is your car the updated version ?...

Hi Chris thank you again for all of your reply’s ( and to others too )Barry, It could be that since 2265xxx production was ending and 435xxxx RHD production was just starting that Karmann built a few of the 2265xxx CSis as RHD. Factory workers don’t get to pick VINs anymore than they get to pick which mirrors to install. Each coupe is assigned a four digit code (3435, 7011, etc) that tells the workers which model they are assembling: LHD/RHD, euro/NA market, stick/automatic, injected/carb. You can see these codes in RealOEM when parts cross many different build codes. Your bulkhead certainly looks to be factory. It would be interesting to see if other RHD 2265xxx owners could share their VINs, are they all near the end of the 2265xxx line? Also, are there any 2800CS RHD conversion owners here who could share pics of their brake boosters to see if they were cobbled together as Roundel has observed (total long shot I know)? Good luck in your odyssey!

I do want to apologise to you , if I am stepping on anybody’s toes as , I am doubting the info on record.

I think this forum is amazing and the help that it provides is second to none !!!

And even though I have never met anyone in person everyone here really makes this forum a real enthusiasts members club and one which I am delighted to be a part of !!!.

I myself work for a German engineering / manufacturing company which has been in business now for over 100 years , I am with them now coming up on 22 years and throughout this time I have come across many parts / assemblies that don’t match the paperwork. I have learned not to always trust records and would always allow the parts or metal speak for itself

The metal won’t ever have secrets , whereas the paperwork might .

So again I hope you don’t mind me asking my questions ( hopefully I’ll stop soon for everybody’s mental health ! )

I did get out to the garage today for an hour actually working on the car , so that means I will have less time to come up with new ways of asking the same questions over and over again !

Hi again , my car had the early seats and wheels , but the boot floor has the later pressing that allows the fuel tank to be removed up into the boot and out of the car , as opposed to the earlier bodies which allowed the fuel tank to be lowered down under the car to remove them .i would say 99% that your car was buily as RHD at the factory. If you look how many E9`s were sold in the UK before September `73 there is no way they were converted in the UK.

As I said the cars converted in the UK were not up to BMW standards, and by then there was a big RHD market in the UK, Australia, New Zealand, Japan, etc...too many numbers to be converted in these countries.......I have seen a lot of RHD 1971/73 E9`s over the years that were 100% factory built......I thought that the chassis number was put on the car at the end of the production process, thats why the Karman number existed as they used that to build the cars to the customers spec ?? But I might be wrong....

As I recall the factory always closed for August...which is why the updated models appeared in September. Is your car the updated version ?...

I’d say my car was built just as the series 2 was coming in , ie a series 2 body put together with series 1 seats and wheels .

When you say the factory closed for august , do you mean BMW or Karmann ?

Even though I’m not involved with RHD, this is still a strangely entertaining read for a lazy day when you’re in the throes of holiday food and drink coma.So again I hope you don’t mind me asking my questions ( hopefully I’ll stop soon for everybody’s mental health ! )

I did get out to the garage today for an hour actually working on the car , so that means I will have less time to come up with new ways of asking the same questions over and over again !

Last edited:

Hee hee , if I don’t put away my phone soon I will be divorced , not to mention maybe thrown out of this forum ( sorry again guys ! )Even though I’m not involved with RHD, this is still an strangely entertaining read for a lazy day when you’re in the throes of holiday food and drink coma.

Barry

How about this for a theory, the production line uses all the parts that are on one rack, when finished they move onto the next rack? Clearly the important things need to match the build sheets, but I can’t see good parts that will fit not being used. I also doubt that the Factory Manager gives any spares to the Parts manager to sell via Parts, they both need to show good profitability and that may be considered as the most important factor for their bonus.

Also, with the intro of a new spec sometimes suppliers are late to change over, so to keep production going the Management and Engineers may have to build a few in between specs. I think Jaguar are famous for a series 1.5, or perhaps 2.5 E type.

And / Or, yours was part built pre August shutdown and then then finished, repaired post summer. The gap may have been several months. FYI I was once the proud owner of a new car which showed many signs of having been cut n stuck prior to me receiving it.

Out of interest does yours have a ballast resister for the coil, or ballast built into a resistance wire that looks a bit like a doorbell wire?

Mine is Dec 1973 build and is a series 2 with many differences to the series 1.

How about this for a theory, the production line uses all the parts that are on one rack, when finished they move onto the next rack? Clearly the important things need to match the build sheets, but I can’t see good parts that will fit not being used. I also doubt that the Factory Manager gives any spares to the Parts manager to sell via Parts, they both need to show good profitability and that may be considered as the most important factor for their bonus.

Also, with the intro of a new spec sometimes suppliers are late to change over, so to keep production going the Management and Engineers may have to build a few in between specs. I think Jaguar are famous for a series 1.5, or perhaps 2.5 E type.

And / Or, yours was part built pre August shutdown and then then finished, repaired post summer. The gap may have been several months. FYI I was once the proud owner of a new car which showed many signs of having been cut n stuck prior to me receiving it.

Out of interest does yours have a ballast resister for the coil, or ballast built into a resistance wire that looks a bit like a doorbell wire?

Mine is Dec 1973 build and is a series 2 with many differences to the series 1.

Barry, I am thoroughly enjoying your search for information on your coupe. Also, all series I coupes have gas tank mounted from above and yours is a series I in all aspects. (And all e9 were fully assembled and distributed from Karmann in Osnabruk, only the predecessor 2000 coupes were shipped to Munich for assembly.)

Barry, I am thoroughly enjoying your search for information on your coupe. Also, all series I coupes have gas tank mounted from above and yours is a series I in all aspects. (And all e9 were fully assembled and distributed from Karmann in Osnabruk, only the predecessor 2000 coupes were shipped to Munich for assembly.)

Hi Chris , thanks again , at the rate I am going I’ll either be sent to the mental hospital , or I’ll eventually get to the bottom of this .

Should the body have a karmann number stamped somewhere by any chance ???

The Karmann body number is stamped under the Karmann plate on driver side door jamb A pillar for LHD. I don't think this will help though, it is just a sequential number assigned by them. The four digit code was on a piece of paper glued to the trunk bulkhead behind the right side passenger seat. BMW's archive has no info on the Karmann body number either. From coupes I have seen I think the 2800CS used 1-9,399 and it started over with 1-21,166 for 3.0CS but this is just my guess.

See this post for model code and Karmann stamp

e9coupe.com

e9coupe.com

Model Code

Here is the model code sheet attached to the trunk bulkhead behind the passenger side seat. 3436 denotes a US spec 3.0CS automatic. All coupes have a four digit model code, CS vs CSi, US vs ROW, manual vs automatic. This is how the assembly line workers knew what they were working on.

e9coupe.com

e9coupe.com

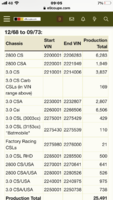

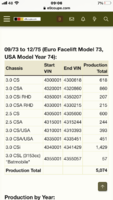

We have number built by year in our FAQ section. There were 10,691 3.0CS built thru Dec 1972. With 6,026 built in calendar year 73, it seems logical the Stephen's stamp of 12,794 indicates roughly 1/3 (2,103/6,026) of the way thru 1973 as his build date is April 1973 and I have seen a US May 73 build date with a number slightly higher as well.

Hi Chris , I didn’t find a label or sticker but someone has been there with a maker at some stage , and they wrote the number 37 on the left ,partially covered by the horse-hair so it must have been done on the production line and 24 on the right twice .We have number built by year in our FAQ section. There were 10,691 3.0CS built thru Dec 1972. With 6,026 built in calendar year 73, it seems logical the Stephen's stamp of 12,794 indicates roughly 1/3 (2,103/6,026) of the way thru 1973 as his build date is April 1973 and I have seen a US May 73 build date with a number slightly higher as well.

Does that mean anything to anyone ???

Barry

How about this for a theory, the production line uses all the parts that are on one rack, when finished they move onto the next rack? Clearly the important things need to match the build sheets, but I can’t see good parts that will fit not being used. I also doubt that the Factory Manager gives any spares to the Parts manager to sell via Parts, they both need to show good profitability and that may be considered as the most important factor for their bonus.

Also, with the intro of a new spec sometimes suppliers are late to change over, so to keep production going the Management and Engineers may have to build a few in between specs. I think Jaguar are famous for a series 1.5, or perhaps 2.5 E type.

And / Or, yours was part built pre August shutdown and then then finished, repaired post summer. The gap may have been several months. FYI I was once the proud owner of a new car which showed many signs of having been cut n stuck prior to me receiving it.

Out of interest does yours have a ballast resister for the coil, or ballast built into a resistance wire that looks a bit like a doorbell wire?

Mine is Dec 1973 build and is a series 2 with many differences to the series 1.

Hi CornishmanBarry

How about this for a theory, the production line uses all the parts that are on one rack, when finished they move onto the next rack? Clearly the important things need to match the build sheets, but I can’t see good parts that will fit not being used. I also doubt that the Factory Manager gives any spares to the Parts manager to sell via Parts, they both need to show good profitability and that may be considered as the most important factor for their bonus.

Also, with the intro of a new spec sometimes suppliers are late to change over, so to keep production going the Management and Engineers may have to build a few in between specs. I think Jaguar are famous for a series 1.5, or perhaps 2.5 E type.

And / Or, yours was part built pre August shutdown and then then finished, repaired post summer. The gap may have been several months. FYI I was once the proud owner of a new car which showed many signs of having been cut n stuck prior to me receiving it.

Out of interest does yours have a ballast resister for the coil, or ballast built into a resistance wire that looks a bit like a doorbell wire?

Mine is Dec 1973 build and is a series 2 with many differences to the series 1.

Sorry for taking so long getting back to you .

Yes those theories do all sound plausible to me .

I would say that even the smallest of parts would all be used up just to be efficient , as the German workforce would always want to be efficient.

I know I might be generalising a group of people here , but I do think that they would always take pride in their work and would always be striving to be more efficient .

I work for a German company so I think I can say that is true .

Anyway

but as it’s now Christmas let’s just settle on they went off on their hols , I wonder where was the place to go to from osnabruck in the summer of 1973 ?

The Boeing 747 was just 3 years old , so far flung places had become closer than ever

Britain Ireland and Denmark had just joined the EEC , so maybe they went to visit their new cousins/ neighbours

Anyway getting back to the coupe , I attached a photo of the coil below , does it match yours???

All series I has the ballast resistor like yours Barry. It was replaced by a resistance wire in series II, facelift/MY74 coupes,

For The the collector , investor, car trader etc etc

The csi to buy is the series 2?, (over the series 1 ie LHD converted to RHD )

with the vin number starting with 435xxxx, total of 207 factory Made RHD cars !!!

So is the factory RHD CSI series 2, with 435xxxx chassis number more valuable than the series 1 ???

How many of the LHD drive csi where converted to RHD for the Uk market ??

Or would it be better to get a factory 1973RHD 3.0 csi, only 66 of them were built .All series I has the ballast resistor like yours Barry. It was replaced by a resistance wire in series II, facelift/MY74 coupes,

Build by year means nothing, all 207 RHD CSi are of the same configuration. Yours may be the rarest, surely fewer than 207?