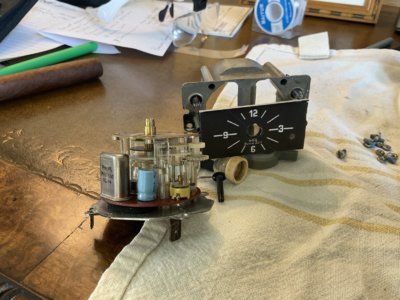

Posted on the parts forum about trying to buy a working kienzle clock. my dash clock and both spares i have when hooked up to 12V do not work. Pretty much got the idea that people sent them out to specialty clock shops paying hundreds of dollars for the work. So i decided what the hell i have the main clock in my dash and two spares in my parts inventory lets open one up and take a crack at doing the repair myself and documenting it for the forum.

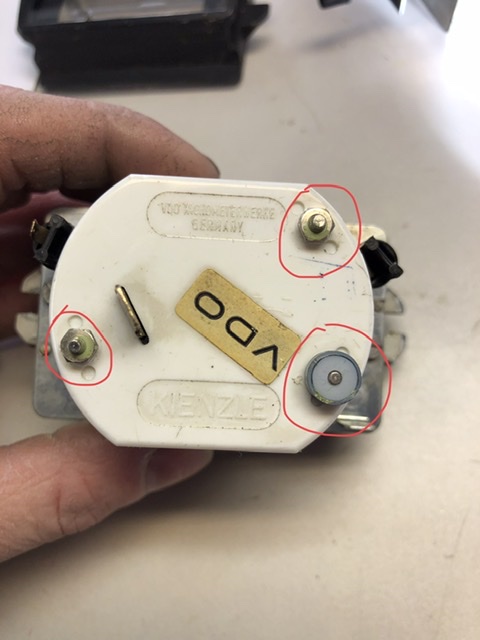

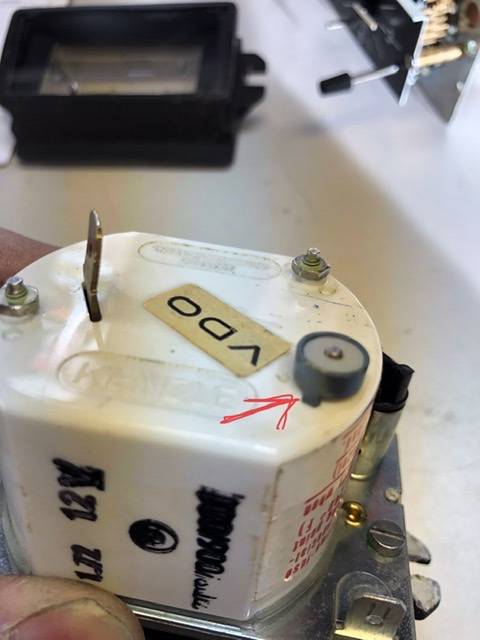

1) having the clock on the work bench you’ll see the plastic white back cover has two nuts and one plastic tamper proof piece. To gain access to the clock movement and gearing this will need to come off.

2) the tamper proof covers the third 5mm nut that needs to come off. I cut the to small plastic ear tabs on the side of the tamper proof cover with a utility knife then just pride off with a small flat head Screw driver

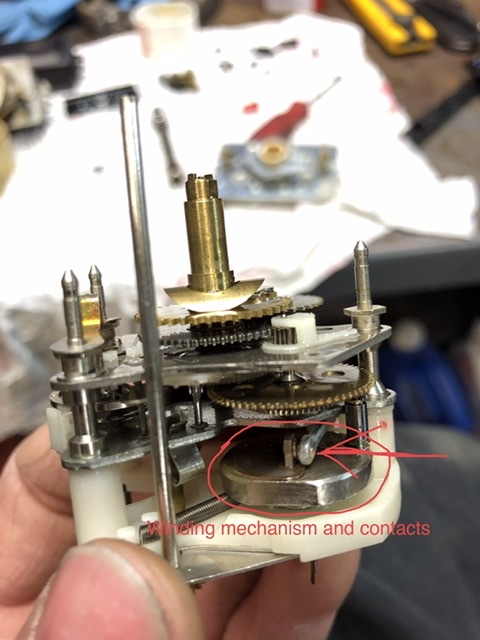

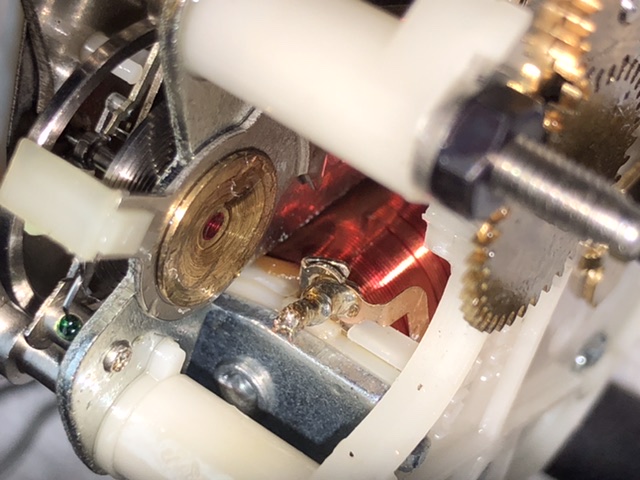

3) after sliding off the back cover you can see all the glory of german engineering. upon close examination of the gears, movements and winding mechanism i found a disintegrated soldered joint between the electrical coil and winding mechanism ( I believe it was ground side)

NOTE-on all three of my clocks this soldered joint had failed!!!

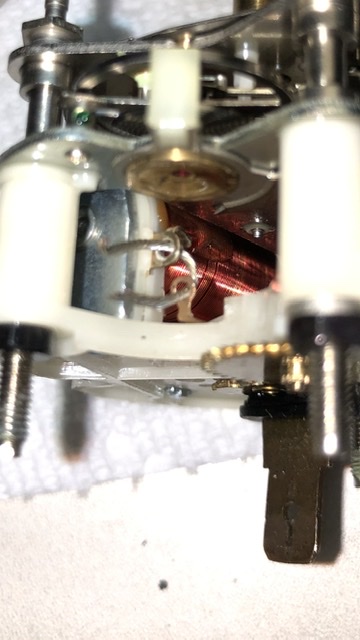

NOTE-this picture of the winding mechanism shows the contacts touching when this happens with uninterrupted power the left contact turns clock wise away from the right side stationary contact. This resets the mechanism and keeps the clock turning Until it happens all over again and again and again.

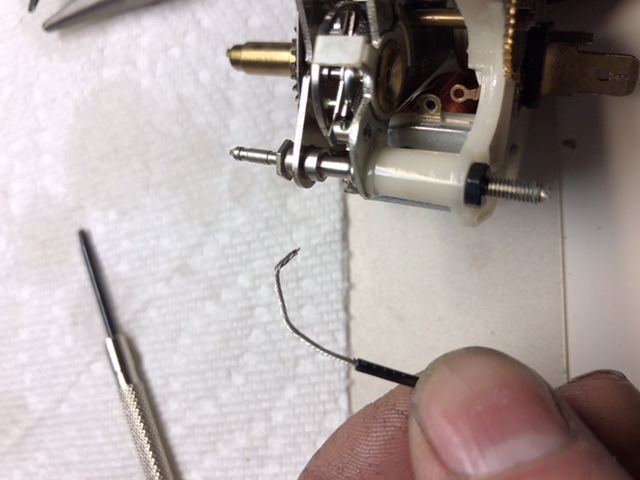

4) I repaired the joint with some 18-20 gauge wire and threaded it between the two eyelets twisted to tighten then resoldered.

5) I went through the gears lightly blew any grim away and oiled all pivot points. Hooked up the clock to 12v and we were back in business and being on time for it as well. winding mechanism winds, movements move and the sound of the classic tick tick tick are great.

i did this same repair one all three of my VDO clocks and it fixed them all. Saved me a couple hundred bucks and wasn’t that tough to do. Hope this helps others out there.

1) having the clock on the work bench you’ll see the plastic white back cover has two nuts and one plastic tamper proof piece. To gain access to the clock movement and gearing this will need to come off.

2) the tamper proof covers the third 5mm nut that needs to come off. I cut the to small plastic ear tabs on the side of the tamper proof cover with a utility knife then just pride off with a small flat head Screw driver

3) after sliding off the back cover you can see all the glory of german engineering. upon close examination of the gears, movements and winding mechanism i found a disintegrated soldered joint between the electrical coil and winding mechanism ( I believe it was ground side)

NOTE-on all three of my clocks this soldered joint had failed!!!

NOTE-this picture of the winding mechanism shows the contacts touching when this happens with uninterrupted power the left contact turns clock wise away from the right side stationary contact. This resets the mechanism and keeps the clock turning Until it happens all over again and again and again.

4) I repaired the joint with some 18-20 gauge wire and threaded it between the two eyelets twisted to tighten then resoldered.

5) I went through the gears lightly blew any grim away and oiled all pivot points. Hooked up the clock to 12v and we were back in business and being on time for it as well. winding mechanism winds, movements move and the sound of the classic tick tick tick are great.

i did this same repair one all three of my VDO clocks and it fixed them all. Saved me a couple hundred bucks and wasn’t that tough to do. Hope this helps others out there.

Last edited: