Part 1:

Often at a Cars & Coffee type event I will get a comment like “Triple sidedrafts - I hear they never stay in tune.” They will stay in tune, but getting them there is the challenge! Here are some tips and suggestions I’ve learned during my often frustrating, multi-year, sidedraft self-flagellation. These are my findings as they relate to the DCOE/DCOM and M30 engine and by no means are the gospel. I will update as new findings and theories dictate and hope others will contribute either by questioning these tips or chiming in if you have your own. All in all, triples are not cheap to install with all the accesories needed to properly set them up, but they deliver in spades on the visceral experience. On to the fun!

Before tuning the carbs:

-If you haven't yet, get a set that has been professionaly rebuilt/restored or a new set from a legitimate Weber supplier - not Chinese knockoffs. Even if you rebuild them yourself there are still pitfalls like leaking throttle shaft bearings, worn tolerances etc. that can derail your tuning efforts and lead to frustration.

-Install an air fuel ratio (AFR) gauge - critical for accurate jetting and idle mixture.

-Ensure ignition system integrity: new NGK or German Bosch plugs gapped correctly (I am using NGK BP5ES set at .030), distributor, cap & rotor, coil, ballast resistor, points & condenser (if using), and plug wires are all in new or proven good condition. You want no doubts on the ignition side.

-Ensure your compression is within spec.

-Regulated fuel pressure at 2.5-3lbs from a high volume, low pressure pump with filter between it and tank. I am happy with the Carter 4070.

-Float levels set at 25mm from the top of main jet stack deck. Make dipsticks out of paper with measurements on them so you know when it gets wet at 25mm.

-Stock timing set correctly (see note below on the 123ignition distibutor for tweaks on this).

-Vacuum advance disconnected and any ports plugged.

-Ensure linkage is working properly with no binding or unusual movements. With engine off have someone press the pedal to the floor and look down the barrel to check throttle plates are open all the way at wide open throttle (WOT) - and closed fully when released.

-For M30 do not use “soft mount” carb manifold gaskets, use plain “base gaskets” from Pierce Manifolds. Soft mounts are not needed and are a potential source of air leaks and supreme frustration.

-For stock engine use 34mm chokes. Larger engines/cams will likely need 36mm from a DCOE45.

-Use a Carbmate gauge if carbs have vacuum ports (emissions carbs like 151/152, DCOM et al).

-Use an STE SK Synchronmeter gauge (the German one) with the STE-6 90 degree adapter if carbs don’t have vacuum ports.

Tools of the trade:

-Use as much air filter as space will allow. The 1” paper style and foam Ramflo’s tend to run richer than others like socks or taller paper ones and will affect jetting more so than others.

-On the carb bodies, replace the paper top cover gaskets with the rubber ones - better for stopping leaks and vapors.

-Ensure the cold start mechanisms are locked in the off (pistons down) position or eliminated altogether - you won’t need them and you don’t want them to leak. They can also be effectively blocked off by tapping for a grub screw to seal off where they flow into the venturis or buying disable kits from Dellorto UK.

-Understand the principles of jetting before buying a bunch of jet sizes, this gets expensive very quickly (more on this below). It's not good when your wife comments on the weekly deliveries from Pierce Manifolds. Download the Weber Tuning Manual in PDF and read it several times:

http://www.lainefamily.com/images/WeberTuningManual.pdf

This writeup is for the interconnect linkage system, adapt this if you have the crossbar/push rod system:

Set throttle plates to cover first progression holes on each carb. A flashlight in the venturi with the inspection covers off will show the position. Or shine the light over the exposed holes from above and locate the throttle plate position. Ideally you want to keep the plate as close as possible to directly under and covering up the first hole (closest to engine) to avoid off-idle flat spots and erratic idle but some deviation is inevitable during the tuning process.

The carb with idle stop screw is the base carb and I use the barrel that is connected to the pedal linkage pull rod as the base barrel for all synching. As a starting point, open the idle mix screws about 2 - 2 1/2 turns. Some model carbs require less open, others more.

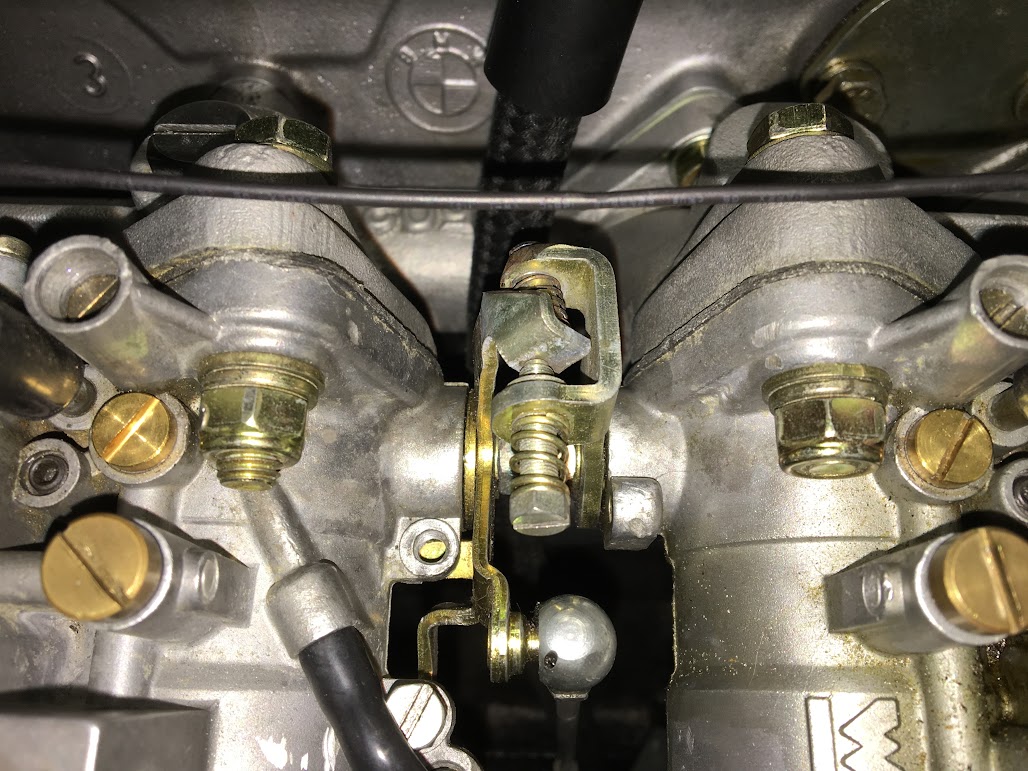

My base carb is #1 carb (front of car), shown here is bbl #2 of that carb which also has the idle set screw (under the black silicon tube opposite the pedal linkage ball and socket connection). The left side of pic on #2 bbl top to bottom is the mixture screw, progression hole cover, and accell pump jet cover. Far left shows the idle bypass (covered by hex grub screw) and rubber covered vacuum port above that. Between the carbs is the lever with adjustment screw used to match the airflow of each carb. All my synching is based on #2 barrel on the left:

Often at a Cars & Coffee type event I will get a comment like “Triple sidedrafts - I hear they never stay in tune.” They will stay in tune, but getting them there is the challenge! Here are some tips and suggestions I’ve learned during my often frustrating, multi-year, sidedraft self-flagellation. These are my findings as they relate to the DCOE/DCOM and M30 engine and by no means are the gospel. I will update as new findings and theories dictate and hope others will contribute either by questioning these tips or chiming in if you have your own. All in all, triples are not cheap to install with all the accesories needed to properly set them up, but they deliver in spades on the visceral experience. On to the fun!

Before tuning the carbs:

-If you haven't yet, get a set that has been professionaly rebuilt/restored or a new set from a legitimate Weber supplier - not Chinese knockoffs. Even if you rebuild them yourself there are still pitfalls like leaking throttle shaft bearings, worn tolerances etc. that can derail your tuning efforts and lead to frustration.

-Install an air fuel ratio (AFR) gauge - critical for accurate jetting and idle mixture.

-Ensure ignition system integrity: new NGK or German Bosch plugs gapped correctly (I am using NGK BP5ES set at .030), distributor, cap & rotor, coil, ballast resistor, points & condenser (if using), and plug wires are all in new or proven good condition. You want no doubts on the ignition side.

-Ensure your compression is within spec.

-Regulated fuel pressure at 2.5-3lbs from a high volume, low pressure pump with filter between it and tank. I am happy with the Carter 4070.

-Float levels set at 25mm from the top of main jet stack deck. Make dipsticks out of paper with measurements on them so you know when it gets wet at 25mm.

-Stock timing set correctly (see note below on the 123ignition distibutor for tweaks on this).

-Vacuum advance disconnected and any ports plugged.

-Ensure linkage is working properly with no binding or unusual movements. With engine off have someone press the pedal to the floor and look down the barrel to check throttle plates are open all the way at wide open throttle (WOT) - and closed fully when released.

-For M30 do not use “soft mount” carb manifold gaskets, use plain “base gaskets” from Pierce Manifolds. Soft mounts are not needed and are a potential source of air leaks and supreme frustration.

-For stock engine use 34mm chokes. Larger engines/cams will likely need 36mm from a DCOE45.

-Use a Carbmate gauge if carbs have vacuum ports (emissions carbs like 151/152, DCOM et al).

-Use an STE SK Synchronmeter gauge (the German one) with the STE-6 90 degree adapter if carbs don’t have vacuum ports.

Tools of the trade:

-Use as much air filter as space will allow. The 1” paper style and foam Ramflo’s tend to run richer than others like socks or taller paper ones and will affect jetting more so than others.

-On the carb bodies, replace the paper top cover gaskets with the rubber ones - better for stopping leaks and vapors.

-Ensure the cold start mechanisms are locked in the off (pistons down) position or eliminated altogether - you won’t need them and you don’t want them to leak. They can also be effectively blocked off by tapping for a grub screw to seal off where they flow into the venturis or buying disable kits from Dellorto UK.

-Understand the principles of jetting before buying a bunch of jet sizes, this gets expensive very quickly (more on this below). It's not good when your wife comments on the weekly deliveries from Pierce Manifolds. Download the Weber Tuning Manual in PDF and read it several times:

http://www.lainefamily.com/images/WeberTuningManual.pdf

This writeup is for the interconnect linkage system, adapt this if you have the crossbar/push rod system:

Set throttle plates to cover first progression holes on each carb. A flashlight in the venturi with the inspection covers off will show the position. Or shine the light over the exposed holes from above and locate the throttle plate position. Ideally you want to keep the plate as close as possible to directly under and covering up the first hole (closest to engine) to avoid off-idle flat spots and erratic idle but some deviation is inevitable during the tuning process.

The carb with idle stop screw is the base carb and I use the barrel that is connected to the pedal linkage pull rod as the base barrel for all synching. As a starting point, open the idle mix screws about 2 - 2 1/2 turns. Some model carbs require less open, others more.

My base carb is #1 carb (front of car), shown here is bbl #2 of that carb which also has the idle set screw (under the black silicon tube opposite the pedal linkage ball and socket connection). The left side of pic on #2 bbl top to bottom is the mixture screw, progression hole cover, and accell pump jet cover. Far left shows the idle bypass (covered by hex grub screw) and rubber covered vacuum port above that. Between the carbs is the lever with adjustment screw used to match the airflow of each carb. All my synching is based on #2 barrel on the left:

Last edited: