Are the condition for the measurements done with the same conditions (what are the conditions on the BMW plot than would be good to ask).

I know from few sources E9 (as other cars w/o frame in 60's-70's) were flexible and thus sensitive to all the parts which are on the car. I heard stories about the cars which were perfectly aligned but have lost the alignment once the engine, suspension and glass/heavy parts were mounted.

Might it be it is somehow related to the way car should have been verified for proper dimensions but also some repair panels are not made from the steel type they have been in the factory (gauge, carbon content...).

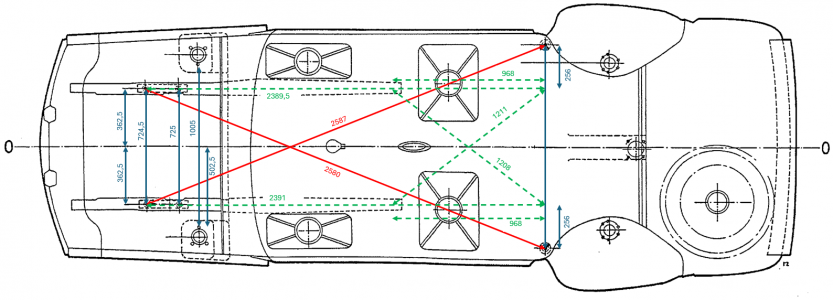

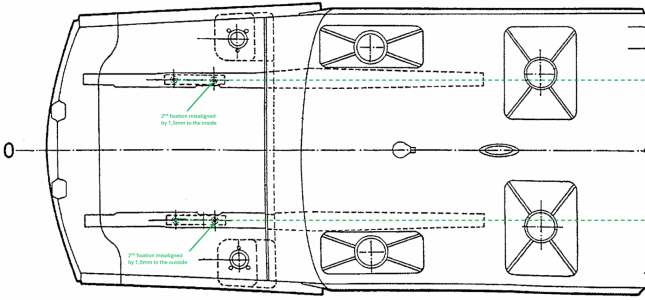

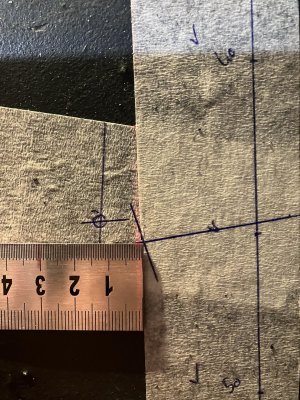

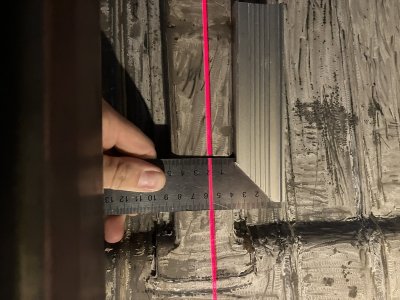

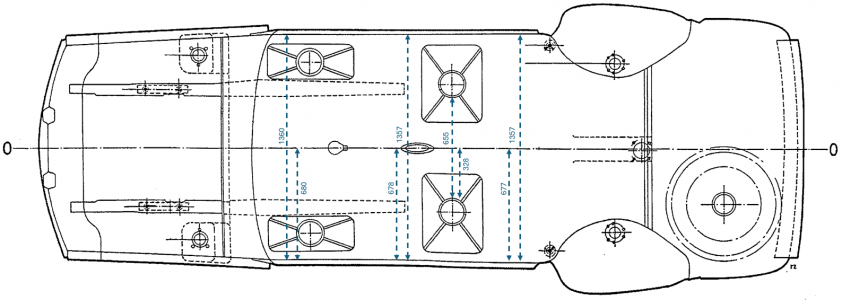

From some reason BMW has not provided front and rear part divided into two dimensions (as they are hard to be measured). What is more, looking on the distance from the differential mount to rear suspension mounts dimensions are different - there is no symmetry there by factory. I would rather than measure total distance as provided on the chart rather than dividing it by symmetry line.

Have you been also checking symmetry on the outer shell to check if they are following suspension/floor assymetry? Than could in some cases confirm body deformation as they are all connected by welds.

I would not be surprised that at least some of the asymmetry came from rust and sills weaker structure combined with chassis fatigue due to age/condition of the car (still assuming no "situations" on the roads in the past).

It is the question how many people are making that measurements during restoration. It would be expected they will step-in and share their experience.

I know from few sources E9 (as other cars w/o frame in 60's-70's) were flexible and thus sensitive to all the parts which are on the car. I heard stories about the cars which were perfectly aligned but have lost the alignment once the engine, suspension and glass/heavy parts were mounted.

Might it be it is somehow related to the way car should have been verified for proper dimensions but also some repair panels are not made from the steel type they have been in the factory (gauge, carbon content...).

From some reason BMW has not provided front and rear part divided into two dimensions (as they are hard to be measured). What is more, looking on the distance from the differential mount to rear suspension mounts dimensions are different - there is no symmetry there by factory. I would rather than measure total distance as provided on the chart rather than dividing it by symmetry line.

Have you been also checking symmetry on the outer shell to check if they are following suspension/floor assymetry? Than could in some cases confirm body deformation as they are all connected by welds.

I would not be surprised that at least some of the asymmetry came from rust and sills weaker structure combined with chassis fatigue due to age/condition of the car (still assuming no "situations" on the roads in the past).

It is the question how many people are making that measurements during restoration. It would be expected they will step-in and share their experience.