Sorry. This was originally posted to the wrong thread so I'm just moving it here now. A rerun.

It's been a while. I had hoped that this thread, and the restoration, was done but the car came back for "warranty repairs". Building a car for a family member means it automatically comes with a lifetime warranty. Sigh. So much for getting time to finish my own coupe. The issues were:

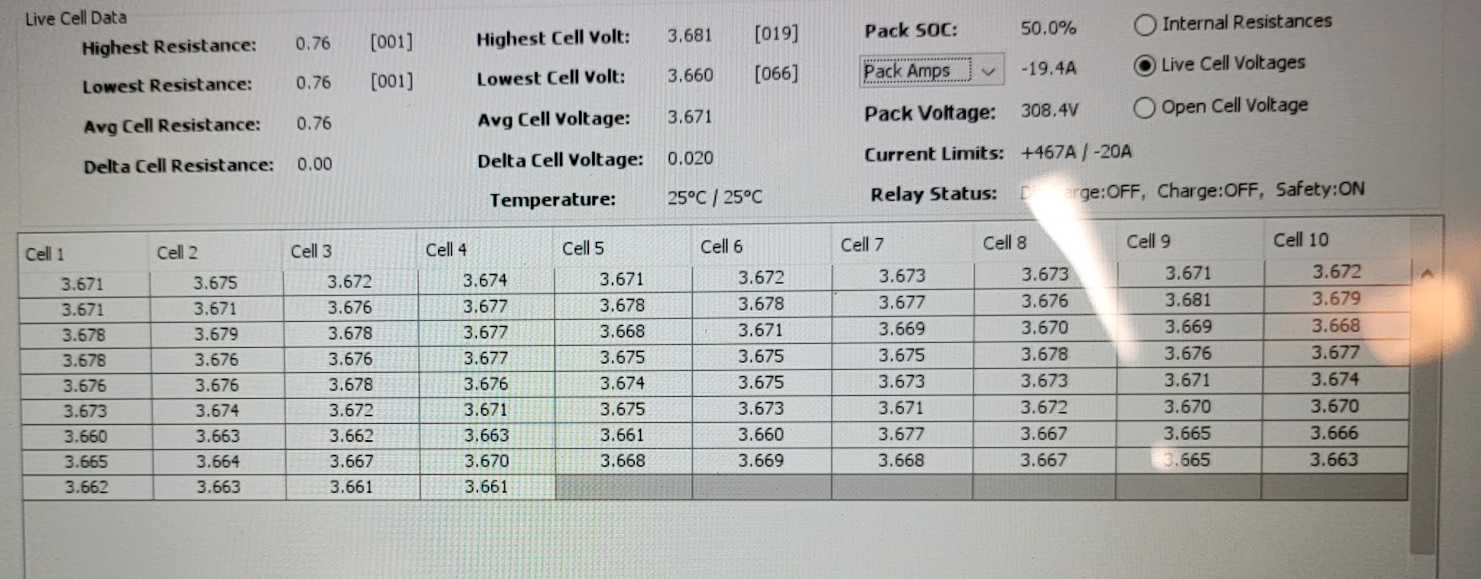

1) State of Charge (remaining energy) calcs weren't perfect

2) One Tesla electric parking brake caliper was sometimes not releasing when shifter moved out of Park

3) Sunroof trim panel sometimes was sticking in track and not moving with sunroof panel

4) Passenger side door was not always locking with power door lock function

5) Door speaker grill was falling off

6) One dash light was intermittent

Intermittent issues are annoying to diagnose but nothing too difficult. However, while test driving the car down to "empty" to better calibrate SOC the car died on the road. This was the first time in the entire development of the car that it had failed to run. It had been so reliable. Oh the shame of waiting for a tow. Voltage seemed way off. What had been 305v was suddenly 145v. The 12v system was reading 8.99v.

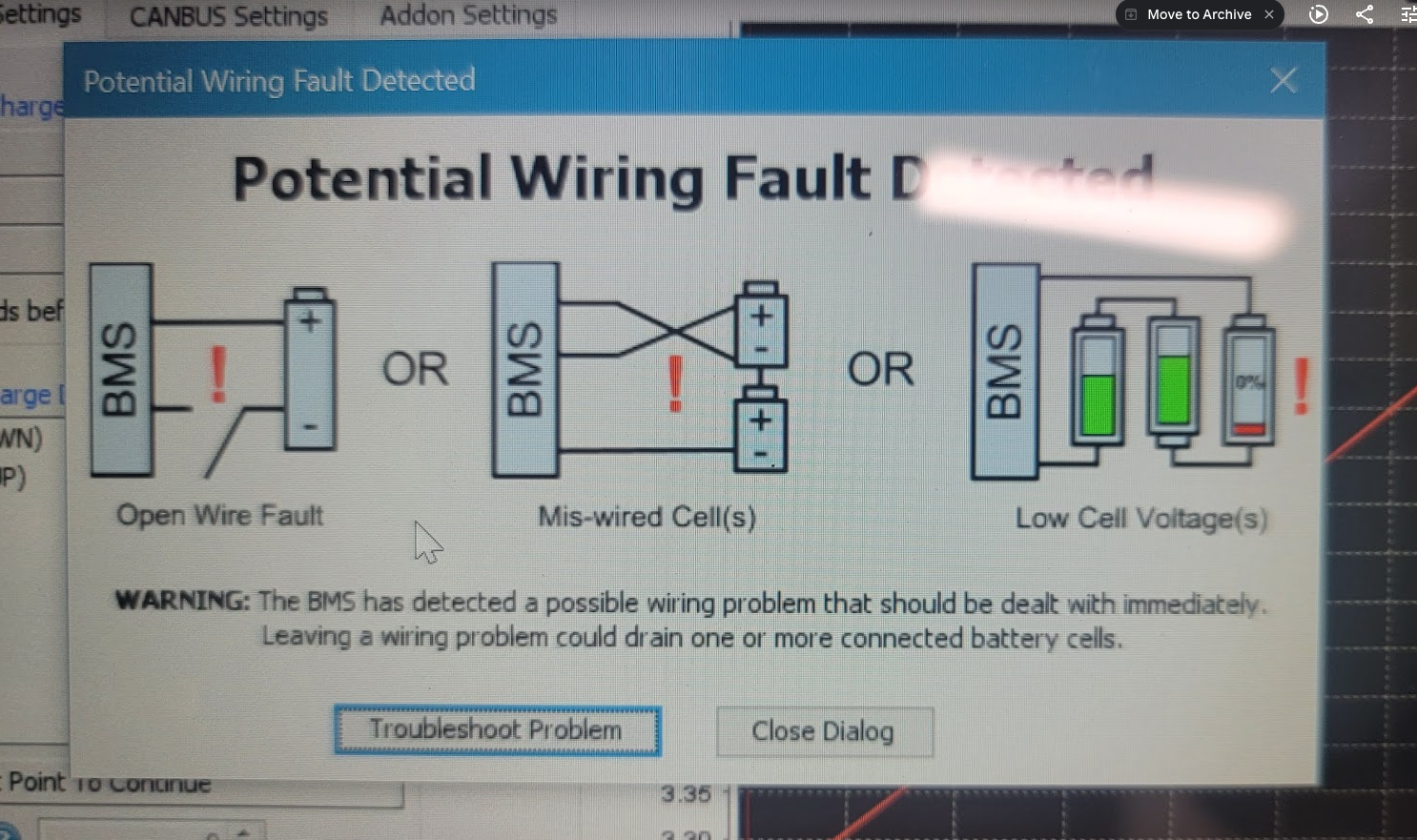

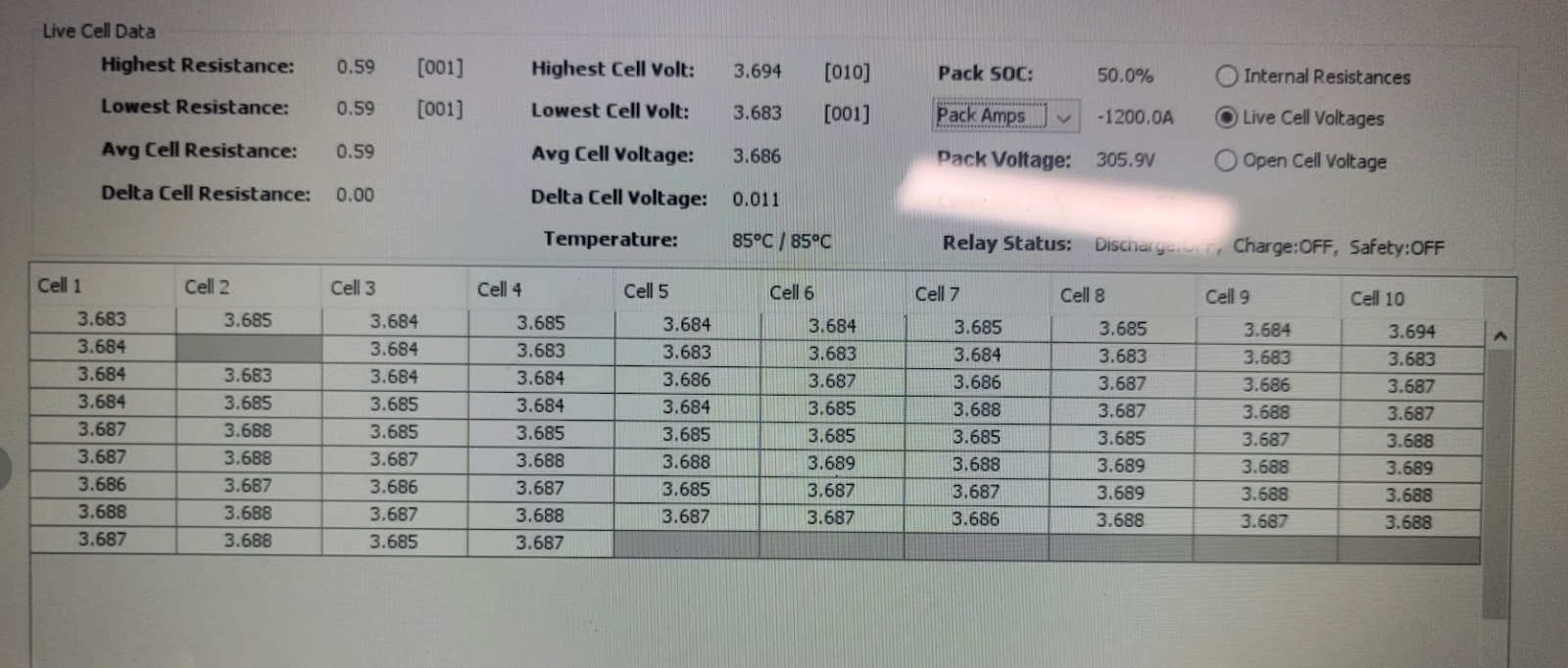

The BMS said there was an open wiring fault and cell #12 was dead so I pulled the battery box, which actually isn't very difficult, just nerve wracking to have that much weight in the air.

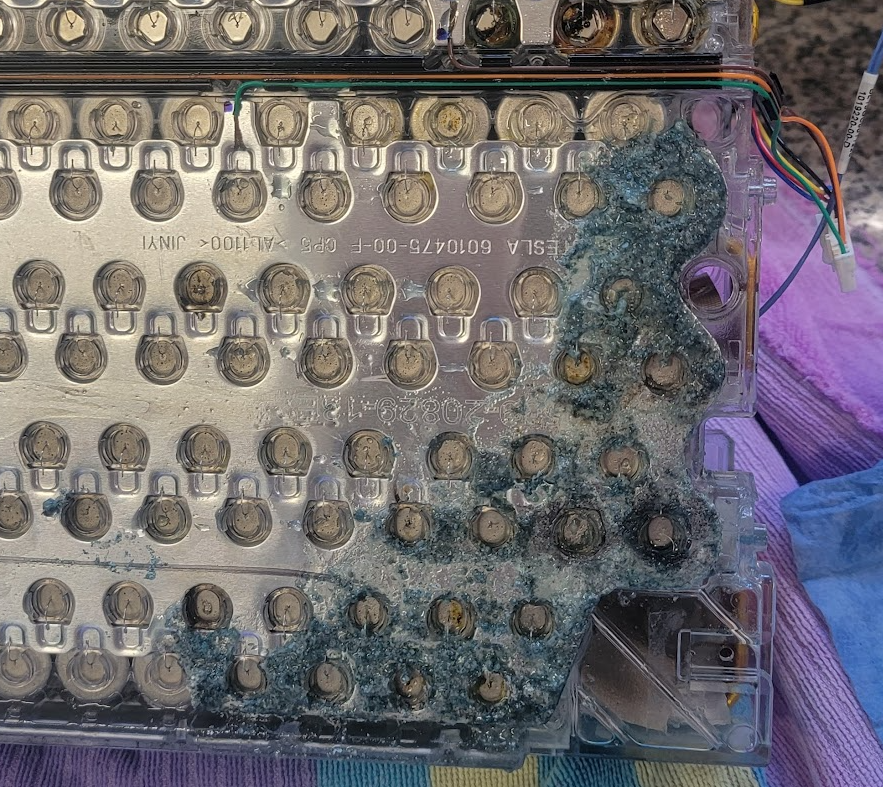

Upon opening the box the problem was readily apparent. I had a small coolant leak. The bottom two batteries had been sitting in a puddle of coolant (Tesla batteries have plastic upper and lower covers and the lower covers acted like trays to hold the coolant). That little design flaw aside, kudos to Tesla for building robust batteries. No fires or huge issues despite a fair amount of corrosion. A couple of the small wire fuses had blown. The real problem was when a drop of coolant fell into the cell tap connector and shorted it.

You (like me) might be wondering how the leak occurred. Tesla batteries have cooling loops with quick connect fuel injector-type fittings on the in and out ports. I used PVC hose and constant tension spring clamps on the barbed Tesla/Dorman fittings to run the cooling lines. It turns out the constant tension clamps with the PVC hose didn't work perfectly together. The clamp allowed the hose to pinch a bit where the clamp had a gap, thus allowing a small leak. Obviously, I didn't notice this during assembly.

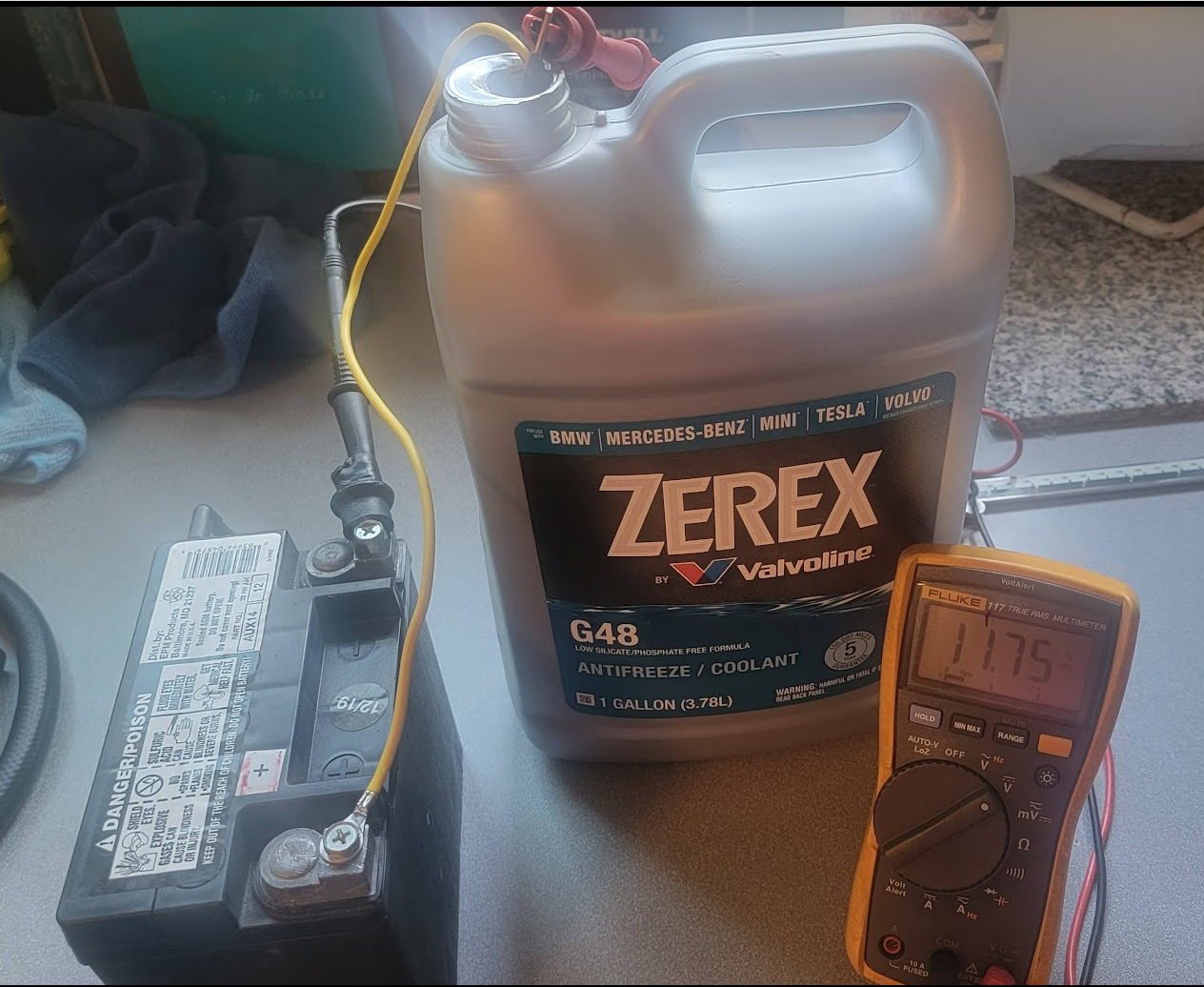

It took a while to decide on what hose and clamps to use. Did you know that rubber fuel hose is conductive? It is. I verified. It has carbon in the rubber to ground static electricity in the fuel system to the chassis. I also verified that G48 coolant designed for EVs is conductive.

Four new batteries (balanced to existing batteries of course), silicon hose with high quality screw clamps and a lot of labor later and the box was back together. Unfortunately, the short also blew a couple fuses inside the BMS (which Orion serviced, out of warranty, for a mere $25) and damaged the Tesla DC/DC converter (thus the low 12v reading). Upon reassembly I had an HV isolation fault which was difficult to find. It turns out the short fried the $10 high voltage digital gauge from Amazon, which also used 12v and chassis ground. That little gauge was allowing HV ground to the chassis. Needless to say, that went into the trash. Reminds me why I use OEM-grade parts for everything else HV. With all that repaired/replaced, the car is back on the road. I also made some changes to the BMS configuration and the dash app to make SOC more accurate.

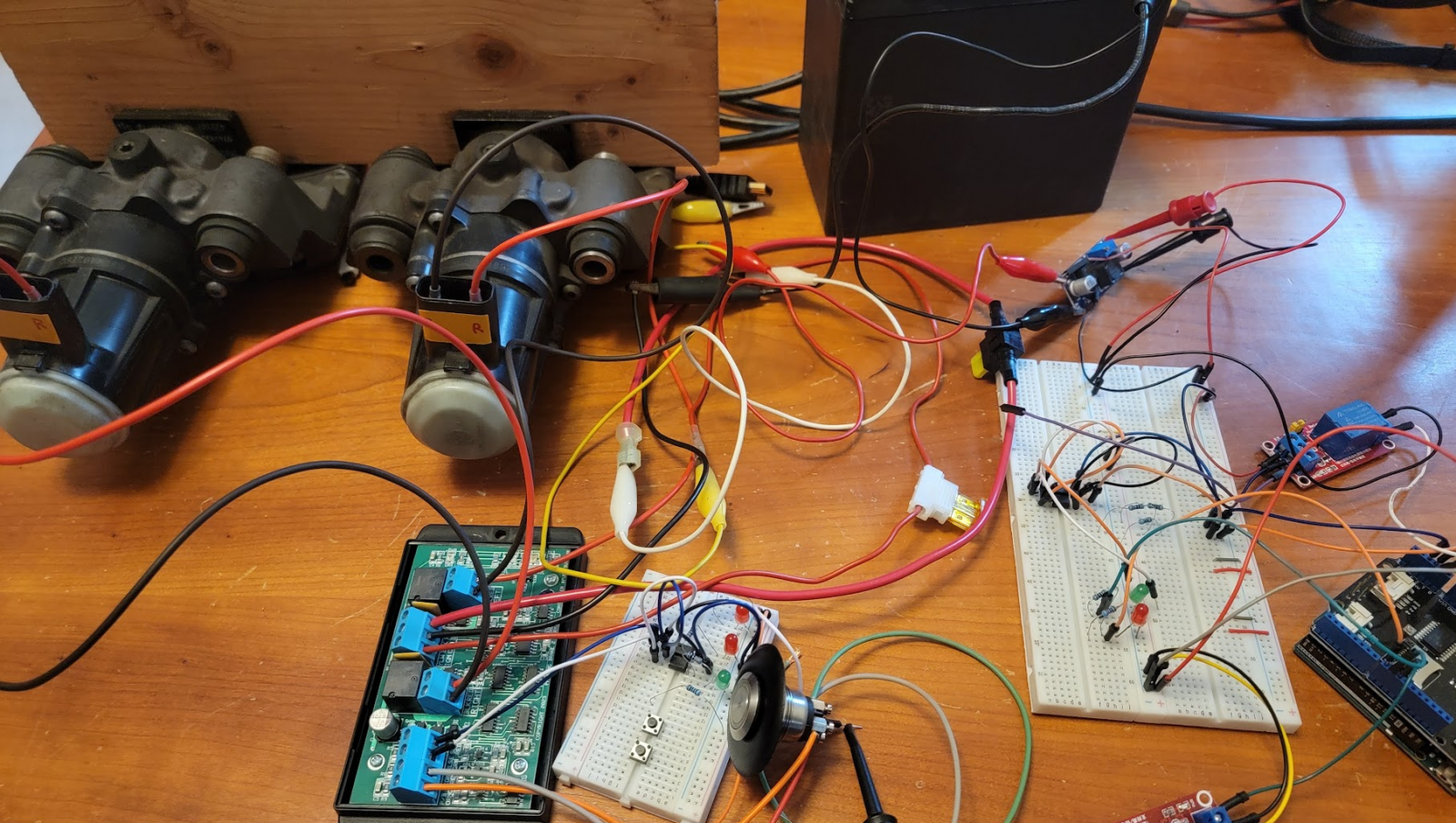

The parking brake issue was challenging to figure out but I replaced the calipers, upgraded the caliper controller, added a new microcontroller to monitor/manage shifter/caliper state, and wrote some code to integrate the caliper status onto the dash app via CANbus so now you can see via icon when the brake is on or released. I also added a button to toggle the caliper status in case it gets out of sync with the shifter for some reason or requires manual override. It has been 100% reliable since.

The sunroof panel clips just needed some adjustment so they hold better, and I made sure the tracks were clean and the fabric on the trim panel had no unglued edges. The passenger side lock has always been finicky. It works on the bench and usually in the car but sometimes the lock mech doesn't move freely. I think it has to do with the lock knob rod but I'm not sure. The mech is clean and lubricated. It might have something to do with the upper door trim and the knob. The door speaker uses magnets to fasten. A bit of RTV secures it better. The dash light was a poor connection -- easy to fix.

It was a frustrating few months but I still feel that, stupid mistakes aside, this conversion is very reliable and a joy to drive.

It's been a while. I had hoped that this thread, and the restoration, was done but the car came back for "warranty repairs". Building a car for a family member means it automatically comes with a lifetime warranty. Sigh. So much for getting time to finish my own coupe. The issues were:

1) State of Charge (remaining energy) calcs weren't perfect

2) One Tesla electric parking brake caliper was sometimes not releasing when shifter moved out of Park

3) Sunroof trim panel sometimes was sticking in track and not moving with sunroof panel

4) Passenger side door was not always locking with power door lock function

5) Door speaker grill was falling off

6) One dash light was intermittent

Intermittent issues are annoying to diagnose but nothing too difficult. However, while test driving the car down to "empty" to better calibrate SOC the car died on the road. This was the first time in the entire development of the car that it had failed to run. It had been so reliable. Oh the shame of waiting for a tow. Voltage seemed way off. What had been 305v was suddenly 145v. The 12v system was reading 8.99v.

The BMS said there was an open wiring fault and cell #12 was dead so I pulled the battery box, which actually isn't very difficult, just nerve wracking to have that much weight in the air.

Upon opening the box the problem was readily apparent. I had a small coolant leak. The bottom two batteries had been sitting in a puddle of coolant (Tesla batteries have plastic upper and lower covers and the lower covers acted like trays to hold the coolant). That little design flaw aside, kudos to Tesla for building robust batteries. No fires or huge issues despite a fair amount of corrosion. A couple of the small wire fuses had blown. The real problem was when a drop of coolant fell into the cell tap connector and shorted it.

You (like me) might be wondering how the leak occurred. Tesla batteries have cooling loops with quick connect fuel injector-type fittings on the in and out ports. I used PVC hose and constant tension spring clamps on the barbed Tesla/Dorman fittings to run the cooling lines. It turns out the constant tension clamps with the PVC hose didn't work perfectly together. The clamp allowed the hose to pinch a bit where the clamp had a gap, thus allowing a small leak. Obviously, I didn't notice this during assembly.

It took a while to decide on what hose and clamps to use. Did you know that rubber fuel hose is conductive? It is. I verified. It has carbon in the rubber to ground static electricity in the fuel system to the chassis. I also verified that G48 coolant designed for EVs is conductive.

Four new batteries (balanced to existing batteries of course), silicon hose with high quality screw clamps and a lot of labor later and the box was back together. Unfortunately, the short also blew a couple fuses inside the BMS (which Orion serviced, out of warranty, for a mere $25) and damaged the Tesla DC/DC converter (thus the low 12v reading). Upon reassembly I had an HV isolation fault which was difficult to find. It turns out the short fried the $10 high voltage digital gauge from Amazon, which also used 12v and chassis ground. That little gauge was allowing HV ground to the chassis. Needless to say, that went into the trash. Reminds me why I use OEM-grade parts for everything else HV. With all that repaired/replaced, the car is back on the road. I also made some changes to the BMS configuration and the dash app to make SOC more accurate.

The parking brake issue was challenging to figure out but I replaced the calipers, upgraded the caliper controller, added a new microcontroller to monitor/manage shifter/caliper state, and wrote some code to integrate the caliper status onto the dash app via CANbus so now you can see via icon when the brake is on or released. I also added a button to toggle the caliper status in case it gets out of sync with the shifter for some reason or requires manual override. It has been 100% reliable since.

The sunroof panel clips just needed some adjustment so they hold better, and I made sure the tracks were clean and the fabric on the trim panel had no unglued edges. The passenger side lock has always been finicky. It works on the bench and usually in the car but sometimes the lock mech doesn't move freely. I think it has to do with the lock knob rod but I'm not sure. The mech is clean and lubricated. It might have something to do with the upper door trim and the knob. The door speaker uses magnets to fasten. A bit of RTV secures it better. The dash light was a poor connection -- easy to fix.

It was a frustrating few months but I still feel that, stupid mistakes aside, this conversion is very reliable and a joy to drive.

Last edited: