At about the same time as I decided to attack the engine & driveline my friend and BMW tech., Jim K., mentioned that he had a complete L-Jet M30 engine available which had come out of a customer's e12. The engine had been tweaked by Ray Korman's shop a couple of decades earlier and though somewhat tired out now, it's capacity had been bumped up to 3.2ltrs with a crankshaft change so I agreed to buy it if we could determine that the major components were serviceable/rebuildable. We spent a couple of hours disassembling and then measuring it in his shop with positive results so the deal was done. A small bonus of the sale was that the original rebuild invoices from Korman were included in the transaction as well as a Korman parts catalogue from the period. The engine's rebuild sheets were signed off by Ray's engine guy, Henry L., who, unbeknownst to me at the time, would (once again) play a major role in the engine's third life.

I wished to reduce the reciprocating (rotating as well) mass of the crankshaft assembly so after determining the next oversize, I sent off one of the pistons from the 3.2 engine to Wiseco who precisely measured the original and then made a lightweight forged set in an appropriate size for the soon-to-be enlarged cylinder bores. A stock connecting rod was sent off to Crower, who made a forged and lightweight set.

While these two companies were making parts, I set out to find an engine builder. I wanted to find someone with extensive experience with M30 engines and with whom I could somewhat custom tailor a power plant to fit my specific intended use of the car. My search turned up mixed results; one company said in essence "We have options A, B & C, but no deviations", while another seemed willing to work with me but then abruptly stopped communication when I suggested a visit to their shop. One day while perusing engine videos on Youtube I came across a modified BMW V12 running on an engine dyno which i thought pretty nifty and that led to my discovery in N.C. of a BMW engine shop owned and operated by the same Henry L. who had once been Korman's engine guy until setting out on his own about 13 years earlier. I called Henry, was impressed with his extensive experience and found him to be very willing to work with (or put up with) me in building an engine. Within a couple of weeks the 3.2's bits and pieces were loaded into the back of my pickup truck and I was off to N.C.. I was impressed with Henry's tidy shop and we had an encouraging and agreeable conversation about achieving the desired result.

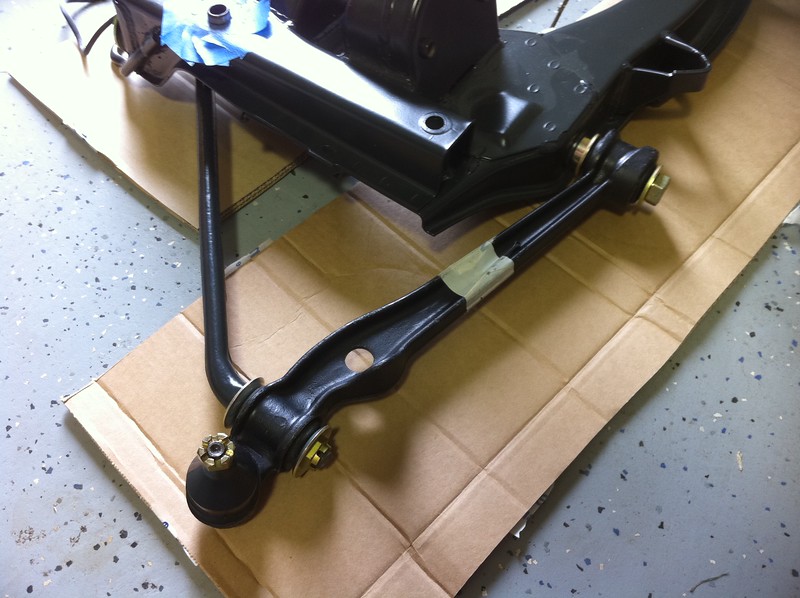

I had previously disassembled the subframes and placed an order with W&N for replacement bushings, tie rod ends, some stressed front end fasteners, differential carrier, control arms and a fairly long list of etcetera bits. Other than the above fasteners sourced new I had sent all of the original stuff out for yellow cad plating. My friend, Scott Z., a motor head of the highest order and owner of a very comprehensive tuning shop, sourced a powder coating shop for me which had a color for the suspension which was a near perfect match for the original gray. They have a number of industrial contracts which take priority but the wait was no issue for me and the stuff looked great when finished. Since placing my initial order with W&N I've started another list, but for now I can begin to reassemble the big pieces of the subframes.

My first real look at the major components from the powder guys:

Sitting at a desktop and with caffeine handy helps my concentration.

These part look so nice that I hate to hide 'em under the car

My friend, Jack F., with a BMW shop in Van Nuys has helped me to find a LSD. This is exactly as found (ex. vent & carrier) in a CA. boneyard - amazing.

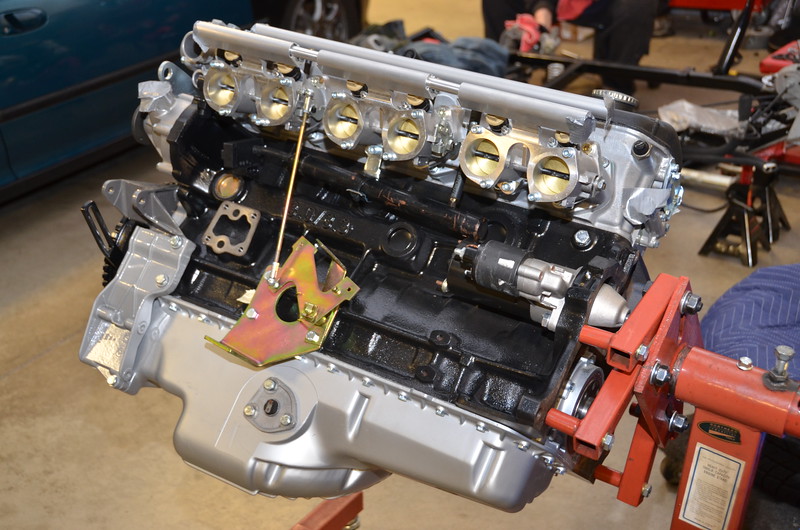

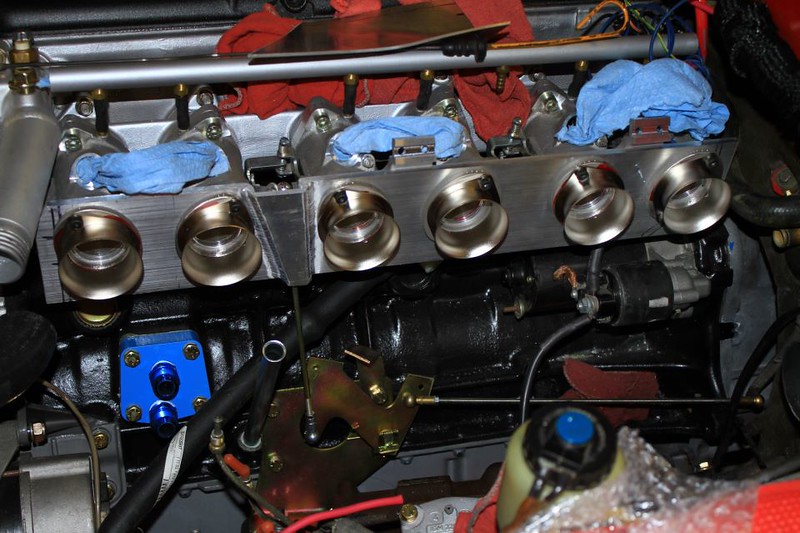

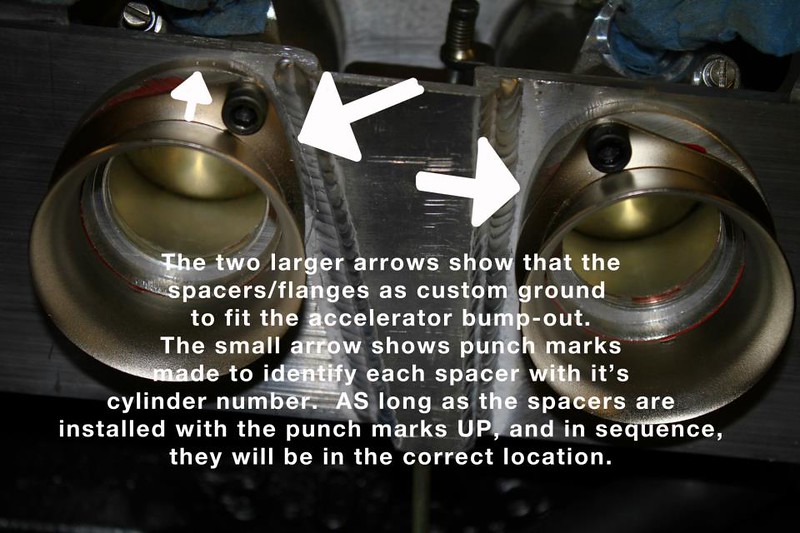

In North Carolina, progress is being made:

As this is taking place, however, I've had some conversations with others who either are using or have used Weber side draft set-ups and I'm beginning to have second thoughts about them for my intended use.

More to come...

Cheers, Jim