Marc-M

Well-Known Member

Not had the time to really get stuck into the car last week, but I have managed to do a few things.

The glove box was delaminating , its now back as it should be and ready for a clean and re flock.

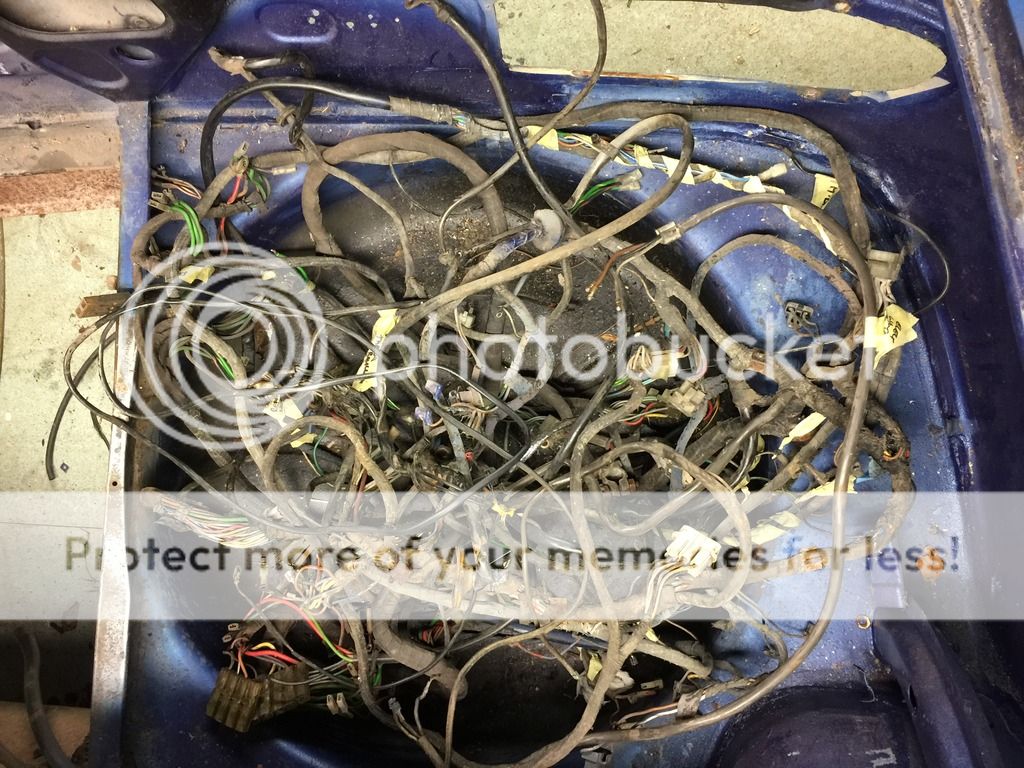

The fuel tank is now out of the car and although it looks a bit scabby it still held ¼ tank of 20 years old stale fuel.

It will be dipped to remove all rust and then I will put in a tank sealer.

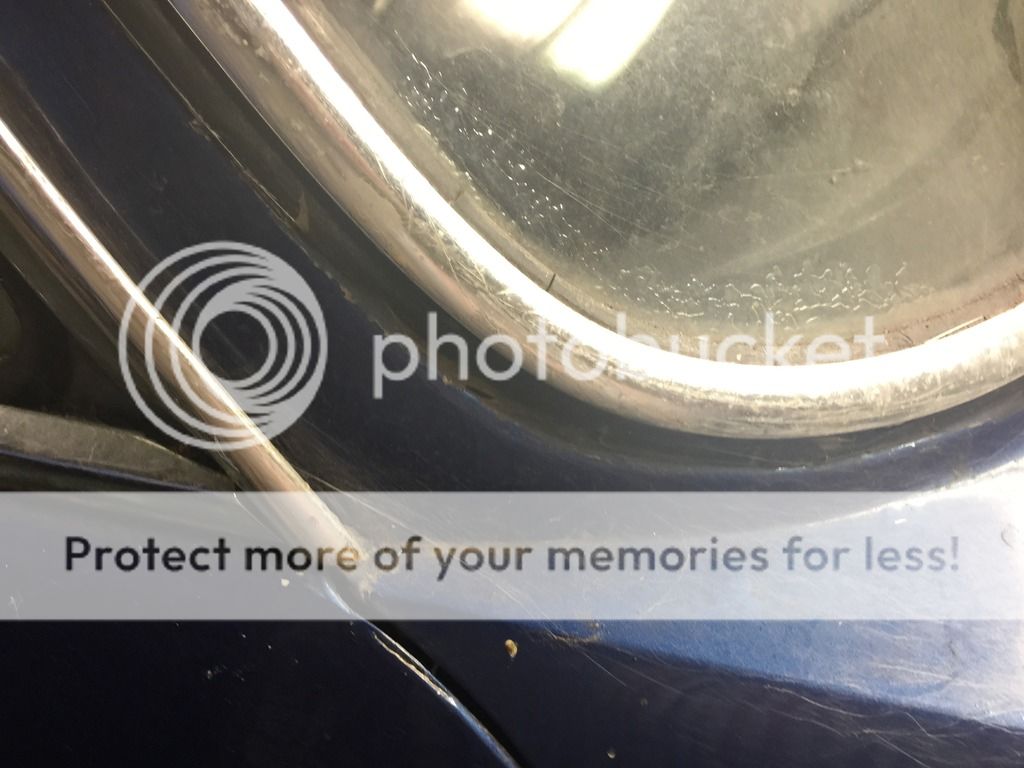

The rear lights are out and will need restoring, over spray all over the insides ..

Does anyone have a good way of removing the coloured lenses out of the chrome surround?

I need to get then re chromed but it looked like they are fused in!!! – my only idea so far would be to carefully grind the rear of the lenses around the aperture to get them out and then stick them back in with epoxy???

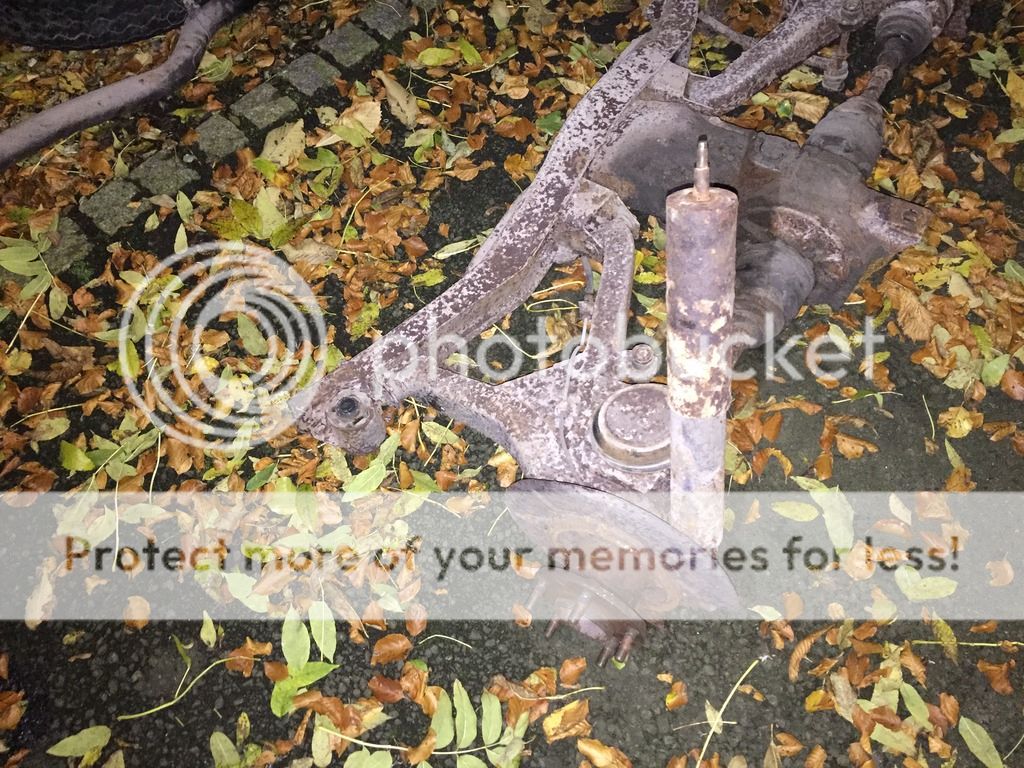

The boot floor looks quite good on first inspection, but a closer look shows some repairs that are just amateur at best, these will be taken out and done correctly.

The spare wheel floor has 1 hone in it so far!

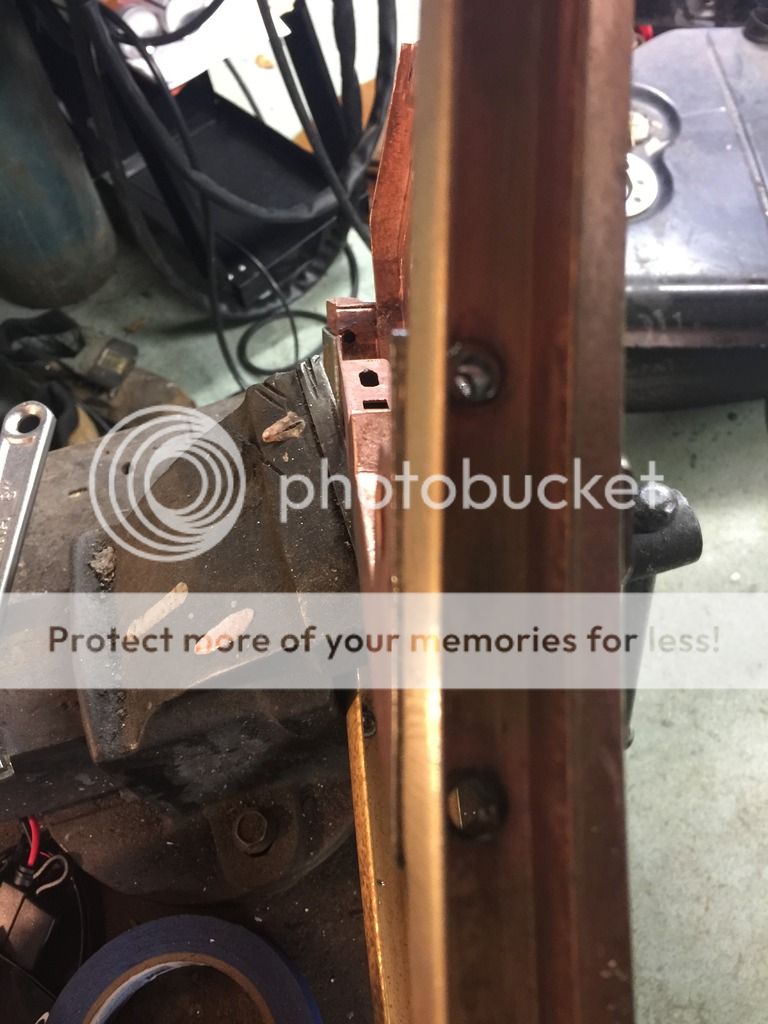

What I am finding with the car is a lot of “home mechanics” work – loads of silicone sticking trim on!

Now bonded, but a good clean and a re flock required

Is this the original fuel cap? looks like it as its had a good battering...

Rear lights out - full of overspray - why do they do this - 2 mins masking up is what it takes - now its a good few hours cleaning and sorting

Looks ok form here - but look at the hole for the fuel tank, the LH edge - not a straight bit- sections put in , but shoddy work.

The glove box was delaminating , its now back as it should be and ready for a clean and re flock.

The fuel tank is now out of the car and although it looks a bit scabby it still held ¼ tank of 20 years old stale fuel.

It will be dipped to remove all rust and then I will put in a tank sealer.

The rear lights are out and will need restoring, over spray all over the insides ..

Does anyone have a good way of removing the coloured lenses out of the chrome surround?

I need to get then re chromed but it looked like they are fused in!!! – my only idea so far would be to carefully grind the rear of the lenses around the aperture to get them out and then stick them back in with epoxy???

The boot floor looks quite good on first inspection, but a closer look shows some repairs that are just amateur at best, these will be taken out and done correctly.

The spare wheel floor has 1 hone in it so far!

What I am finding with the car is a lot of “home mechanics” work – loads of silicone sticking trim on!

Now bonded, but a good clean and a re flock required

Is this the original fuel cap? looks like it as its had a good battering...

Rear lights out - full of overspray - why do they do this - 2 mins masking up is what it takes - now its a good few hours cleaning and sorting

Looks ok form here - but look at the hole for the fuel tank, the LH edge - not a straight bit- sections put in , but shoddy work.