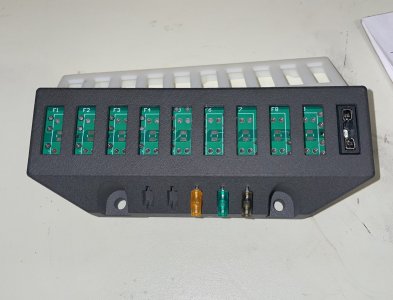

Hello again, I finally got the chance to work on the fuse box design.

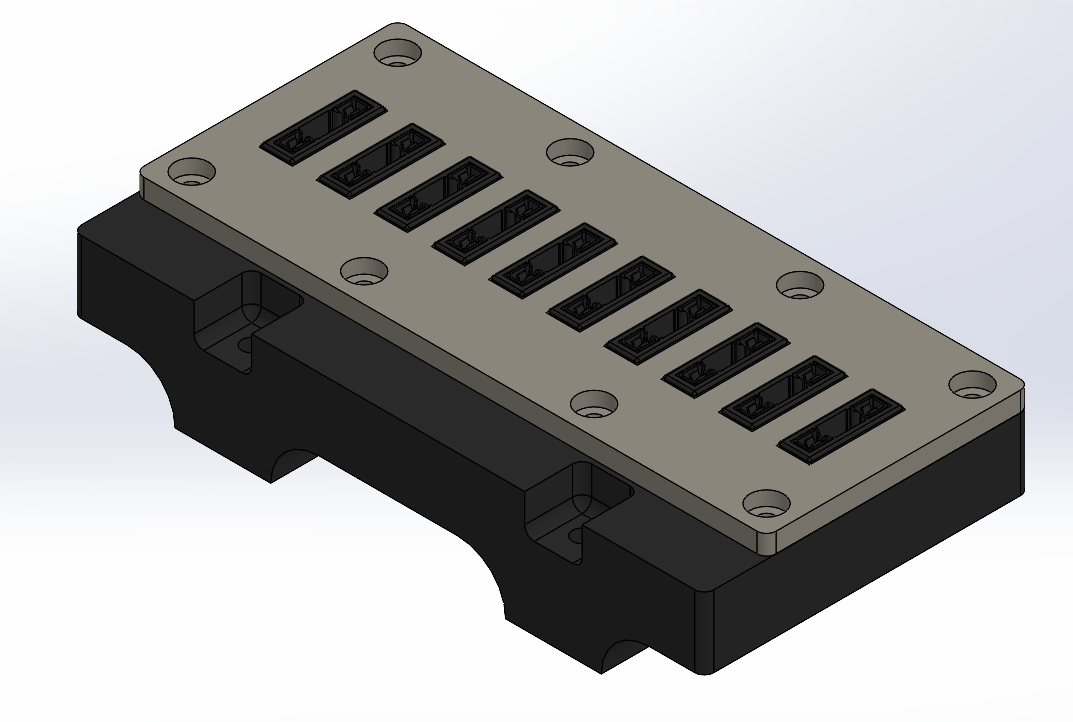

The main update to the design is the additional 4 screws to ensure the PCB is rigidly held to the fuse box body. I also improved the PCB layout but nothing major. The screen shot below missing the spare fuse holders for now. They will be included in the final design.

The main update to the design is the additional 4 screws to ensure the PCB is rigidly held to the fuse box body. I also improved the PCB layout but nothing major. The screen shot below missing the spare fuse holders for now. They will be included in the final design.