You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LAN e9 empresas y tribulaciones, an epiphany in 042BBlau. OPUS MAGNA. XXXXXXXXXXXXXXXXXXXXXXXXXX

- Thread starter deQuincey

- Start date

of oil pumps, oil dipsticks,

I have put a new oil pump, two surprises and an anecdote

The first surprise is that there are no pumps on the market, normally you have to renew the one you have or look for another used one, good luck with it! it is not easy to find

the second is that the new replacement pump (which I bought 6 years ago) is different and does not fit, let me explain...

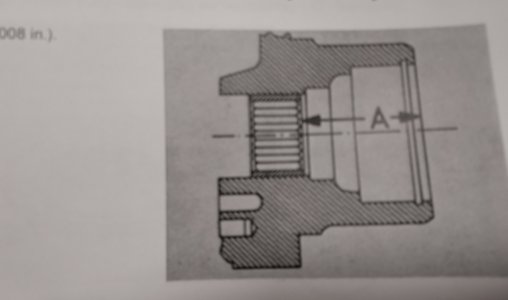

This is the new replacement model, it changes the fastening of the front sprocket going from a plate with three screws to a single central nut, (by the way it is rare metric and rare thread step)

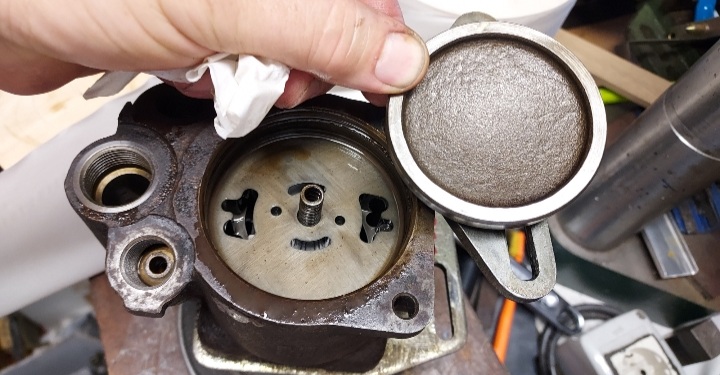

In addition, observant people can see a prominent cup in the suction end, and this is the other surprise, it does not fit in the carter, so you have to cut the cup, it does not look elegant, but it is worse to leave the carter open ;-)

here with the bowl cut:

And now the curiosity, I have wondered how the oil dipstick looks down there, well this is the answer...

matching the level (in the photo the engine is not level as it would later be in the car)

this would be approximately the situation of oil level in the middle

and one last thing that I have learned, and that is that the pump must be assembled with oil so that it is primed, otherwise it will not suck...

BTW, i do have 8 nuts for sale, i was forced to buy 10, i installed one and i will keep one as a spare, so if you plan to install this type of oil pump and you need a nut, do not hestate to ask for it. buyer will pay postage.

I have put a new oil pump, two surprises and an anecdote

The first surprise is that there are no pumps on the market, normally you have to renew the one you have or look for another used one, good luck with it! it is not easy to find

the second is that the new replacement pump (which I bought 6 years ago) is different and does not fit, let me explain...

This is the new replacement model, it changes the fastening of the front sprocket going from a plate with three screws to a single central nut, (by the way it is rare metric and rare thread step)

In addition, observant people can see a prominent cup in the suction end, and this is the other surprise, it does not fit in the carter, so you have to cut the cup, it does not look elegant, but it is worse to leave the carter open ;-)

here with the bowl cut:

And now the curiosity, I have wondered how the oil dipstick looks down there, well this is the answer...

matching the level (in the photo the engine is not level as it would later be in the car)

this would be approximately the situation of oil level in the middle

and one last thing that I have learned, and that is that the pump must be assembled with oil so that it is primed, otherwise it will not suck...

BTW, i do have 8 nuts for sale, i was forced to buy 10, i installed one and i will keep one as a spare, so if you plan to install this type of oil pump and you need a nut, do not hestate to ask for it. buyer will pay postage.

Last edited:

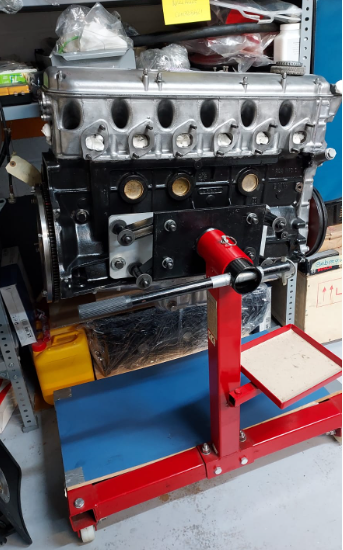

so at home now to final details and bits

plan to install anciliaries and renew eccentrics and make a nice valve adjustment calmly

plan to install anciliaries and renew eccentrics and make a nice valve adjustment calmly

Meanwhile with the excellent company of T.E.Lawrence aka @Stevehose ....

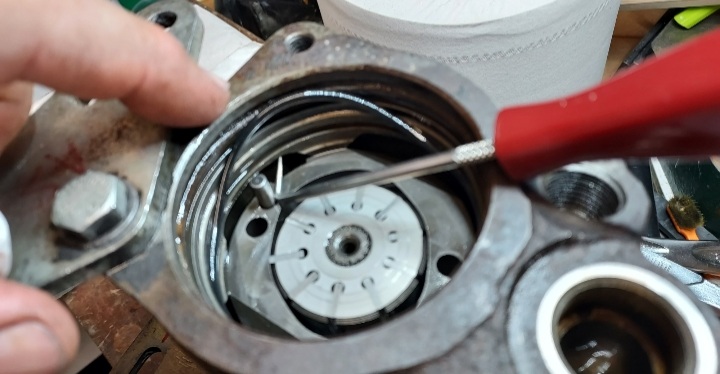

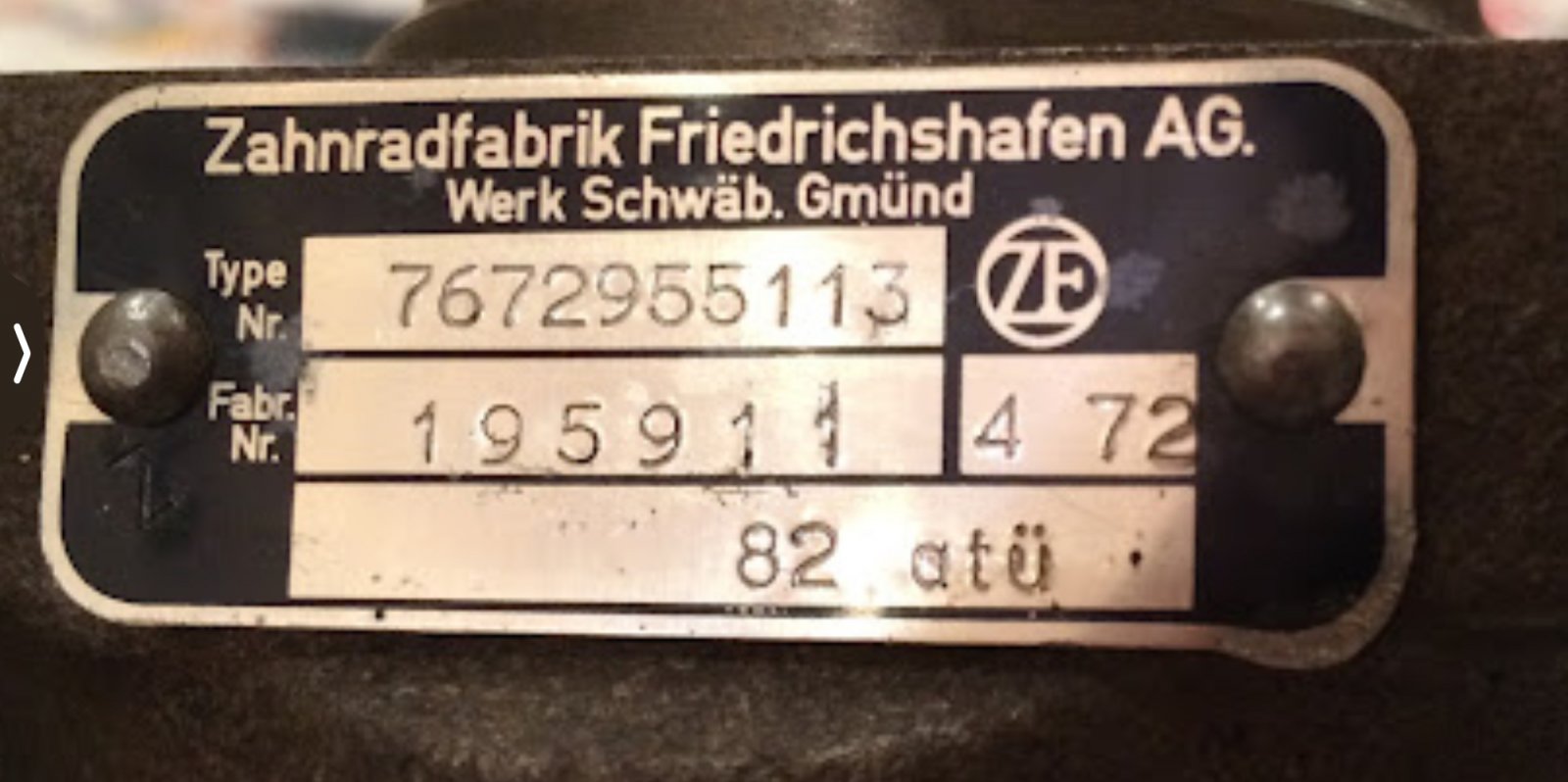

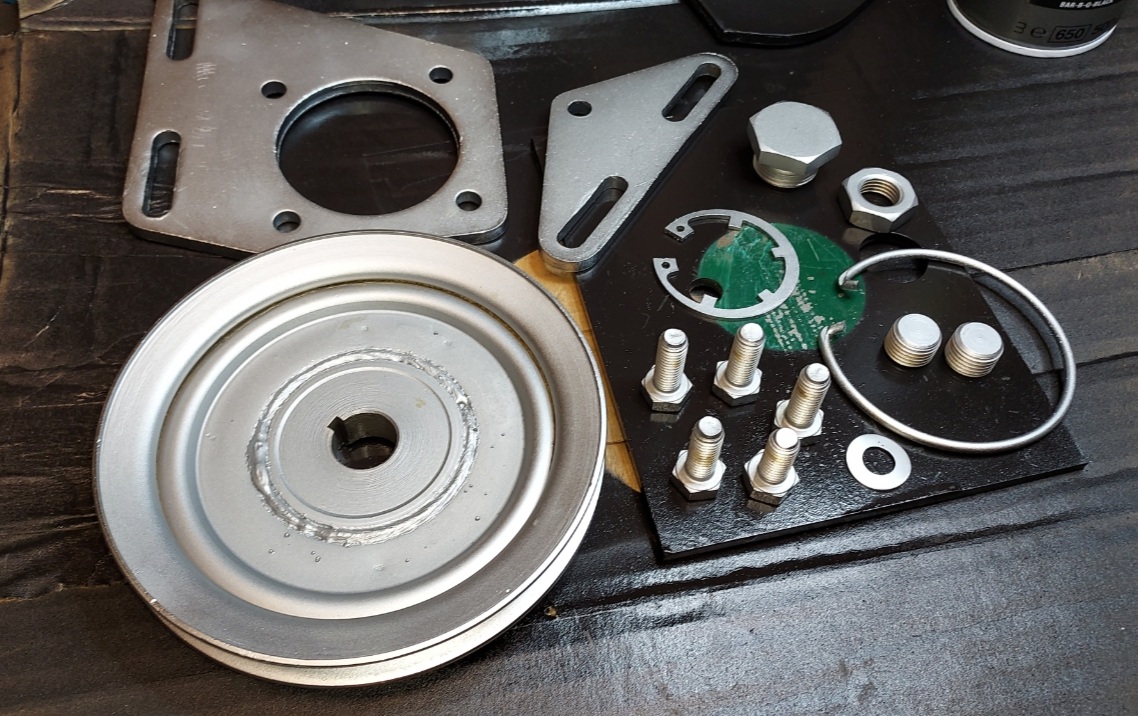

The mighty steering pump...

pressure valve

one oring

this is from 1970

the target…as Steve-in-kitchen demonstrated…

The mighty steering pump...

pressure valve

one oring

this is from 1970

the target…as Steve-in-kitchen demonstrated…

Last edited:

Curious production number high increase in only 2years

older,

newer, 72, less than 2 years, number is increased in 100.000

older,

newer, 72, less than 2 years, number is increased in 100.000

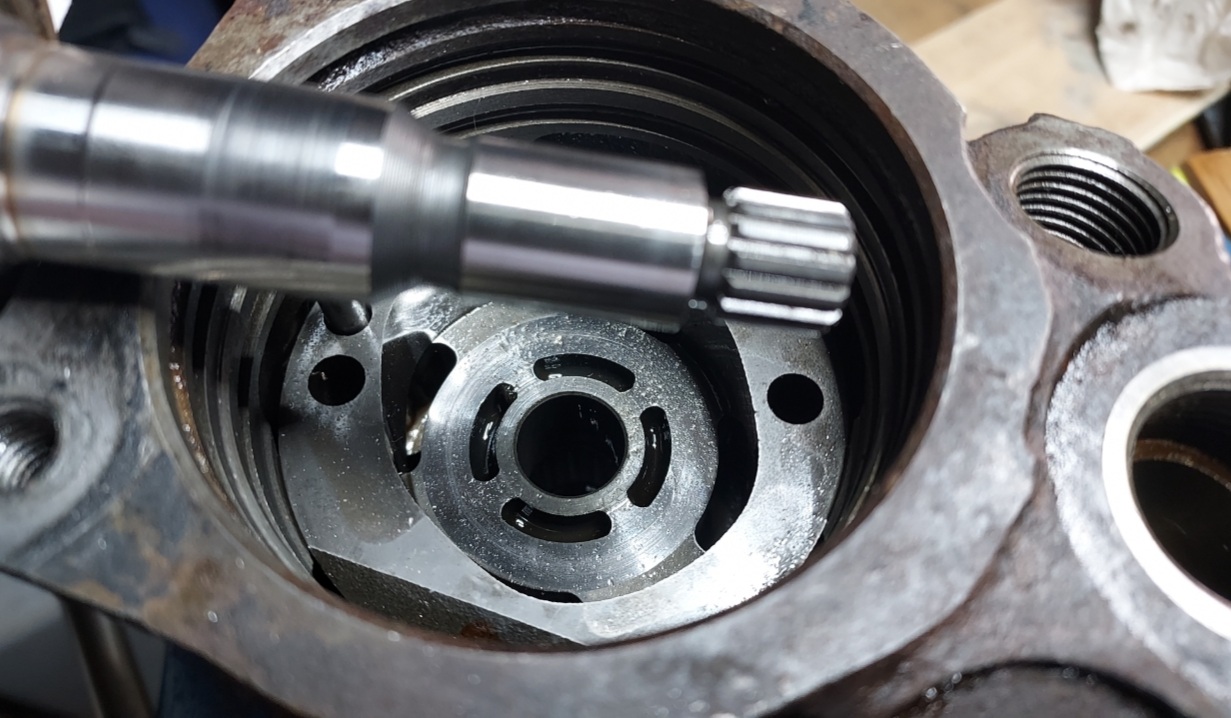

some more...

careful, this will fall down when upside down

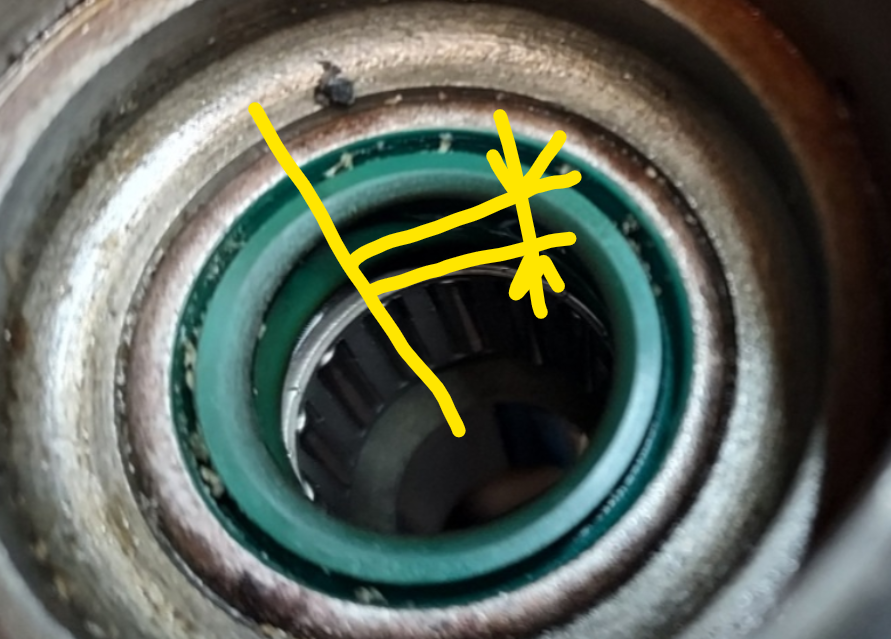

the seal sits flush with the wall, see the needle bearing below

to extract this one use a proper stick and hit from the other side

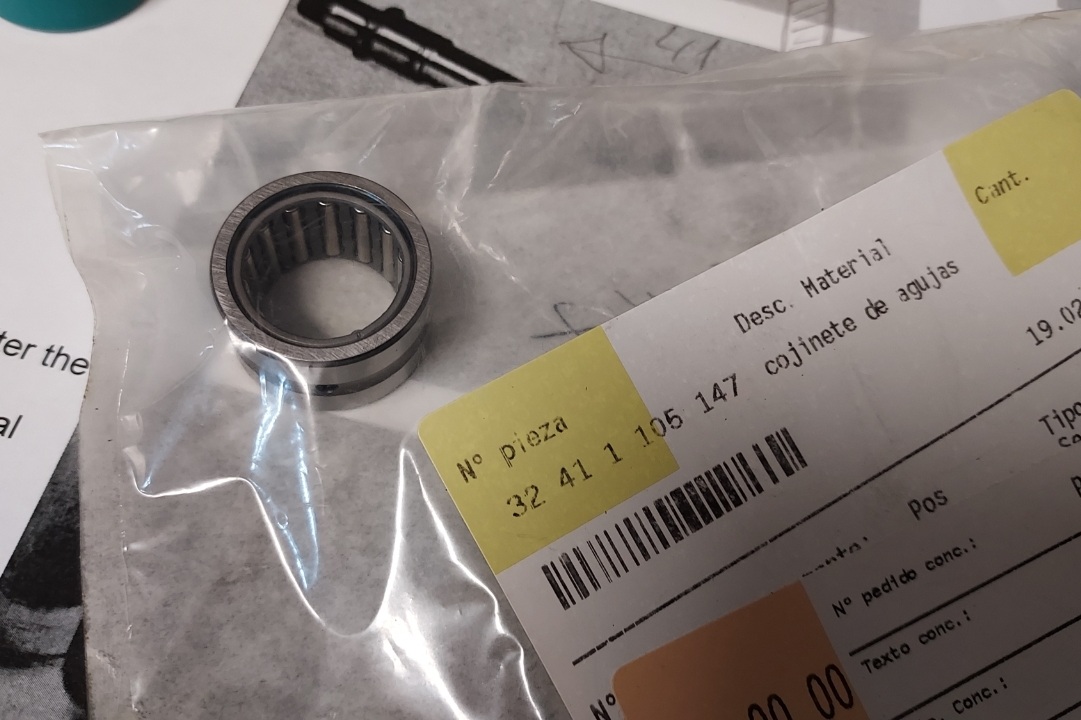

to extract the needle bearing and the seal use a 18mm hex vase, and a proper tool to not hit it with a hammer

this setup works very smoothly

if you place a piece of paper pressed upon the cage, the needles will not fall down

careful, this will fall down when upside down

the seal sits flush with the wall, see the needle bearing below

to extract this one use a proper stick and hit from the other side

to extract the needle bearing and the seal use a 18mm hex vase, and a proper tool to not hit it with a hammer

this setup works very smoothly

if you place a piece of paper pressed upon the cage, the needles will not fall down

hi, @Stevehose

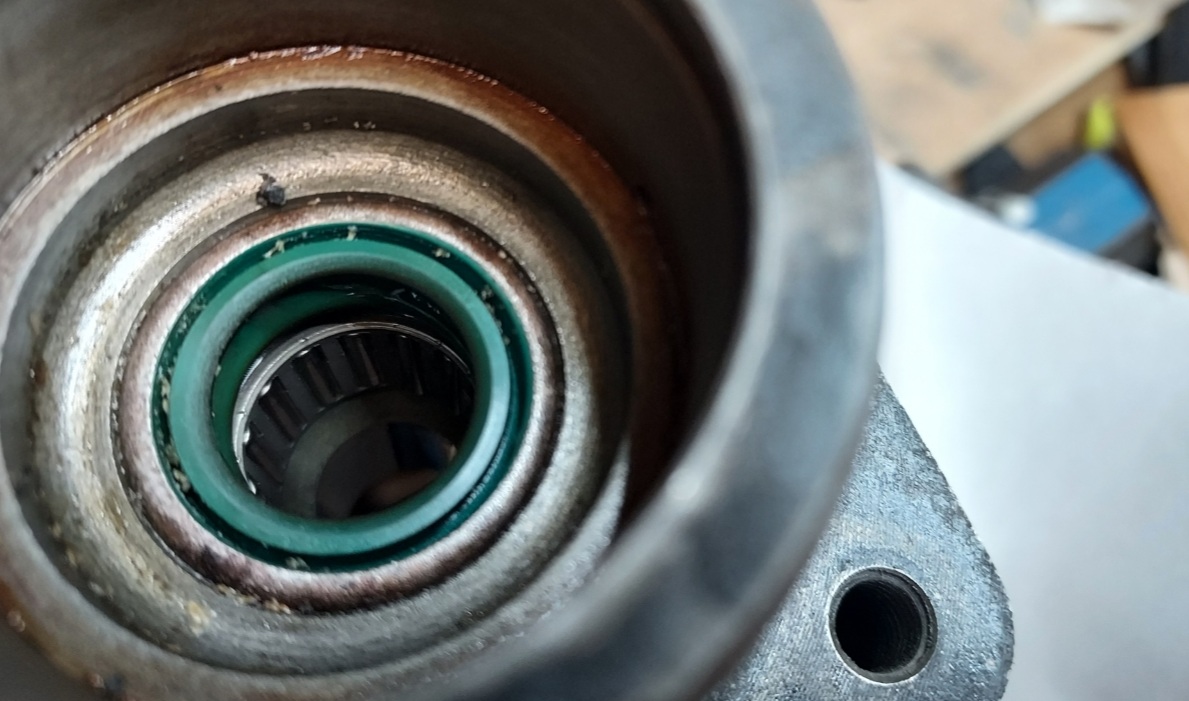

i do have a concern as i found a discrepancy: the position of the saft seal in the steering pump, as i have seen in your pics (see below)

it seems that you put the lip with the spring on top:

but as per my pics on disassembly it is clear that my seal appeared to be mounted just the opposite:

once extrated you can see the seal to identify the sides:

now see the seal and see the spring on the other side

IMHO, you should not tap the rubber side when introducing a seal, as you did (@Stevehose ), that is why the seal has a steel cage to be pushed from that side

comments ?

i do have a concern as i found a discrepancy: the position of the saft seal in the steering pump, as i have seen in your pics (see below)

it seems that you put the lip with the spring on top:

but as per my pics on disassembly it is clear that my seal appeared to be mounted just the opposite:

once extrated you can see the seal to identify the sides:

now see the seal and see the spring on the other side

IMHO, you should not tap the rubber side when introducing a seal, as you did (@Stevehose ), that is why the seal has a steel cage to be pushed from that side

comments ?

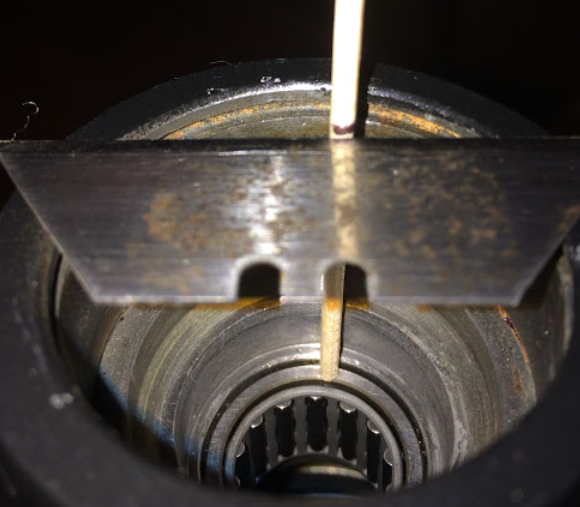

another point @Stevehose

you did a profoundness gauge check

in my case i found the needle bearing to be simply bottomed in place, and found a gap between bearing and seal, see here:

can not tell the relevance

regards

you did a profoundness gauge check

in my case i found the needle bearing to be simply bottomed in place, and found a gap between bearing and seal, see here:

can not tell the relevance

regards

I probably put the seal in backwards unless it happened to be that way upon removal for me, fortunately no leaks and working fine all these years. I did the measurement per the manual instructions and I definitely had room for adjustment before bottoming out. Great pics.

You are right SteveI probably put the seal in backwards unless it happened to be that way upon removal for me, fortunately no leaks and working fine all these years. I did the measurement per the manual instructions and I definitely had room for adjustment before bottoming out. Great pics.

some paint and chroming of the steel bits

some time in the kitchen as Steve did

remove old bearing

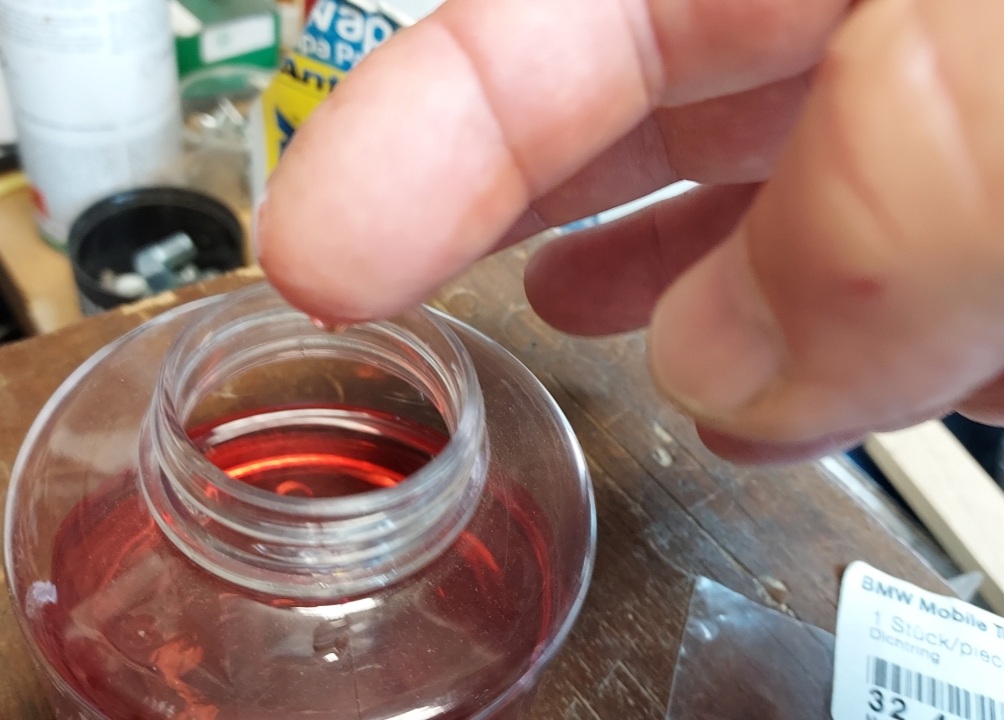

Using ATF oil to help assembly

some time in the kitchen as Steve did

remove old bearing

Using ATF oil to help assembly

Last edited:

Put a drop of atf oil

Comparing old and new seals

this side to hit with the vase

Comparing old and new seals

this side to hit with the vase

Last edited:

Gear box speedo pinion and seal

you probably will remember this pic from @Stevehose

He was the first to tackle this job

so I have done it myself

you can see the old black rubber seal still in its place

the small steel sort of thick washer is out a bit PITA by the way

you probably will remember this pic from @Stevehose

He was the first to tackle this job

so I have done it myself

you can see the old black rubber seal still in its place

the small steel sort of thick washer is out a bit PITA by the way

Removed the seal using a special tool

Seal was destroyed,

Use washers and pressure to instert the new seal,