assembly almost done, some facts and tips

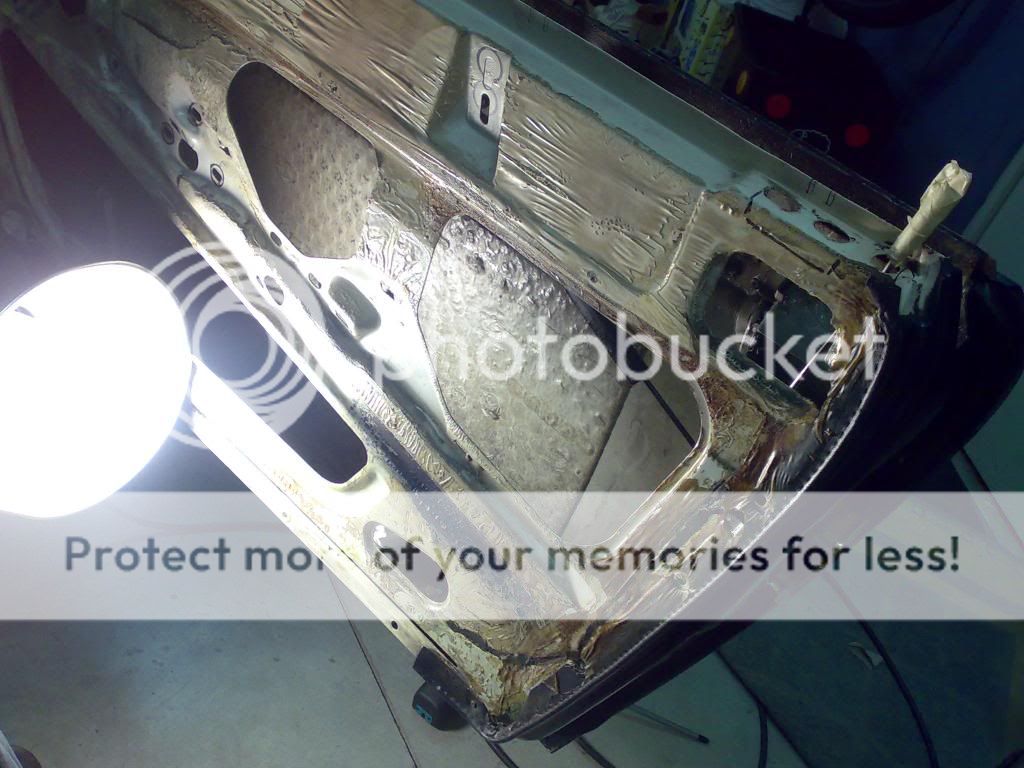

the assembly of all the elements is not difficult, but there are two important aspects,

first of all is the need of a sequence, some elements can be assembled, others can be compromised and impossible to introduce once other parts are mounted

second, is the inherent difficulty of the adjustment of all the elements to provide a correct movement and fit of the window

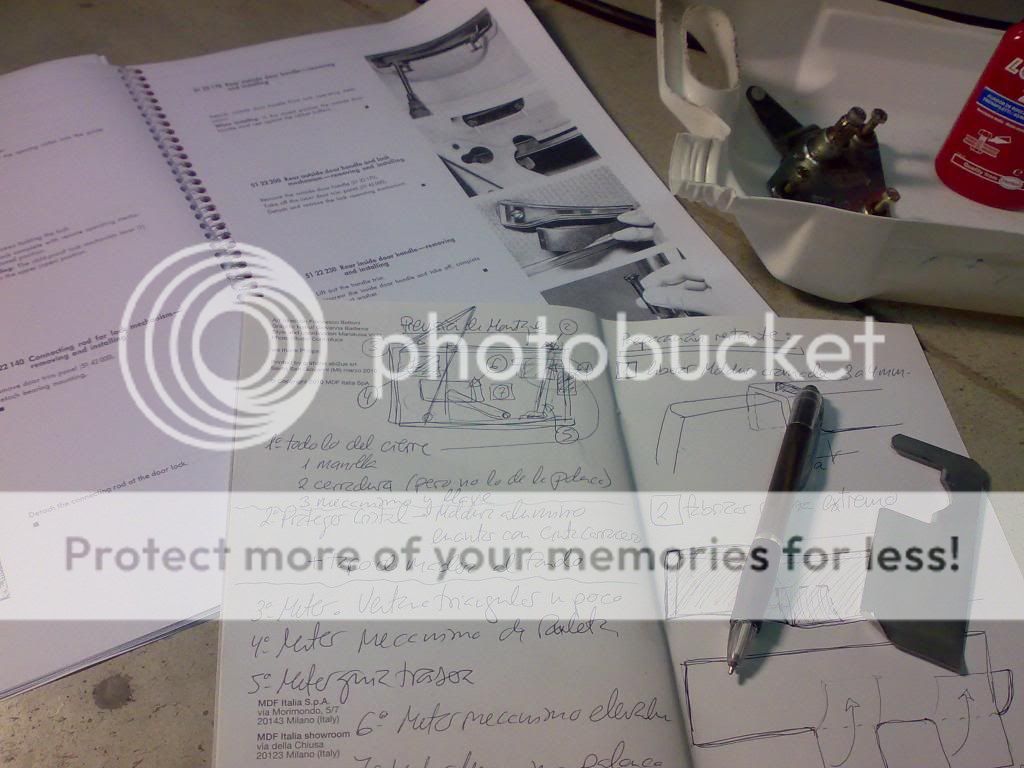

my experience says, that for a completely dissasembled door, the sequence is :

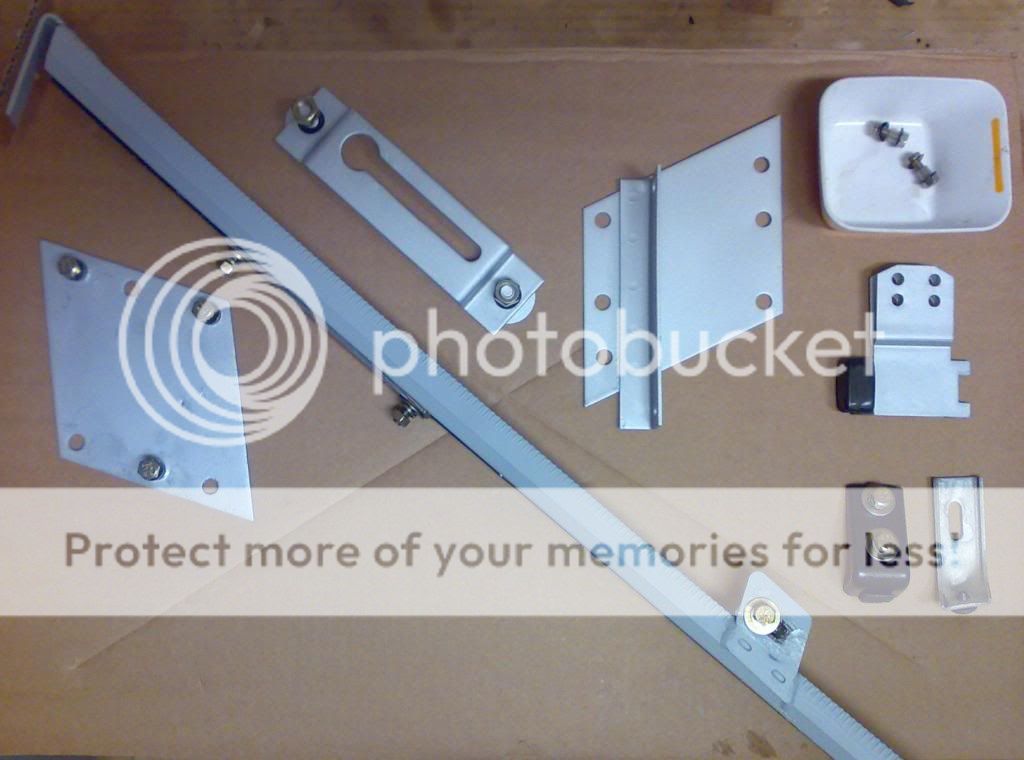

first is the outer handle and its mechanism, then is the door lock mechanism, then the door lock itself, following this sequence it is straight forward, but one last issue, the final adjustment of the outer handle must be done at the end of this block of parts

(do not assembly now the inner handle mechanism, this IMHO is the last mech to be assembled in the whole door)

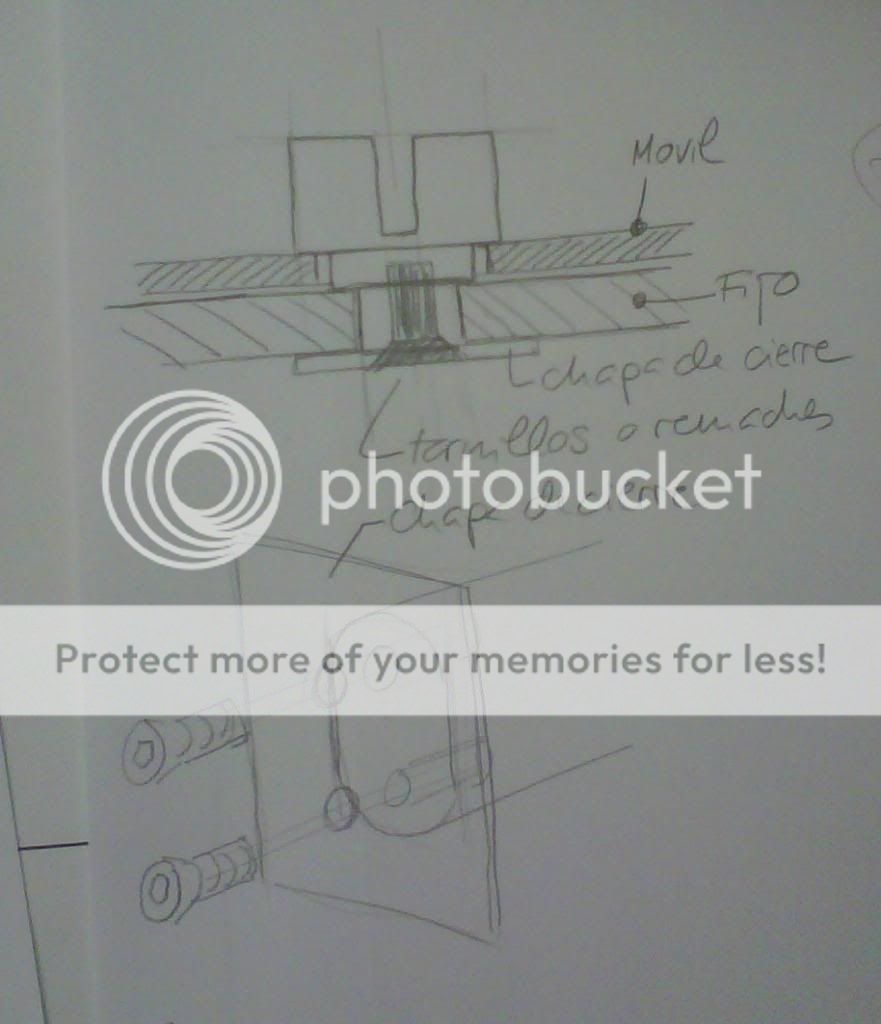

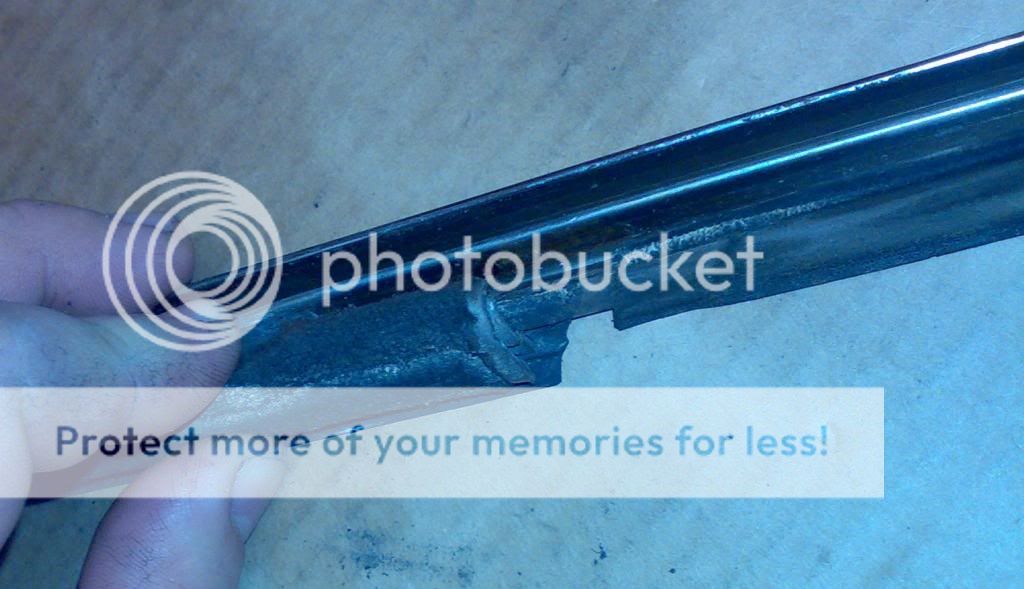

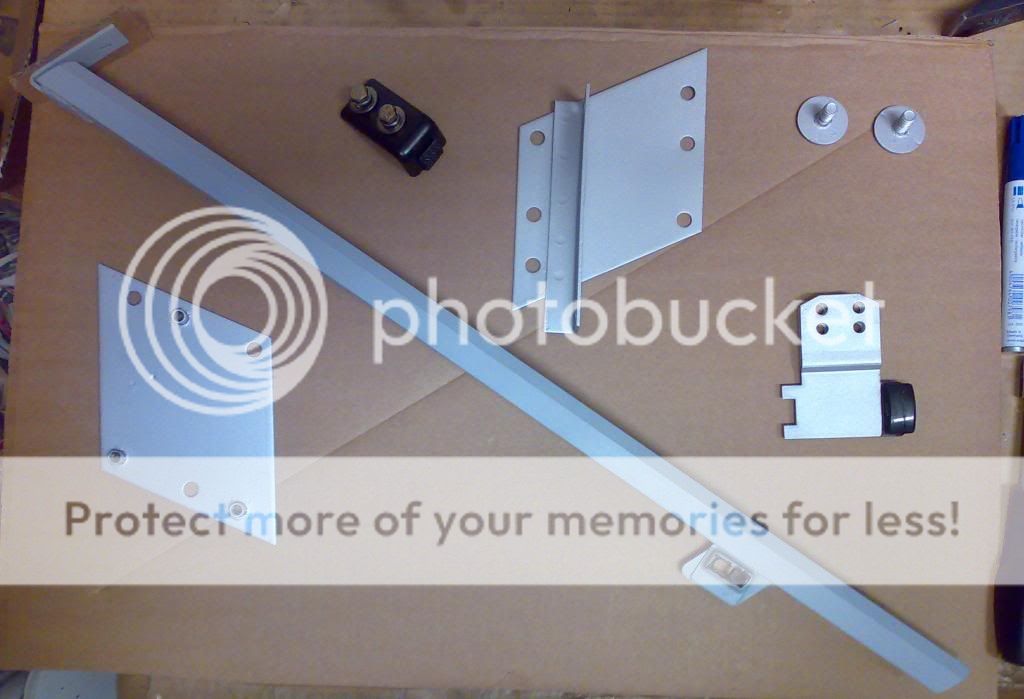

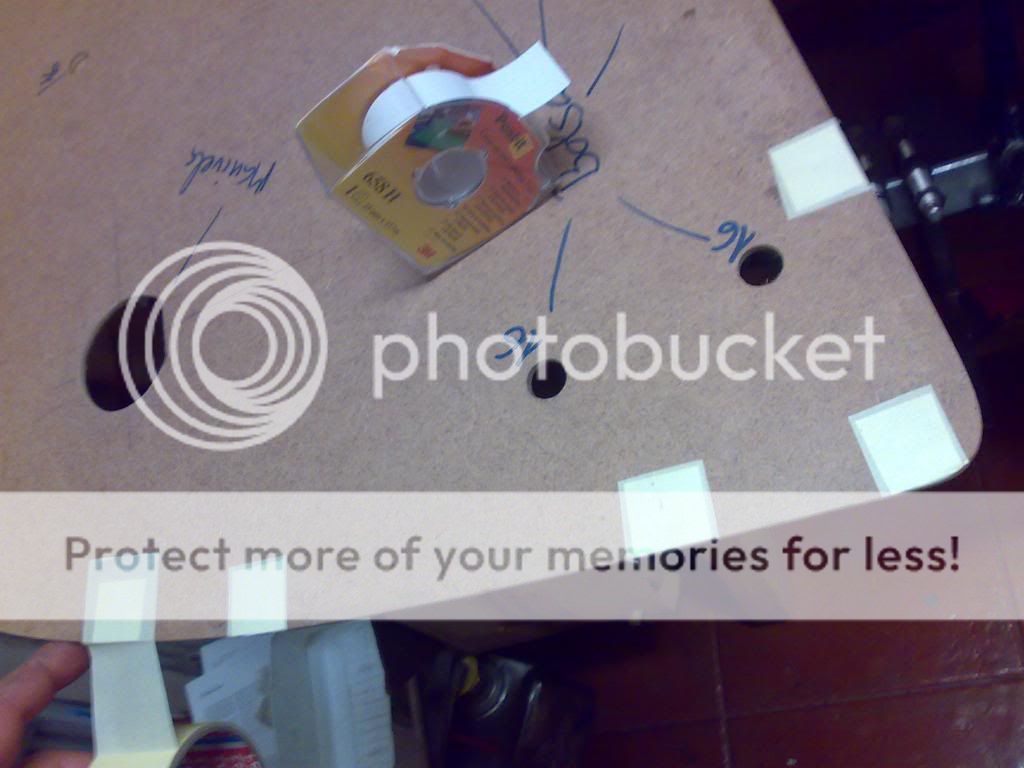

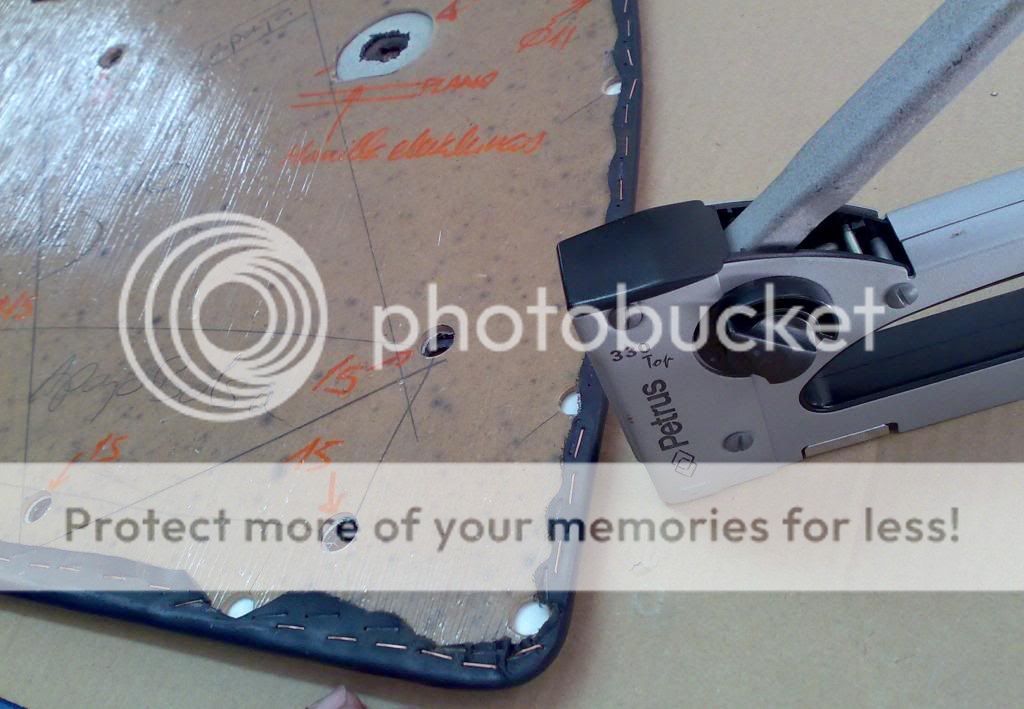

when this is finished, the next part is the triangular vent window, the complete frame, place it in its position , but do not tighten the nuts and bolts

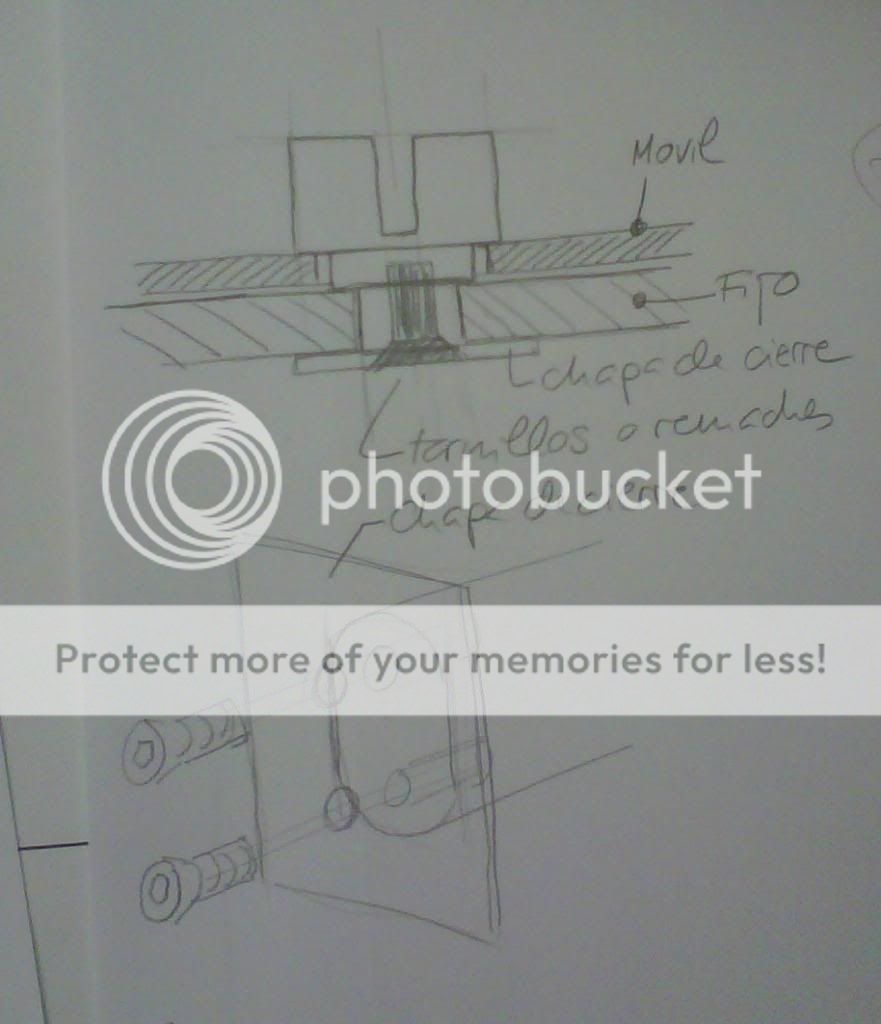

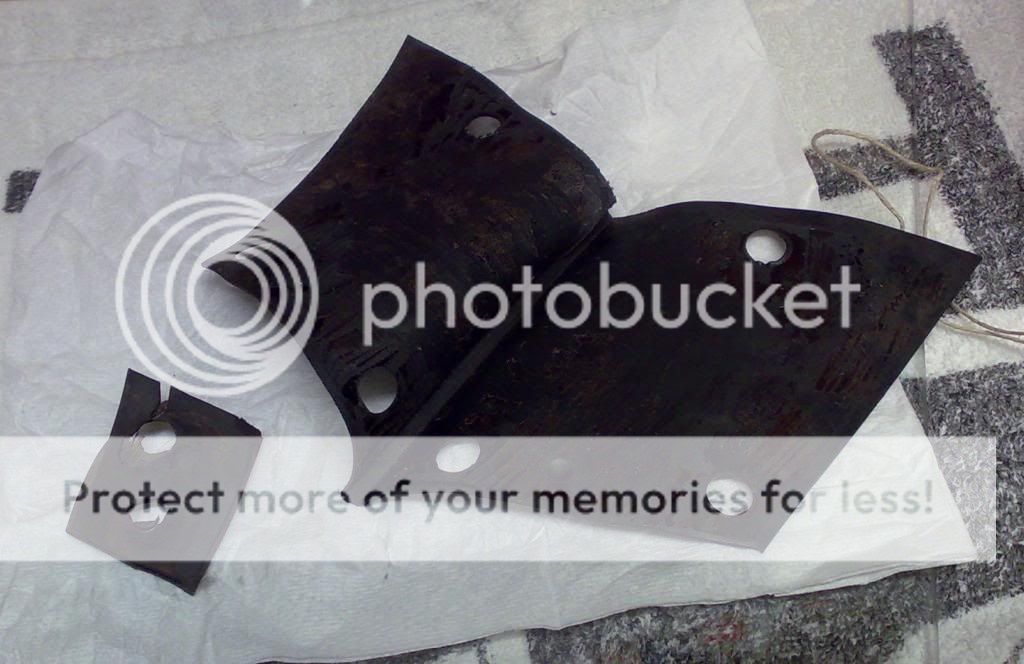

then the window glass itself, but to introduce it you will have to remove the big support that move along the rear guide,

then introduce the rear guide, and with this part in position, introduce and fix the above mentioned support,

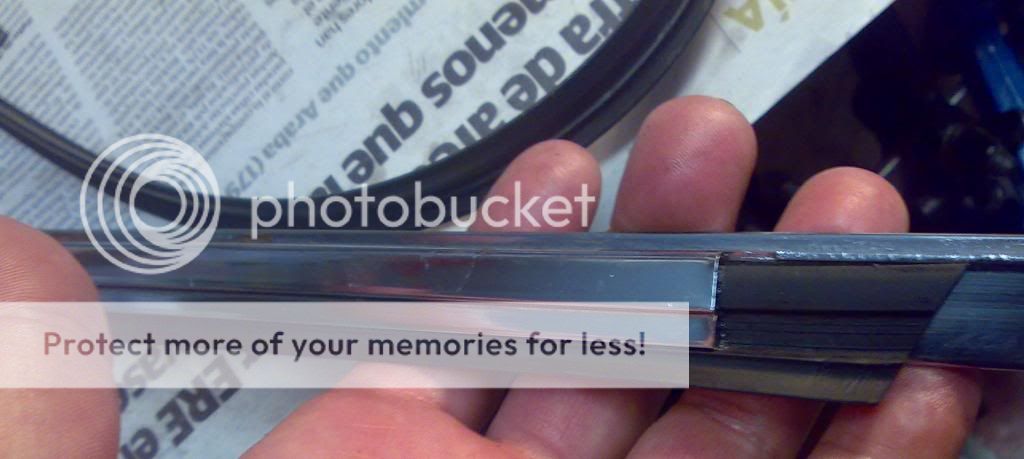

now introduce the vent window mechanism from under

before any window adjustment, introduce the window lift mechanism, the adjustment will be influenced by the whole system

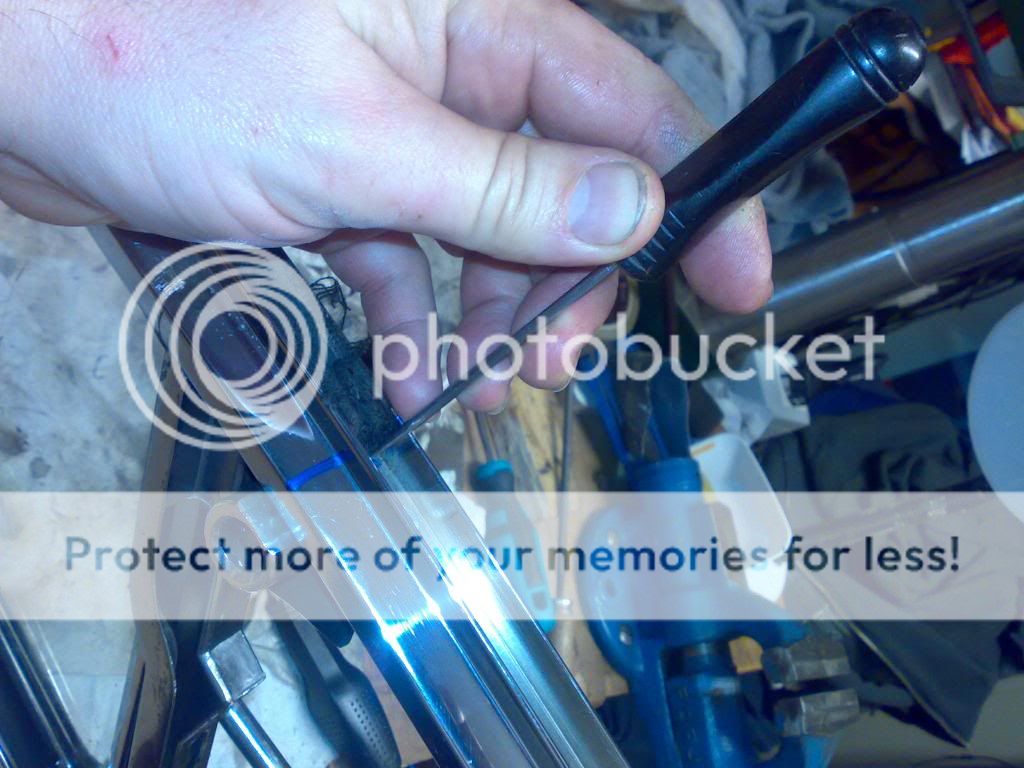

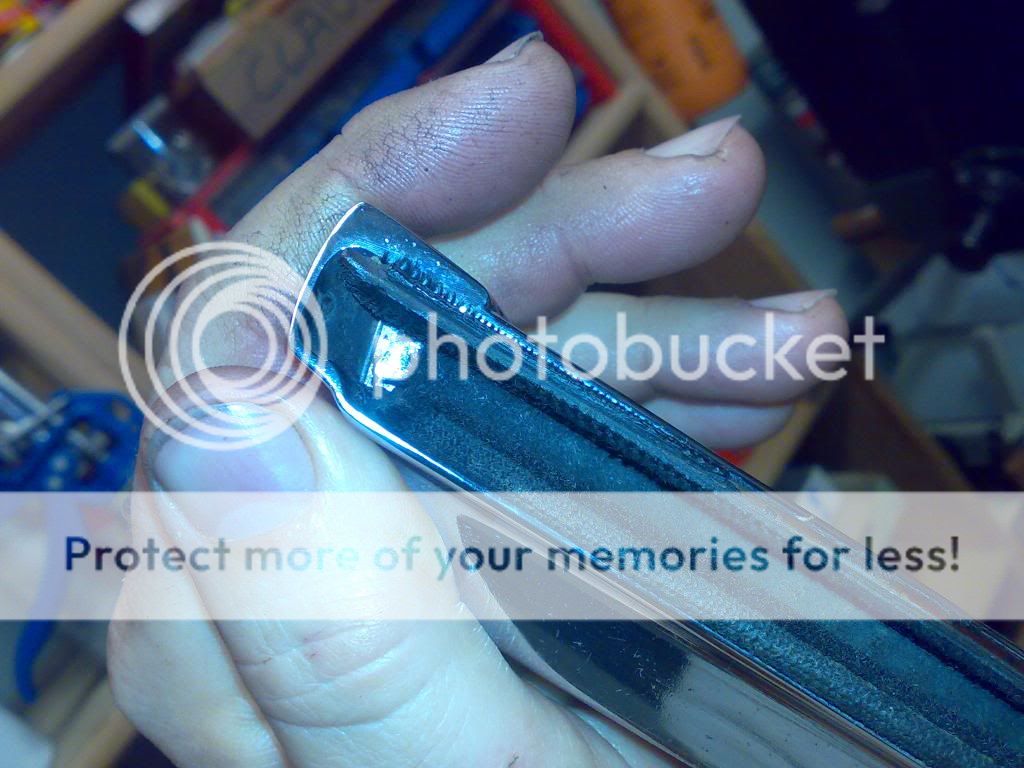

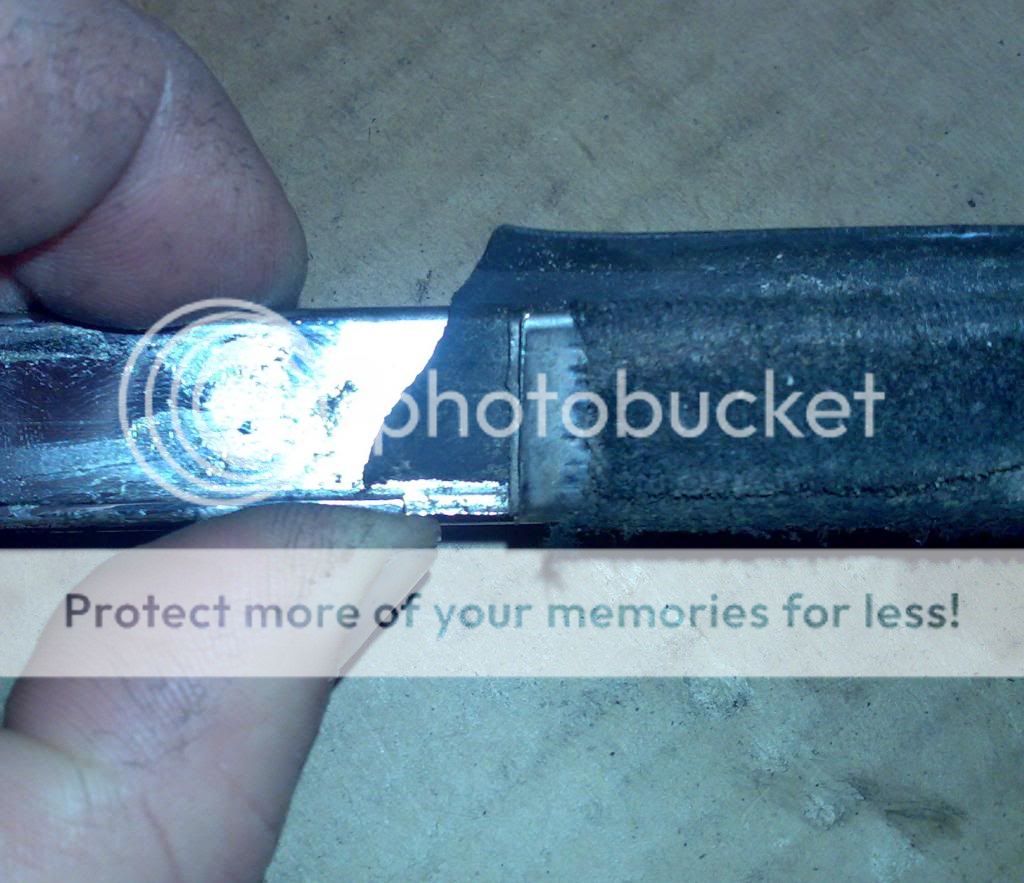

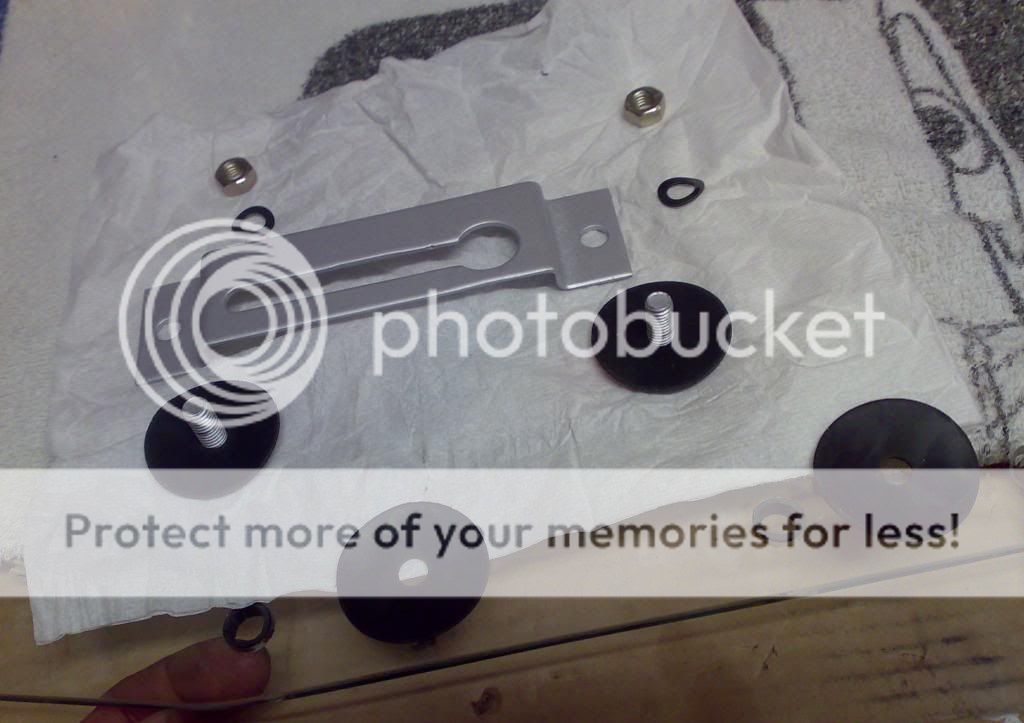

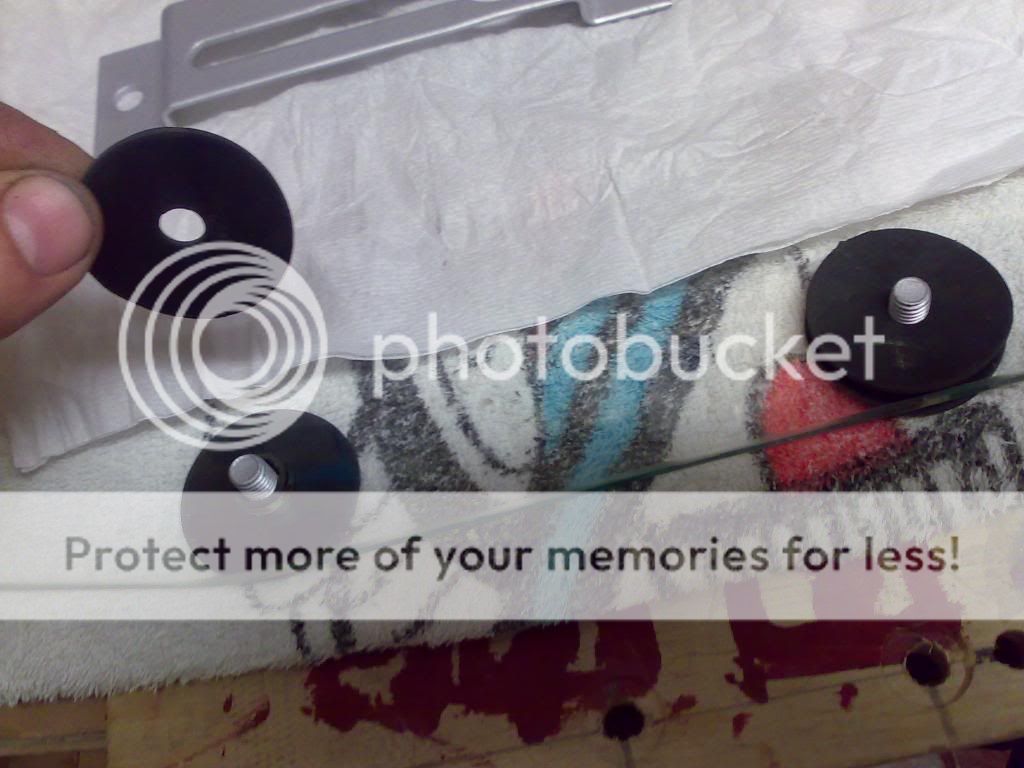

in my experience, the adjustment is too complicate, not only you will have to compensate the paralelism of the guides, but the position of the mentioned big support within the window glass is also an aspect to be considered

it is also critical the position of the lower supports of the guides, these two points, one in the front and the other in the rear are the responsibles for the top of the window to move inwards or outwards

this adjustment is critical for a good closing of the front and rear windows one against the other, but is critical for the closure of the triangular and front window against the door top frame too

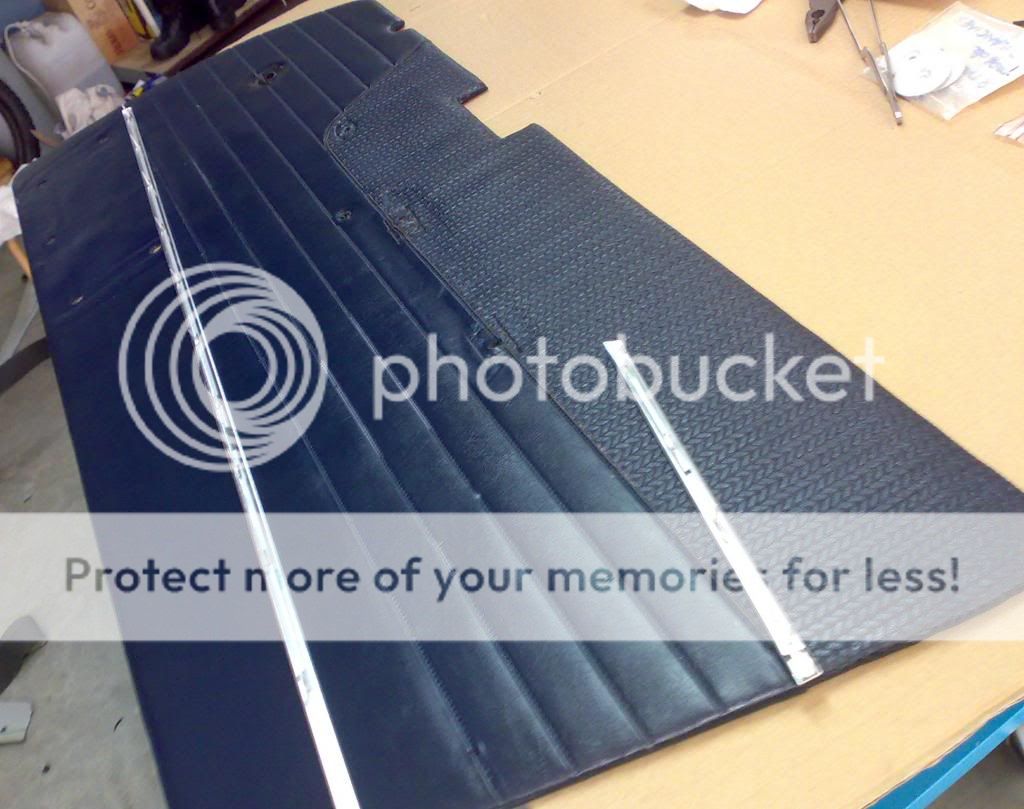

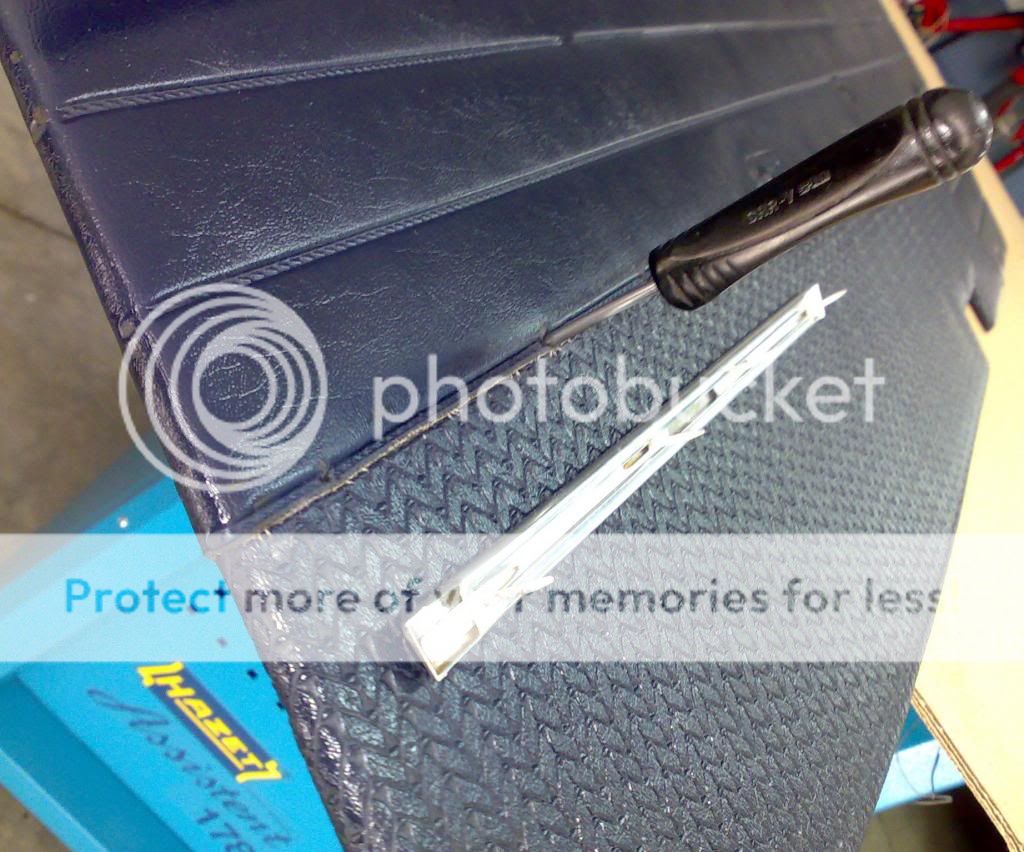

i am still preparing an alternative rubber part for the NLA one in the weatherstrip, so my experience finishes here, but i assume that now i will have to assembly the outer weatherstrip, then the inner one that carries the wood trim part too

then the door foil (this will not be done for some weeks while testing that all works correctly)

then the door panel, and then the arm support, the door handle, the window lifter handle, the ashtray

....und das ist alles !