The hood mechanism failures are due to a few different reasons, so it doesn't mean that you should replace the whole assembly if it doesn't work properly. Getting it functional again can perhaps also be fixed by replacing only the failed subcomponent. For anyone considering making parts, perhaps half of the problems can be solved with a fresh single part only.

First problem is associated with the welds breaking between the (thin!) tube and it's left and right half arm parts. This is easily fixed with a fresh weld, or better: with a new steel tube with it a bit thicker wall section. If you choose something a bit thicker, it isn't hard to weld in. But yes, for someone looking for a solution without welding it would be good if the tube+2 arms could be made available.

pic of failed part from

@Stevehose from this thread:

https://e9coupe.com/forum/threads/hood-support.23738/post-175119:

welded up:

secondly, the small L-brackets used on E9 are flimsy and under-designed. ( E3 is different; stop is integrated). As a result the 'finger' often bend out. Some members have made them themselves in a thicker steel. This could be an easy laser cut upgrade part.

replacement:

Link to thread on replacement parts:

https://e9coupe.com/forum/threads/hood-torsion-bar-repair.34893/post-326659

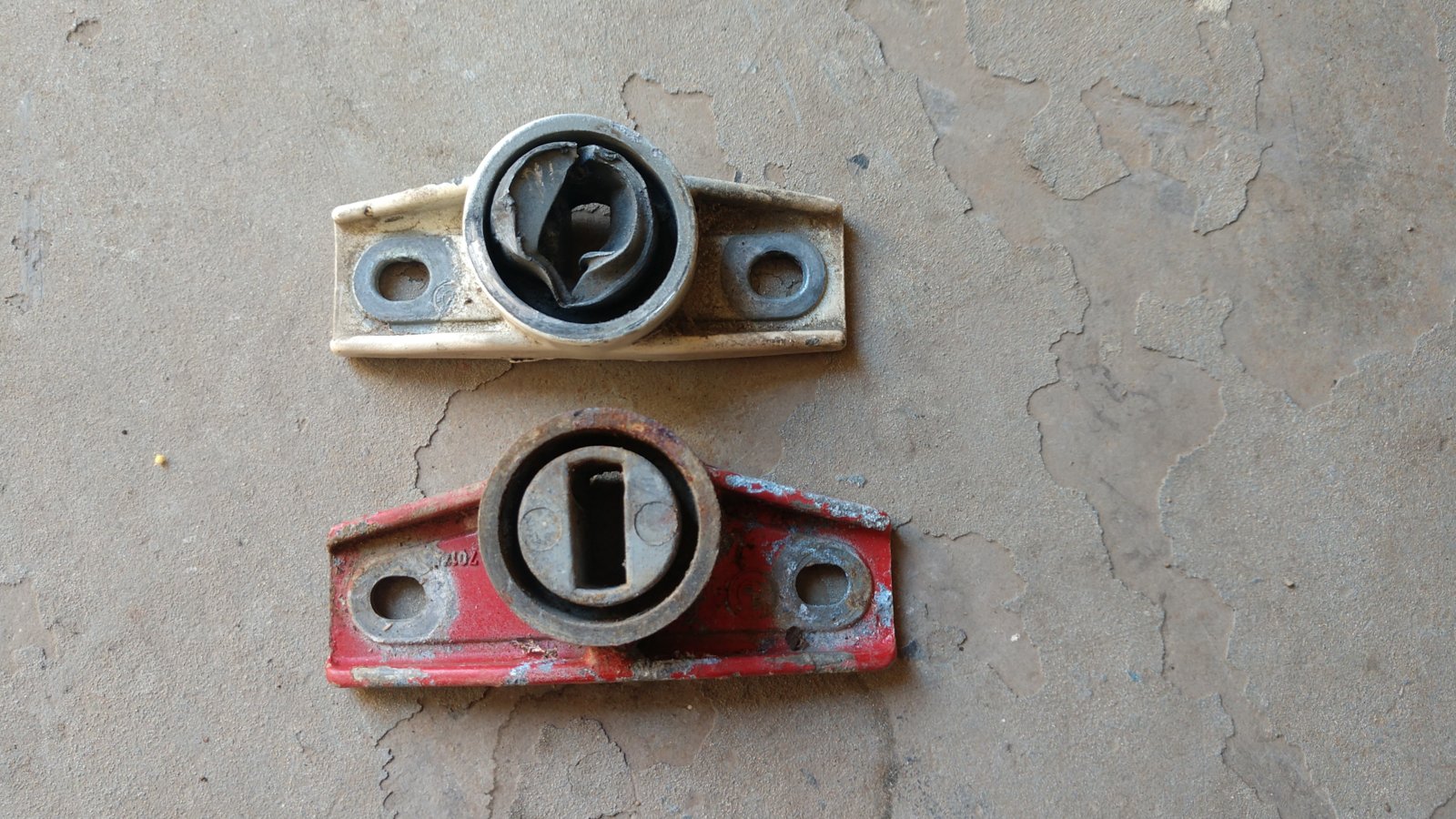

another failure is this soft metal part that locks one spring end; it deforms for some reasons. Good example of the deformation is shown in the pics of a 2002 part, as documented by

@dang on the 2002 forum. The e3/9 part fails in a similar manner.

-e3 part failed vs almost identical fresh 02 part (thanks Dang for that all important attention to details)

E3/E9 parts:

Several weeks ago I reached out/begged to those on the site if they any experience with hoods that would not close because of torsion bar hinges that would not fold neatly under the hood and instead collided with the top of the fender. Thanks to Bill Williams and Michael Hollister (Dubois) and sl...

www.bmw2002faq.com