Belgiumbarry

Well-Known Member

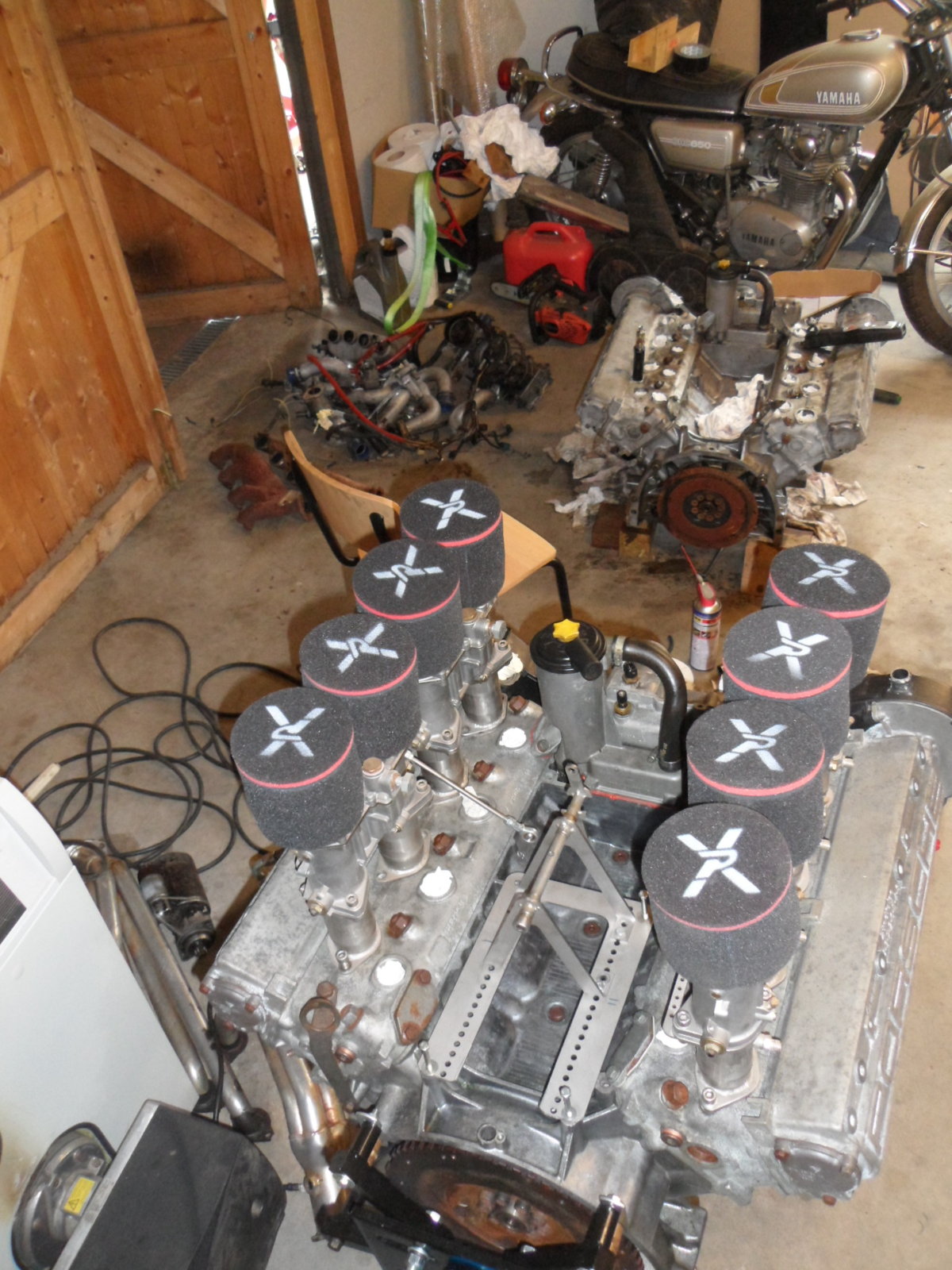

working on the engine build i got pitty for my spare engine , laying in the shed.... which i hauled myself out of the grey race car 10 years ago , running good. So i pulled it inside and demounted all oem injection stuff, which i will never use. Got if filled with a mix ATF/diesel .

This is the oem "300 HP" M28/12 , my build now is the M28/22 "310 HP" , it has slightly more agressieve cams.

This "spare" was used in a few track races and i see indeed some porting on the inlets. ( PO crashed his race 928 and used this one shortly )

It has been here all "BMW" the last years, now my garage seems a Porsche shop

I can mount it later on the engine stand and have a perfect model to design a four 45 DCOE Weber setup... wish i had it build like this in the first place ( instead of the IDA48's ) . With the long cross-over tubing that must be great for torque ! and keeps everything under the hood. This example i found on the net... at least it is possible

This is the oem "300 HP" M28/12 , my build now is the M28/22 "310 HP" , it has slightly more agressieve cams.

This "spare" was used in a few track races and i see indeed some porting on the inlets. ( PO crashed his race 928 and used this one shortly )

It has been here all "BMW" the last years, now my garage seems a Porsche shop

I can mount it later on the engine stand and have a perfect model to design a four 45 DCOE Weber setup... wish i had it build like this in the first place ( instead of the IDA48's ) . With the long cross-over tubing that must be great for torque ! and keeps everything under the hood. This example i found on the net... at least it is possible