Hi Merdad,Hi,

Are you happy with Autospark wiring?

We are thinking of getting an order to them. Takes 8 weeks to make since they don’t have a LHD system available.

Thanks

Merdad

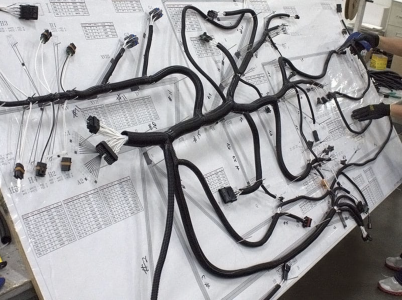

Yes, very good quality work to my opinion. I haven’t put the harness in my car yet, so need to experience how the lengths of the wires are, but they simply copy the harness. In all honesty I also didn’t check all color codes but what I saw it was copy exact (need to verifiy). But look and feel, connectors, plugs, everything looks well made.

The FI harness was also nicely done. If you want more pictures of it I can make a few this week and share.