You guys are so impressive. I needed a new rain barrel stand, so pulled some rusty old gas pipe & scraps from storage to cobble this together. And I finally found a use for the Bilstein-supplied rear rubber mounts. Yes, Girls & I just finished re-watching Marvel movies. Iron Man II will be the front end dolly for when I pull the sub-frame.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

what mechanical works are you doing now that you are locked in your house

- Thread starter deQuincey

- Start date

Some great grains there. You may consider contacting Ben Wilborn. He is a luthier of some repute and he may be interested in what you have. He made a guitar for me using Cuban mahogany and redwood cedar,Sorry for the late reply - but I had to get a few photos to accompany the response. While I readily pitch construction lumber cut-offs, I do have a habit of keeping "good wood" Here's some photos of what I am storing at the house right now. The rack includes prefinished (by us) cedar for the house, about $3,000 worth of perfectly straight grained African mahogany that was ear marked for the wooden boat project, and other pieces from my luthier days. I may use some of the straight grained mahogany for the e9 dash and doors - we'll see...

View attachment 91276View attachment 91277View attachment 91278

Last edited:

Had a scene out of the Simpson's play out with my motorcycle trailer. DOH! Spent quite a bit of time pondering how I could slide my folding aluminum ramp underneath the trailer in one smooth motion. Made an angle iron door that gives me room when folded down, and takes up the space when folded up and locked.(This trailer is parked in a VERY sketchy area) Needed a halfway point to use as a guide and lever to keep it sliding straight in and positioned into the front part that holds it up and keeps it from sliding further forward. After tack welding it in place, I took it outside and flipped it over, trial fit the ramp and realized instantly I hadn't thought about the space needed for the axle to absorb bumps with the 600 pound load on top. I'd have an inch of suspension travel between the axle and the ramp before even loading it up.. I clearly have a stunted thought process! Hope it is not age related.

It is not all a loss though. The ramp slips in place with great ease...and I suppose I can store the damn ramp there when not using it, rather than in the over crowded shop in the fast degrading neighbourhood. Now have to think of a top side storage system for the ramp when the trailer is being used with a motorcycle on top. Todays job will be trying to make the trailer harder to steal. Already been two attempts on that ugly piece of scrap if you can picture that.

It is not all a loss though. The ramp slips in place with great ease...and I suppose I can store the damn ramp there when not using it, rather than in the over crowded shop in the fast degrading neighbourhood. Now have to think of a top side storage system for the ramp when the trailer is being used with a motorcycle on top. Todays job will be trying to make the trailer harder to steal. Already been two attempts on that ugly piece of scrap if you can picture that.

Attachments

Had a scene out of the Simpson's play out with my motorcycle trailer. DOH! Spent quite a bit of time pondering how I could slide my folding aluminum ramp underneath the trailer in one smooth motion. Made an angle iron door that gives me room when folded down, and takes up the space when folded up and locked.(This trailer is parked in a VERY sketchy area) Needed a halfway point to use as a guide and lever to keep it sliding straight in and positioned into the front part that holds it up and keeps it from sliding further forward. After tack welding it in place, I took it outside and flipped it over, trial fit the ramp and realized instantly I hadn't thought about the space needed for the axle to absorb bumps with the 600 pound load on top. I'd have an inch of suspension travel between the axle and the ramp before even loading it up.. I clearly have a stunted thought process! Hope it is not age related.

It is not all a loss though. The ramp slips in place with great ease...and I suppose I can store the damn ramp there when not using it, rather than in the over crowded shop in the fast degrading neighbourhood. Now have to think of a top side storage system for the ramp when the trailer is being used with a motorcycle on top. Todays job will be trying to make the trailer harder to steal. Already been two attempts on that ugly piece of scrap if you can picture that.

Hi @Nicad,

Before you fab up anything else. Consider flipping the axle so it is under the leaf springs. This is a common modification for tent trailers to gain ground clearance. It is also common in the off-road world on older vehicles, known as an SOA (spring over axle) conversion. When you have power to the axles you need to worry about axle wrap. Not so much with a trailer but read about trailer mods before moving forward.

Most solid trailer axles have a bow in them to straighten the axle under load. That means that you will need to flip the spring pads so the bow isn’t upside down.

Anyway, that would likely give you 5” of travel instead of 1”. Your ramps may be too short though.

Thanks for the suggestion Markos, but I think I am done with this part. I'd have to redo the fender mounting bit, which took an agonizingly long time to do. And I'd hate the Hillbilly look. If anything, I'd like it to be a low rider. Wish Uhaul would just sell one of their excellent motorcycle or utility trailers when they are done with it. U Haul does not ever sell their old trailers. They are an incredible deal to rent. $10.66 USD per day up here.Hi @Nicad,

Before you fab up anything else. Consider flipping the axle so it is under the leaf springs. This is a common modification for tent trailers to gain ground clearance. It is also common in the off-road world on older vehicles, known as an SOA (spring over axle) conversion. When you have power to the axles you need to worry about axle wrap. Not so much with a trailer but read about trailer mods before moving forward.

Most solid trailer axles have a bow in them to straighten the axle under load. That means that you will need to flip the spring pads so the bow isn’t upside down.

Anyway, that would likely give you 5” of travel instead of 1”. Your ramps may be too short though.

Thanks for the suggestion Markos, but I think I am done with this part. I'd have to redo the fender mounting bit, which took an agonizingly long time to do. And I'd hate the Hillbilly look. If anything, I'd like it to be a low rider. Wish Uhaul would just sell one of their excellent motorcycle or utility trailers when they are done with it. U Haul does not ever sell their old trailers. They are an incredible deal to rent. $10.66 USD per day up here.

I rent uhaul trailers a few times a month for most

of the year. I get the 5x9 open trailer for $20. They are so cheap that I have no desire to own/store one, or to buy a pickup truck.

I do have a habit of keeping "good wood" Here's some photos of what I am storing at the house right now.

I don’t see ‘sticker’ between the boards. How do you maintain uniform moisture content?

Jihn

Great question. On that wall there is a collection of cedar that has been finished on all sides with two coats of Sikkens high performing finish. I don't worry about it (see below). There's also the African Mahogany - a fairly hygroscopic wood within the mahogany family. All of this wood has been dried down to an extremely low (luthiery level) moisture content. Same for the remaining scraps of guitar wood that I am hanging onto (I sold most of it already). The space is temperature and humidity controlled. It ranges between 30% and maybe almost 40% relative humidity with temps of mid 60's to low 70's all year. The concrete walls are water proofed and insulated on the outside surface, and the floor has radiant heat. The environment in that shop is very tightly controlled. The wood, as a result, maintains an EMC of between 6% and 8%. It is at that level already, and it doesn't change in this environment. Sticking would be beneficial if the humidity/EMC had the propensity to change. That would potentially allow non-uniform movement (warping) in the boards as some areas would be exposed to the change while others would be more protected within. Fortunately, I don't see that here. Also, the end grain of some of the critical wood is waxed to prevent checking.I don’t see ‘sticker’ between the boards. How do you maintain uniform moisture content?

Jihn

I will say, there is some wood on that wall (also African Mahogany) that is already warped. I received a batch of wood that was re-sawn in poor conditions and the wood did what it wanted. That specific wood is for an office project that I may never get around to. But you probably pick it out on the wall, as it is the wood that is not sitting flat and neat.

If only we all had such a well designed wood shop. It gives me inspiration for building my shop, after I retire.

Do you think we would like to retire to what we wanted to do all along?

In my case the dream would be to have a 600 sq mtr workshop set up with woodworking and metalworking equipment for project building, a separate space for cars ( of course ), and a lounge / kitchenette area for when friends are over. If you wanted to find me you'd know where to look.

In my case the dream would be to have a 600 sq mtr workshop set up with woodworking and metalworking equipment for project building, a separate space for cars ( of course ), and a lounge / kitchenette area for when friends are over. If you wanted to find me you'd know where to look.

Last edited:

This weekend I am refreshing the finish on my patio furniture. Two more chairs to tape. Ugh I hate prep work!

Edit: Painted. Two more swivel chairs to prep and need to spray the underside of the four fixed chairs. I’m using the ACE ripoff of hammered paint. I love hammered paint because it is very forgiving. The spray pattern on the ACE paint is terrible though.

Also, I picked up a TIG welder so I am wiring a 50a 240v receptacle. I already ran the wire to a gang box when I did my garage. Already half-done but I need to move my compressor.

Fresh Argon. I already tipped the full bottle over once so I tucked it in nicely First project will be a cart.

Edit: Painted. Two more swivel chairs to prep and need to spray the underside of the four fixed chairs. I’m using the ACE ripoff of hammered paint. I love hammered paint because it is very forgiving. The spray pattern on the ACE paint is terrible though.

Also, I picked up a TIG welder so I am wiring a 50a 240v receptacle. I already ran the wire to a gang box when I did my garage. Already half-done but I need to move my compressor.

Fresh Argon. I already tipped the full bottle over once so I tucked it in nicely First project will be a cart.

Last edited:

With all historic racing events cancelled till through June, I’ve been feeding my old car addiction doing weekend drives with a few other old car enthusiasts. We practice all recommended covid-19 safety measures like air hugs and standing at least 6 ft apart while taking a leak in the woods.

In the evenings I’ve been working on the Italian version of the tii.

John

In the evenings I’ve been working on the Italian version of the tii.

John

Markos, what a coincidence. I also picked up a second hand TIG and am trying to get good with thin Aluminum.

John

John

I hope you were careful to not cross streams in the woods there.With all historic racing events cancelled till through June, I’ve been feeding my old car addiction doing weekend drives with a few other old car enthusiasts. We practice all recommended covid-19 safety measures like air hugs and standing at least 6 ft apart while taking a leak in the woods.

In the evenings I’ve been working on the Italian version of the tii.

John

View attachment 93329View attachment 93330

View attachment 93335

View attachment 93336

That's the first time I've seen pictures where I could go in and edit them in the post. So, clockwise from the top - Moved the cars to Uzbekistan, topiaried the trees to look like urinals, resized the sticker so that it covers the entire inside of the trunk lid and finished off the interior in faux Leopard skin throughout.

Let me know when you have had enough of driving around in Uzbekistan and I'll bring you back.

Last edited:

I have a very Nice Tig, but don't have the room yet to properly set it up at a table, so just stick with Mig for now. I do love my Mig welder. (Miller 211) With a spool gun it does some decent but sloppy Aluminum welds. Hopefully one day I get the hang of Tig....just like one day I learn how to use an old lathe I bought from a used tool place and took apart to repaint years ago. (Standard Modern, made in Toronto, which used to be in the High school system when they taught youth how to do stuff). Ultimately I am quite intimidated by lathes. Enjoy your two Tig welders and developing the skillset to use them. Hopefully you have a metal saw that makes cutting up stuff easy. (I want a dry cut saw).

I spent the last two days in mud under the cottage with about 3.5 feet of clearance. After given the Green light to leave the city by our Governing political Masters I came North with my daughter to find out that the water system which I had drained (Thought I did anyway) suffered quite a bit of damage over the winter. It seems there were two drains I failed to notice under the place which involves crawling through mud to get to. This was the first year I winterized the place as usually a local plumbing company comes and shuts it off in the fall and turns it on in the spring. Seeing how they charge plumbers rates plus the Cityot tax (City Idiot, also know as the 416 tax) I decided with Youtube videos I should keep the money and also be 100% self reliant up here. When I informed the plumbing company late in the season that I was shutting the place down and staying longer than usual, they said with a bit of a threat that should I have problems with the system they would not be able to come out till sometime in July to switch me back on. Well I have leaks... lots of them. So back and forth to Home Depot (Trying to appear like I am not from Toronto, which is easy for me) to stock up on Plumbing tools and watch Youtube videos on soldering copper. No more leaks. Think I have the hot water back now. Seems the water intake at the lake end is picking up way too much sand and clogging the filter after one day. Might have to go swimming in 50 degree water, which the Dog seems to like.

Here is a shot of the re energized dog, glad to be on the island, swimming and in full mischief mode. She photographs better than Mud and Darkness.

I spent the last two days in mud under the cottage with about 3.5 feet of clearance. After given the Green light to leave the city by our Governing political Masters I came North with my daughter to find out that the water system which I had drained (Thought I did anyway) suffered quite a bit of damage over the winter. It seems there were two drains I failed to notice under the place which involves crawling through mud to get to. This was the first year I winterized the place as usually a local plumbing company comes and shuts it off in the fall and turns it on in the spring. Seeing how they charge plumbers rates plus the Cityot tax (City Idiot, also know as the 416 tax) I decided with Youtube videos I should keep the money and also be 100% self reliant up here. When I informed the plumbing company late in the season that I was shutting the place down and staying longer than usual, they said with a bit of a threat that should I have problems with the system they would not be able to come out till sometime in July to switch me back on. Well I have leaks... lots of them. So back and forth to Home Depot (Trying to appear like I am not from Toronto, which is easy for me) to stock up on Plumbing tools and watch Youtube videos on soldering copper. No more leaks. Think I have the hot water back now. Seems the water intake at the lake end is picking up way too much sand and clogging the filter after one day. Might have to go swimming in 50 degree water, which the Dog seems to like.

Here is a shot of the re energized dog, glad to be on the island, swimming and in full mischief mode. She photographs better than Mud and Darkness.

Attachments

Last edited:

Sorry to hear about the plumbing. How about installing a few electrically controlled drain valves at designed-in low points under your cottage. To winterize, just flip a switch and open the taps. My plumber friend only uses crimp on fittings these days, no more sweating joints. It’s so fast...

Wish my dog would fetch and liked classic cars... she hates the noise and all she wants to do in herd me toward the food pantry.

Wish my dog would fetch and liked classic cars... she hates the noise and all she wants to do in herd me toward the food pantry.

Those are excellent ideas, but do not take care of the dishwasher, washing machine etc, which you have to cycle anti freeze through. The last plumber's assistant who showed up said some of these fancy cottages have very elaborate washing machines and fridges that they scratch their head trying to figure out how to get the computer to turn them on. I am actually OK with what happened, as I think I know pretty well all the plumbing now. Hopefully never phone that Plumber again. Those Sharkbite push on connectors that can hook up copper or Pex make a lot of sense. If starting over I'd run plastic as it can take some degree of freezing. Already looking forward to next Spring!Sorry to hear about the plumbing. How about installing a few electrically controlled drain valves at designed-in low points under your cottage. To winterize, just flip a switch and open the taps. My plumber friend only uses crimp on fittings these days, no more sweating joints. It’s so fast...

Wish my dog would fetch and liked classic cars... she hates the noise and all she wants to do in herd me toward the food pantry.

@Nicad and @bfeng,

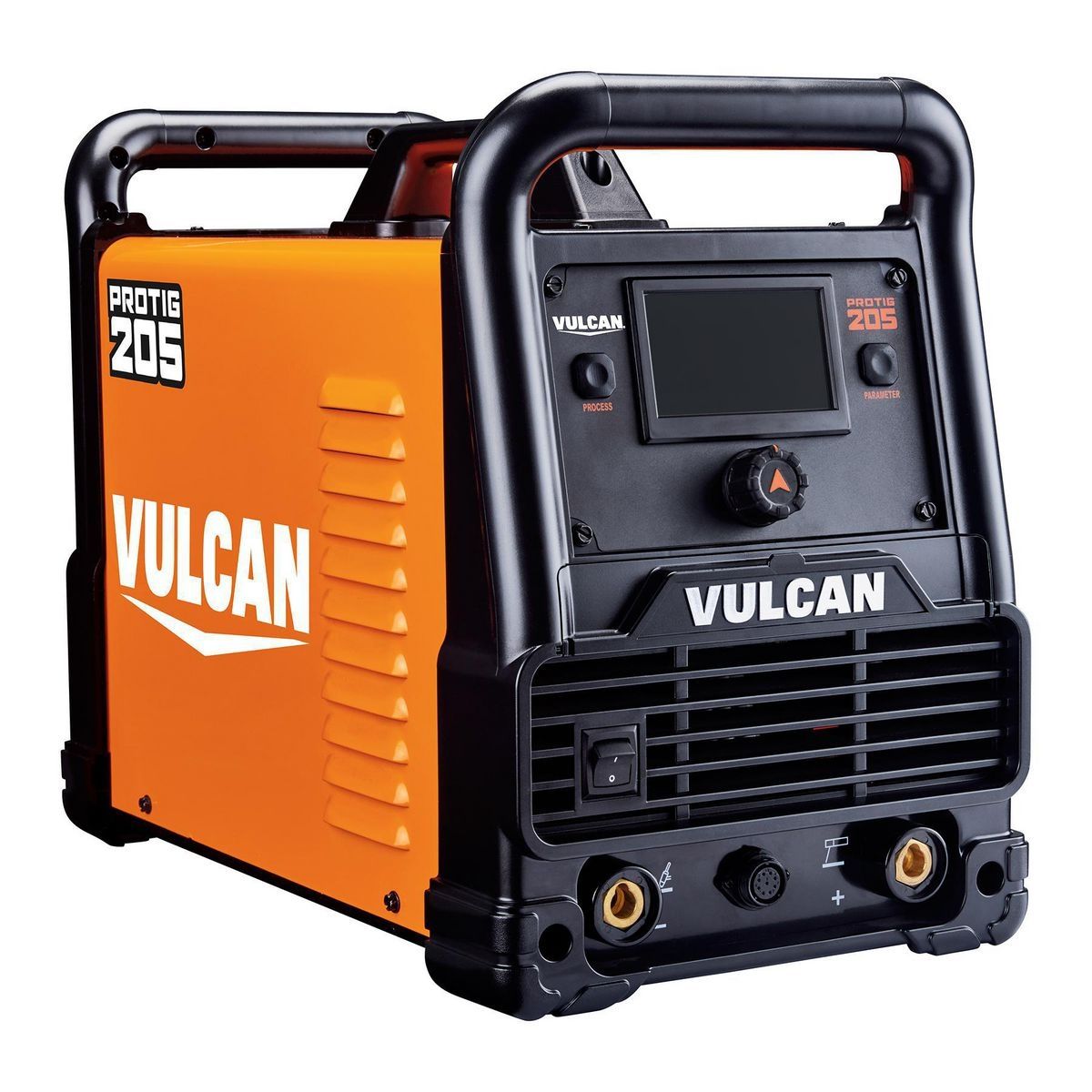

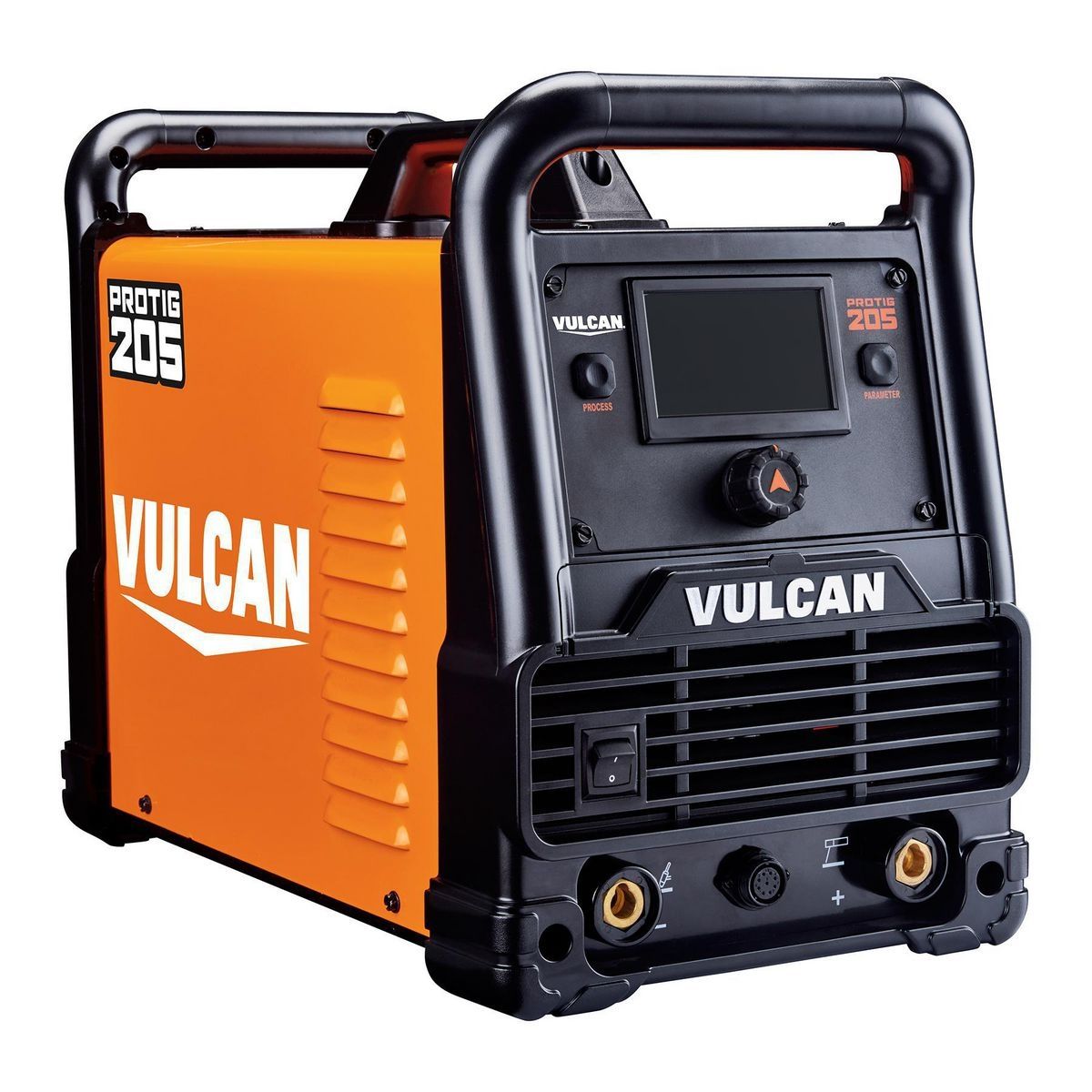

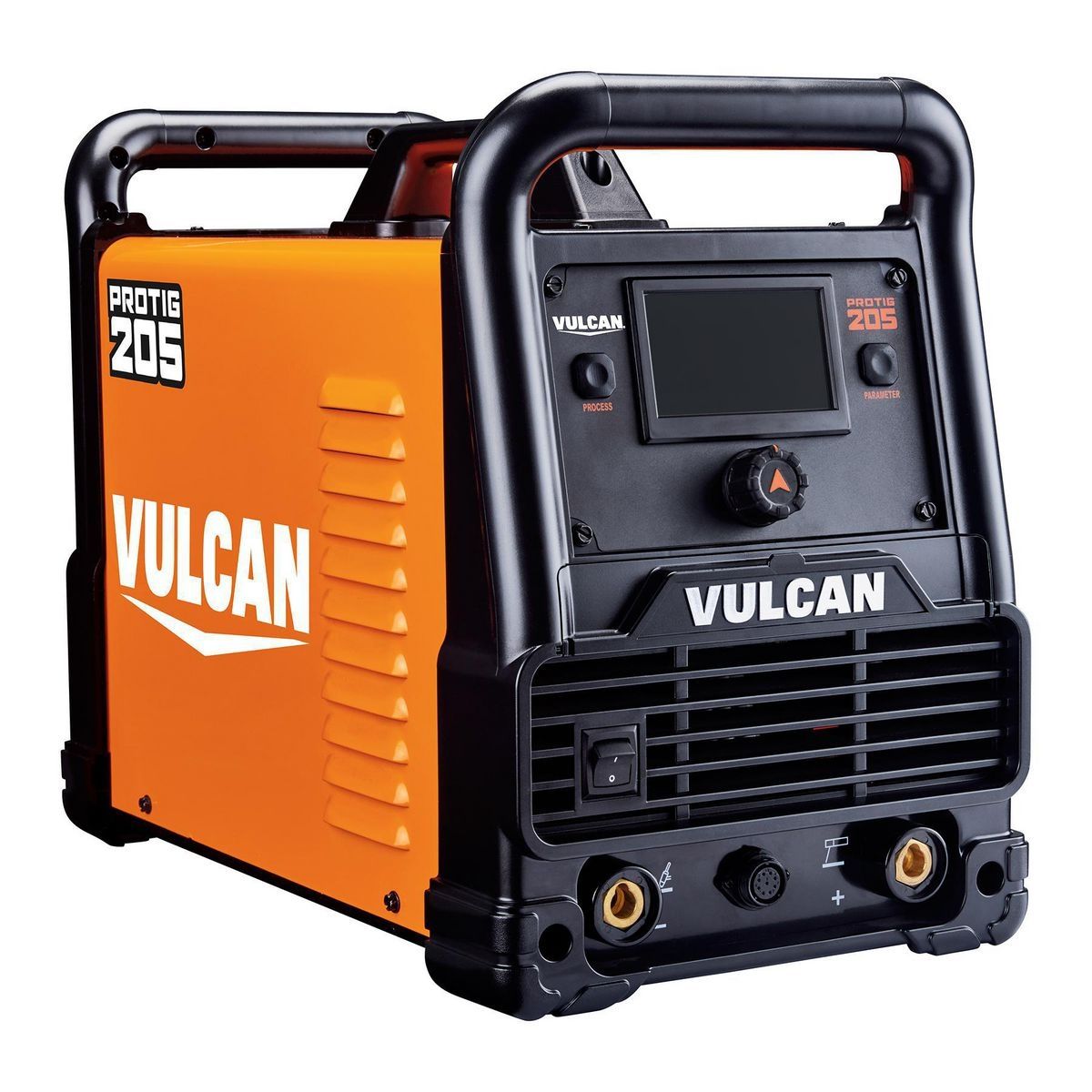

I have only used TIG on steel. I had a few requirements. I want a tig because it is ve try quiet and doesn’t throw sparks. Sparks burn my epoxy floor. I also really like the bead that TIG lays. They aren’t great for body work because they are slow and require footwork. So my requirement was a thumb control. This cheap TIG only has an on/off without flow. I spent another $150 on a nice flow meter. Fortunately the gauge of my material will be constant and a fixed thumb control should be adequate. I also wanted high frequency so I didn’t have to scratch start. I do plan to weld aluminum in the future so I wanted an AC/DC tig. Otherwise I would have purchased the Harbor Freight Vulcan 165 two years ago.

My mig is a terrible flux core that I totally abuse. The tig came with an extra tank so I’ll likely pickup a low-end blue or red mig. I’m honestly pretty sloppy with Mig, even with a good machine. I have a lot of time on my POS buzz box but you will never get great welds from a cheap 110v flux core.

This HF TIG is on sale for $899 through June (coupon online). I personally think it is the best Tig money can buy. HF completely ripped off Miller with the Tig 200. They took it down for a year, made some Chinese interpretations of the patent, and released the 205. In reality we should all be buying American welders right now but I don’t have $2,500+ to spend.

www.harborfreight.com

www.harborfreight.com

I picked up this mine for $450 with two tanks, thumb control, and some consumables. I figured even if the welder craps out I’ll have a head start on the collateral bits.

I have only used TIG on steel. I had a few requirements. I want a tig because it is ve try quiet and doesn’t throw sparks. Sparks burn my epoxy floor. I also really like the bead that TIG lays. They aren’t great for body work because they are slow and require footwork. So my requirement was a thumb control. This cheap TIG only has an on/off without flow. I spent another $150 on a nice flow meter. Fortunately the gauge of my material will be constant and a fixed thumb control should be adequate. I also wanted high frequency so I didn’t have to scratch start. I do plan to weld aluminum in the future so I wanted an AC/DC tig. Otherwise I would have purchased the Harbor Freight Vulcan 165 two years ago.

My mig is a terrible flux core that I totally abuse. The tig came with an extra tank so I’ll likely pickup a low-end blue or red mig. I’m honestly pretty sloppy with Mig, even with a good machine. I have a lot of time on my POS buzz box but you will never get great welds from a cheap 110v flux core.

This HF TIG is on sale for $899 through June (coupon online). I personally think it is the best Tig money can buy. HF completely ripped off Miller with the Tig 200. They took it down for a year, made some Chinese interpretations of the patent, and released the 205. In reality we should all be buying American welders right now but I don’t have $2,500+ to spend.

ProTIG™ 205 Industrial Welder with 120/240V Input

Amazing deals on this Protig 205 Industrial Tig Welder at Harbor Freight. Quality tools & low prices.

I picked up this mine for $450 with two tanks, thumb control, and some consumables. I figured even if the welder craps out I’ll have a head start on the collateral bits.

Last edited:

Pretty sure the new Miller Migs are made in Mexico if that helps. Not sure about their Tig lineup. I'd love to have the skillset to weld stainless with a Tig. Welding is a great liberator.@Nicad and @bfeng,

I have only used TIG on steel. I had a few requirements. I want a tig because it is ve try quiet and doesn’t throw sparks. Sparks burn my epoxy floor. I also really like the bead that TIG lays. They aren’t great for body work because they are slow and require footwork. So my requirement was a thumb control. This cheap TIG only has an on/off without flow. I spent another $150 on a nice flow meter. Fortunately the gauge of my material will be constant and a fixed thumb control should be adequate. I also wanted high frequency so I didn’t have to scratch start. I do plan to weld aluminum in the future so I wanted an AC/DC tig. Otherwise I would have purchased the Harbor Freight Vulcan 165 two years ago.

My mig is a terrible flux core that I totally abuse. The tig came with an extra tank so I’ll likely pickup a low-end blue or red mig. I’m honestly pretty sloppy with Mig, even with a good machine. I have a lot of time on my POS buzz box but you will never get great welds from a cheap 110v flux core.

This HF TIG is on sale for $899 through June (coupon online). I personally think it is the best Tig money can buy. HF completely ripped off Miller with the Tig 200. They took it down for a year, made some Chinese interpretations of the patent, and released the 205. In reality we should all be buying American welders right now but I don’t have $2,500+ to spend.

ProTIG™ 205 Industrial Welder with 120/240V Input

Amazing deals on this Protig 205 Industrial Tig Welder at Harbor Freight. Quality tools & low prices.www.harborfreight.com

I picked up this mine for $450 with two tanks, thumb control, and some consumables. I figured even if the welder craps out I’ll have a head start on the collateral bits.

Todays mechanical addition

DOH...yes really. Over the Winter I bought an old Suzuki 92 Quad Runner 300.. delivered it to the island over the ice and hope to use it to do stuff I am too old and feeble to do with limited Muscle. Move rocks, haul wood, pull stuff with the winch. So this Spring when the ice melted and before lockdown, I Kayaked over to check the place over (And go for a spin) I had removed the battery and put it on a tender. So when I got there spent the night, got up early and put the battery in. All I got was a spinning sound, no engine turn over. At this point I was cursing myself for buying an old one, and a lot of stuff looks worn out on this 92' Wiring needs attention, etc, but it seemed to at least run well and go through the gears nicely. I really didn't spend too much time assessing it's condition as I had missed out on a lot of local deals I had been following.

So anyway I tried the pull starter and it worked first or second pull. Happy again. Drove it around through the snow, ran it through the gears. Started and stopped it a few times. Well then it would not start. No matter how I pulled. It also was very difficult to pull over. So it was stuck there, under a tarp till yesterday when I got back to the island. I have read up on how much has to come apart to get to the suspected starter clutch (A lot) Tried pull starting it with starting fluid this time....no luck. Then I saw the battery. The start button still turns over the starter motor....but what is this? Battery hooked up ass backwards!! Switched it around, turns over and starts instantly. Wonder if I fried the Stator? This time outdoors has caused the shift linkage to become stiff, so it only goes in gear after pulling up then pushing down a bit....but it is running and at this point I am stoked to make it better, clean off the rust, Lube everything, set up things correctly, and get that trailer and move wood. I'm impressed it survived that level of stupidity and actually ran for a while. I'm making a habit of this.

DOH...yes really. Over the Winter I bought an old Suzuki 92 Quad Runner 300.. delivered it to the island over the ice and hope to use it to do stuff I am too old and feeble to do with limited Muscle. Move rocks, haul wood, pull stuff with the winch. So this Spring when the ice melted and before lockdown, I Kayaked over to check the place over (And go for a spin) I had removed the battery and put it on a tender. So when I got there spent the night, got up early and put the battery in. All I got was a spinning sound, no engine turn over. At this point I was cursing myself for buying an old one, and a lot of stuff looks worn out on this 92' Wiring needs attention, etc, but it seemed to at least run well and go through the gears nicely. I really didn't spend too much time assessing it's condition as I had missed out on a lot of local deals I had been following.

So anyway I tried the pull starter and it worked first or second pull. Happy again. Drove it around through the snow, ran it through the gears. Started and stopped it a few times. Well then it would not start. No matter how I pulled. It also was very difficult to pull over. So it was stuck there, under a tarp till yesterday when I got back to the island. I have read up on how much has to come apart to get to the suspected starter clutch (A lot) Tried pull starting it with starting fluid this time....no luck. Then I saw the battery. The start button still turns over the starter motor....but what is this? Battery hooked up ass backwards!! Switched it around, turns over and starts instantly. Wonder if I fried the Stator? This time outdoors has caused the shift linkage to become stiff, so it only goes in gear after pulling up then pushing down a bit....but it is running and at this point I am stoked to make it better, clean off the rust, Lube everything, set up things correctly, and get that trailer and move wood. I'm impressed it survived that level of stupidity and actually ran for a while. I'm making a habit of this.