Pm sentSeriously if anyone needs anything, let me know.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine rebuild and engine bay resto thread - 2240284 '72 CS

- Thread starter Stevehose

- Start date

Thanks, I'm just happy to be in the yellow zinc-front suspension-big washer club after all these years of rusty silver ones! Soon will be back on the road dodging (or not) rocks again!Steve, nothing short of amazing ... which is what we all expect from you and your work.

I noticed that first. I think my bushings were. New when I got the car but they didn’t put new yellow zinc big washers on. Have to add that to the list … or put the air dam back on. I was leaning to leaving it off

The car is getting there, I’ve been trying to put mileage on the engine, I’m up to 500 rev-limited miles (4k limit set in the 123 distributor). Carbs are dialed in for the most part.

Because I swapped out my 3:64 diff for a 3:45, here are my impressions:

-it makes 1st and 2nd more useful, certainly 1st as it is no longer a tractor gear only to get you moving. There is a 20 mph speed limit in our neighborhood until you’re out and I can do this easily in 1st, before I had to lug along in 2nd.

-2nd gear is more useful around town, I no longer have to lug in 3rd.

-3rd still kicks ass and is as fun as ever, just going faster and bumping easily up against higher speed limits.

-I haven’t had it in 4th for more than a few times during break in but revs are significantly lower and I can easily blow the speed limits on the Interstate.

-I have yet to get it into 5th, I suspect the 3:45 renders this basically obsolete except for fast highway cruising, and from what I’ve experienced with the other gears, if I go into 5th I risk jail time even on the Interstate. No wonder the euro coupes didn’t need overdrive.

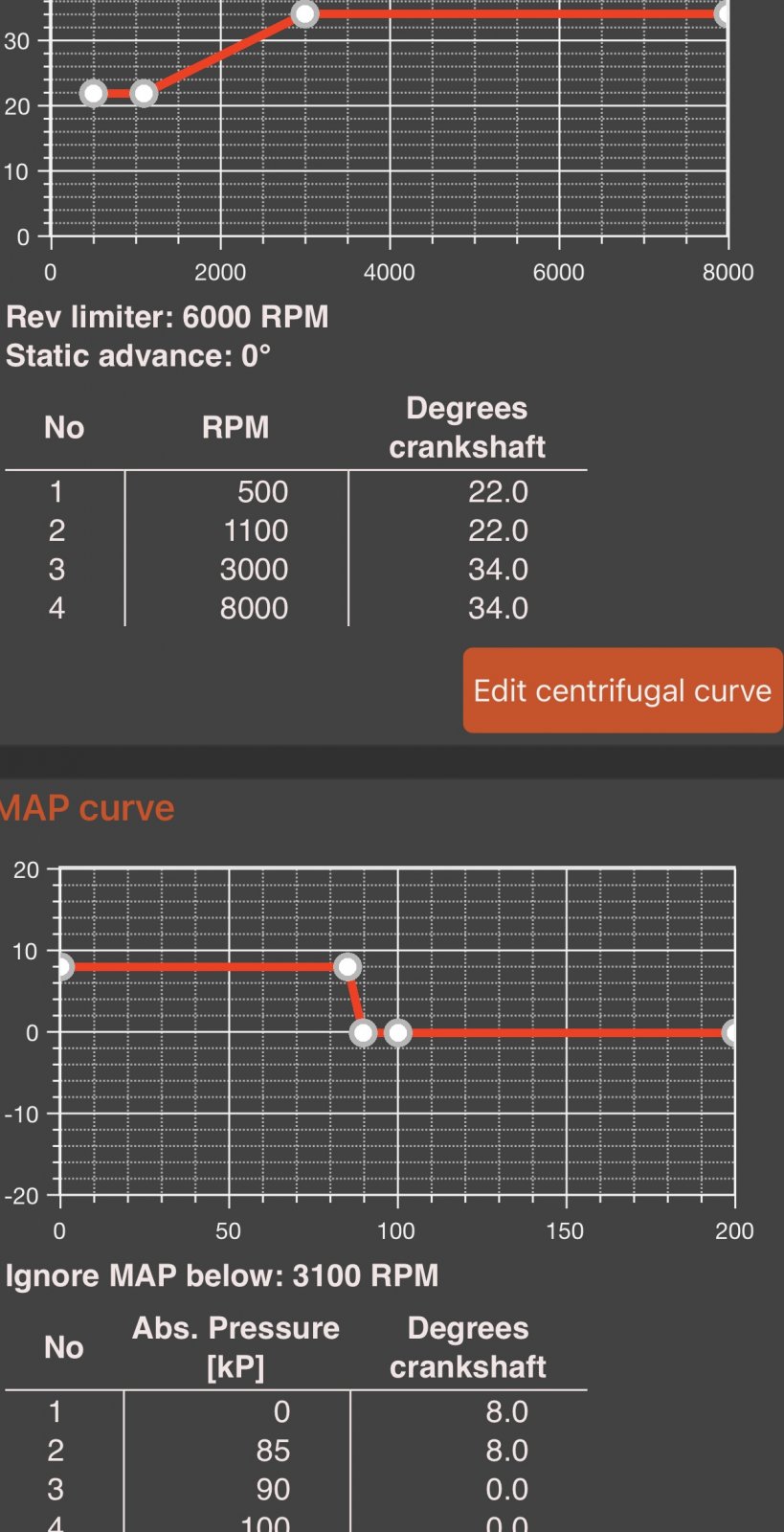

I am experimenting with crank, mechanical, and vacuum advance. Reading some performance material I see several racers recommend having as much advance at idle as the engine likes, and as little mechanical as necessary. Apparently back in the day, manufacturers put in less advance at idle in order to meet an emissions number, but it isn’t efficient. My engine likes to idle at 20 degrees, and I have 12 mechanical while the engine breaks in, total of all-in 32. This higher idle advance leads to higher idle rpm and allows me to get my triple Weber throttle plates to close more and sit right before the first progression hole which then activates the mixture screws better. It leaps to life off-idle and while accelerating. It wants to blow past the rev limit of 4k. Soon. Vacuum advance is another 8 degrees under low load.

Feels good to have it back on the streets, it looks sinister at night:

Because I swapped out my 3:64 diff for a 3:45, here are my impressions:

-it makes 1st and 2nd more useful, certainly 1st as it is no longer a tractor gear only to get you moving. There is a 20 mph speed limit in our neighborhood until you’re out and I can do this easily in 1st, before I had to lug along in 2nd.

-2nd gear is more useful around town, I no longer have to lug in 3rd.

-3rd still kicks ass and is as fun as ever, just going faster and bumping easily up against higher speed limits.

-I haven’t had it in 4th for more than a few times during break in but revs are significantly lower and I can easily blow the speed limits on the Interstate.

-I have yet to get it into 5th, I suspect the 3:45 renders this basically obsolete except for fast highway cruising, and from what I’ve experienced with the other gears, if I go into 5th I risk jail time even on the Interstate. No wonder the euro coupes didn’t need overdrive.

I am experimenting with crank, mechanical, and vacuum advance. Reading some performance material I see several racers recommend having as much advance at idle as the engine likes, and as little mechanical as necessary. Apparently back in the day, manufacturers put in less advance at idle in order to meet an emissions number, but it isn’t efficient. My engine likes to idle at 20 degrees, and I have 12 mechanical while the engine breaks in, total of all-in 32. This higher idle advance leads to higher idle rpm and allows me to get my triple Weber throttle plates to close more and sit right before the first progression hole which then activates the mixture screws better. It leaps to life off-idle and while accelerating. It wants to blow past the rev limit of 4k. Soon. Vacuum advance is another 8 degrees under low load.

Feels good to have it back on the streets, it looks sinister at night:

Thanks, it’s a work in progress and I will update previous sidedraft/123 posts to reflect latest theory/practice.Steve, you carb and timing research-based posts are archival quality for me. Great info above on the idle-carb idle tuning. Thanks for posting.

Agree with Luis on the carb tuning - keep it coming. In particular, I would like to see what your vacuum advance curve looks like (I find it difficult to translate what I think I want into what is required to program the distrubutor.)

On another note, I thought I-75 south of you was something of a no speed enforcement zone, making the run down to Naples very nice. Have they changed that?

On another note, I thought I-75 south of you was something of a no speed enforcement zone, making the run down to Naples very nice. Have they changed that?

Will post the curves when I've had a chance to test highway cruise vacuum advance. Regarding I-75, yes the speed of traffic is 85-90, if you want to go faster just wait for a crazed pickup truck driver to blow by and then follow. However, the state troopers will occasionally sit in the medians and pull over the fastest of the herd.Agree with Luis on the carb tuning - keep it coming. In particular, I would like to see what your vacuum advance curve looks like (I find it difficult to translate what I think I want into what is required to program the distrubutor.)

On another note, I thought I-75 south of you was something of a no speed enforcement zone, making the run down to Naples very nice. Have they changed that?

Tomorrow the car is going back on stands so I can bleed the clutch and brakes one last time, fix some exhaust leaks, and see why my reverse lights are not working, hopefullly just a disconnected tranny wire, the switch is new. Then this weekend I will eliminate the rpm restiction and give it a go on the highway in 5th with the fuzzbuster hooked up.

TodB

Well-Known Member

Sounds like great progress. Looking forward to seeing your curves. Might want to have Waze going along with your fuzzbuster  . Home stretch!

. Home stretch!

Steve, I was looking back through some of your build thread and found a picture (copied below) that shows your AC lines. Could you share what you used to wrap the copper hard lines?

I used this plus taped the ends:Steve, I was looking back through some of your build thread and found a picture (copied below) that shows your AC lines. Could you share what you used to wrap the copper hard lines?

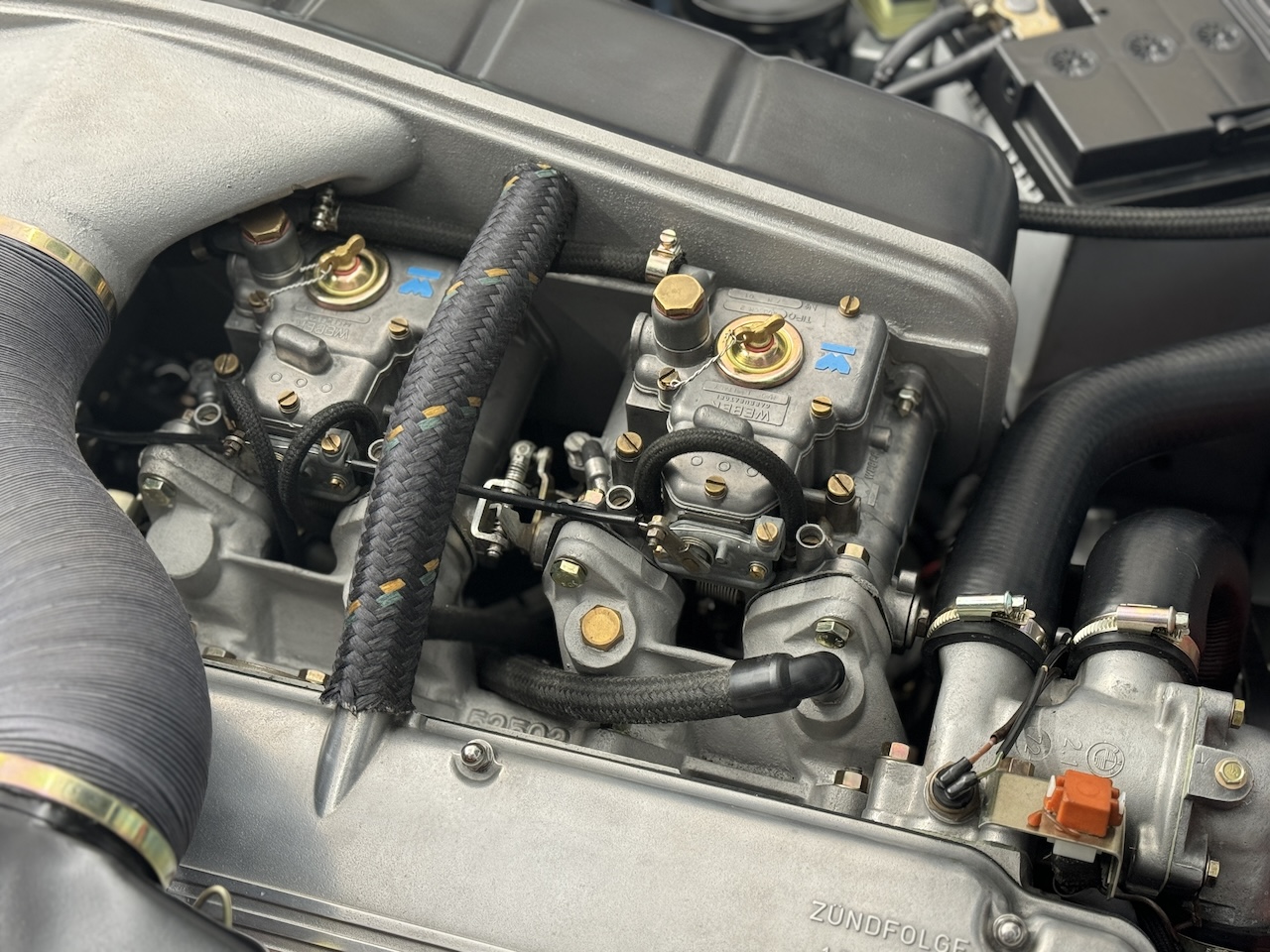

Today I took my car out for an early morning run, having tuned my sidedraft carbs and 123 distributor curve/vac advance to my liking. It has never run better, due to the engine rebuild/upgrade but I also think from some tuning theories put into practice that I've been dwelling on for 9 months. It howls from 4k rpm on up. Here is the tuning process I use, keeping in mind I have 40DCOM Webers, which are the last model Weber made in Italy, are "emissons" carbs, meaning they have 5 progression holes (period DCOE's have 2 or 3), and have the Delorto style adjustable accelerator pumps. They also have air bleed screws for balancing each carb's barrels and manifold vacuum ports for each cylinder and one ported vacuum port (not used). They are also plumbed differently as the idle jets get fuel from the main jet stack, where in the DCOE they get fuel from the fuel bowl, so idle & main jet selection and transition are different than DCOE. But most of these tuning principles also apply to the DCOE, I will note where they differ. This also takes into account the technology available from the 123 distributor, but a traditional distributor could be recurved to do something similar, just more time consuming and less adjustable. An AFR gauge is almost essential. This is about how to optimize throttle plate position, not about how to jet which is a separate topic.

Throttle plate setting process:

1. Set your linkage so that all carbs begin to open when the throttle rod is moved. I have the intercouple linkage with the adjustment screw between 1&2 and 2&3 carbs which makes this simple to do. I don't know how to do the crossbar style linkage but the same theory applies.

2. Back out the idle speed screw so that the linkage bottoms out and you can see a gap between the linkage and the adjustment screw. Then turn the screw in until it touches the linkage then go another 1/2 turn. If your progression holes have an access cover (mine didn't so I tapped and added them), check that the throttle plates are just covering the first progression holes and that the slightest movement begins to uncover them. You want as little fuel as possible getting past the holes at idle. A flashlight into the venturi helps with this. Check this on all carbs and adjust accordingly. This will likely lower the idle speed screw to 1/4 turn in which is fine for now, the point is to have all throttle plates uncover the first progression hole at exactly the same time.

3. Set your idle advance curve on the 123 to 15 degrees BTDC (or stock distributor but remember that increasing idle advance to 15 or 20 on a stock distributor without compensating on the total advance will put you way over the max all in advance limit at higher revs). I bracket this in the range of 500-1100 rpm so the advance doesn't hunt from slight idle rpm fluctuations. See attached curve. A standard distributor can be rotated counter-clockwise to increase advance, once ideal idle advance is determined then you could have the distributor recurved to only have the mechanical advance you want, say 10-12 degrees instead of the stock 20+ (see below).

4. Start the engine and when warm, adjust the idle speed screw to 1000 rpm. This will likely require turning in past the 1/4 turn base mark but that's ok for now.

5. Synch the carbs with a Synchronmeter so they all flow the same air at idle. If you have idle bleed screws, screw the higher flowing barrel screw in completely and open the lower flowing barrel screw until it matches the other. There should only be 1 air bleed screw in use (if needed) for each carb, with 1 closed. If the idle speed has changed, adjust back to 1000rpm. Synch the linkage and air bleeds again with the meter.

6. Adjust each idle mixture screw by turning in until the idle drops, then back it out until the idle goes highest, then back to just before it starts to drop again. Use an accurate digital tach, mine is built into the timing light. Listen for misfires and pops and how idle mixture affects them. Your dash tach is not accurate enough for this. Blip the throttle so that the throats clear and then recheck. Idle mixture is always the final setting, not the linkage screw.

7. If necessary, repeat steps 5 & 6 until you're at 975-1000 rpm (or wherever you want to be but I find sidedrafts like this rpm range, especially if you have a bigger cam. Also helps with a/c.

8. With the 123 software or by twisting the stock distributor, slowly advance the idle timing and watch your rpm rise. Advance until you get diminishing or no returns or idle drops/stumbles then back off until it runs smoothly again, then maybe back a little more for a safety buffer. Mine peaks at 25 BTDC or so, so I set it at 22. You can use a vacuum gauge to view this improvement as well. The reason I want more idle advance is twofold: First, your idle quality will likely get smoother and off-line acceleration will be quicker. Emissions and manufacturing tolerance were the reasons that manufacturers did not use this much idle advance; some racing tuners prefer more idle advance and less mechanical advance to get their total advance instead of vice-versa. Second, by raising the idle rpm with more advance, you will be able to back the throttle screw out some and therefore get the throttle plates closer to covering the 1st progression hole. If your throttle plates are in perfect positon then back off the idle advance to get to ideal idle if too high.

Throttle plate setting process:

1. Set your linkage so that all carbs begin to open when the throttle rod is moved. I have the intercouple linkage with the adjustment screw between 1&2 and 2&3 carbs which makes this simple to do. I don't know how to do the crossbar style linkage but the same theory applies.

2. Back out the idle speed screw so that the linkage bottoms out and you can see a gap between the linkage and the adjustment screw. Then turn the screw in until it touches the linkage then go another 1/2 turn. If your progression holes have an access cover (mine didn't so I tapped and added them), check that the throttle plates are just covering the first progression holes and that the slightest movement begins to uncover them. You want as little fuel as possible getting past the holes at idle. A flashlight into the venturi helps with this. Check this on all carbs and adjust accordingly. This will likely lower the idle speed screw to 1/4 turn in which is fine for now, the point is to have all throttle plates uncover the first progression hole at exactly the same time.

3. Set your idle advance curve on the 123 to 15 degrees BTDC (or stock distributor but remember that increasing idle advance to 15 or 20 on a stock distributor without compensating on the total advance will put you way over the max all in advance limit at higher revs). I bracket this in the range of 500-1100 rpm so the advance doesn't hunt from slight idle rpm fluctuations. See attached curve. A standard distributor can be rotated counter-clockwise to increase advance, once ideal idle advance is determined then you could have the distributor recurved to only have the mechanical advance you want, say 10-12 degrees instead of the stock 20+ (see below).

4. Start the engine and when warm, adjust the idle speed screw to 1000 rpm. This will likely require turning in past the 1/4 turn base mark but that's ok for now.

5. Synch the carbs with a Synchronmeter so they all flow the same air at idle. If you have idle bleed screws, screw the higher flowing barrel screw in completely and open the lower flowing barrel screw until it matches the other. There should only be 1 air bleed screw in use (if needed) for each carb, with 1 closed. If the idle speed has changed, adjust back to 1000rpm. Synch the linkage and air bleeds again with the meter.

6. Adjust each idle mixture screw by turning in until the idle drops, then back it out until the idle goes highest, then back to just before it starts to drop again. Use an accurate digital tach, mine is built into the timing light. Listen for misfires and pops and how idle mixture affects them. Your dash tach is not accurate enough for this. Blip the throttle so that the throats clear and then recheck. Idle mixture is always the final setting, not the linkage screw.

7. If necessary, repeat steps 5 & 6 until you're at 975-1000 rpm (or wherever you want to be but I find sidedrafts like this rpm range, especially if you have a bigger cam. Also helps with a/c.

8. With the 123 software or by twisting the stock distributor, slowly advance the idle timing and watch your rpm rise. Advance until you get diminishing or no returns or idle drops/stumbles then back off until it runs smoothly again, then maybe back a little more for a safety buffer. Mine peaks at 25 BTDC or so, so I set it at 22. You can use a vacuum gauge to view this improvement as well. The reason I want more idle advance is twofold: First, your idle quality will likely get smoother and off-line acceleration will be quicker. Emissions and manufacturing tolerance were the reasons that manufacturers did not use this much idle advance; some racing tuners prefer more idle advance and less mechanical advance to get their total advance instead of vice-versa. Second, by raising the idle rpm with more advance, you will be able to back the throttle screw out some and therefore get the throttle plates closer to covering the 1st progression hole. If your throttle plates are in perfect positon then back off the idle advance to get to ideal idle if too high.

Last edited:

9. The goal is to balance the higher idle advance with keeping the throttle plates close to covering the 1st progression hole. You may find that your engine likes 10, 15, 20, or more degrees. Advance the timing as much as the engine likes and then close the throttle plates accordingly to stay around 1k rpm. Don't go too far on the timing and don't go further behind the back edge of the first progression hole with the throttle plates. You will likely end up exposing a tiny amount of 1st progression hole. The reason you want the throttle plates to cover the 1st progession hole as much as possible is that it will activate the mixture screw more and you will suck less idle gas in from the progression hole - both will improve idle quality and off-idle performance.

10. Use these idle advance and throttle plate adjustments to get to 950-1000 rpm. Adjust the mixtures screws each time and keep repeating until you get to desired idle rpm. Again, idle mixture is always the last adjustment.

11. Drive the car and check all of the above. If the engine pings off idle then back off the advance, but I doubt this will happen. Check AFR's and then you can contemplate any needed idle jet and main stack jet changes. If your throttle plates are not positioned as above, it makes selecting the proper jets very difficult, frustrating, and expensive. AMHIK. Getting this physical baseline set here makes the variable adjustments easier later.

12. My engine likes to idle at around 12.3 AFR. Keep in mind that exhaust gas dilution can throw you a curve ball with AFR readings at idle so don't get obsessed trying to get a 14.5 idle AFR or whatever the internet says. Set it where your engine likes it and just on the edge of idle dropping from going too lean, but you can target for 12 or above, if it likes higher, great. If lower, then you may need a smaller idle jet. Your spark plugs will tell you if too rich at idle. Also, ambient temperature and humidity will affect AFR readings so don't freak out if they change with the weather. Cold, low humidity air will give higher AFR readings than hot, humid air. Also, AFR readings are just the amount of unburned 02 past the sensor, reisst the internet BS about timing "changing your air fuel mixture" - the only thing that can change mixture is a physical adjustment of either air or fuel. That's why the AFR gauge is not to be obsessed over - use it as a guide and let the engine and your butt tell you the rest. Ultimately the dyno will be the final judge.

13. Benefits of a higher idle advance for me include better off-idle acceleration, ideal idle throttle plate position, better cold engine idle/warm up, cooler idle temperature, and less drag on the engine when the a/c compressor kicks on.

14. Accelerator pumps. I use the smallest diameter jets as are effective (.35) so fuel is not gratuitously wasted (as much). I noticed that when the accel pumps are engaged by the gas pedal, I was going too rich and bogging down off idle and at low rpm's. I finally determined that this is because the default setting for DCOE's is for them to shoot right as the throttle plates open. But given that my carbs have 5 progression holes, they get plenty of fuel off-idle and this setting was too much. So I adjusted them to activate around the time the throttle plates pass the 5th hole and before the main jets are brought in. This covers that area where more air than fuel is likely to rush in under acceleration. This solved the rich bog as well as gave me nice acceleration response in the mid range before going WOT. On a DCOE, you may be able to delay the accel pumps a little by using a different pump rod spring, but because they have fewer progression holes this situation is less likely. On DCOM you adjust the pump lever nut under the carb by turning it clockwise up closer to the carb body. More turns, the later they come in. With the engine off, you can uncover all the accel jet covers and confirm a) they are in synch, and b) they are coming in when you want them to.

15. Vacuum advance. Pretty simple, I add 8 degrees advance at high vacuum readings over 3100 rpm (the most likely highway cruise scenario). If I gun the gas pedal, the vacuum drops and so does the extra advance. This is an engine-specific setting arrived at by trial and error. You want the vacuum advance to drop out before your engine vacuum gets too low to avoid possible detonation. I am still playing with this because I haven't had the Interstate clear enough to get to 3100 rpm in 5th gear. The highest I got this morning was 2700 rpm and I was going 80mph according to the gps and 123 app. So this will be bumping up against law enforcement's patience and I am not sure what more I will do here if anything. I tee the vacuum ports from cylinders 3&4 because they provide the smoothest vacuum signal and I cap the other ports. I'm not convinced having vacuum advance on triple Webers while cruising does a damned thing for fuel economy anyway. I may drop the vacuum advance activation rpm to 3000 or less, or just not use it at all. To be determined.

16. My curve. Pretty simple. 34 degrees all in by 3k rpm. 22 idle advance. Vacuum advance drops completely out at -3 Hg (10kP), you'll have to test the sensitivity and where you want yours to drop out based on your gas pedal position accelerating out of cruise. I have rev's limited to 6k rpm for now, will do 6400 eventually but I don't ever rev that high anyway.

Would love to hear input from the engine specialists (you know who you are) about increasing idle advance as I have done. Will post more feedback as I drive and tweak-it's a work in process.

10. Use these idle advance and throttle plate adjustments to get to 950-1000 rpm. Adjust the mixtures screws each time and keep repeating until you get to desired idle rpm. Again, idle mixture is always the last adjustment.

11. Drive the car and check all of the above. If the engine pings off idle then back off the advance, but I doubt this will happen. Check AFR's and then you can contemplate any needed idle jet and main stack jet changes. If your throttle plates are not positioned as above, it makes selecting the proper jets very difficult, frustrating, and expensive. AMHIK. Getting this physical baseline set here makes the variable adjustments easier later.

12. My engine likes to idle at around 12.3 AFR. Keep in mind that exhaust gas dilution can throw you a curve ball with AFR readings at idle so don't get obsessed trying to get a 14.5 idle AFR or whatever the internet says. Set it where your engine likes it and just on the edge of idle dropping from going too lean, but you can target for 12 or above, if it likes higher, great. If lower, then you may need a smaller idle jet. Your spark plugs will tell you if too rich at idle. Also, ambient temperature and humidity will affect AFR readings so don't freak out if they change with the weather. Cold, low humidity air will give higher AFR readings than hot, humid air. Also, AFR readings are just the amount of unburned 02 past the sensor, reisst the internet BS about timing "changing your air fuel mixture" - the only thing that can change mixture is a physical adjustment of either air or fuel. That's why the AFR gauge is not to be obsessed over - use it as a guide and let the engine and your butt tell you the rest. Ultimately the dyno will be the final judge.

13. Benefits of a higher idle advance for me include better off-idle acceleration, ideal idle throttle plate position, better cold engine idle/warm up, cooler idle temperature, and less drag on the engine when the a/c compressor kicks on.

14. Accelerator pumps. I use the smallest diameter jets as are effective (.35) so fuel is not gratuitously wasted (as much). I noticed that when the accel pumps are engaged by the gas pedal, I was going too rich and bogging down off idle and at low rpm's. I finally determined that this is because the default setting for DCOE's is for them to shoot right as the throttle plates open. But given that my carbs have 5 progression holes, they get plenty of fuel off-idle and this setting was too much. So I adjusted them to activate around the time the throttle plates pass the 5th hole and before the main jets are brought in. This covers that area where more air than fuel is likely to rush in under acceleration. This solved the rich bog as well as gave me nice acceleration response in the mid range before going WOT. On a DCOE, you may be able to delay the accel pumps a little by using a different pump rod spring, but because they have fewer progression holes this situation is less likely. On DCOM you adjust the pump lever nut under the carb by turning it clockwise up closer to the carb body. More turns, the later they come in. With the engine off, you can uncover all the accel jet covers and confirm a) they are in synch, and b) they are coming in when you want them to.

15. Vacuum advance. Pretty simple, I add 8 degrees advance at high vacuum readings over 3100 rpm (the most likely highway cruise scenario). If I gun the gas pedal, the vacuum drops and so does the extra advance. This is an engine-specific setting arrived at by trial and error. You want the vacuum advance to drop out before your engine vacuum gets too low to avoid possible detonation. I am still playing with this because I haven't had the Interstate clear enough to get to 3100 rpm in 5th gear. The highest I got this morning was 2700 rpm and I was going 80mph according to the gps and 123 app. So this will be bumping up against law enforcement's patience and I am not sure what more I will do here if anything. I tee the vacuum ports from cylinders 3&4 because they provide the smoothest vacuum signal and I cap the other ports. I'm not convinced having vacuum advance on triple Webers while cruising does a damned thing for fuel economy anyway. I may drop the vacuum advance activation rpm to 3000 or less, or just not use it at all. To be determined.

16. My curve. Pretty simple. 34 degrees all in by 3k rpm. 22 idle advance. Vacuum advance drops completely out at -3 Hg (10kP), you'll have to test the sensitivity and where you want yours to drop out based on your gas pedal position accelerating out of cruise. I have rev's limited to 6k rpm for now, will do 6400 eventually but I don't ever rev that high anyway.

Would love to hear input from the engine specialists (you know who you are) about increasing idle advance as I have done. Will post more feedback as I drive and tweak-it's a work in process.

Last edited:

Wow. My head is spinning trying to follow this. I am running a slight variation on one of your 123 curves posted a couple of years ago and am hesitant to tweak (mess with) it as I am getting good gas mileage without any pinging/ carb backfiring.

Then don't change a thing! I tend to go overboard on things that interest me, often times ending with the old "I should have quit while I was ahead" adage.Wow. My head is spinning trying to follow this. I am running a slight variation on one of your 123 curves posted a couple of years ago and am hesitant to tweak (mess with) it as I am getting good gas mileage without any pinging/ carb backfiring.

- Messages

- 395

- Reaction score

- 237

Hey Steve, hope the rebuild is going well. What are you having Don do while he's in there - assume some resto-moding? FYI. I was driving my other German classic, a 1987 Mercedes-Benz 16V, from Virginia to Nashville TN a year ago to a mechanic who's similar to Don in so many ways (E9 savant...) for a mild restoration, mechanical upgrade and new paint. In the last 30 miles of a 650 mile drive, the engine all of a sudden felt like it was on three cylinders and was sounding terrible. I should have pulled over and simply towed the car the rest of the way, but she was drivable and I kept going. Turns out a valve seal had failed and the valve went where it was not supposed to! That added a full engine rebuild to my list (ditched the paint job which was not out of budget) so I went with high compression pistons, lightened and forged connecting rods, a sportier cam and Megasquirt plus and an overbore of plus 1 since the cylinder walls had been honed by the previous owner but not well and that was causing severe oil consumption...Can't wait for the car to be done in another few months (yes, over 1 year and that's mostly because finding parts for 16Vs is twice as hard as the E9 where there is at least some factory and aftermarket support)...

Sorry to hear of your misfortune on the 16 valve, but then again, this means you will have to drive your e9 when you hang out with us!Hey Steve, hope the rebuild is going well. What are you having Don do while he's in there - assume some resto-moding? FYI. I was driving my other German classic, a 1987 Mercedes-Benz 16V, from Virginia to Nashville TN a year ago to a mechanic who's similar to Don in so many ways (E9 savant...) for a mild restoration, mechanical upgrade and new paint. In the last 30 miles of a 650 mile drive, the engine all of a sudden felt like it was on three cylinders and was sounding terrible. I should have pulled over and simply towed the car the rest of the way, but she was drivable and I kept going. Turns out a valve seal had failed and the valve went where it was not supposed to! That added a full engine rebuild to my list (ditched the paint job which was not out of budget) so I went with high compression pistons, lightened and forged connecting rods, a sportier cam and Megasquirt plus and an overbore of plus 1 since the cylinder walls had been honed by the previous owner but not well and that was causing severe oil consumption...Can't wait for the car to be done in another few months (yes, over 1 year and that's mostly because finding parts for 16Vs is twice as hard as the E9 where there is at least some factory and aftermarket support)...

Don graciously took care of the head, oil pump, and port matching. He is also my trusted consigliere for the project whether he knows it or notWhat are you having Don do while he's in there - assume some resto-moding?

This thread shows the shebang as it unfulds - yes lots of "resto-improvments" as I like to call them!

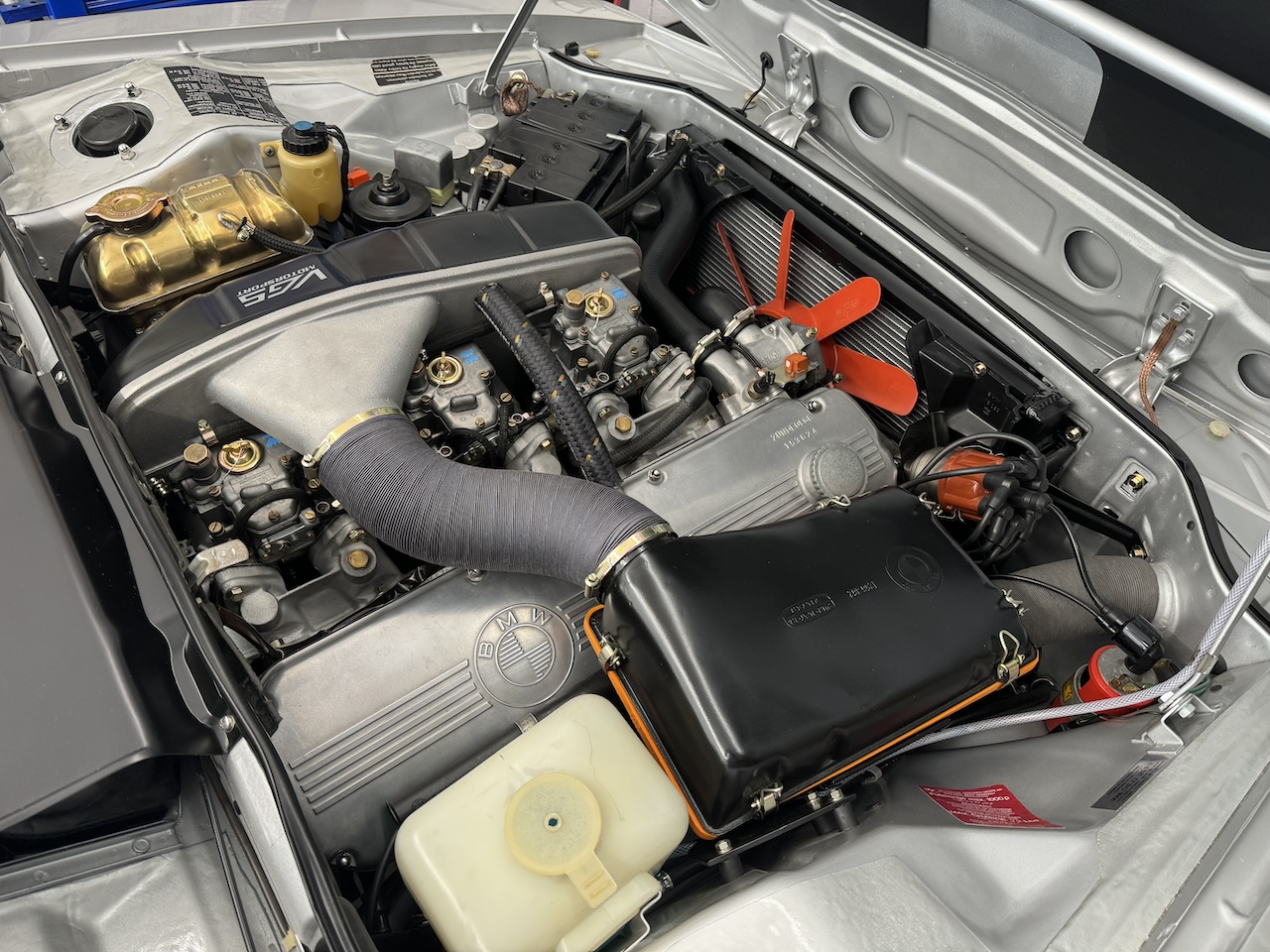

Ok, the long and winding engine compartment road has reached its destination for now. I'm on to fine tuning the engine as best I can before taking it to a dyno after I have more miles on it.

Here are some pics:

OCD carb details:

Closer shot of the red fan to replace my busted up previous ones (thanks to @rsporsche ) and new radiator: I went back to a 130mm water pump pulley as the 102mm one snacked on 3 fan blades and one radiator due to over spinning.

Restored original radio suppression ground strap:

Simplified the coil connections, nos red coil and distributor/diagnostic port plug wires:

Details:

It was a tremendous amount of work, my hands and back will likely ache for eternity. Thanks again to all forum members for your assistance!

Here are some pics:

OCD carb details:

Closer shot of the red fan to replace my busted up previous ones (thanks to @rsporsche ) and new radiator: I went back to a 130mm water pump pulley as the 102mm one snacked on 3 fan blades and one radiator due to over spinning.

Restored original radio suppression ground strap:

Simplified the coil connections, nos red coil and distributor/diagnostic port plug wires:

Details:

It was a tremendous amount of work, my hands and back will likely ache for eternity. Thanks again to all forum members for your assistance!

Last edited: