It's the original engine with Schrick cam, triple webers, and soon 10:1 pistons.What engine is this 3.2L ?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine rebuild and engine bay resto thread - 2240284 '72 CS

- Thread starter Stevehose

- Start date

Tonight I dropped the front subframe. Why not - I've mission creeped this far, may as well keep going  Actually, it's nice to have it out of the way so I can A) paint it and B) clean and paint the mounting points on the frame rails body color. Access to sitting and working in the engine bay is greatly improved as well.

Actually, it's nice to have it out of the way so I can A) paint it and B) clean and paint the mounting points on the frame rails body color. Access to sitting and working in the engine bay is greatly improved as well.

It appears my car came with the dark olive green rear subframe and a black front one. I am going to paint the front dark green, I like the contrast it provides with the other parts. Driver side tow hook needs welding courtesy of a New Orleans pothole parting gift a year ago which I will also take care of.

I have a ton of undercoating on my car, including the frame rails, which appears to have been put on by the dealer. Or did the factory put on an undercoat prior to painting?? Strangely enough when scraping it away with a putty knife it appears to be primer underneath...I will inspect more closely in daylight. Regardless, it has protected my car's metal in stellar fashion. This is post scraping and pre-wire brush/sanding, coming along:

The subframe mounting "boxes" attached under the rails have drain holes in them which are clogged with gunk, so these will be cleaned out and cavity waxed before paint and re-install.

It appears my car came with the dark olive green rear subframe and a black front one. I am going to paint the front dark green, I like the contrast it provides with the other parts. Driver side tow hook needs welding courtesy of a New Orleans pothole parting gift a year ago which I will also take care of.

I have a ton of undercoating on my car, including the frame rails, which appears to have been put on by the dealer. Or did the factory put on an undercoat prior to painting?? Strangely enough when scraping it away with a putty knife it appears to be primer underneath...I will inspect more closely in daylight. Regardless, it has protected my car's metal in stellar fashion. This is post scraping and pre-wire brush/sanding, coming along:

The subframe mounting "boxes" attached under the rails have drain holes in them which are clogged with gunk, so these will be cleaned out and cavity waxed before paint and re-install.

Last edited:

Oh, you’re having fun now Steve. Take the sub-frame and get it powder coated. It won’t run you that much($150?)and it will look great. Not sure they can match your green, but probably come close. They have a lot of colors and you won’t have to do all that scraping and cleaning yourself.(down the rabbit hole you go.) you’re gonna love it.

Exactly, it went to the blaster yesterday, they are also going to weld the broken tow loop (and also reinforce with additional welds on both loops). Then they are going to powdercoat in RAL 6015 "Schwartzolive." I then had 2 cans of 2k 6015 mixed at the paint store for the struts. Oh yeah, the strutsOh, you’re having fun now Steve. Take the sub-frame and get it powder coated. It won’t run you that much($150?)and it will look great. Not sure they can match your green, but probably come close. They have a lot of colors and you won’t have to do all that scraping and cleaning yourself.(down the rabbit hole you go.) you’re gonna love it.

Last edited:

Good call on the powder coating. I painted mine and, although it has held well so far, with all the rocks and road debris that fly around down there I really would have felt better knowing was powder coated.

Take the big compliance washer to the welder. Make sure it still fits inside the tow loop after they weld.

coupe2800cs

Well-Known Member

Little more compression never hurts, it's quench that does to a degree, taking that little amount off won't hurt anything.Block got decked today, .004" (.1mm) removed and now clean and true. Next up, order the pistons (eta 6 weeks), then they will measure each one and bore accordingly for each cylinder. I am going 89.5mm piston size and 10:1 compression. Will also replace the wrist pin bushings. So now my deck height is 217.5mm (stock) - .1mm = 217.4mm and will let the piston maker know the new decking measurement if it matters?

View attachment 163046

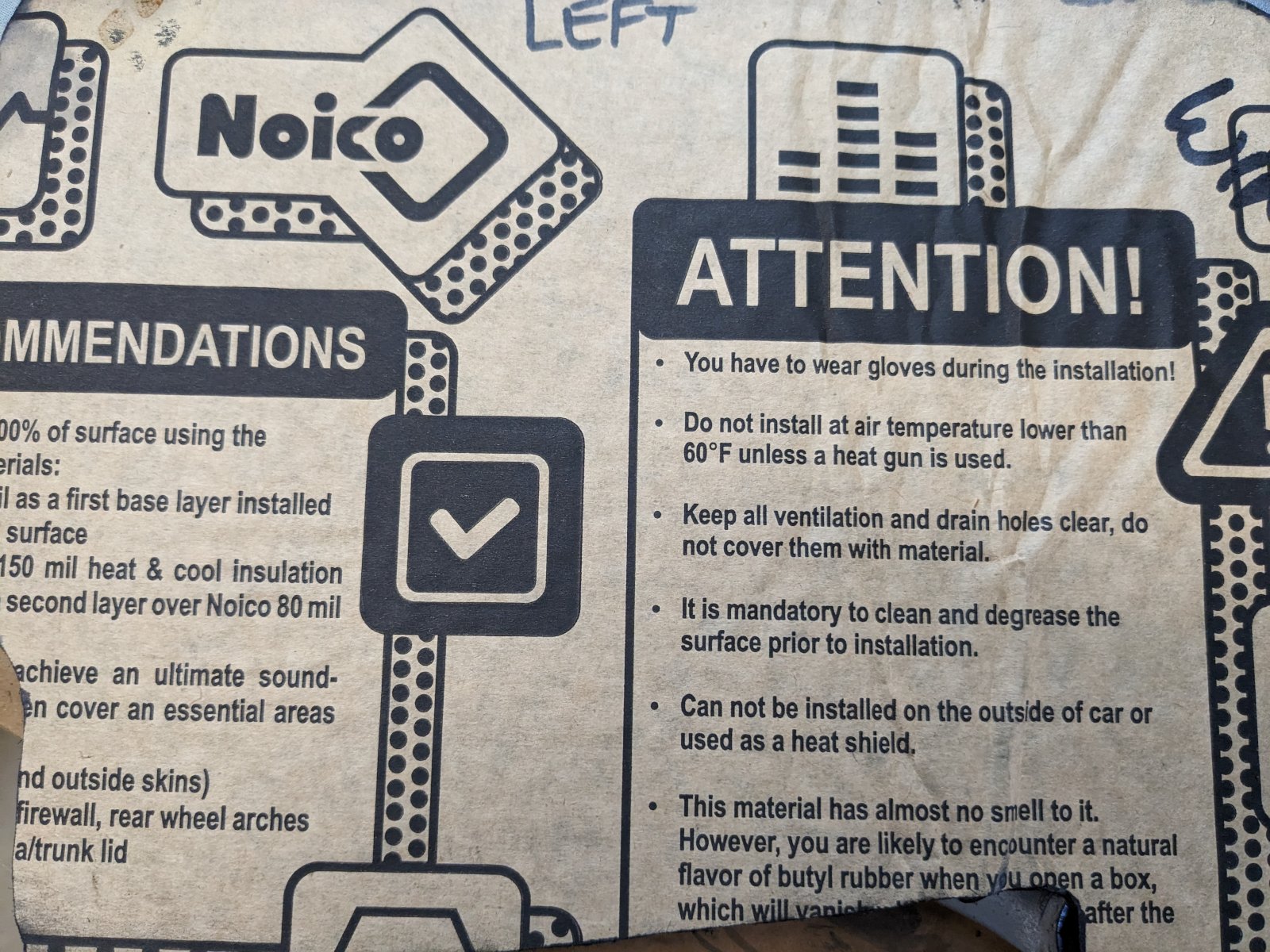

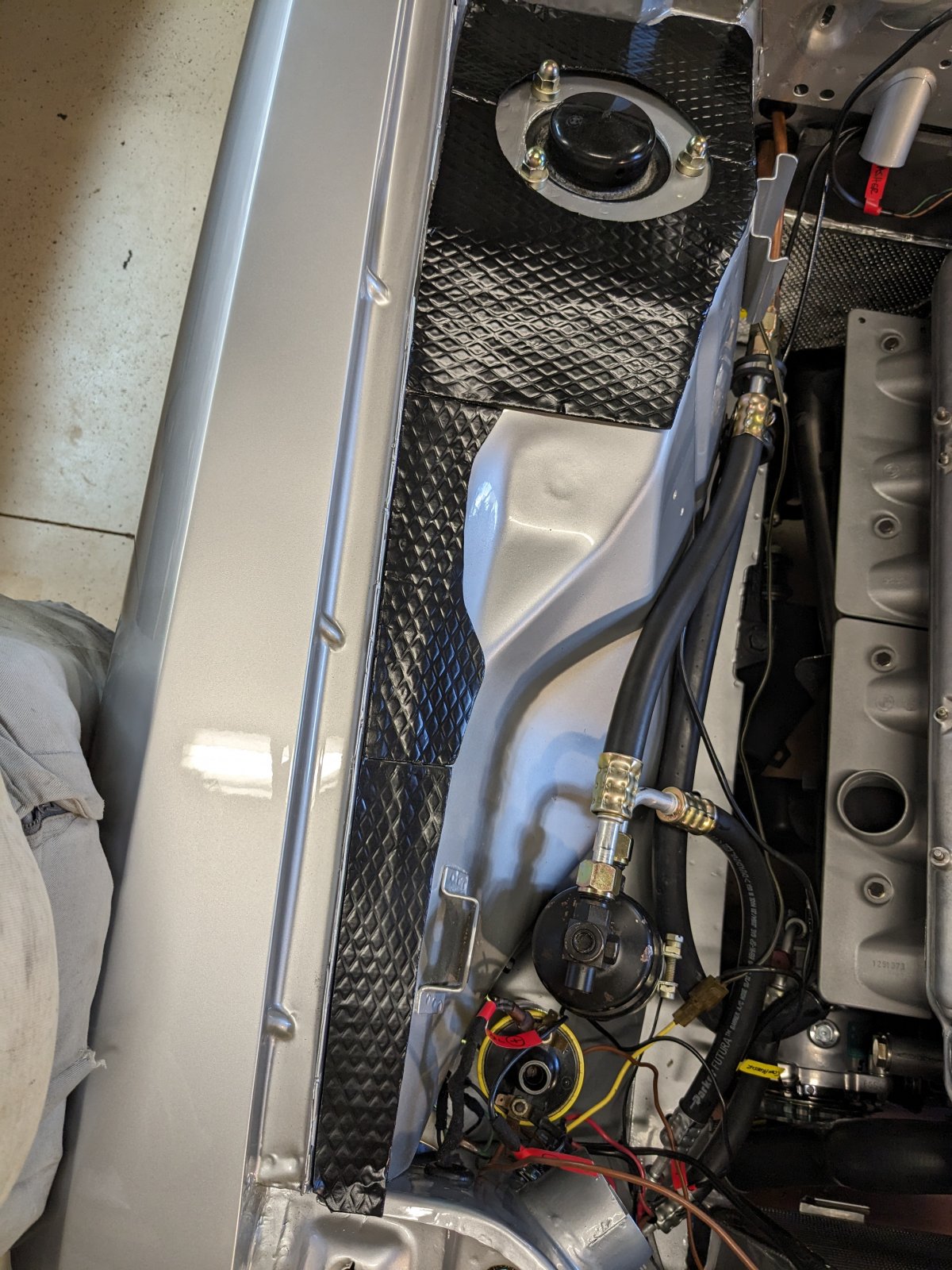

I know this has been covered in the past but it was brought up again in this thread. With regard to the strut tower insulation (sound deadening), I am going to use this stuff. Not Original but looks ok and we just cut ours from patterns that were posted a while ago. I am not going to paint the pieces at this time as I kind of like the black contrast to the silver. May change our mind in the future.

Another reason to use the sound deadening is to cover up my welds. My "rust free" CA car was not so rust free in that area once you start digging! The photos show the pieces just laying in place for illustration but not stuck down yet.

Stevehose condition of his fenders are remarkably clean, again a lot cleaner than my "rust free" car.

jjs2800cs

Another reason to use the sound deadening is to cover up my welds. My "rust free" CA car was not so rust free in that area once you start digging! The photos show the pieces just laying in place for illustration but not stuck down yet.

Stevehose condition of his fenders are remarkably clean, again a lot cleaner than my "rust free" car.

jjs2800cs

I know this has been covered in the past but it was brought up again in this thread. With regard to the strut tower insulation (sound deadening), I am going to use this stuff. Not Original but looks ok and we just cut ours from patterns that were posted a while ago. I am not going to paint the pieces at this time as I kind of like the black contrast to the silver. May change our mind in the future.

Another reason to use the sound deadening is to cover up my welds. My "rust free" CA car was not so rust free in that area once you start digging! The photos show the pieces just laying in place for illustration but not stuck down yet.

Stevehose condition of his fenders are remarkably clean, again a lot cleaner than my "rust free" car.

jjs2800csView attachment 166784View attachment 166785View attachment 166786View attachment 166787

your car, YOUR RULES,

but I would definitely paint them

Get contrast elsewhere,

IMHO

I know this has been covered in the past but it was brought up again in this thread. With regard to the strut tower insulation (sound deadening), I am going to use this stuff. Not Original but looks ok and we just cut ours from patterns that were posted a while ago. I am not going to paint the pieces at this time as I kind of like the black contrast to the silver. May change our mind in the future.

Another reason to use the sound deadening is to cover up my welds. My "rust free" CA car was not so rust free in that area once you start digging! The photos show the pieces just laying in place for illustration but not stuck down yet.

Stevehose condition of his fenders are remarkably clean, again a lot cleaner than my "rust free" car.

jjs2800csView attachment 166784View attachment 166785View attachment 166786View attachment 166787

I would also consider replacing the top portion to get pattern flow in the same direction.

Great idea, just hope I have enough material left to do so. Until I took the photo I had not really laid all the pieces out on the fender, so had not noticed. Cut them well over a year ago.I would also consider replacing the top portion to get pattern flow in the same direction.

As I said, in time might very well end up painting, maybe sooner than later as we finish the engine bay as might be too much contrast with all the piece in place.

Thanks

jjs2800cs

I have an insane amount of projects going on at once, and am often talking myself off a cliff to keep from being overwhelmed. But progress is being made. First, I have finished scraping and sanding the engine bay. This has taken an inordinate amount of time, each time I think I am done, I find more to do. I have also put cavity wax into every seam, and sprayed it into every space. Any flash rust was converted (the black in the pic). Anyway, pics of before and after priming (I ran out of primer so that's why it has a camo-look), the nastiness is gone:

Next up will be to sand it down again and finish priming. Then sand again, seam sealer, and paint.

I had the front subframe blasted, tow hooks welded, and powder coated in Schwartzolive and is being picked up tomorrow:

I had some of the same RAL color put into rattle cans at the paint supply store and will do the struts the same - cleaning them up also revealed they were once the same color:

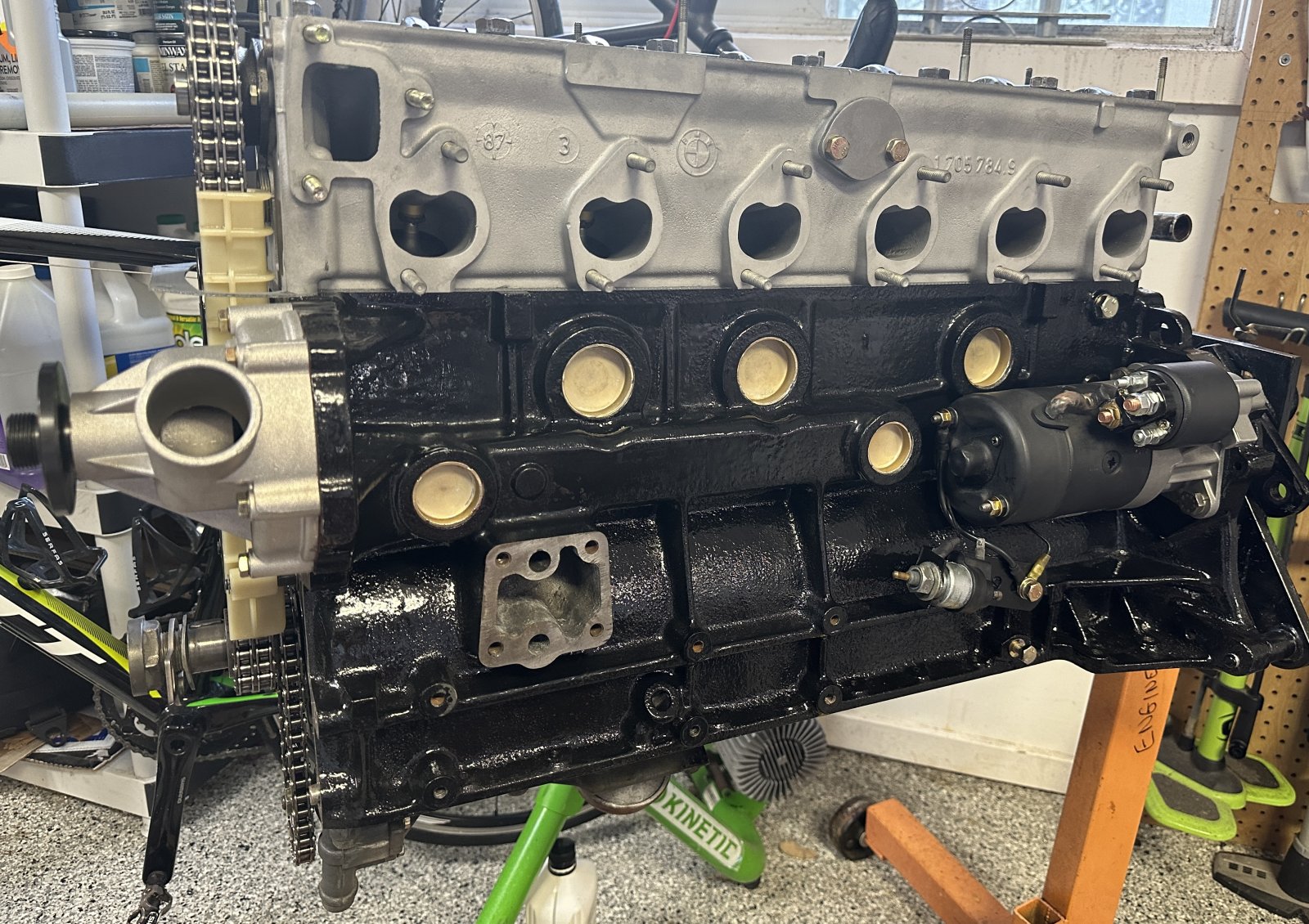

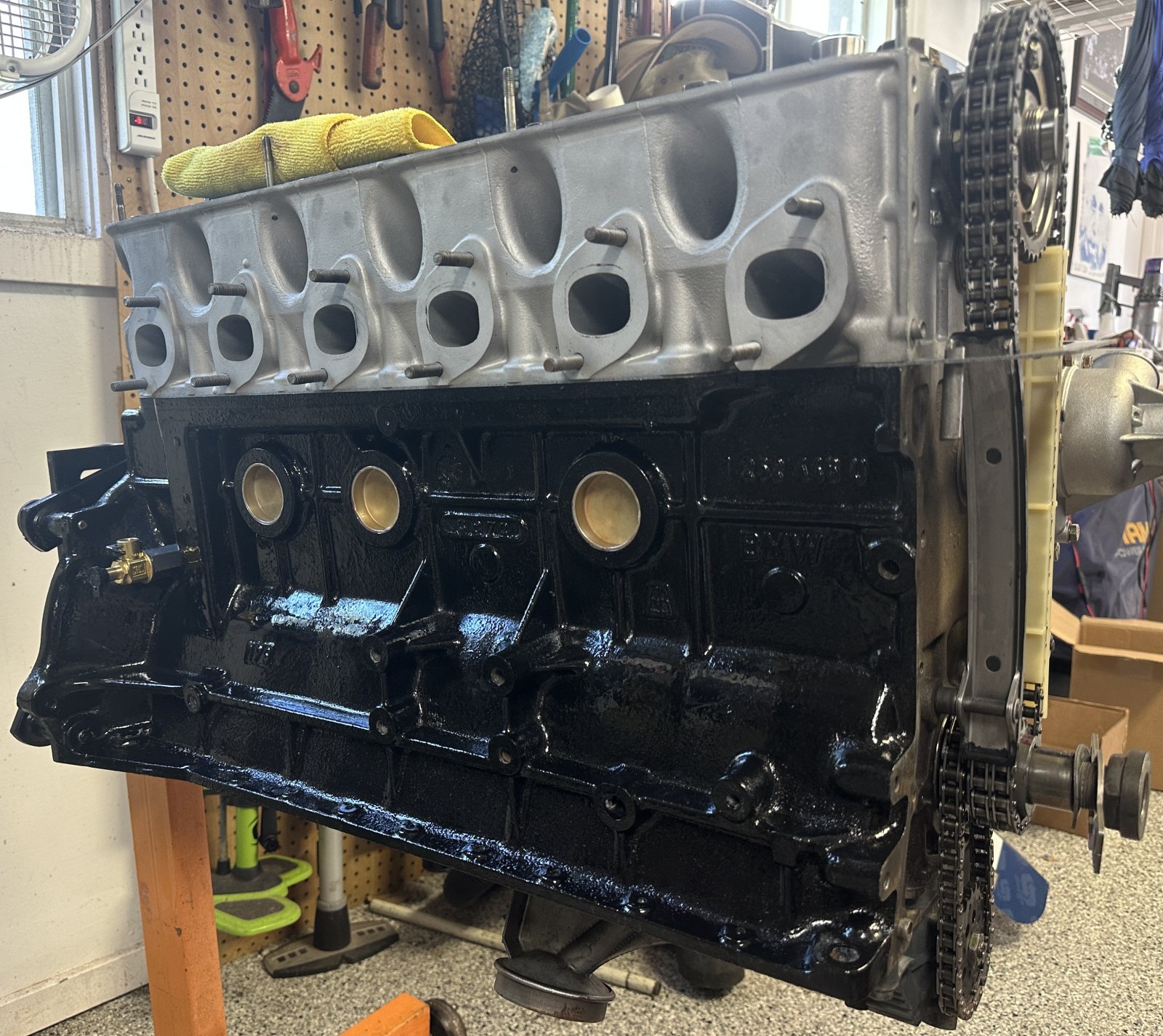

Also tomorrow is engine pickup day at the machinist! The block has been cleaned, decked .004" and bored for 10:1 JE pistons now installed, crank is polished and new bearings for it and the rods all in the block. I will rebuild the rest:

I will be painting the block black with the POR-15 system. While dodging a hurricane, I got into the front bumper, I POR-15'd the insides of the pieces, repainted the brackets and now ready for final polish, rubber and trim pieces for both front and back bumpers on way from W&N so they should look good when all is said and done:

I also cleaned up, cavity waxed, and POR-15'd the entire front clip on both sides, it was nasty. Easier than trying to spray primer and paint into there, and better protection against the elements:

All the engine parts to finish the rebuild are in stock, the brake booster, front calipers, and steering box have been rebuilt and ready to go. Onward!

Next up will be to sand it down again and finish priming. Then sand again, seam sealer, and paint.

I had the front subframe blasted, tow hooks welded, and powder coated in Schwartzolive and is being picked up tomorrow:

I had some of the same RAL color put into rattle cans at the paint supply store and will do the struts the same - cleaning them up also revealed they were once the same color:

Also tomorrow is engine pickup day at the machinist! The block has been cleaned, decked .004" and bored for 10:1 JE pistons now installed, crank is polished and new bearings for it and the rods all in the block. I will rebuild the rest:

I will be painting the block black with the POR-15 system. While dodging a hurricane, I got into the front bumper, I POR-15'd the insides of the pieces, repainted the brackets and now ready for final polish, rubber and trim pieces for both front and back bumpers on way from W&N so they should look good when all is said and done:

I also cleaned up, cavity waxed, and POR-15'd the entire front clip on both sides, it was nasty. Easier than trying to spray primer and paint into there, and better protection against the elements:

All the engine parts to finish the rebuild are in stock, the brake booster, front calipers, and steering box have been rebuilt and ready to go. Onward!

Last edited:

Impressive Steve. I mean it is exhausting just thinking about this list of projects you attacked and mastered. Begs the question, you living on Espresso, or Red Bull energy drinks? I mean you have accomplished so much! MikeI have an insane amount of projects going on at once, and am often talking myself off a cliff to keep from being overwhelmed. But progress is being made. First, I have finished scraping and sanding the engine bay. This has taken an inordinate amount of time, each time I think I am done, I find more to do. I have also put cavity wax into every seam, and sprayed it into every space. Any flash rust was converted (the black in the pic). Anyway, pics of before and after priming (I ran out of primer so that's why it has a camo-look), the nastiness is gone:

View attachment 167866

View attachment 167868

Next up will be to sand it down again and finish priming. Then sand again, seam sealer, and paint.

I had the front subframe blasted, tow hooks welded, and powder coated in Schwartzolive and is being picked up tomorrow:

View attachment 167871

I had some of the same RAL color put into rattle cans at the paint supply store and will do the struts the same - cleaning them up also revealed they were once the same color:

View attachment 167872

Also tomorrow is engine pickup day at the machinist! The block has been cleaned, decked .004" and bored for 10:1 JE pistons now installed, crank is polished and new bearings for it and the rods all in the block. I will rebuild the rest:

View attachment 167873

I will be painting the block black with the POR-15 system. While dodging a hurricane, I got into the front bumper, I POR-15'd the insides of the pieces, repainted the brackets and now ready for final polish, rubber and trim pieces for both front and back bumpers on way from W&N so they should look good when all is said and done:

View attachment 167874

I also cleaned up, cavity waxed, and POR-15'd the entire front clip on both sides, it was nasty. Easier than trying to spray primer and paint into there, and better protection against the elements:

View attachment 167876

View attachment 167877

All the engine parts to finish the rebuild are in stock, the brake booster, front calipers, and steering box have been rebuilt and ready to go. Onward!

Espresso cold brew and fear!Impressive Steve. I mean it is exhausting just thinking about this list of projects you attacked and mastered. Begs the question, you living on Espresso, or Red Bull energy drinks? I mean you have accomplished so much! Mike

Don’t think you have to sand the primer that much, you just need to knock down any high spots or runs and sags. After I shot the color I sanded nothing and it looks great, you won’t be able to see 75% of it once everything is installed.

Looking really awesome Steve! The engine compartment was a bitch with many scraped knuckles, and mine was partially media blasted. I also don’t think I’ll ever touch Por 15 again, that stuff is really nasty. Eastwood makes a really good rust converter and I’m pretty sure the car will now outlast me without por 15.

That short block with the Pistons looks spectacular. One day I might have a motor.

That short block with the Pistons looks spectacular. One day I might have a motor.

It's been a while since I have updated this thread, I have been rolling around in my sweat under and in the engine bay in 95 degree heat and humidity hacking away at numerous resto and resto-mod projects for months now. Thanks to @sfdon the pieces I need to install my hi-flo oil pump are here so I have been able to shim the smaller chain & cog correctly and then proceed to assemble the remaining ancillary bits. At this point the block is de-rusted, primed, and painted with POR-15, that stuff is nasty in a good way - glossy, but some hours of heat will likely temper it. After installing the oil pump, I temporarily mounted the head to check the piston-head rotating clearance; this has kept me up at night worrying if the calculations for 10:1 pistons are correct. It has seemingly passed the test so onward to completely mounting the head with the last oem Goetze head gasket i could find (from Egypt). Also, the new Bosch SR444 850csi V12 starter is on (looks suitable for a B-52), the a/c solenoid, and a new German water pump. I have a new front lower timing cover crank seal coming - I ruined it despite having done this job a few times in the past. Duly noted not to try this again after the gummy kicks in...Once that is installed I will install both timing covers then the sump cover, all with appropriate amounts of Dirko sealant.

I also added an industrial petcock for the block coolant drain:

I got the chain tensioner from Maximillian, apparently they had some made specially for them (??) and of all the new crappy tensioners on the market (I've tried 'em all), this is the best. A friend made me a crank nut lock plate (he said Alpina made these back in the day??), Don says he's never seen a nut come off if properly installed but yours truly isn't going to ruin his streak!

In the resto-mod dept, I ran the a/c relay wires through the frame rail (accessed through the passenger floor pan hole), so the only stuff on the passenger fender from the firewall will be 2 reduced size barrier a/c hoses. I am sourcing a rubber seal to install on the perimeter edge of the front clip a/c hole, these were obviously hacked open by the dealer when installing a/c.

The engine bay is coming along slowly but surely, currently I am at war with the 2 lower subframe bushings, I hope to have a methodolgy to post on this soon if my latest install contraption/technique works. So far the bushings are winning 2-nil but there is still time on the clock...

I also added an industrial petcock for the block coolant drain:

I got the chain tensioner from Maximillian, apparently they had some made specially for them (??) and of all the new crappy tensioners on the market (I've tried 'em all), this is the best. A friend made me a crank nut lock plate (he said Alpina made these back in the day??), Don says he's never seen a nut come off if properly installed but yours truly isn't going to ruin his streak!

In the resto-mod dept, I ran the a/c relay wires through the frame rail (accessed through the passenger floor pan hole), so the only stuff on the passenger fender from the firewall will be 2 reduced size barrier a/c hoses. I am sourcing a rubber seal to install on the perimeter edge of the front clip a/c hole, these were obviously hacked open by the dealer when installing a/c.

The engine bay is coming along slowly but surely, currently I am at war with the 2 lower subframe bushings, I hope to have a methodolgy to post on this soon if my latest install contraption/technique works. So far the bushings are winning 2-nil but there is still time on the clock...

Last edited:

When I have an ugly grimy motor to transport, I place in on an old tire and then strap it down. Only good use for an old tire.

Hose- are you having trouble with the compliance bushings? By the tow hooks?

The ones from W&N?

If so- I can help with ones from an earlier production run.

The ones from W&N?

If so- I can help with ones from an earlier production run.

Thanks for updating Steve, there may be light at the end of the rabbit hole. Very impressive that you are doing

the engine assembly. But, all in all, it looks like you’re having fun, which is what I mean one of these vehicles is about. Cheers.

the engine assembly. But, all in all, it looks like you’re having fun, which is what I mean one of these vehicles is about. Cheers.